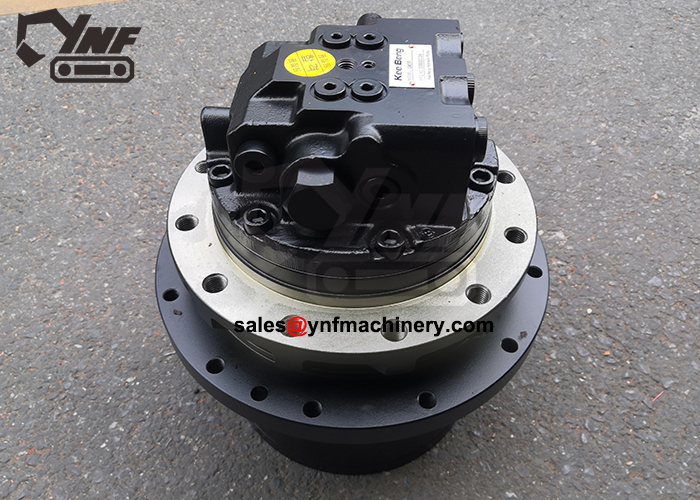

TM09 Final Drive Description

The YNF16386 Final Drive Assembly (Model TM09) is a premium travel motor and reduction gear unit tailored for 10–20 ton excavators and similar crawler-type machinery. Featuring a powerful hydraulic motor paired with a precision-engineered planetary gearbox, it ensures smooth machine movement, excellent torque delivery, and long service life under harsh job site conditions. This robust unit is ideal for OEM replacement, field repair, or aftermarket stocking—offering easy installation and compatibility with a wide range of machines. Backed by YNF’s manufacturing standards, the TM09 is a proven performer in high-load applications. Learn more about hydraulic final drive systems from our technical team.

TM09 Final Drive Technical Sheet

| Parameter |

Detail |

| Model Number |

TM09 |

| YNF Code |

YNF16386 |

| Product Category |

Travel Motor / Final Drive Assemblies |

| Applicable Machine |

10~20 Ton Excavators / Crawler Equipment |

| Gear Reduction Type |

Planetary Multi-Stage Gearbox |

| Torque Output |

High Torque (as per TM09 specs) |

| Material |

Forged Alloy Steel + Heat-Treated Gears |

| Seal Structure |

Advanced Multi-Lip Oil Seal Design |

| Mounting Type |

Flanged Output Shaft |

| Brand |

YNF |

| Origin |

China |

| MOQ |

1 Unit |

| Shipping Method |

Air, Sea, Courier |

| Payment Method |

T/T, PayPal, Western Union |

TM09 Final Drive Applications

| Equipment Type |

Application Scenario |

| Medium Excavators |

High-torque drive and terrain mobility |

| Crawler Cranes |

Stable travel for large lifting equipment |

| Construction Equipment |

Site navigation in muddy or inclined terrains |

| Demolition Machinery |

Track-based movement with high-impact load |

TM09 Travel Drive Detail Display

Related Products:

-

Swing motors for 10-20 ton excavators

-

Undercarriage track rollers and sprockets

-

Excavator main hydraulic pumps

-

Drive motor seal kits and gear sets

FAQ:

Q: What’s the average service life of this unit?

A: Typically 3,000–5,000 working hours under standard operating conditions.

Q: Is the TM09 compatible with multiple brands?

A: Yes, it’s commonly used across various OEM platforms. Confirm installation specs before order.

Knowledge Base:

Proper final drive selection improves machine traction, reduces wear on undercarriage components, and ensures fuel-efficient operation across various ground conditions.