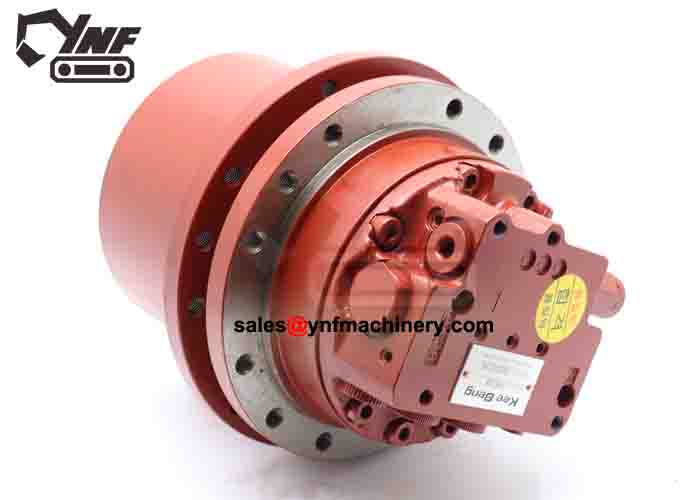

Final Drive Description

The YNF16383 Final Drive and Motor Assembly (Model TM02B) is a compact, high-torque travel motor unit engineered for mini and mid-size excavators. Integrating a hydraulic motor with a precision planetary reduction gearbox, this assembly ensures smooth and efficient machine propulsion across varied terrain. The TM02B unit is manufactured to tight tolerances using high-strength alloy steel and heat-treated gears to reduce wear and withstand continuous shock loads. This makes it a durable solution for equipment dealers, fleet maintenance teams, and hydraulic specialists needing reliable mobility solutions. For more insights into excavator travel motor systems, contact our technical consultants.

Final Drive Technical Sheet

| Parameter |

Detail |

| Model Number |

TM02B |

| YNF Code |

YNF16383 |

| Product Category |

Travel Motor Assemblies / Final Drive Units |

| Structure |

Motor + Planetary Gearbox Integrated |

| Application Range |

Mini/Mid Excavators, Crawler Machines |

| Output Torque |

High Torque (per TM02B spec) |

| Gear Reduction Ratio |

Planetary Type, Multi-stage |

| Mounting Type |

Bolt-on Flange, Shaft Output |

| Material |

Forged Steel + Hardened Gearsets |

| Origin |

China |

| Brand |

YNF |

| MOQ |

1 Set |

| Shipping Method |

Sea / Air / Express |

| Payment Method |

T/T, PayPal, Western Union |

| Warranty |

12 Months (OEM spec usage conditions) |

Final Drive Applications

| Equipment Type |

Application Scenario |

| Mini Excavators |

Travel and rotation drive in compact chassis |

| Crawler Drills |

Terrain movement for tracked drilling rigs |

| Forestry Equipment |

Track-based mobility in rough conditions |

| Mining Support Units |

Propulsion in low-speed high-torque environments |

Final Drive TM02B Detail Display

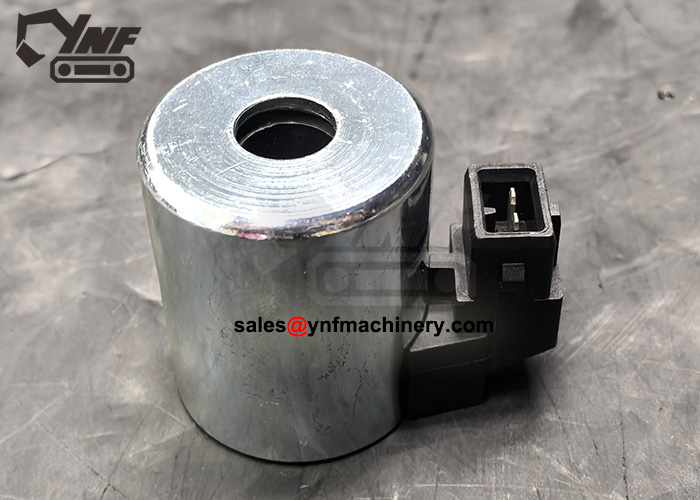

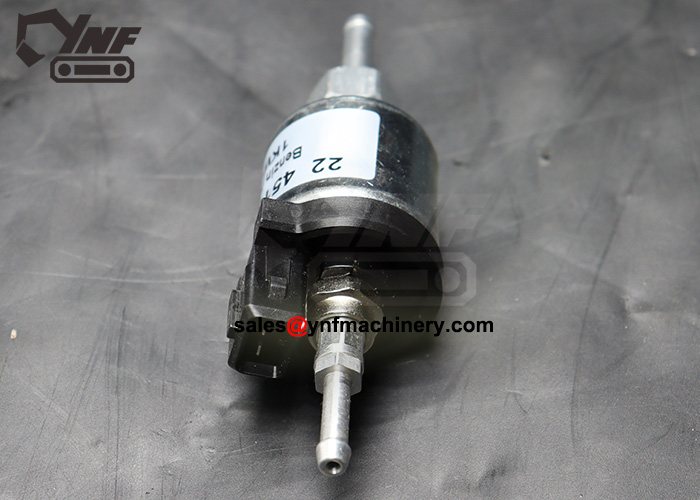

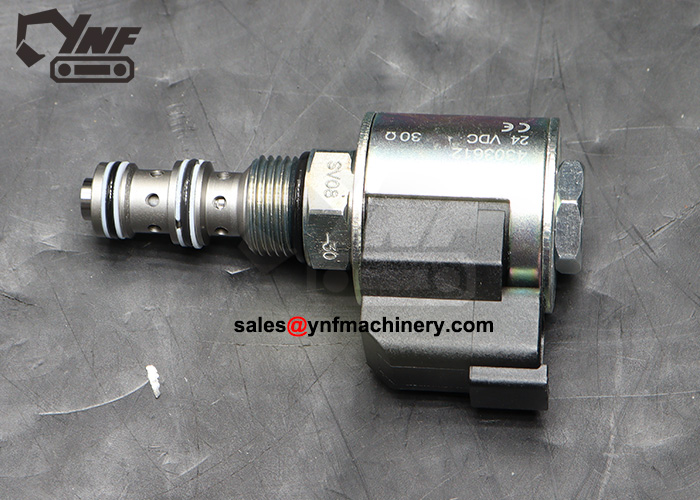

Related Products:

-

Hydraulic track motors for 2-6 ton excavators

-

Travel gearboxes for crawler chassis

-

Swing motors and reduction gears

-

Drive sprockets and track rollers

FAQ:

Q: Can this final drive be installed on other brands?

A: Yes, it can be adapted to various mini/mid excavators. Please confirm shaft and flange dimensions.

Q: What’s the typical service life?

A: Under normal use, 3,000–5,000 working hours. Regular maintenance improves lifespan.

Knowledge Base:

Final drive assemblies are critical to equipment mobility. Choosing a properly matched drive reduces fuel consumption, extends undercarriage life, and ensures smooth operator control.