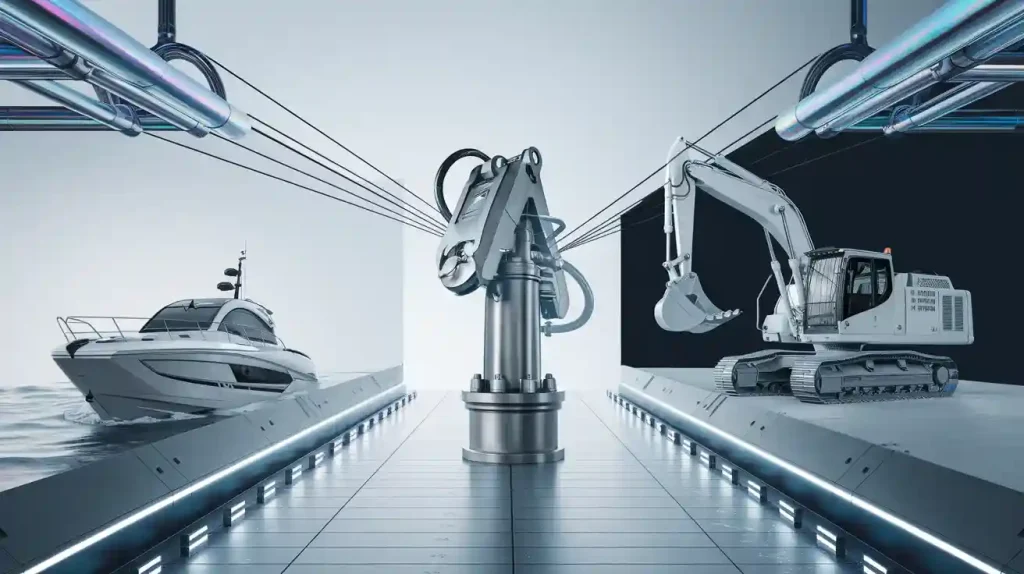

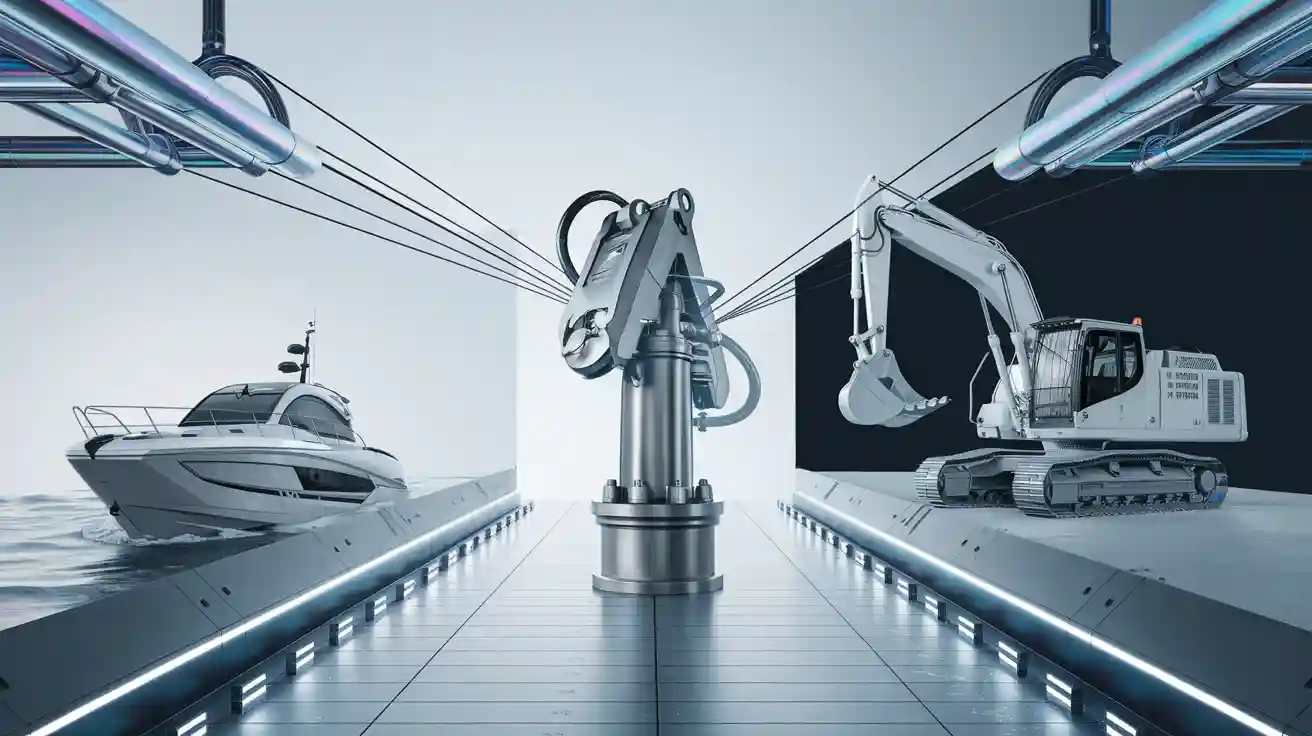

When selecting a hydraulic pump for your boat or excavator, it’s important to ensure the pump type matches your equipment’s requirements. Always verify that the pump’s specifications are compatible with your system, especially when considering boat steering parts excavator hydraulic pump options. Pay close attention to the pressure and flow rate. Choose a pump that meets the specific needs of your boat steering parts or excavator hydraulic pump system. Selecting the correct hydraulic pump group is essential for optimal performance.

Key Takeaways

Learn about the types of hydraulic pumps: gear, piston, and vane. Each type is made for certain jobs and works best in special situations.

Always look at the flow rate and pressure before you buy a pump. Make sure these match your equipment for the best results and to stop problems.

Think about the thickness and kind of hydraulic fluid. The right fluid helps the pump work well and last longer.

Make sure the pump fits your system. Check the fittings, pressure ratings, and fluid types to stop leaks and damage.

Regular care is important. Check the fluid every day and change the filter every 500 hours. This keeps your pump working well and stops expensive repairs.

Types of Hydraulic Pumps

If you want to pick a hydraulic pump for your boat or excavator, you should know the main types. Each type works best for different jobs. The main types are gear pumps, piston pumps, and vane pumps. These hydraulic pump groups help you choose the right pump for your equipment.

Gear Pumps

Gear pumps are very common. They are found in many hydraulic pump groups. Their design is simple. They work well in systems with low or medium pressure. Gear pumps can move different fluids. They are reliable. You often see gear pumps in boat steering systems. Smaller excavators use them too.

Tip: Gear pumps are simple to take care of and do not cost much for basic hydraulic jobs.

Here is a table that shows what is good and bad about gear pumps:

Advantages | Disadvantages |

|---|---|

Simple design | Only works as a fixed displacement pump |

Reliability | Can be noisy and have force imbalance |

Handles many fluids well | Wears out and is hard to fix |

Piston Pumps

Piston pumps are part of hydraulic pump groups that give high pressure and work very well. You use piston pumps when you need strong force and good control. These pumps can reach very high pressures, over 400 bar (5800 psi). They are great for big excavators and advanced boat steering parts.

Piston pumps make more pressure than gear and vane pumps.

They are best for jobs that need strong force and changing flow rates.

Piston pumps work better in fast systems.

Vane Pumps

Vane pumps are another key type in hydraulic pump groups. You use vane pumps in places with medium pressure. They work smoothly and are reliable. In excavators, vane pumps move hydraulic cylinders for the boom and arm, bucket, and swing. Vane pumps also power hydraulic motors for track movement and turning attachments.

Hydraulic cylinders move in and out and work the bucket.

Hydraulic motors help tracks move and attachments turn.

Hydraulic Pump Groups

Hydraulic pump groups sort pumps by how they are made and what they do. There are two main hydraulic pump groups: fixed displacement and variable displacement.

Type | Key Characteristics |

|---|---|

Fixed Displacement Pumps | Always give the same flow, simple, easy to care for, cheap, good for steady hydraulic jobs. |

Variable Displacement Pumps | Flow can change, saves energy, more complex, costs more, good for systems that change a lot. |

When you pick a pump, think about how hydraulic pump groups are designed. Fixed displacement pumps are good if you need steady flow. Variable displacement pumps are better for systems that change. Hydraulic pump groups are used in factories, businesses, and homes. Always match the hydraulic pump group to what your equipment needs.

Note: Knowing the types of hydraulic pumps and hydraulic pump groups helps you pick the best one for your boat or excavator.

Key Selection Criteria

Picking the right hydraulic pump for your boat or excavator is important. You need to look at a few key things. The pump’s features must fit what your equipment needs. This part will show you what to check before buying.

Flow Rate & Pressure

First, check the flow rate and pressure. Flow rate means how fast the pump moves hydraulic fluid. Pressure is how much force the pump makes. In excavators, flow rate controls how fast the boom and bucket move. If the flow rate is too low, your machine will be slow and not work well. On boats, flow rate helps with steering and stabilizers. This keeps the boat safe when moving.

Picking the wrong flow rate or pressure can cause:

Slower work cycles

Pressure or flow that changes too much

Equipment that cannot do simple jobs

More energy used

Movements that are jerky or rough

Always check the manufacturer’s rules for high or low pressure. This helps you avoid problems and keeps your equipment working well.

Fluid Viscosity & Type

Hydraulic systems use different fluids. Viscosity means how thick or thin the fluid is. This changes how well the pump works. Thick fluids need more energy to move. This can make more friction and lower how well it works. Thin fluids might leak or make bubbles that hurt the pump.

Thick fluids make more friction and lower how well it works.

Thin fluids may leak and make bubbles.

The right thickness helps the pump last longer.

Wrong thickness can break your equipment and make it wear out faster.

Good thickness gives smooth movement and keeps parts safe.

Thin fluids can make heat and metal parts touch.

Thick fluids can slow things down and make air bubbles.

Always use a fluid that fits your pump and system. This helps your hydraulic pump work its best.

Power & Torque Ratings

You need to check the power and torque ratings. Power shows how much work the pump can do. Torque is the turning force the pump gives. If the ratings are too low, your equipment may not work right. If they are too high, you waste energy and money.

Match the pump’s power to your system.

Make sure the torque rating is right for the job.

Look at the manufacturer’s data for these numbers.

Fixed vs Variable Displacement

There are two main types of hydraulic pumps. Fixed displacement pumps always move the same amount of fluid. Variable displacement pumps can change the flow to fit what you need.

Pump Type | Scenario |

|---|---|

Fixed Displacement Pump | Good for jobs that stay the same. |

Variable Displacement Pump | Best for jobs that change, saves energy. |

Variable displacement pumps are good for excavators and loaders. They give you more control and save energy. You get better results for jobs that need different power. Fixed displacement pumps are good for simple, steady jobs.

Variable displacement pumps save energy, give better control, and last longer with less fixing.

Compatibility

You must make sure your new hydraulic pump fits your system. If the fittings do not match, you can get leaks or even breaks, especially with high pressure. The pump and fittings must work with the fluid you use. Always check the pressure and make sure your pump can handle it. Figure out how much fluid and flow you need. Make sure your pump works in your temperature range.

Check if the pump fits your hoses and fittings.

Make sure all parts do not rust, especially on boats.

Use pumps that work with your fluid, like mineral oil or water-glycol.

Pick small pumps if you do not have much space.

Think about the total cost, including fixing and energy.

Tip: Always check if everything fits before you buy. This helps you avoid mistakes and keeps your system safe.

Application Matching

Choosing the right hydraulic pump for your boat or excavator means looking at how the pump fits your real-world needs. You want your boat steering parts excavator hydraulic pump to work smoothly, last long, and handle tough conditions. This section will help you match pump features to your equipment and environment.

Boat Steering Parts

When you pick a hydraulic pump for boat steering, you need to think about more than just size. The right boat steering parts excavator hydraulic pump makes steering easy and safe. Here are the main things you should check:

Factor | Description |

|---|---|

Boat Size and Type of Motor | The system must match the boat’s size and motor type, as different setups require different specifications. |

Steering Load | The load on the steering system is influenced by engine horsepower and boat speed, affecting steering ease. |

Budget | Costs vary based on brand, size, and features, with DIY installation potentially saving money. |

Personal Preferences | Individual comfort and handling preferences play a crucial role in selecting the right system. |

You should always match the pump’s flow and pressure to your boat’s steering needs. A small boat with a light motor needs less force. A large boat with a powerful engine needs a stronger pump. If you choose the wrong boat steering parts excavator hydraulic pump, you may find steering hard or even unsafe. Always check your boat’s manual for the right specs.

Tip: Try the steering system before you buy. Make sure it feels comfortable and easy to use.

Excavator Hydraulic Pump

Excavators need strong and reliable pumps. The right boat steering parts excavator hydraulic pump helps your machine dig, lift, and move with power. Here are some tips to help you choose:

Check the pump’s pressure rating. Excavators often need high pressure for digging and lifting.

Look at the flow rate. Fast-moving arms and buckets need more flow.

Make sure the pump fits your excavator’s hydraulic system. The wrong fit can cause leaks or damage.

Think about the type of work. Heavy digging needs a pump that can handle tough jobs every day.

Choose a pump that matches your machine’s size and power.

If you use your excavator in different ways, a variable displacement pump may work best. It saves energy and gives you more control. For simple jobs, a fixed displacement pump may be enough. Always match the boat steering parts excavator hydraulic pump to your machine’s needs.

Environmental Factors

Your boat steering parts excavator hydraulic pump must work in many different environments. Some places are hot, cold, wet, or dirty. These conditions can change how your pump works.

Cavitation and fluid turbulence can waste energy and make your pump wear out faster.

Temperature changes can make fluid thin or thick. High heat can cause leaks. Cold can slow the pump.

Dirt and dust can get into the system and damage parts.

Poor maintenance can make your pump break down sooner.

If you use your boat or excavator in harsh places, you need a pump that can handle it. Some pumps, like the Rexroth A11V Axial Piston Variable Pump, use special seals and materials to fight rust and damage. You should also pick hydraulic fluids that work in hot or cold weather. Look for fluids with anti-wear agents and rust blockers. These keep your boat steering parts excavator hydraulic pump safe and working well.

Note: Always check your pump and fluid for signs of trouble. Good care helps your pump last longer, even in tough places.

Practical Tips

Quality & Reliability

When you pick a hydraulic pump, check for quality marks. These marks show the pump is safe and works well. Look for pumps that follow ISO, ANSI, CEN, or NFPA rules. These groups make rules for how pumps are made and tested.

Standard Organization | Description |

|---|---|

ISO | Makes world rules for pump design, testing, and safety. ISO 4412 checks noise. ISO 6743 checks fluid use. |

ANSI | Gives rules for how pumps should work and how strong they are. |

CEN | Sets rules for pumps in the EU. This helps keep products safe and easy to sell. |

NFPA | Makes rules for pump use, setup, and care in North America. |

You should also look at how reliable the pump is. Pumps with backup parts, energy-saving features, and simple builds last longer. They work better in hard places.

Reliability Metric | Description |

|---|---|

Redundant Design | Has backup parts so it keeps working if one part breaks. |

Energy-Saving Design | Uses less power and breaks down less often. |

Environmentally Resistant Design | Can handle tough places like water or salt. |

Simplified Design | Has fewer parts, so fewer things can break. |

Tip: YNF Machinery sells pumps that meet high quality and reliability rules for boats and excavators.

Maintenance

Taking care of your hydraulic pump helps it work well. You should check fluid every day. Change filters every 500 hours.

Doing regular care makes your pump last longer. Clean oil and good setup stop breakdowns. If you skip care, dirt and bad oil can break your pump.

Note: Always follow the care plan to stop expensive repairs.

Cost Considerations

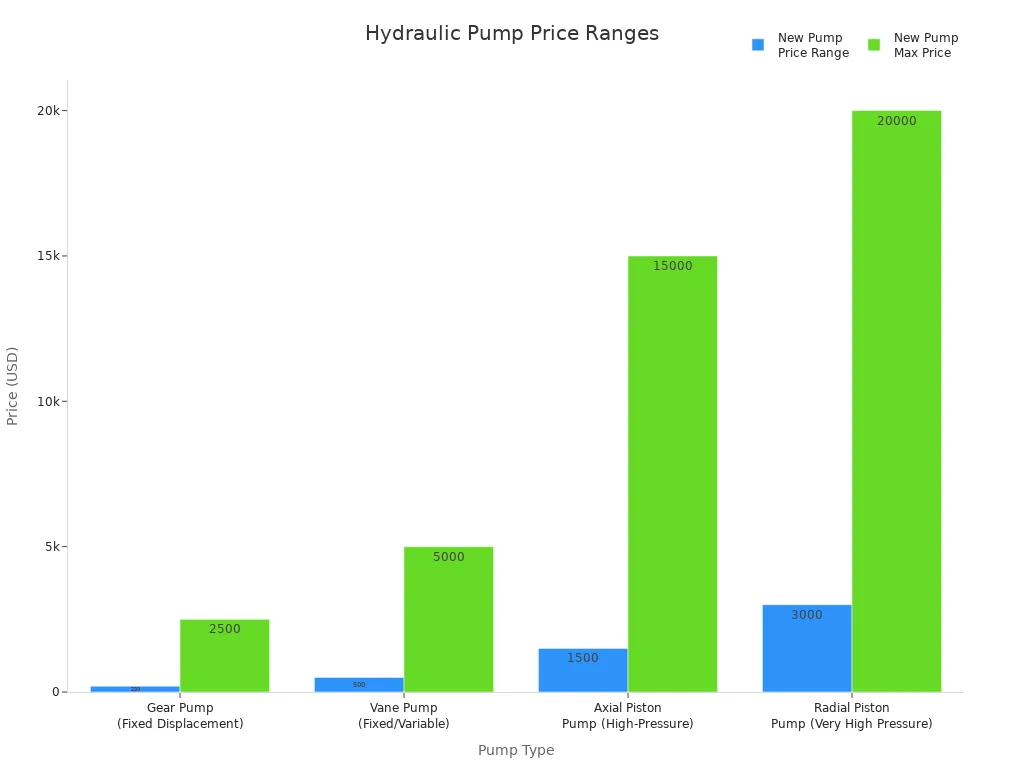

Hydraulic pump prices are not all the same. Gear pumps cost less. Piston and vane pumps cost more but work better. Here is a quick price guide:

Pump Type | Price Range (New) | Rebuild Cost | Common Applications |

|---|---|---|---|

Gear Pump (Fixed Displacement) | $200 – $2,500 | $150 – $1,200 | Used in low-pressure jobs and farms. |

Vane Pump (Fixed/Variable) | $500 – $5,000 | $300 – $2,500 | Used in machines and factories. |

Axial Piston Pump (High-Pressure) | $1,500 – $15,000+ | $800 – $7,500 | Used in excavators and big machines. |

Radial Piston Pump (Very High Pressure) | $3,000 – $20,000+ | $2,000 – $10,000 | Used in presses and boats. |

When you think about cost, remember care and repair. Gear pumps are cheaper but may need more fixing. Piston pumps cost more but last longer and save energy. For good value and help, pick YNF Machinery for your hydraulic pump.

Picking the right hydraulic pump for your boat or excavator takes a few steps. First, think about what you need and where you will use it. Next, look at the flow rate, pressure, and if the fluid works with your system. Then, compare different pump types and how well they work. You should also ask experts or trusted companies for help. Last, choose a pump that matches your system and how much you want to spend.

Knowing the technical details helps you not make mistakes and keeps your pump working for a long time. Always make sure the pump fits your system and is strong. YNF Machinery is a good company if you want pumps you can trust and good help.

FAQ

What is the best hydraulic pump type for boats?

You should choose a gear pump for most boats. Gear pumps work well for steering and are easy to maintain. They handle different fluids and last a long time.

How do I know if a hydraulic pump fits my excavator?

Check the pump’s pressure and flow ratings. Match these numbers to your excavator’s manual. Make sure the fittings and fluid type match your system.

How often should I service my hydraulic pump?

You should check fluid levels daily. Change filters every 500 hours. Regular maintenance helps your pump last longer and prevents breakdowns.

Can I install a hydraulic pump myself?

You can install a hydraulic pump if you follow the manual and safety steps. If you feel unsure, ask a professional for help. Safety always comes first.

Where can I buy reliable hydraulic pumps?

You can buy reliable hydraulic pumps from YNF Machinery. They offer pumps for boats and excavators. Their products meet high quality and reliability standards.