You rely on your excavator every day to get tough jobs done. Regular maintenance and timely replacement of heavy excavator parts keep your machine safe and efficient. Neglecting these tasks can lead to unexpected breakdowns, costly repairs, or even serious accidents. In 2021, the construction industry saw 951 fatalities, with 17% caused by contact with equipment. Poor maintenance often leads to issues like detachment of attachments or sudden equipment failures. When you pay close attention to your excavator and replace worn heavy excavator parts, you protect your team and extend your machine’s life.

Key Takeaways

Regular maintenance keeps your excavator safe, reliable, and efficient, preventing costly breakdowns and accidents.

Daily checks, proper lubrication, and cleaning help spot problems early and extend the life of key parts like hydraulics and undercarriage.

Use maintenance logs to track repairs and service dates, which supports timely replacements and better machine performance.

Replace worn parts before failure by following manufacturer guidelines and watching for signs like leaks, cracks, or performance drops.

Always follow safety steps during maintenance and choose quality parts to protect your investment and keep your team safe.

Why Maintenance Matters

Performance and Safety

You depend on your excavator to deliver strong performance every day. Proper excavator maintenance ensures that your machine works at its best. When you monitor key systems, such as the hydraulic system, you can spot problems early. For example, checking for metallic particles in hydraulic oil helps you find wear before it leads to bigger issues. This approach, called condition-based maintenance, keeps your excavator running smoothly and helps you avoid sudden breakdowns.

Regular maintenance also means you can plan repairs before they become emergencies. You reduce the risk of unexpected failures that could put your team in danger. While studies show that maintenance boosts performance, they also suggest that keeping your excavator in top shape lowers the chance of accidents caused by equipment failure.

A well-maintained excavator responds better to controls and handles heavy loads with ease. You notice fewer leaks, strange noises, or slow movements. This attention to detail keeps your job site safe and your work efficient.

Cost and Longevity

Excavator maintenance saves you money over time. Routine maintenance tasks, like oil and filter changes, cost much less than major repairs. For example, changing oil and filters every 250-500 hours costs between $150 and $600. In contrast, an undercarriage rebuild can cost up to $40,000. By investing in regular maintenance, you avoid these high repair bills.

You also extend the life of your excavator. Proactive maintenance programs can cut downtime by up to 40%. This means your machine spends more time working and less time in the shop. Maintenance agreements from trusted brands help you plan service and protect your investment. Cleaning, rust prevention, and using the right parts all add years to your equipment’s life.

Tip: Keep a maintenance log to track service dates and repairs. This simple step helps you stay ahead of problems and supports better performance.

Heavy Excavator Parts Overview

Understanding the main excavator parts and names helps you keep your machine running smoothly. Each system plays a unique role in performance and reliability. Here’s what you need to know about the most important heavy excavator parts and their functions.

Hydraulic System

The hydraulic system powers most excavator body parts, including the boom, arm, and bucket. You rely on hydraulic pressure to dig, lift, and swing. Hydraulic systems have fewer moving parts than mechanical systems, which means less wear and smoother operation. Overload protection and quality hydraulic oil help extend the life of these excavator parts.

Hydraulic system failure often shows as pressure drops over 10% or oil temperature rises above 10°C.

Replace hydraulic oil every 2,000–3,000 hours and clean filters every 1,000 hours to prevent contamination.

The engine and hydraulic systems together cause nearly 80% of total excavator failures, so regular checks are critical.

Upgrading hydraulic cylinders and seals can double the service life of these parts, making your excavator more reliable.

Undercarriage

The undercarriage supports the excavator and allows it to move across rough terrain. Key undercarriage parts include track chains, rollers, shoes, sprockets, and idlers.

Track wear rate should be checked every 1,000 hours.

Proper track tension adjustment can reduce chassis failure rates by 15%.

Track wear over 30% or shock absorption loss over 15% means you need to replace parts.

Advances in materials, like high-strength steel, and smart sensors help you monitor undercarriage maintenance and reduce downtime. High replacement rates for track chains show how vital these excavator parts are for smooth operation.

Engine Components

The engine powers the hydraulic system and the powertrain. Commonly failing engine parts include the engine control module, pumps, and transmission.

Most engine failures come from age, fluid contamination, or operator error.

Clean engine parts often and protect electronics from dust and debris.

Change fluids and lubricate moving parts as the manufacturer recommends.

You can extend engine life by following a strict maintenance schedule and training operators to avoid mistakes.

Attachments

Attachments expand what your excavator can do. Buckets, breakers, and grapples are some of the most common excavator body parts.

Productivity studies show that optimized attachments improve digging force, lifting capacity, and cycle time.

Lightweight designs and advanced materials make attachments stronger and more efficient.

Regular maintenance and proper selection ensure attachments work safely and last longer.

Electrical Parts

Electrical parts control and power many excavator functions. These include wiring, sensors, alternators, and starters.

Electric excavators have higher upfront costs but can become more cost-effective over time, especially in larger models.

Maintenance costs for electric and diesel models are similar, but electric motors usually need less service.

Protect electrical parts from moisture and dust to avoid failures.

Excavator Size | Type | Upfront Cost Factors | Cost-Effectiveness Over 6 Years (NPV) |

|---|---|---|---|

8.5-ton | Electric | Battery cost included | Higher cost than diesel |

17.5-ton | Electric | Installation cost (~650,000 NOK) | Higher cost than diesel |

38-ton | Electric | Installation cost (~650,000 NOK) | More cost-effective by year 5 |

All sizes | Diesel | Lower upfront cost | Higher operating costs |

Knowing your excavator parts and names helps you plan maintenance and replacement, keeping your heavy excavator parts in top condition for every job.

Excavator Maintenance Essentials

Daily Checks

You set the foundation for reliable excavator maintenance with daily checks. These quick inspections help you catch small issues before they become major problems. Start each day by walking around your excavator and looking for leaks, loose bolts, or visible damage. Check fluid levels, including engine oil, coolant, and hydraulic fluid. Make sure the track tension is correct and inspect the undercarriage for debris or wear. Test all safety equipment, such as lights, alarms, and fire extinguishers.

Here is a simple daily checklist you can follow:

Inspect hydraulic fluid, engine oil, and coolant levels.

Look for leaks under the machine and around hoses.

Check track tension and undercarriage condition.

Test brakes, lights, and alarms.

Examine attachments for cracks or loose pins.

Clean cab windows and mirrors for clear visibility.

Consistent daily inspections improve excavator reliability and help you avoid costly downtime. Industry guidelines recommend tailoring your maintenance plan to your specific equipment and job site needs.

Lubrication

Lubrication is a key part of excavator maintenance. You need to keep all moving parts well-lubricated to prevent friction and wear. Use manufacturer-recommended oils and greases for the best results. Focus on pins, bushings, swing bearings, and joints. Some modern excavators have auto-lube systems that grease parts automatically, reducing manual errors and extending component life.

Follow these lubrication tips:

Lubricate all grease points daily or as recommended in your manual.

Use synthetic oils or long-life hydraulic fluids to extend service intervals.

Check for signs of dry or squeaky joints, which may indicate missed lubrication.

Wipe away excess grease to prevent dirt buildup.

Proper lubrication reduces wear, lowers maintenance costs, and keeps your excavator running smoothly. Advanced bushings and auto-lube systems can further reduce the need for frequent manual greasing.

Cleaning

Routine cleaning is essential for effective excavator maintenance. Dirt, mud, and debris can cause premature wear, especially on the undercarriage and hydraulic system. Clean your machine after each shift, paying special attention to the tracks, rollers, and engine compartment. Use a pressure washer for tough grime, but avoid spraying directly at electrical parts.

Maintenance/Cleaning Aspect | Description | Impact on Lifespan and Performance |

|---|---|---|

Sealed and lubricated track pins | Never need greasing | Reduces maintenance frequency, lowers costs, improves uptime |

Enlarged rollers and easier undercarriage cleanout | Design for easy cleaning | Extends undercarriage life, reduces downtime |

Ground-level fluid change ports | Easier access | Speeds up maintenance, prolongs component life |

Auto-lube systems | Automated greasing | Ensures consistent lubrication, extends component life |

Use of synthetic oils | Extended oil change intervals | Reduces wear, improves uptime |

Reversible cooling fans | Clears debris | Prevents overheating, maintains fuel efficiency |

Telematics and diagnostics | Real-time monitoring | Enables proactive maintenance, reduces failures |

Regular cleaning routines, combined with design improvements, statistically extend the operational lifespan of your excavator. Clean machines run cooler, last longer, and perform better.

Maintenance Logs

Keeping detailed maintenance logs is one of the most effective maintenance and replacement tips. Accurate records help you track service dates, parts replaced, and issues found during inspections. Use standardized forms or digital software to make logging easy and consistent. Update your log after every maintenance task, including daily inspections, lubrication, and cleaning.

Best practices for maintenance logs include:

Record machine details, service dates, and types of maintenance performed.

Document inspection results and note any problems or repairs.

Use digital tools for automated reminders and trend analysis.

Assign responsibility for updating logs to a specific team member.

Analyze log data to spot patterns and schedule preventive maintenance.

Maintenance logs help you detect early signs of component wear or failure. They also support compliance with your periodic maintenance schedule and improve accountability. Smart technology, such as IoT sensors and predictive software, can further enhance your record-keeping and maintenance planning.

By following these excavator maintenance essentials, you protect your investment and ensure safe, efficient operation. Stick to your routine maintenance plan, use the right oils and parts, and keep your records up to date. These steps form the backbone of effective excavator maintenance and replacement tips.

Signs of Worn Excavator Parts

Visual Damage

You can spot early signs of wear on your excavator by looking for visual damage. Scratches, dents, and cracks on the boom, arm, or bucket signal that parts may need repairs or replacement. Worn paint or exposed metal often means the protective coating has failed. Rust on the undercarriage or hydraulic cylinders can weaken the structure and lead to costly repairs. Loose or missing bolts on engine covers or attachment points also indicate that maintenance is overdue. Regular inspections help you catch these issues before they affect performance.

Tip: Use a flashlight during your walk-around inspection to check for hidden cracks or leaks on hard-to-see excavator parts.

Leaks and Noises

Leaks and unusual noises often point to problems with hydraulic systems or the undercarriage. You might notice oil or coolant pooling under the machine, which suggests a damaged seal or hose. Hissing, grinding, or knocking sounds from the engine or hydraulic pumps mean that parts are wearing out. These noises can signal that repairs or replacement are needed soon. Ignoring leaks can cause hydraulic pressure loss, which reduces performance and increases the risk of breakdowns. Addressing leaks and noises quickly keeps your excavator running safely.

Performance Issues

Performance issues in your excavator show up as slow cycle times, weak digging force, or jerky movements. You can measure these problems using diagnostic tools that track flow rate, pressure, and efficiency in the hydraulic system. Regular performance tests help you find early signs of wear in key parts. Delayed maintenance leads to more frequent breakdowns and higher repair costs. Predictive maintenance technologies, such as IoT sensors and AI, allow you to monitor equipment in real time. These tools help you schedule repairs and replacement before failures occur, keeping your excavator productive. Tracking productivity metrics, like excavation rate, gives you a clear benchmark for equipment performance and helps you spot gaps that need attention.

Note: Keeping detailed records of performance tests and repairs supports better excavator maintenance and helps you plan for timely replacement of worn parts.

Excavator Parts Replacement

When to Replace

You need to know when to replace essential replacement parts to keep your excavator running safely and efficiently. Each part has a specific lifespan. You should not wait for a complete failure before acting. Instead, follow the manufacturer’s guidelines and your maintenance log to track the hours and condition of each component.

Look for these signs that tell you it is time for replacement:

Hydraulic hoses show cracks, bulges, or leaks.

Filters become clogged or show signs of contamination.

The undercarriage has worn tracks, loose rollers, or damaged sprockets.

Seals leak oil or hydraulic fluid.

Attachments lose efficiency or show visible damage.

You should also schedule replacement based on usage hours. For example, most hydraulic hoses need replacement every 2,000 hours. Filters often require changing every 500 hours. The undercarriage may need new parts after 1,200 to 2,000 hours, depending on the terrain and workload. If you notice performance drops, such as slower cycle times or reduced digging force, check for worn parts immediately.

Tip: Proactive replacement prevents costly repairs and keeps your excavator safe for operators.

Replacement Steps

You can handle many replacement tasks with the right tools and preparation. Always consult your equipment manual before starting. Here is a step-by-step guide for replacing key excavator parts:

Prepare the Work Area

Park the excavator on level ground.

Turn off the engine and remove the key.

Allow the machine to cool down.

Gather Tools and Parts

Collect all essential replacement parts, such as new hoses, filters, or seals.

Use only manufacturer-approved components for best results.

Remove the Old Part

Release any built-up pressure in the hydraulic system.

Use proper wrenches and tools to disconnect hoses, filters, or undercarriage parts.

Keep track of bolts and fittings.

Install the New Part

Fit the new part securely in place.

Tighten bolts to the recommended torque.

Replace seals and gaskets as needed.

Test the System

Refill fluids if necessary.

Start the excavator and check for leaks or abnormal noises.

Test the function of the replaced part.

Update Maintenance Logs

Record the replacement date and part details.

Note any issues found during the process.

Note: Timely replacement of essential replacement parts reduces downtime and extends the life of your excavator.

Safety Tips

You must follow strict safety procedures during every replacement. These steps protect you and your team from injury and prevent damage to your excavator.

Wear personal protective equipment (PPE), such as gloves, safety glasses, and steel-toed boots.

Use lockout/tagout procedures to ensure the machine cannot start during maintenance.

Never work under a raised boom or arm without proper supports.

Relieve hydraulic pressure before disconnecting hoses or fittings.

Dispose of old fluids and parts according to environmental regulations.

Double-check all connections before restarting the excavator.

Safety Step | Why It Matters |

|---|---|

Wear PPE | Prevents injuries from sharp parts |

Lockout/Tagout | Stops accidental machine startup |

Relieve Hydraulic Pressure | Avoids fluid spray and burns |

Use Proper Supports | Prevents crushing injuries |

Follow Disposal Rules | Protects the environment |

Always prioritize safety during replacement. Rushing or skipping steps can lead to accidents or expensive repairs.

By following these maintenance and replacement tips, you ensure that your excavator stays reliable and safe. Timely wear parts replacement keeps your machine in top condition and reduces the risk of unexpected breakdowns.

Choosing Excavator Parts

OEM vs Aftermarket

When you need new parts for your excavator, you face a choice between OEM (Original Equipment Manufacturer) and aftermarket options. OEM parts come directly from the company that built your machine. These parts fit perfectly and meet strict quality standards. You can trust them to work well with your equipment. Aftermarket parts come from other companies. Some offer lower prices and good performance, but quality can vary. You must check reviews and ask for warranties before you buy. If you want peace of mind and easy installation, OEM parts are a safe bet. If you want to save money, high-quality aftermarket parts may work if you choose carefully.

Tip: Always compare the warranty and support offered by both OEM and aftermarket suppliers before making your decision.

Supplier Selection

You want a supplier who delivers reliable parts on time and at a fair price. Look for companies with a strong track record and positive customer feedback. Shipment frequency and volume data help you judge if a supplier can meet your needs. Price analysis across different suppliers lets you spot cost savings. Many buyers find that imported used excavators from China offer big savings and reliable service because of the wide availability of parts and support. Scientific methods, like finite element analysis, help you check if a supplier’s parts meet safety and performance standards. You should also consider shipping time and proximity, as these factors can lower freight costs and improve delivery reliability.

Supplier Criteria | Why It Matters |

|---|---|

Shipment frequency | Ensures steady parts supply |

Price analysis | Helps you save money |

Proximity | Reduces shipping time and cost |

Scientific testing | Confirms part reliability |

Compatibility

You must make sure new parts fit and work with your excavator. Technical tests, like Multibody Dynamics and Discrete Element Method co-simulations, help engineers check how different parts interact. These tests look at things like bucket shape, wear patterns, and how parts handle different materials. They show if a part will last and perform well under real job conditions. When you focus on compatibility, you avoid costly mistakes and downtime. Always match part numbers and check with your supplier if you have questions about fit. Choosing quality excavator spare parts and using reliable parts keeps your machine running smoothly and safely.

Note: Ask your supplier if their parts have passed technical compatibility tests for your specific excavator model.

Troubleshooting Excavator Issues

Hydraulic Problems

You often face hydraulic problems when operating heavy excavators. Leaks, slow movement, or weak digging force signal trouble in the hydraulic system. Start troubleshooting common issues by checking fluid levels and inspecting hoses for cracks or bulges. Air in the system can cause jerky movements. Bleed the lines if you notice this symptom. Dirty or clogged filters also reduce performance. Replace filters as part of your regular maintenance routine. Listen for unusual noises from pumps or cylinders. These sounds may mean internal wear or contamination. Use manufacturer-recommended fluids to keep your hydraulic system running smoothly. Schedule periodic maintenance to catch problems early and avoid costly repairs.

Tip: Always check for leaks under the machine after each shift. Early detection prevents bigger failures.

Engine Issues

Engine issues can stop your excavator and delay your project. You need to monitor key data to keep the engine healthy. Use professional diagnostic tools like engine health testers, infrared thermometers, and IoT-based platforms. These tools track oil pressure, temperature, vibration, and fault codes. Regular monitoring helps you spot problems before they become serious.

Oil pressure and temperature readings show early signs of trouble.

Vibration analysis detects worn parts or misalignment.

Fault code databases and trend analysis reduce failure rates by up to 30%.

Maintenance record management systems remind you of needed service.

Komatsu’s real-world case shows the value of early detection. Their MineCare system caught a failing head gasket by monitoring coolant pressure and sending alerts. Maintenance teams fixed the problem before it caused engine failure, saving $250,000 in repairs and downtime. On large sites, these systems prevent millions in losses each year.

Note: Keep your maintenance schedule up to date. Early action saves money and keeps your excavator working.

Undercarriage Wear

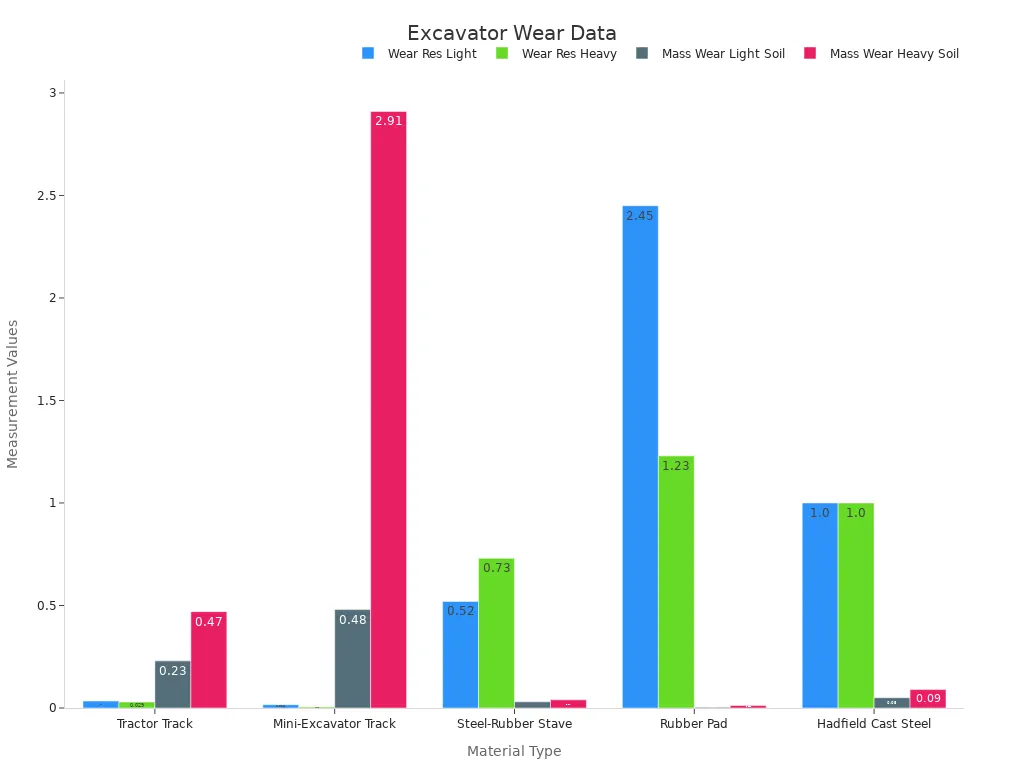

Undercarriage wear affects your excavator’s stability and movement. You need to check tracks, rollers, and pads for signs of damage. Wear patterns change based on soil type and material. Studies show that rubber pads made from high-density polyethylene last more than twice as long as traditional steel in light soil. Mini-excavator tracks wear out fastest, especially in heavy, wet soil.

Material Type | Wear Resistance Index (Kb) Light Soil | Wear Resistance Index (Kb) Heavy Soil | Mass Wear (g) Light Soil | Mass Wear (g) Heavy Soil |

|---|---|---|---|---|

Tractor Track | ~0.034 | ~0.029 | ~0.23 | ~0.47 |

Mini-Excavator Track | ~0.016 | ~0.005 | ~0.48 | ~2.91 |

Steel-Rubber Stave | ~0.52 | ~0.73 | ~0.03 | ~0.04 |

Rubber Pad | ~2.45 | ~1.23 | ~0.0035 | ~0.012 |

Hadfield Cast Steel | 1.00 | 1.00 | ~0.05 | ~0.09 |

You should inspect the undercarriage after working in harsh conditions. Look for scratching, furrowing, or tearing on the surface. Replace worn parts before they fail. Regular cleaning and scheduled maintenance extend the life of your undercarriage and reduce downtime.

You protect your investment when you follow a strong excavator maintenance plan. Regular maintenance keeps your machine safe, reliable, and efficient. You lower repair costs and avoid sudden breakdowns. Use quality parts and stick to a clear maintenance schedule. Track your work in a log. Check your equipment every day. Replace worn parts before they fail. Stay proactive and make maintenance a top priority. Your team and your business will benefit.

Keep your excavator maintenance routine simple.

Choose trusted parts for every repair.

Make maintenance a habit, not an afterthought.

Take action today. Start your maintenance plan and keep your excavator working at its best.

FAQ

How often should you inspect your excavator for wear?

You should inspect your excavator daily. Look for leaks, cracks, and loose bolts before each shift. Regular checks help you spot problems early and keep your machine safe.

What is the best way to keep a maintenance log?

Use a notebook or digital app to record every service, repair, and inspection. Write down dates, parts replaced, and any issues found. This habit helps you track patterns and plan future maintenance.

Can you use aftermarket parts without voiding your warranty?

Some warranties require OEM parts. Always check your warranty terms before using aftermarket options. If you choose aftermarket parts, ask your supplier for documentation that proves compatibility.

Why does your excavator lose power during operation?

Low hydraulic fluid, clogged filters, or worn engine parts can cause power loss. Check fluid levels and replace filters first. If the problem continues, inspect the engine and hydraulic system for damage.

How do you know when to replace undercarriage parts?

Watch for worn tracks, loose rollers, or strange noises. If you see cracks or the machine moves unevenly, replace the damaged parts. Regular cleaning and inspection extend undercarriage life.