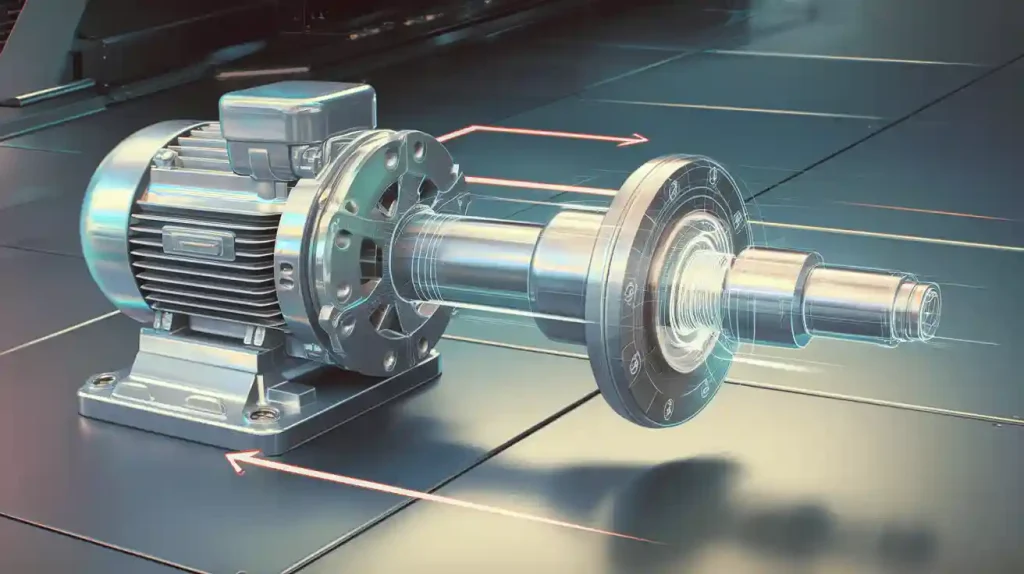

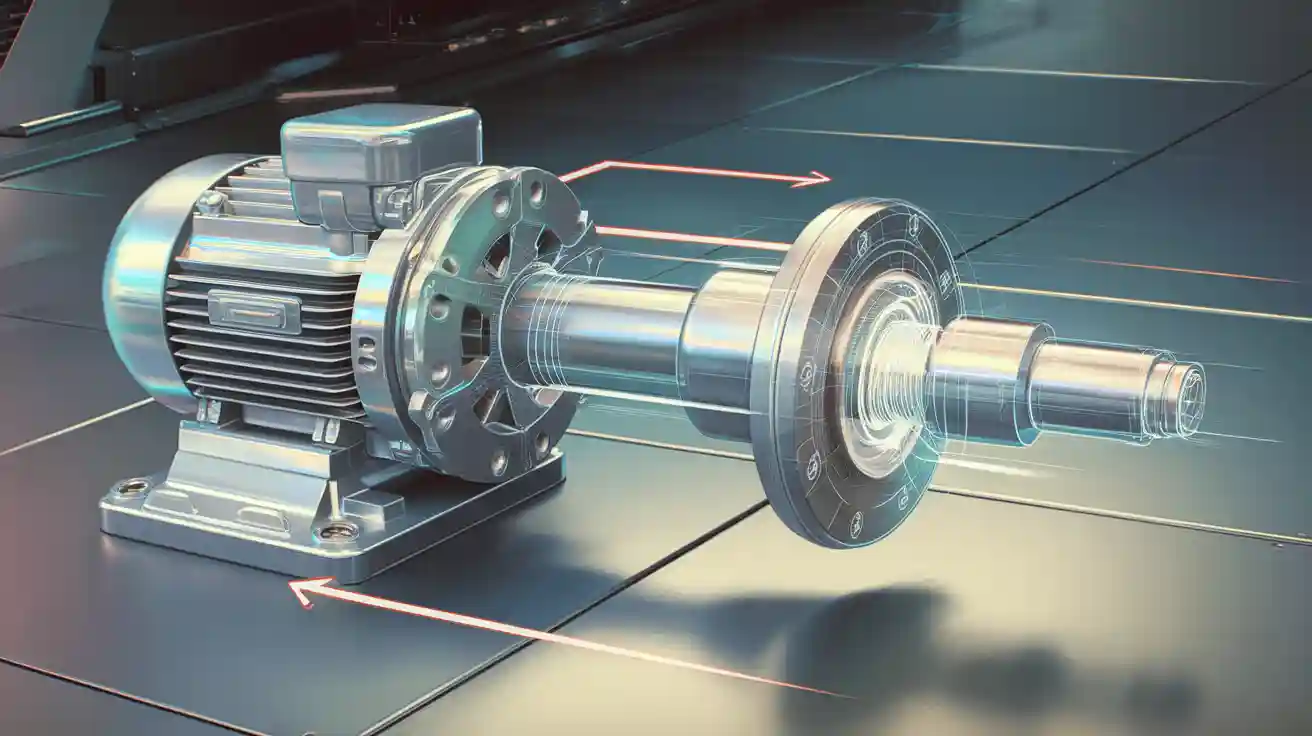

A motor coupling joins two shafts at their ends. This lets power move from one side to the other. You can think of it like a strong bridge. It links two spinning rods and lets energy pass easily. Motor couplings are important for machines to work well. They help cut down on shaking. They protect parts from sudden heavy loads. They also let shafts be a little out of line.

Here are standard definitions from mechanical engineering sources:

Definition | Description |

|---|---|

Coupling Shaft | Sends spinning motion between two shafts. It uses cast bosses, fasteners, and a key in matching slots. |

Coupling | Joins two shafts to send power. It allows a little misalignment or movement. |

Mechanical Element | Links two shafts to send power correctly. It also takes care of mounting mistakes (misalignment). |

Key Takeaways

Motor couplings join two shafts together. They let power move easily between them. This helps machines work well.

Couplings take in shocks and vibrations. They keep important machine parts safe from harm. This makes machines last longer.

Picking the right coupling type is very important. Think about misalignment, load, and speed. This helps machines work their best.

It is important to take care of couplings often. Look for damage or worn parts. This stops sudden problems and keeps machines working well.

Each coupling type has its own job. Rigid couplings need perfect alignment. Flexible couplings can handle misalignment and shocks.

Motor Coupling Functions

A motor coupling does more than just link two shafts. It has many jobs that help machines work well and stay safe. Let’s see what shaft couplings do and how they help your equipment.

Transmit Power

The main job of a coupling is to send power from one shaft to another. When you start a machine, the motor makes turning force called torque. The coupling connects the motor shaft to the driven shaft, like a pump or conveyor. This link lets power move from the motor to the part that needs to move.

Couplings join two shafts so power moves smoothly.

Rigid couplings make a strong link and do not allow misalignment.

Flexible couplings can handle small misalignment and soften shocks and shakes.

Fluid couplings use hydraulic fluid to send power, which helps machines start and stop gently.

You want your machine to work well. Most shaft couplings send power with high efficiency. For example, if the friction coefficient is 0.4 and the misalignment ratio is 0.01, the efficiency can be 98.7%. If friction drops to 0.3, efficiency goes up to 99%.

Friction Coefficient (µ) | Misalignment Ratio (e/Dex) | Efficiency (η) |

|---|---|---|

0.4 | 0.01 | 0.987 |

0.3 | 0.01 | 0.99 |

A coupling also helps change the power from the motor into movement for the driven part. This smooth transfer of torque keeps machines running without sudden stops or jerks.

Absorb Shock

Machines sometimes face quick changes in load or speed. These changes can cause shocks and shakes that may hurt parts. Shaft couplings help soak up vibration and lower the effect of these shocks.

Mechanism | Description |

|---|---|

Misalignment Compensation | Handles shaft misalignments, stops stress on parts, and lowers wear. |

Vibration Damping & Shock Absorption | Soaks up shakes and shock loads, protects sensitive parts, and lowers noise. |

Enhanced Load Distribution | Spreads loads evenly, lowers stress, and helps stop part failure. |

You may notice machines are quieter and last longer with the right coupling. Flexible shaft couplings act like cushions. They soak up energy from twisting, sudden load changes, and shakes during use. This protection helps stop damage to both the motor and the driven equipment.

Compensate Misalignment

It is hard to line up two shafts perfectly. Even small mistakes can cause problems over time. Shaft couplings help by fixing misalignment between the motor shaft and the driven shaft. There are three main types of misalignment:

Angular misalignment (shafts are at an angle)

Parallel misalignment (shafts are side by side but not lined up)

Axial misalignment (shafts move closer or farther apart)

Different couplings fix misalignment in different ways. Elastomeric couplings use flexible stuff to handle misalignment. Gear couplings work well for angular misalignment. Grid couplings give shock absorption and flexibility. Diaphragm couplings fix axial misalignment, and Oldham couplings are good for parallel misalignment.

Here is a chart showing the most misalignment allowed for some shaft couplings:

Coupling Type | Parallel Misalignment (inches) | Angular Misalignment (degrees) |

|---|---|---|

S-Flex Endurance Coupling | 0.062 | 1 |

Size | Maximum Angular Misalignment (inches) | Maximum Parallel Offset (inches) |

|---|---|---|

1020T | 0.003 | 0.006 |

1030T | 0.003 | 0.006 |

1040T | 0.003 | 0.006 |

1050T | 0.004 | 0.008 |

1060T | 0.005 | 0.008 |

1070T | 0.005 | 0.008 |

1080T | 0.006 | 0.008 |

1090T | 0.007 | 0.008 |

When you pick the right shaft coupling, you help your machine handle small alignment mistakes. This lowers wear, keeps the drive working well, and helps your equipment last longer. For example, a pump coupling can keep a water pump working even if the shafts are not lined up perfectly.

Tip: Always check what kind and how much misalignment your machine can handle. Using the right coupling keeps your equipment safe and helps your system work its best.

Types of Shaft Couplings

Machines use different shaft couplings for different jobs. Each kind works best in certain situations. Let’s look at the main types you might find.

Rigid Coupling

Rigid couplings join two shafts into one solid piece. You use them when shafts must line up perfectly and need strong power.

Keep shafts lined up for exact power transfer.

Handle high torque without slipping.

Used in pumps, compressors, conveyors, and mixers.

Found in electric motors and material handling systems.

Rigid couplings help machines last longer by lowering vibration and keeping things steady. Their simple design makes them easy to use and care for.

Here is a quick list of good and bad points:

Advantages | Disadvantages |

|---|---|

Exact Power Transfer | Sensitive to Misalignment |

Simple Design | Not Good at Absorbing Shocks |

Strong and Stable | Needs Perfect Shaft Alignment |

You should use rigid couplings only if you can line up shafts very well. If not, these couplings can cause stress and damage.

Flexible Coupling

Flexible couplings help when shafts are not lined up just right. They use elastic parts to connect shafts and can handle shakes and shocks.

Send torque while soaking up vibration.

Allow for parallel, angular, and axial misalignment.

Lower noise and protect equipment from sudden loads.

Used in motors, pumps, fans, and transmission systems.

Some types are jaw, diaphragm, and spring couplings. Flexible couplings also act as a safety part. If your machine faces too much force, the coupling can break first and save other parts.

Tip: Flexible shaft couplings keep your drive smooth, even if things move or shift.

Fluid Coupling

Fluid couplings use oil or another liquid to join shafts. They do not have a solid link. Instead, moving fluid sends power from one shaft to the other.

Use hydraulic fluid for smooth power transfer.

Let the motor reach full speed before moving the load.

Help machines start and stop gently.

Used in heavy-duty drives, like conveyors and crushers.

Fluid couplings need regular checks and fluid changes. They are less efficient because some energy is lost in the fluid. You may need more power to do the same work, and you must keep up with maintenance.

Note: Fluid shaft couplings are good for soft starts and protect machines from sudden shocks.

Here are some other shaft couplings you might see:

Coupling Type | Description |

|---|---|

Flange Couplings | Two flanges joined with bolts for strong connections. |

Gear Couplings | Use gear teeth for high torque jobs. |

Grid Couplings | Use a spring steel strip for flexibility and shock absorption. |

Tire Couplings | Use rubber or polyurethane for misalignment and vibration control. |

Bellows Couplings | Give exact rotation with no backlash. |

Drum Couplings | Connect rope drums to gearboxes for heavy loads. |

Choosing a Coupling

Picking the right shaft couplings helps your machine work well and last longer. You should think about a few things before you pick a coupling for your motor shaft or drive. Here is how you can choose the best one.

Application Needs

First, think about what your machine does every day. Each job has its own needs. Some machines need to move torque smoothly. Others must stop and start a lot. You should see if your system needs exact power transfer or if it can handle some misalignment. For example, a pump coupling in a water system may need to soak up shakes and let shafts be a little off.

Check what kind of shaft misalignment you have (angular, parallel, or axial).

See if your job needs a stiff coupling for exact timing.

Think about how often your machine starts and stops.

Tip: YNF Machinery has many shaft couplings for different jobs. Their experts can help you find the right one.

Load and Speed

You need to know the load and speed your shaft couplings will face. Couplings must move torque without slipping or breaking. Some couplings can take much higher torque for a short time, like when starting up.

Most shaft couplings work well up to 3,600 rpm.

If your drive goes faster than 10,000 rpm, check the maker’s speed limits.

Elastomeric couplings might stretch at high speeds, but metallic ones can get stressed.

Pick a coupling that matches your drive’s speed and torque. This keeps your system safe. Using the wrong coupling can cause shakes, imbalance, or even break your machine.

Environment

Where your machine works matters when picking shaft couplings.

Very hot or cold places can make some materials weak or brittle.

Wet places can cause rust and mess with lubrication.

Chemicals can hurt the coupling or make it less flexible.

For example, elastomeric couplings might not work in the cold, but special alloys like MP35N do better in tough places. Always check if your coupling can handle the area around your drive.

Maintenance

Different shaft couplings need different care. Some need almost no care, but others need regular checks and oil.

Here is a table to help you compare:

Coupling Type | Maintenance Needs | Life Expectancy |

|---|---|---|

Disc Coupling | No oil, almost no care needed | ~20 years |

Gear Coupling | Needs oil and checks | 3-5 years |

Universal Joint | Needs oil and checks sometimes | Varies |

Fluid Coupling | Needs little care, check alignment | Varies |

Rubber couplings need a look every 2,500 hours and bolt checks every 5,000 hours. Gear couplings need new oil every 6 months to a year.

Doing regular care keeps your shaft couplings working well and helps stop sudden problems.

Picking the right coupling helps your machine work well and stay safe. It also saves energy and helps parts move to the right spot.

The right choice keeps torque even and makes the system steady.

If you ignore misalignment or do not follow the maker’s rules, things can break early, cost a lot to fix, or even hurt someone.

You can read more about coupling types, how to put them in, and how to take care of them. There are many guides and articles that show you how to pick the best one for your job.

FAQ

What are shaft couplings used for?

You use shaft couplings to connect two shafts in a machine. They help transfer power, absorb shock, and fix misalignment. Shaft couplings keep your equipment running smoothly and protect parts from damage.

How do I know which shaft couplings to choose?

You should check your machine’s needs. Look at load, speed, and alignment. Shaft couplings come in different types for different jobs. If you need help, YNF Machinery can guide you to the right choice.

Can shaft couplings fix misalignment?

Yes, shaft couplings can fix small misalignments between shafts. Flexible shaft couplings work best for this job. They help prevent extra wear and keep your machine safe.

How often should I check shaft couplings?

You should check shaft couplings during regular maintenance. Look for signs of wear, noise, or vibration. Early checks help you avoid bigger problems and keep your system working well.

Where can I buy quality shaft couplings?

You can buy quality shaft couplings from YNF Machinery. They offer many options and can help you pick the best coupling for your needs.