A rigid coupling makes a strong link between two shafts. It lets power move straight from one shaft to the other. This coupling does not bend or flex at all. The shafts must stay lined up perfectly. Rigid couplings can handle a lot of force very well. They work best when even small mistakes in alignment can cause trouble. You can find rigid couplings used in many places, such as:

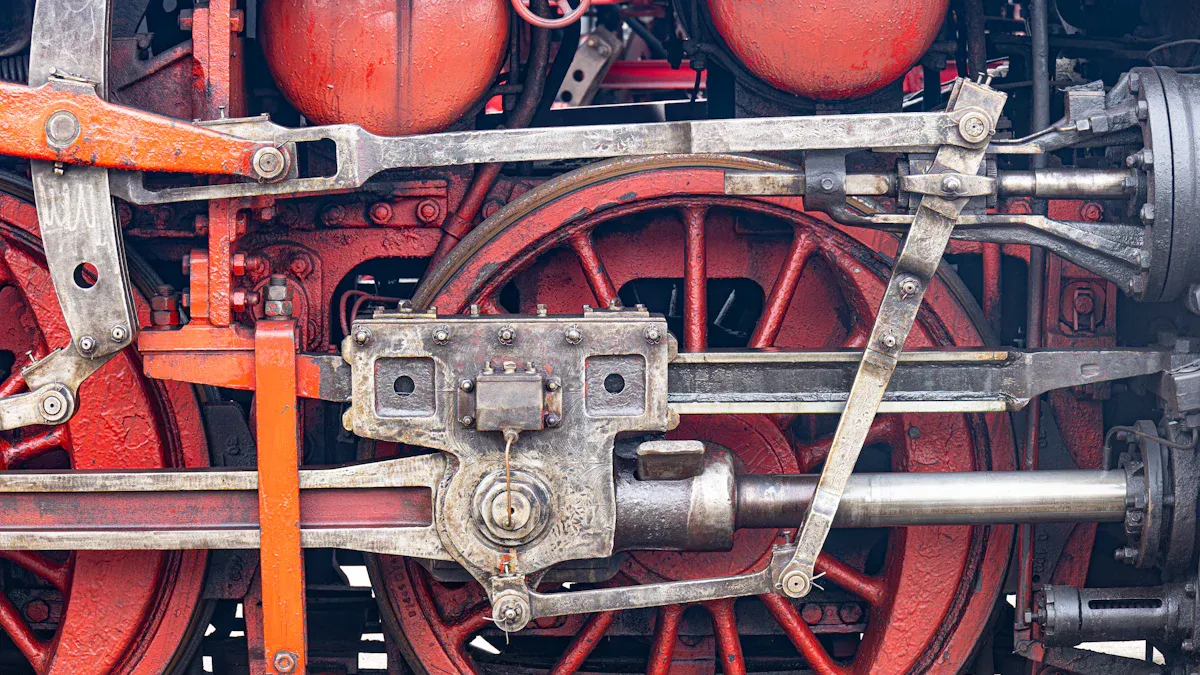

Industrial machines like pumps and conveyors

Car and airplane drive shafts

Electric motors joined to other equipment

Material handling systems that need tight alignment

Key Takeaways

A rigid coupling joins two shafts together. It lets power move straight through. The shafts do not bend or flex. The shafts must line up perfectly for it to work well.

A rigid coupling gives strong torque transmission. This makes it good for jobs that need high precision. Machines like CNC equipment and pumps use it.

You should check and maintain a rigid coupling often. Keeping it aligned can stop damage. It also helps the coupling last longer. It is best to inspect it every month.

Rigid couplings are made from different materials. These include steel, stainless steel, and aluminum. Each material works best for certain jobs and places.

People make mistakes with rigid couplings. They may not align them right. They may use the wrong type. Following the steps for installation can help stop these problems.

Rigid Coupling Basics

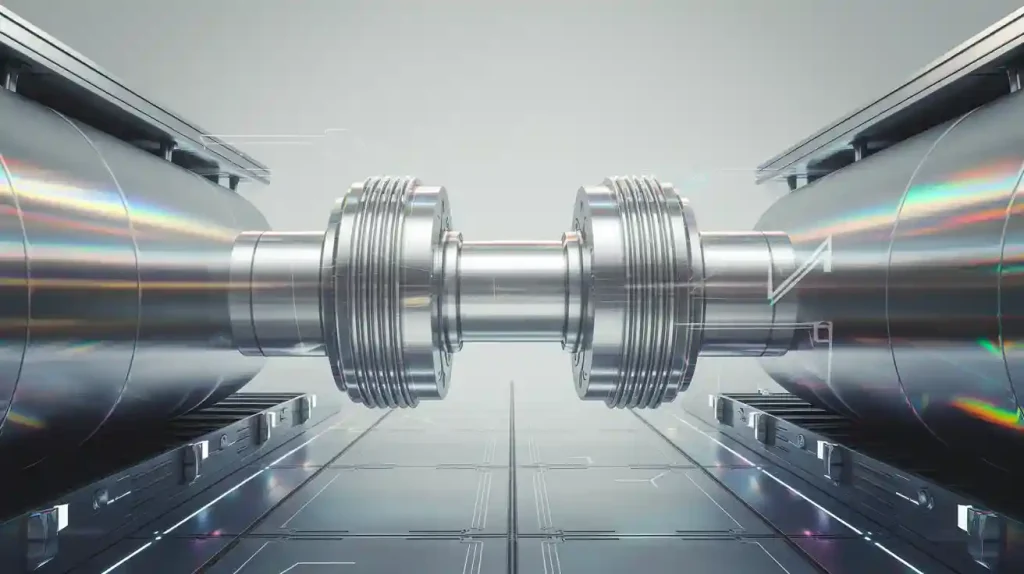

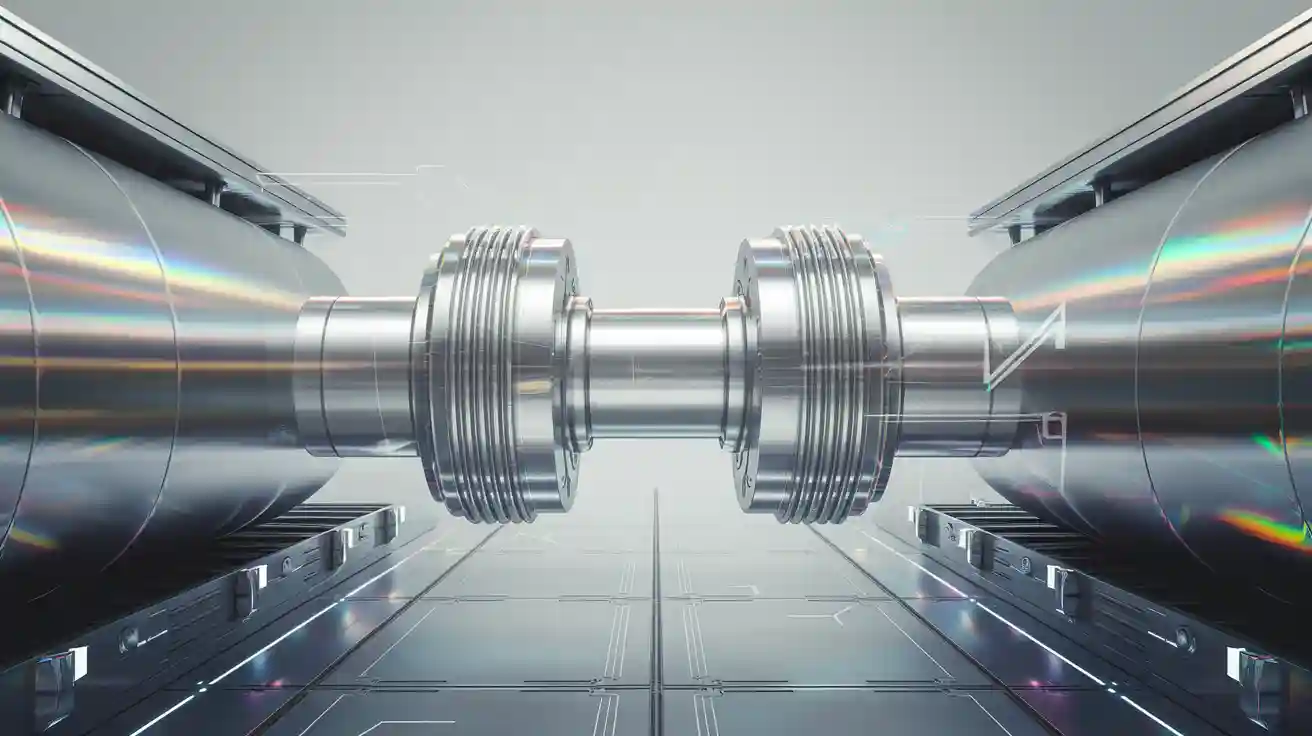

What is a Rigid Coupling

A rigid coupling joins two shafts in a straight line. It makes a solid link between the shafts. There is no movement or bending at all. You use a rigid coupling to move power directly and quickly. The design is simple, so it is easy to use. You see rigid coupling in machines that need to be very exact and steady.

Tip: Always check if the shafts are lined up before you put on a rigid coupling. Even a small mistake in alignment can cause trouble.

How It Works

A rigid coupling locks two shafts together so they spin as one. Both shafts must be lined up just right. If not, the rigid coupling can wear out fast or break. The main job is to move torque from one shaft to the other with no loss. You get a strong and steady link, but you must keep things lined up.

Here is a table that shows the main ideas behind how a rigid coupling works:

Mechanical Principle | Explanation |

|---|---|

Connection of shafts | You join two shafts in a straight line. There is no side or end movement. |

Torque transmission | The rigid coupling moves torque and spinning power between shafts. |

Alignment requirement | You need perfect alignment to stop stress and damage. |

Design simplicity | The simple design helps keep things steady. |

Maintenance necessity | You should check and oil it often for best results. |

You can see that a rigid coupling is best when you need a strong, direct link. You must watch alignment and do upkeep to keep your system working well.

Features

Design

You see a rigid coupling as a solid joint that connects two shafts. The design uses strong materials to make sure the joint does not bend or twist. Most couplings use steel, stainless steel, or aluminum. Each material has its own benefits. Steel gives you strength for heavy-duty jobs. Stainless steel works well in places that need to stay clean, like food factories. Aluminum is light and easy to spot in high-visibility areas.

Material | Description |

|---|---|

Steel | Most common; types like 1215, 1045, and 1026 offer strength and durability. |

Stainless Steel | Good for wash down; type 303 meets FDA rules for clean environments. |

Aluminum | Light, non-magnetic, and bright for easy visibility. |

The design clamps tightly onto both shafts. This makes the joint act like one solid piece. You get high torsional stiffness, which means the coupling can handle a lot of force without slipping. The simple shape helps you install it quickly and keeps the connection steady.

Alignment

You must line up the shafts perfectly before you install a rigid coupling. The joint does not allow any movement between the shafts. If you miss the alignment, you risk damage. Even a small mistake can cause big problems. Industry standards say that rigid couplings need full alignment. If you do not follow this rule, you put stress on the shafts and bearings. This can lead to machine failure.

Note: Research shows that misalignment causes over half of machine downtime in some industries. Most machines run outside the best alignment range, which leads to higher costs and more repairs.

Common problems from poor alignment include:

Excessive vibration

Premature wear on drive parts

Higher energy use

Loose foundation screws

Hot bearings and leaking seals

Performance

Rigid couplings give you the best torque transmission. The joint does not allow any unwanted movement, so you get almost zero windup. This means you can use the coupling in high-precision jobs. The connection stays strong, even under heavy loads. Some types, like ZAPEX, can handle up to 7,200,000 Nm of torque. You do not get this level of performance with flexible couplings.

Coupling Type | Torque Transmission | Misalignment Handling | Precision |

|---|---|---|---|

Rigid Coupling | Superior | None | High |

Flexible Coupling | Limited | Yes | Moderate |

You should use a rigid coupling when you need a solid joint and perfect alignment. If you want the best performance and high torque, this is the right choice.

Advantages and Drawbacks

Benefits

Using a rigid coupling gives you many good things. It makes a strong link between two shafts. You can trust it for exact work and steady torque. The design does not have moving parts, so it does not wear out fast. You do not need to change it often. This helps you save money on repairs.

Here is a table that lists the main benefits for machines that need to be exact:

Benefit | Description |

|---|---|

Precision | Keeps shafts lined up for accurate control. |

Torque Transmission | Handles lots of torque, good for tough jobs. |

Maintenance Cost | No parts to wear out, so upkeep is cheaper. |

Energy Efficiency | Almost no power loss, which saves energy. |

Longevity | Lasts longer, so you change parts less. |

You also get zero-backlash, so the joint does not slip. This matters for CNC machines and robot arms. The rigid coupling helps your system react fast and keeps it working well.

Limitations

You need to know what a rigid coupling cannot do. This joint cannot handle shafts that are not lined up. If the shafts are off, your equipment can get damaged. The joint does not soak up vibration or shock, so your system may feel more force.

Limitation | Rigid Couplings | Flexible Couplings |

|---|---|---|

Misalignment Tolerance | Cannot handle shafts that are off | Can handle small misalignment |

Vibration Absorption | Do not soak up vibrations | Soak up vibrations and shocks |

Maintenance Requirements | Need checks to keep alignment | Need less upkeep |

Application Suitability | Best for strong, lined-up shafts | Good for jobs with some movement |

If you put the coupling on wrong, it can hurt the joint and other parts. This can make it break early. Common problems are bad alignment, no oil, and not checking the joint enough.

Note: Always check if things are lined up before and after you install. Bad alignment is the main reason joints break in many places.

Applications

You find rigid couplings where you need a solid and exact link. These joints work best for jobs with lots of torque and need to be very precise. Some common uses are:

Vertical pump systems

CNC machines and robot arms

Factory conveyor drives

Electric motor and gearbox links

You should use a rigid coupling when you need perfect alignment and strong torque. This joint helps your system run well and saves energy in tough jobs.

Rigid Coupling Types

Common Types

You can find several main types of rigid couplings in industrial settings. Each type connects shafts in a different way, but all create a solid joint. Here are the most common types you might see:

Set Screw Couplings: These use screws to lock the coupling onto the shaft. You often use them for light to medium loads.

One-Piece Couplings: This type has a single solid body. You slide it over the shafts and tighten it for a strong joint.

Two-Piece Couplings: These come in two halves. You bolt them together around the shafts, which makes installation easy, even if you cannot move the shafts.

Flange Couplings: These use flanges, bolts, and nuts to create a rigid connection. They help keep the shafts lined up and reduce vibration.

Sleeve Couplings: This type uses a simple cylindrical sleeve to join the shafts. It works well for basic jobs with lower torque.

Ribbed Couplings: These have extra ribs for better grip and strength.

You can see that each type has its own use. For example, flange couplings work best when you need to move a lot of torque. Sleeve couplings are good for simple jobs.

Here is a table to help you compare flange and sleeve couplings:

Feature | Flange Couplings | Sleeve Couplings |

|---|---|---|

Connection Method | Uses bolts and nuts for a rigid connection | Cylindrical sleeve connects shafts directly |

Structural Features | Keeps shafts aligned with spigot and recess | Simple design, no special alignment features |

Application | High torque jobs | Lower torque, basic jobs |

Tip: If you need a reliable shaft coupling for your project, you can consider YNF Machinery. They offer a range of rigid couplings for different needs.

Installation

You need to follow careful steps to install a rigid coupling and keep your joint strong. Here is a simple guide:

Pre-Installation Checks: Clean the shafts and check their size. Make sure they match the coupling.

Measuring and Aligning: Use a straightedge, dial indicator, or laser tool to line up the shafts.

Installation: Slide the coupling onto the shafts. Tighten the set screws or bolts evenly. Do not overtighten.

Post-Installation Checks: Check the alignment again to make sure everything is correct.

If you follow these steps, your joint will last longer and work better.

Best Practices

You can keep your rigid coupling working well by following some best practices:

Use cross-cuts in the coupling to help it grip the shaft and fit small size changes.

Tighten screws in an alternating pattern. This spreads the force and keeps the joint even.

Use screws with nylon patches to stop them from loosening when the machine vibrates.

Check your coupling every month for signs of wear, loose bolts, or misalignment.

Always check alignment regularly. This helps prevent early failure.

Inspection Type | Frequency | Actions |

|---|---|---|

Visual Inspections | Monthly | Look for misalignment, corrosion, damage, loose bolts, and wear. |

Alignment Check | Regularly | Make sure the shafts stay lined up. |

When you choose a rigid coupling, think about how much misalignment you can allow, the type of misalignment, the torque you need, and how the system handles changes in motion. These factors help you pick the right joint for your job.

Rigid couplings make a strong and direct link between shafts. You use them when you need high torque and perfect alignment. It is important to line up the shafts the right way. Good alignment keeps things cool and stops vibration. This helps your equipment last longer:

Cooler parts help the coupling last longer.

Less shaking keeps bearings safe and stops early breaks.

People often make mistakes when putting in couplings:

Picking the wrong size or type of coupler.

Not checking if the shafts are lined up.

Making bolts too tight or too loose.

Always use the right steps to keep your system working well.

FAQ

What is the main job of a rigid coupling?

A rigid coupling connects two shafts so they spin together. You use it when you need a strong, direct link and perfect alignment. It helps move power without any loss.

Can you fix misalignment with a rigid coupling?

No, you cannot fix misalignment with a rigid coupling. You must line up the shafts perfectly before you install it. Even small mistakes can cause damage or make the machine fail.

How often should you check a rigid coupling?

You should check your rigid coupling every month. Look for signs of wear, loose bolts, or misalignment. Regular checks help your equipment last longer and work better.

Where can you buy rigid couplings?

You can buy rigid couplings from YNF Machinery. They offer many types for different jobs. You get strong, reliable products for your machines.

What materials do rigid couplings use?

Rigid couplings use steel, stainless steel, or aluminum. Steel works for heavy-duty jobs. Stainless steel fits clean places like food factories. Aluminum is light and easy to spot.