O-Ring Seal Description

The YNF16810 O-ring seal (2H-6184) is a precision-engineered rubber sealing ring used in a wide range of excavator hydraulic systems. Designed to provide reliable static and dynamic sealing, it prevents leakage of oil and hydraulic fluid under pressure. It is manufactured using high-quality NBR or optional FKM material, making it suitable for both standard and high-temperature environments. The seal fits various CAT machines and is essential in repair kits and parts inventories for machinery dealers and service teams.

O-Ring Seal Technical Sheet

| Item |

Details |

| YNF Code |

YNF16810 |

| OEM Part Number |

2H-6184 |

| Product Name |

Seal-O-Ring |

| Material |

NBR (Standard), FKM (Optional) |

| Application Area |

Hydraulic sealing |

| Diameter/Spec |

OEM standard tolerance |

| Temperature Range |

-30°C to +200°C |

| Pressure Resistance |

Up to 40 MPa |

| Machine Compatibility |

Caterpillar, Komatsu, Hitachi |

| MOQ |

100 pcs |

| Packaging |

Individual sealed bag + carton |

| Origin |

China |

| Shipping Options |

Air, Sea, Express |

| Payment Terms |

T/T, Western Union, L/C |

O-Ring Seal Applications

| Application Component |

Description |

| Hydraulic Pumps |

Shaft and port sealing |

| Hydraulic Cylinders |

End cover and piston sealing |

| Control Valves |

Preventing internal oil leakage |

| Excavator Fittings |

Sealing hose and pipe junctions |

| Service Maintenance Kits |

Essential spare in hydraulic repair kits |

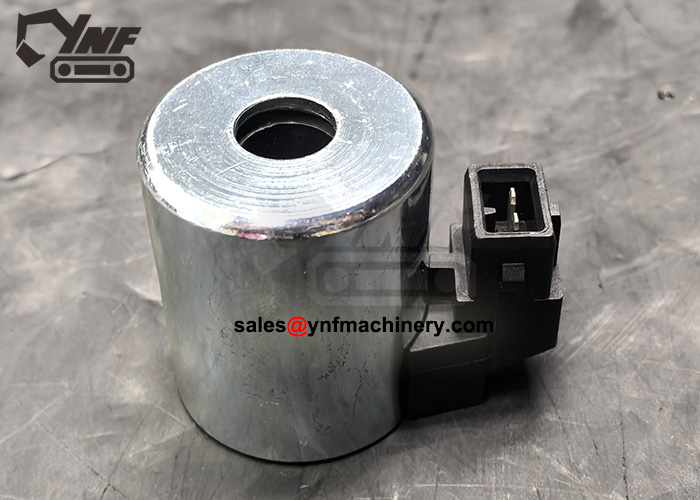

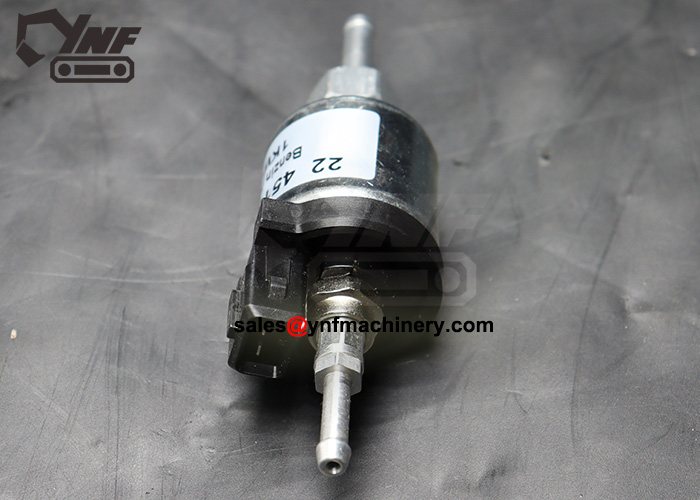

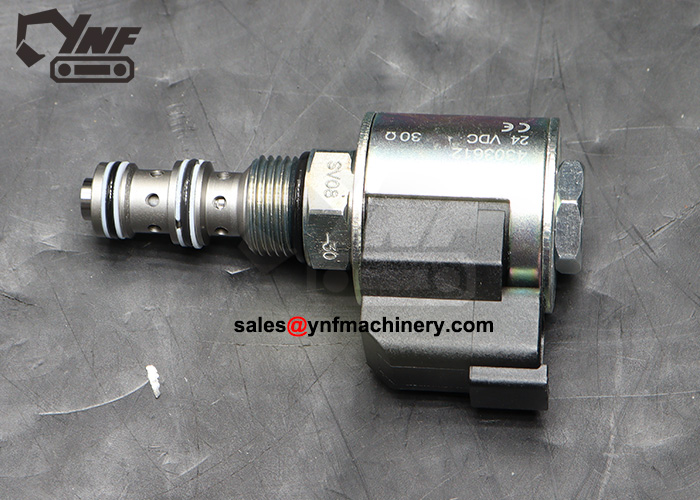

Hydraulic O-Ring 2H-6184 Detail Display

Related Knowledge:

-

O-rings are the backbone of hydraulic sealing solutions in heavy machinery.

-

NBR is preferred for oil resistance; FKM is suited for higher temperatures and chemicals.

-

Proper installation using lubricants can extend O-ring life and performance.

Related Products:

-

O-ring seal 5P-8356

-

Hydraulic seal kits for CAT cylinders

-

Excavator piston seals and rod seals

-

Backup rings and wear rings

FAQs:

-

Q: Can this O-ring be added to a complete seal kit?

A: Yes, we offer custom seal kit packaging with your selected part numbers.

-

Q: How do I choose between NBR and FKM?

A: Choose FKM for higher temperature or chemical exposure applications; NBR is sufficient for general use.