When you select aftermarket john deere excavator parts, you need to weigh the choice between new and used options carefully. New parts often offer longer life span and better warranty, while used parts may give you cost savings. Always check fit and compatibility, since quality and uniformity keep your john deere equipment running smoothly. Supplier reputation matters, as it impacts warranty, performance, and the true value of aftermarket john deere excavator parts. The table below shows key performance metrics you should consider:

Performance Metric | Explanation | Why It Matters |

|---|---|---|

Quality | Determines longevity and functionality. | Ensures proper fit and function. |

Life Span | How long the part lasts. | New parts usually last longer. |

Uniformity | Match to original part. | Prevents early wear and fit issues. |

Performance | Maintains equipment function. | Compatible parts keep john deere equipment at peak performance. |

Warranty | Shows supplier confidence. | Longer warranty means higher trust. |

Cost | Balances budget and reliability. | Supplier reputation impacts value. |

With aftermarket parts deere excavators, genuine john deere parts set the standard, but aftermarket john deere excavator parts can deliver strong performance when you make the right choice. Many new and used aftermarket john deere excavator parts offer great value for your equipment, provided you check all the key factors. Genuine john deere parts remain a trusted option, but aftermarket options—both new and used—can meet your needs.

Key Takeaways

Always check part numbers and compatibility to ensure the aftermarket part fits your John Deere excavator perfectly.

Choose high-quality parts tested for durability to keep your equipment running smoothly and reduce breakdowns.

Balance cost and value by comparing new and used parts based on your budget, equipment needs, and long-term performance.

Buy from reputable suppliers with good reviews, certifications, and clear warranty policies to protect your investment.

Use trusted resources like official manuals and digital catalogs to confirm part details and avoid costly mistakes.

Aftermarket Parts Deere Excavators

What Are Aftermarket John Deere Excavator Parts

You find aftermarket john deere excavator parts from manufacturers other than John Deere. These parts fit and function like original components. Many suppliers design aftermarket parts deere excavators to meet or exceed industry standards. John Deere Electronics Test Labs holds accreditation from the American Association for Laboratory Accreditation (A2LA). This means their testing follows ISO/IEC 17025 standards. You can trust that aftermarket john deere excavator parts often undergo similar rigorous testing. Manufacturers use advanced methods such as Highly Accelerated Life Test (HALT), environmental stress, and vibration testing. These processes ensure aftermarket parts deere excavators deliver consistent quality and reliability.

John Deere holds certifications like ISO 9001:2015 and ISO 14001:2015.

Accredited labs use specialized equipment for testing.

International standards help guarantee aftermarket quality.

Benefits of Aftermarket Parts

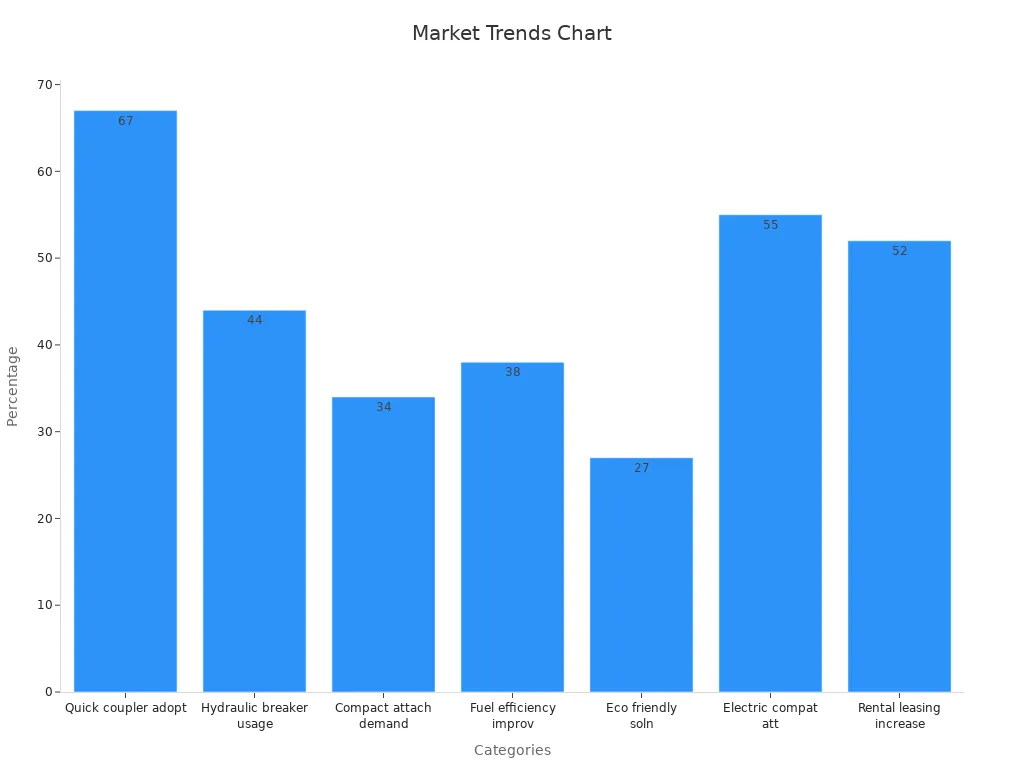

You gain several benefits when you choose aftermarket john deere excavator parts. The aftermarket offers a wide range of options for different budgets and needs. You can often find parts faster and at a lower cost than original equipment. The growing demand for aftermarket parts deere excavators comes from rapid urban development, mining, and road-building projects. The market for aftermarket john deere excavator parts reached $6.15 billion in 2024 and could grow to $13.28 billion by 2033. This growth shows strong confidence in the aftermarket.

Benefit | Description |

|---|---|

Cost Savings | Aftermarket parts deere excavators often cost less than OEM parts. |

Availability | You find a wide selection of aftermarket john deere excavator parts quickly. |

Performance | Many aftermarket parts match or exceed OEM quality. |

Sustainability | New aftermarket options focus on fuel efficiency and eco-friendly solutions. |

Tip: The aftermarket now includes electric-compatible attachments and eco-friendly solutions. You can support sustainability while maintaining your equipment.

You see the aftermarket for John Deere excavators growing fast. Rental and leasing markets have increased by 52%. This trend gives you more flexibility and access to high-quality aftermarket john deere excavator parts. The aftermarket delivers value, reliability, and performance for your equipment.

Types of Aftermarket Parts

New Aftermarket Parts

When you choose new aftermarket parts for your John Deere excavator, you get components built to meet or exceed original equipment standards. Manufacturers design these new parts with advanced technology and precision. You benefit from high reliability, consistent fit, and strong performance. New aftermarket parts often come with a warranty, which reduces your risk and gives you peace of mind. These parts undergo rigorous testing, such as accelerated lifecycle and failure mode analysis, to ensure durability.

You see many advantages with new aftermarket parts. For example, the 85 P-Tier model offers an 18% increase in engine horsepower and advanced features like a turbo for high-altitude work. The 510 P-Tier model provides up to 25% lower maintenance costs and 20% lower fuel consumption. New aftermarket parts also improve operator comfort with features like larger cabs and advanced camera systems.

Note: John Deere remanufactured parts receive 100% dynamic testing and come with a one-year, unlimited-hour warranty if installed by an authorized dealer. This warranty covers both parts and labor, helping you avoid unexpected costs.

Performance Metric | New Aftermarket Parts |

|---|---|

First Pass Yield (FPY) | High reliability; consistent performance |

Overall Equipment Effectiveness | High due to new materials and precise design |

Availability | Easy to find for most John Deere models |

Warranty | Typically included, providing risk mitigation |

Durability and Lifespan | Longer-lasting; tested for durability |

You can count on new aftermarket parts to reduce downtime and keep your excavator running at peak performance.

Used Aftermarket Parts

Used aftermarket parts offer a cost-effective solution for your John Deere excavator, especially when you need to manage your budget. These parts come from previously owned equipment and may show signs of wear. The quality of used aftermarket parts depends on their condition, maintenance history, and the reputation of the seller. You may find used parts for older models that are no longer in production.

The market for used aftermarket parts continues to grow, driven by sustainability and the need for affordable options. Remanufactured parts, which are a type of used part, undergo strict testing and often come with warranties. However, standard used parts may not include a warranty, which increases your risk.

Part Type | Reliability & Quality | Pros | Cons |

|---|---|---|---|

Used Aftermarket | Quality varies; some meet OEM standards | Affordable; widely available | Quality inconsistency; possible fit issues |

Remanufactured | Rigorous testing; often warranty-backed | Reliable; eco-friendly; cost-effective | Shorter lifespan than new; limited supply |

Salvage/Used Parts | Highly variable; often sold as-is | Very affordable; good for rare models | No durability guarantee; limited warranty |

You should always inspect used aftermarket parts closely and buy from trusted suppliers. Used parts can help you save money, but you must balance cost with the risk of early failure or compatibility issues.

Key Factors

Fit and Compatibility

You need to ensure every part matches your John Deere equipment exactly. Fit and compatibility play a crucial role in keeping your excavator running smoothly. Always check the part number against your machine’s manual. This step helps you avoid costly mistakes and downtime. Model-specific compatibility matters because even small differences between models can cause major issues. Use manufacturer catalogs and online databases to confirm the fit. If you have doubts, contact the supplier for guidance. Genuine John Deere parts set the standard for fit, but high-quality aftermarket options can also deliver reliable results when you verify compatibility.

Tip: Keep a record of your equipment’s serial numbers and part numbers. This habit speeds up the search for the right part and reduces errors.

Quality and Durability

Quality and durability determine how well a part performs over time. You want parts that last and keep your John Deere equipment working hard. Inspect the material and construction of each new or used part. High-quality parts, such as hydraulic cylinders, often cost more but provide longer service life and better performance. Genuine John Deere parts offer proven durability, but some aftermarket parts can match or exceed these standards. Always look for parts tested under tough conditions. Durability supports long-term performance and reduces the risk of breakdowns.

Factor | What to Check | Why It Matters |

|---|---|---|

Material | Steel grade, finish, and thickness | Impacts strength and lifespan |

Manufacturing Process | Precision and quality control | Ensures consistent performance |

Testing Standards | ISO certifications, stress tests | Confirms reliability |

You should avoid used parts that show signs of excessive wear or poor maintenance. Remanufactured parts can offer a balance between cost and quality, especially when backed by a warranty.

Price and Value

You must balance cost with value when choosing new or used parts. Price-to-performance comparisons help you make smart decisions for your budget. Excavator parts vary in price and quality based on material, brand, and type. High-quality parts justify higher prices through longer service life and better performance. Aftermarket parts often cost less than genuine John Deere parts, but quality can vary. Always weigh the initial investment against the lifetime value of the part.

Aftermarket parts usually offer cost savings, helping you manage your budget.

Wider availability of aftermarket parts can reduce downtime, especially for discontinued models.

Some aftermarket parts include enhancements that improve machine capabilities.

Quality and reliability vary among aftermarket manufacturers, so careful selection is key.

Initial investment should be weighed against long-term value; higher upfront cost can mean better durability and lower maintenance.

Maintenance costs and machine history affect long-term value.

Customization options can improve adaptability and future cost-effectiveness.

Serviceability and parts availability influence downtime and efficiency.

Financing options can affect the effective cost and value over time.

You should compare prices from several suppliers. Look for promotions or bulk discounts. Always factor in shipping costs and potential downtime when calculating total value.

Supplier Reputation

Supplier reputation affects your confidence in every purchase. You want to buy from suppliers with a strong track record for reliability and customer support. Start by checking online reviews, ratings, and testimonials. Look for suppliers with industry awards and certifications like ISO 9001. Contact previous customers to ask about their experiences with communication, problem-solving, and professionalism. Site visits or audits can reveal a supplier’s production capacity and quality control.

Check the supplier’s online presence and third-party reviews to gauge expertise and customer satisfaction.

Contact previous or current customers for direct feedback on performance and professionalism.

Conduct site visits or audits to observe quality control and staff qualifications.

Request references to understand the supplier’s track record.

Evaluate certifications such as ISO 9001 to confirm quality commitment.

Assess performance metrics like on-time delivery and defect rates.

Positive customer reviews and industry recognition signal a reliable supplier.

Compliance with industry standards ensures parts meet safety and durability requirements.

Reputable manufacturers provide expert advice to help you select the right parts.

A proven track record of delivering quality parts builds trust.

Strong customer support and after-sales service, including prompt responses and easy returns, enhance reputation.

Timely delivery through efficient logistics minimizes disruptions.

Note: Always ask about warranty, customer support, and part availability before making a purchase. These factors protect your investment and keep your John Deere equipment running at its best.

Fit and Compatibility

Checking Part Numbers

You need to check part numbers carefully to ensure the right fit for your John Deere excavator. Each part number links to a specific component, so even a small mistake can lead to problems. Always match the part number from your equipment with the number listed in official resources. This step helps you avoid costly errors and keeps your machine running smoothly.

You can use several types of documentation to verify part numbers:

John Deere operator and technical manuals provide detailed part information.

Parts catalogs are available online at John Deere Parts Catalog.

Technical manuals can be downloaded or purchased from official John Deere sites.

The Customer Service ADVISOR™ offers digital access to operator, diagnostic, and technical manuals.

These resources help you confirm that each part will fit your machine. Manufacturer-certified manuals include covered serial numbers and official part numbers, which support high accuracy for part compatibility.

Tip: Always double-check the part number before ordering. This habit saves time and prevents installation issues.

Using Catalogs and Manuals

You can rely on catalogs and manuals to identify the correct fit for your excavator. Traditional paper catalogs often caused mistakes and delays. Today, electronic parts catalogs (EPCs) make the process faster and more accurate.

EPCs link directly to original bills of materials.

You can search by serial number or use barcode scanning.

3-D modeling helps you visualize the part and its fit.

EPCs update automatically with supplier and component changes.

These features reduce human error and help you find the right fit every time. John Deere’s digitized manuals provide manufacturer-certified information, covering every detail you need for proper part identification. You get comprehensive, up-to-date data that supports the best fit for your equipment.

Note: Using digital catalogs and manuals ensures you always have the latest information for part selection and fit.

Making the Right Choice

When to Choose New Aftermarket Parts

You should choose new aftermarket parts when you want the highest reliability and the longest service life for your John Deere excavator. New parts give you the latest technology and precise engineering. You get a warranty with most new aftermarket parts, which protects your investment and reduces risk. If your equipment works in tough conditions or handles heavy workloads, new parts help you avoid unexpected breakdowns. You also benefit from improved safety and better fuel efficiency. New parts often fit perfectly, so you spend less time on installation and repairs.

If your project has a strict deadline, new aftermarket parts help you keep your excavator running without delays. You should also pick new parts when you want to upgrade your machine’s features or improve its operational performance. New parts work best for newer models or when you want to extend the life of your equipment. When you have a larger budget, new aftermarket parts give you peace of mind and long-term value.

Tip: Always check if the new part meets industry standards like ISO9001/2015 or ASTM. This ensures you get quality and safety.

When to Choose Used Aftermarket Parts

You may want to choose used aftermarket parts when you need to save money or when your excavator is an older model. Used parts can help you manage your budget, especially if you only need a temporary fix or if your equipment is near the end of its service life. You find used parts helpful when new parts are hard to find or when you need a quick replacement to keep your machine working.

Used parts work well for non-critical systems or for backup machines that do not run every day. If you have a tight budget, used parts let you keep your excavator running without a big investment. You should always inspect used parts for wear and ask the supplier about the part’s history. Some used parts come from remanufactured sources, which means they have been tested and may include a short warranty. Used parts can be a smart choice for rare or discontinued models.

Note: Always buy used parts from trusted suppliers. Ask for details about the part’s condition and any available warranty.

Balancing Cost and Performance

You need to balance cost and performance when choosing between new and used aftermarket parts. Start by looking at your budget and the needs of your equipment. If you want the best performance and the lowest risk, new aftermarket parts are the right choice. If you need to control costs, used parts may fit your needs.

To make the best decision, follow this step-by-step framework:

Check Supplier Technical Expertise: Look for suppliers with certifications like ISO9001/2015. Make sure they follow standards such as ASTM, AWS, or EN. This helps you get safe and high-quality parts.

Review Inventory Management: Choose suppliers who keep a wide range of new and used parts in stock. This reduces downtime and helps you control operational costs.

Plan Procurement Strategies: Weigh the immediate cost savings of used parts against the long-term reliability of new parts. Consider how quickly the supplier can deliver and what service policies they offer.

Build Supplier Relationships: Work with suppliers who provide consistent quality and good service. Treat your supplier as a partner in your operation.

Analyze Cost vs. Performance Trade-off: Think about how part quality and availability affect your equipment’s uptime and repair costs. Make sure your choice does not hurt your operational performance.

You should compare prices, warranties, and delivery times from several suppliers. Ask for technical support and check customer reviews. Always match the part number to your machine. If you have questions, contact the supplier for advice.

Step | What to Do | Why It Matters |

|---|---|---|

Check Certifications | Ask about ISO9001/2015, ASTM, AWS, or EN | Ensures quality and safety |

Review Inventory | Confirm new and used parts are in stock | Reduces downtime and cost |

Compare Procurement Options | Balance cost savings with long-term reliability | Protects your budget and equipment |

Build Relationships | Choose reliable, responsive suppliers | Improves service and support |

Analyze Trade-offs | Weigh cost vs. performance | Keeps your excavator running smoothly |

Callout: Always balance your budget with the need for reliable performance. The right choice depends on your equipment, your workload, and your long-term goals.

You can make a confident purchase by following these steps. Take time to review your options and ask questions. The right aftermarket part keeps your John Deere excavator working hard and helps you get the most value for your investment.

You can select the best aftermarket parts for your John Deere excavator by following a few key steps. Always check fit and part numbers to ensure proper compatibility. Focus on quality and supplier reliability to keep your equipment running smoothly. Review the availability of parts before you buy. Compare options from trusted suppliers and confirm availability for your specific model. Strong availability helps you reduce downtime and maintain performance.

FAQ

How do you know if an aftermarket part fits your John Deere excavator?

Always check the part number in your operator’s manual. Match it with the supplier’s listing. Use online catalogs or ask the supplier for confirmation. If you feel unsure, contact customer support for help.

Are aftermarket parts as reliable as genuine John Deere parts?

Many aftermarket parts meet or exceed OEM standards. You should check for certifications and reviews. Reliable suppliers provide quality assurance. Some aftermarket parts offer similar durability and performance as genuine parts.

What should you look for in a reputable aftermarket parts supplier?

Look for suppliers with positive customer reviews, industry certifications, and clear warranty policies. Reliable suppliers offer technical support and fast shipping. You can use this checklist:

Verified certifications

Good customer feedback

Warranty options

Responsive support

Can you return aftermarket parts if they do not fit?

Most reputable suppliers accept returns if the part does not fit. Always review the return policy before you buy. Keep the original packaging and receipt. Contact the supplier quickly if you need to return a part.