You will find many important excavator chassis parts in an excavator chassis. These include the undercarriage, main frame, swing drive, and slewing ring. The undercarriage helps the excavator move and stay steady on various surfaces. The main frame supports the weight and connects all other parts together. The swing drive allows the top part to rotate, while the slewing ring enables the upper body to spin smoothly. Each of these excavator chassis parts is crucial for the machine to operate efficiently. The table below highlights why certain excavator parts matter and their functions. For instance, composite materials can reduce the weight of a hydraulic cylinder by up to 87% while maintaining safety.

Excavator Part | Numerical Data / Performance Metric | Description / Significance |

|---|---|---|

Hydraulic cylinder | Weight reduction of about 87% (from 2286 N to 314 N) | Composite material cylinder shows similar safety factor to steel but much lighter |

Excavator arms | Total weight reduction up to 64.1% | Composite materials with elliptical section replace steel rectangular section for lighter design |

Load bearing capacity | Improved through structure optimization based on validated FEM | Demonstrates mechanical performance enhancement via numerical methods |

Key Takeaways

The excavator chassis has important parts like the main frame, undercarriage, and swing system. These parts work together to help the machine move, carry heavy things, and turn easily.

The undercarriage has tracks, rollers, sprockets, and idlers. These help the excavator move and stay balanced. You should check and clean them often. This keeps them working well and stops them from breaking.

The main frame is like a strong backbone. It holds all the parts together. Good design and care help the excavator stay safe and last a long time.

The swing system lets the top part turn around. This helps the machine work faster and use less energy. Taking care of the swing drive and slewing ring makes the machine work better and last longer.

You should take care of all parts, like bolts, track pads, and use enough oil. This stops damage, lowers repair needs, and keeps your excavator ready for any job.

Excavator Chassis Parts Overview

When you look at an excavator, you see many parts. These parts work together to help the machine do its job. The main chassis has the main frame, undercarriage, and swing system. Each part helps the excavator move, hold weight, or turn.

Main Frame

The main frame is like the backbone of the excavator. It is a strong base that holds everything in place. It links the top and bottom parts. It also carries heavy loads from the arm, boom, and bucket. Engineers use special computer tools to check how the main frame handles stress. They look for places where stress is high, like near welded joints. These spots can get very stressed, so designers make them extra strong. The main frame must hold up all the parts and handle forces from moving arms and hydraulic cylinders. Careful design helps the excavator last longer and stay safe.

Undercarriage

The undercarriage is at the bottom of the excavator. It has tracks, rollers, idlers, and more. The undercarriage lets the machine move on rough ground. It also keeps the excavator steady. Tracks go around the undercarriage and spread out the weight. This stops the excavator from sinking in soft dirt. Each track is linked to rollers and idlers. These help guide and support the tracks. The undercarriage also takes in shocks and keeps the machine balanced. When you check the undercarriage, you look at these parts to make sure they work well. A good undercarriage helps the excavator move easily and do hard work.

Swing System

The swing system lets the top of the excavator turn. It has the swing drive and slewing ring. When you use the excavator, the swing system lets you turn the cab and arm. This helps you reach different places without moving the whole machine. Studies show the swing system uses a lot of power. It also takes up almost half the time when digging. This makes the swing system very important for getting work done. If it works well, you finish jobs faster and save energy. The swing system works with other chassis parts to keep movements smooth and easy.

Note: Knowing about the main excavator parts helps you see how they work together. When you understand the main frame, undercarriage, and swing system, you can take better care of your machine and find problems early.

Undercarriage Components

The excavator undercarriage holds many important parts that help your machine move and stay balanced. Each part has a special job. When you know how these parts work together, you can keep your excavator running smoothly and safely.

Tracks

Tracks give your excavator the ability to move across different surfaces. They spread the machine’s weight over a large area, so you do not sink into soft ground. You can choose from rubber, steel, or hybrid tracks. Each type works best on certain terrain. The table below shows how different tracks perform:

Track Type | Terrain Suitability | Performance Characteristics |

|---|---|---|

Rubber Tracks | Mud, pavement, urban, landscaping, light construction | Smooth ride, low ground disturbance, quieter, lighter, better fuel efficiency, less durable on rocks |

Steel Tracks | Rocky, uneven, abrasive, muddy, rough terrain | High durability, strong traction, heavier, higher fuel use, longer lifespan, more costly to replace |

Hybrid Tracks | Variable terrain conditions | Mix of rubber and steel benefits, replaceable pads, moderate cost, less surface damage |

You get better traction and stability with new excavator tracks. Upgraded tracks last longer and help you finish projects on time. Good grip on tough ground keeps you safe and lets you work faster. If you clean and check your tracks often, you will save money and avoid breakdowns.

Track Pads (Shoes)

Track pads, also called shoes, attach to the tracks and touch the ground. They give your excavator grip and help control how much the machine sinks into soft soil. Wide pads spread the weight out, so you do not get stuck in mud. Narrow pads help you move better on hard ground. You can pick different pad shapes for different jobs. When you use the right pads, you protect the ground and make your excavator more stable.

Track Chains

Track chains hold the track pads together and form the main loop of the tracks. They connect to the sprockets and idlers, letting the tracks move around the undercarriage. Strong track chains keep the tracks tight and lined up. If a chain wears out or breaks, the tracks can slip or come off. You need to check the chains often to make sure your excavator moves smoothly and safely.

Track Bolts

Track bolts fasten the track pads to the track chains. They keep everything tight and secure. If a bolt comes loose or breaks, the pad can fall off or shift. This can damage the tracks and make your excavator unsafe. You should check the bolts often and tighten or replace them when needed. Good bolts help your undercarriage last longer and work better.

Rock Guards

Rock guards protect the undercarriage from rocks, debris, and other hard objects. They stop things from getting stuck in the tracks or hitting the rollers and chains. When you work in rocky areas, rock guards keep your excavator parts safe from damage. They also help keep the tracks lined up and moving smoothly.

Tip: If you use your excavator in rough or rocky places, always check your rock guards for dents or cracks. Replacing damaged guards keeps your undercarriage safe.

Sprockets

Sprockets are toothed wheels that drive the tracks. When you move the excavator, the sprockets turn and pull the tracks along. Good sprockets give you strong traction and help you climb over obstacles. Worn sprockets can slip or damage the track chains. You should check the teeth for wear and replace them if needed. Healthy sprockets keep your excavator moving with power and control.

Rollers

Rollers support the weight of the excavator and guide the tracks as they move. There are two types: top rollers and bottom rollers. Top rollers hold up the top part of the tracks, while bottom rollers carry the weight on the ground. Rollers help the tracks move smoothly and keep them from sagging. If a roller gets stuck or worn out, the tracks can drag or come off. You should keep the rollers clean and well-oiled for the best performance.

Idlers

Idlers sit at the front and sometimes the back of the undercarriage. They guide the tracks and keep them tight. The idler works with a hydraulic adjuster to push forward or backward, making sure the track is not too loose or too tight. This tension helps your excavator stay stable and move smoothly. Idlers also help spread the weight and keep the tracks lined up with the rollers and sprockets. When you keep the idlers in good shape, you get better stability and longer life from your undercarriage.

All these undercarriage parts work together to give your excavator strong movement and balance. When you take care of each part, you get better performance and fewer repairs. Knowing about excavator parts and their functions helps you spot problems early and keep your machine working hard.

Main Frame and Structure

The main frame and structure are the center of your excavator. This strong base holds all the parts together. It helps keep the machine safe and steady. Each part of the frame has its own job. These jobs help the whole excavator work well.

Upper Frame

The upper frame sits on top of the chassis. It holds the cab, engine, hydraulic system, and swing system. Some frames use a D-channel shape to protect important parts. Some models have guards on the sides. These guards keep the engine and hydraulic lines safe from hits. Steel castings make the frame stronger at key spots. These spots are where the boom and arm connect. Heavy-duty plates at the arm ends help the frame last longer. These features make the upper frame tough for hard work. You get less downtime and more use from your machine.

The upper frame may have:

D-channel shape for better protection

Side guards for extra safety

Steel castings at strong points

Drive motors set inside for less harm

Note: A tough upper frame keeps your excavator safe and working in rough places.

Lower Frame

The lower frame is under the upper frame. It connects to the undercarriage. This part holds up the whole machine’s weight. Some excavators use an X-Chassis for more strength. Extra material in the lower frame makes it last longer. It also helps the machine carry heavy loads. The lower frame keeps the excavator steady when digging or lifting. A strong lower frame helps your machine stay balanced on any ground.

Support Functions

Support functions help the main frame work better and last longer. Smart Power Control saves fuel by changing speed and power. Auto idle and shutdown save energy when you stop. Some excavators have boom float mode. This lets the boom move with the ground. It saves fuel and helps finish jobs faster. Engineers use computers to test the frame’s strength. They try to make it lighter but still strong. They check digging force and stress at key spots. This makes sure the frame is safe and meets standards.

When you know about excavator parts, you see how the main frame and structure help your machine. Each part works with the others for the best results and trust.

Swing System Parts of an Excavator

The swing system lets you turn the top part of your excavator. This helps you move the boom, arm, and bucket without moving the whole machine. The swing system has two main parts: the swing drive and the slewing ring. Each part does a special job to keep your excavator working well.

Swing Drive

The swing drive makes the top part turn. It uses a hydraulic motor to spin gears. These gears turn the cab and the working arm. You control the swing drive from inside the cab. This makes it easy to dig, load, or grade.

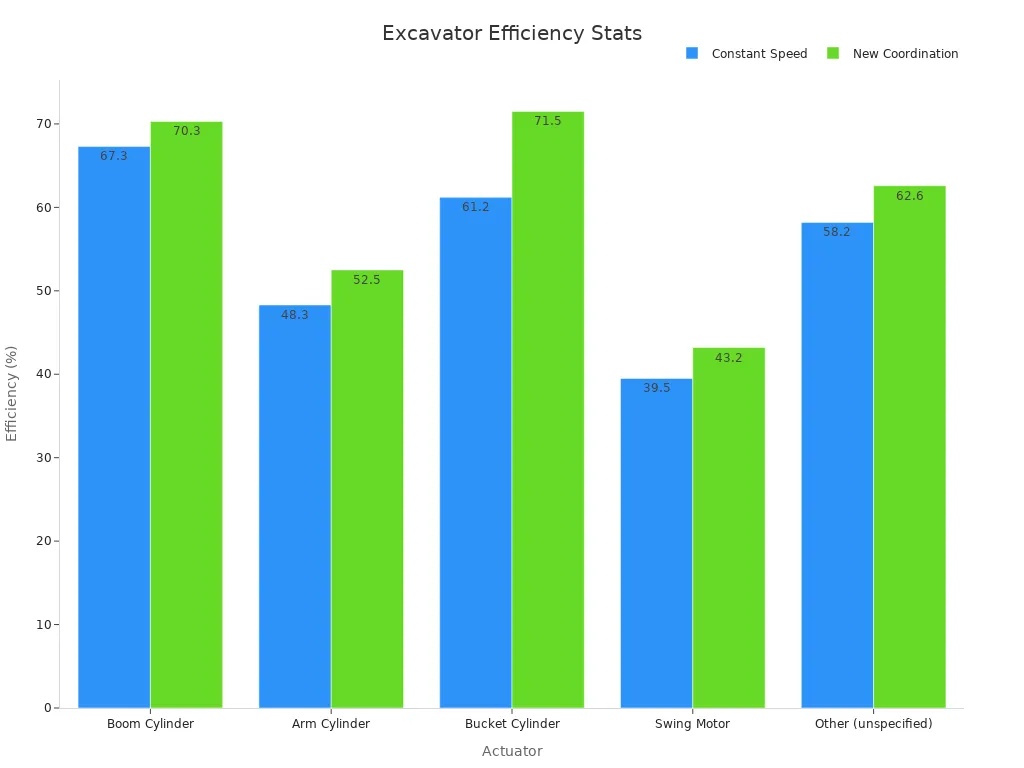

The swing drive is important for saving energy. The swing motor is a big part of the swing drive. It has an energy efficiency of 39.5% with the constant speed method. With a new method, the efficiency goes up to 43.2%. This means you use less fuel and get more work done. The chart below shows how the swing motor compares to other actuators:

Actuator | Energy Efficiency (Constant Speed Method) | Energy Efficiency (New Coordination Method) |

|---|---|---|

Boom Cylinder | 67.3% | 70.3% |

Arm Cylinder | 48.3% | 52.5% |

Bucket Cylinder | 61.2% | 71.5% |

Swing Motor | 39.5% | 43.2% |

Other | 58.2% | 62.6% |

Swing drives work in many different situations. Engineers use sensors on the bucket, arm, boom, and cab to collect data. They test the swing drive at different angles and digging depths. They also use different materials like sand, gravel, and clay. The table below shows how these tests help make the swing drive better:

Aspect | Details |

|---|---|

Data Source | Motion data from 4 IMUs on excavator parts |

Sampling Frequency | 200 Hz |

Dataset Duration | About 3 hours (2,160,000 data points per sensor) |

Operational Conditions | Swing angles: 60° to 120°; Digging depths: up to 2 meters; Materials: sand, gravel, clay |

Weather & Operator Skill | Varied weather; both experienced and new operators |

Machine Learning Techniques | SVM, KNN, Decision Tree, Naive Bayes |

Classification Accuracy | Up to 99% (SVM with MRMR feature selection) |

Application | Recognizes working cycles (loading, trenching, grading, idling) |

Significance | Helps boost productivity and adapt to real job sites |

Tip: If you take care of the swing drive, you can finish jobs faster and your excavator will last longer.

Slewing Ring

The slewing ring is a big bearing between the top and bottom frames. It lets the top part spin smoothly while holding heavy loads. The slewing ring supports the cab, boom, and arm as you turn the excavator.

You must take good care of the slewing ring. Most problems—over 96%—happen because of bad lubrication or dirt. If you do not keep the slewing ring clean and oiled, it can crack or break. Too much weight or bad installation can also cause trouble. Checking and fixing problems early saves money and stops breakdowns.

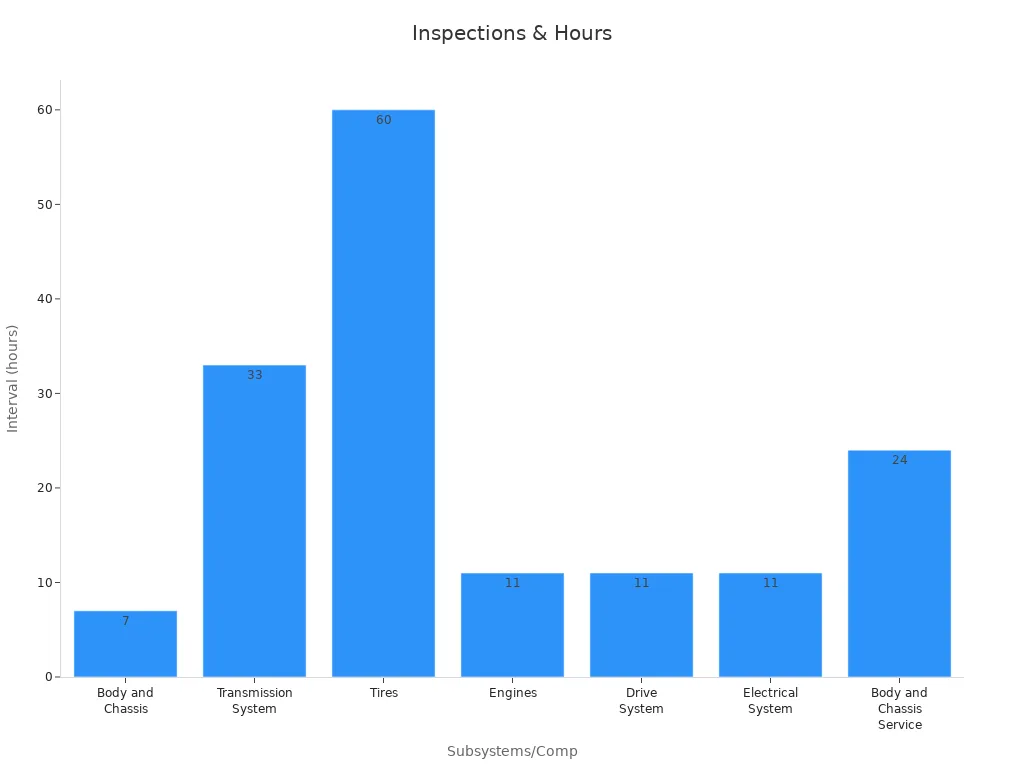

Here are some important steps for slewing ring care:

Check bolts after 100 hours, 504 hours, and every 1,000 hours.

Lubricate the raceways and clean the area often.

Look at oil seals and change them if needed.

Check gear fit and tighten bolts.

Watch for wear on rolling parts and raceways.

Do not use too much grease and pick the right kind.

Fix loose bolts fast to stop cracks.

Note: Taking care of the slewing ring helps your excavator last longer and keeps all parts working well.

Excavator Parts and Their Functions Summary

Excavators have many parts that help them work well. Each part does a job to keep the machine moving, digging, and lifting safely. When you know how these parts fit together, you can find problems sooner. This helps your excavator last longer.

Here is how the main parts work as a team:

The undercarriage lets the machine move with strong tracks.

Tracks and the track frame help the excavator go forward and turn.

Final drives make each track move, so you can steer.

The engine gives power to the tracks and hydraulic pumps.

Hydraulic pumps send oil to the swing motor and arms.

The operator cab has the controls and keeps you safe inside.

The counterweight helps balance the machine and stops tipping.

The boom lifts and lowers the arm up and down.

The stick connects to the boom and helps you dig holes.

The bucket scoops up dirt or rocks and dumps them out.

Tip: If you take care of each part, you can stop breakdowns and keep your excavator safe.

Studies show how you use your excavator and the shape of its parts change how well it works. For example, what the operator does and how old the machine is can change how much it shakes. The table below shows some numbers from real job sites:

Statistic / Measure | Value / Description |

|---|---|

Number of operator observations | 43 |

Median operator age | 35 years (range 19 to 54) |

Average vibration acceleration A(8) | 0.548 m/s² (median 0.560 m/s²) |

Seat efficiency factor range | 48% to 108% |

Regression model R² | 0.448 (adjusted R² = 0.338) |

Significant factors (p-values) | Task type (p=0.001); equipment age and experience not significant |

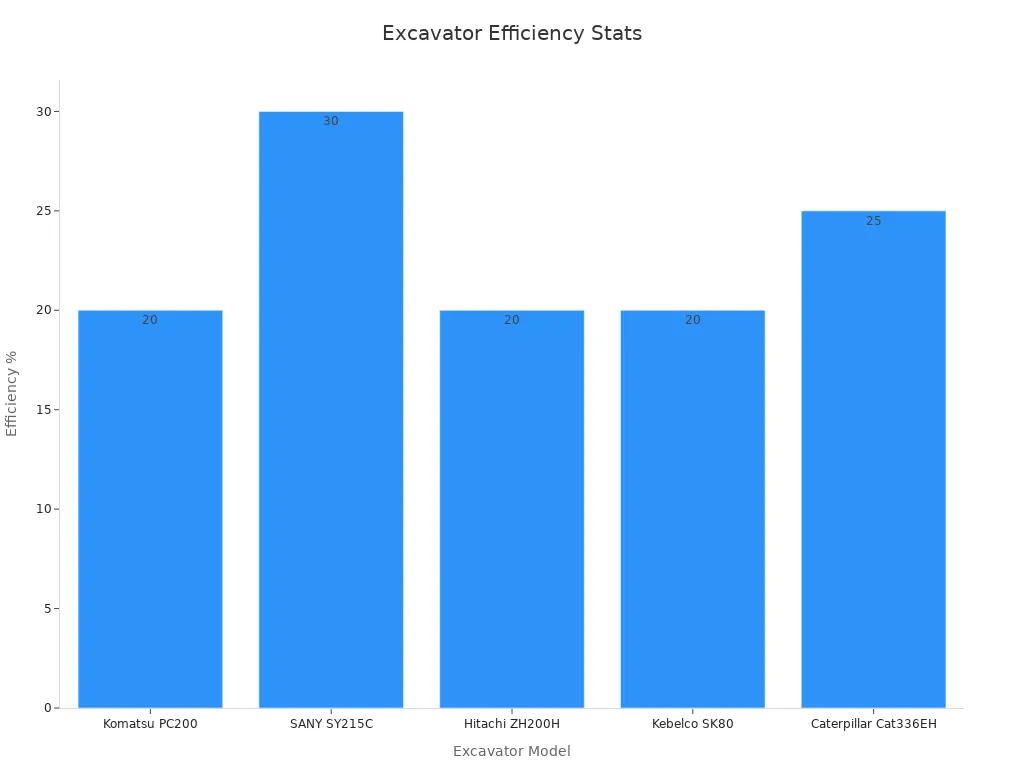

You can also see how different hybrid designs in excavators save energy:

Manufacturer | Model | Hybrid Structure | Energy-saving Efficiency |

|---|---|---|---|

Komatsu | PC200 | Parallel | 20% |

SANY | SY215C | Parallel | 30% |

Hitachi | ZH200H | Parallel | 20% |

Kebelco | SK80 | Serial | 20% |

Caterpillar | Cat336EH | Parallel | 25% |

You should always take care of every part. Clean the tracks, check the bolts, and look at the swing system often. Good care means fewer repairs and a safer excavator. If you follow a regular plan, each part works better and your machine lasts longer. You will also have less downtime and do better work.

Remember: If you keep up with maintenance, your excavator will be ready for any job and last longer.

Knowing about each excavator chassis part helps you keep your machine safe and steady. If you take care of tracks, rollers, idlers, sprockets, and chains, your excavator will not break down as much. This also helps the machine work better. The table below shows how checking parts on time makes them last longer and keeps everyone safe:

Component | Lifespan (hours) | Signs of Wear / Symptoms | Maintenance Tips / Impact on Safety and Performance |

|---|---|---|---|

Track Shoes | 2,000 – 3,000 | Thinning, cracks, loss of traction | Checking often stops slipping and keeps the machine steady |

Rollers | 3,000 – 5,000 | Noise, vibration, oil leaks | Taking care of rollers stops problems and helps the machine move |

Idlers | 4,000 – 6,000 | Noises, misalignment, damage | Keeping the right tension stops accidents and keeps things lined up |

Sprockets | 3,000 – 4,000 | Worn teeth, chain skipping | Good sprockets help power move right and stop breakdowns |

Track Chains | 3,000 – 5,000 | Link elongation, track sag | Checking chains keeps the machine safe and working without stops |

If you check your excavator every 7 hours, it will work better and not break as much. Use this chart to find problems early and help your machine last a long time.

FAQ

What does the excavator hydraulic system do?

You use the excavator hydraulic system to move the boom, arm, stick, and bucket. This system gives power to lift, dig, and swing. You control the flow of oil with levers or joysticks. The hydraulic system makes your excavator strong and fast.

How do you control the excavator boom and arm?

You use the controls inside the cab to move the excavator boom and excavator arm. Each lever or joystick lets you lift, lower, or swing these parts. Good controls help you dig, lift, and load with more accuracy and safety.

What is the function of the excavator bucket and its function?

The excavator bucket and its function help you scoop, carry, and dump soil or rocks. You attach the bucket to the stick. You can choose different bucket shapes for digging, grading, or trenching. The right bucket makes your work easier and faster.

Why should you check the stick and bucket often?

You should check the stick and bucket for cracks, loose bolts, or worn edges. These parts work hard every day. Regular checks help you find problems early. This keeps your excavator safe and ready for any job.