You count on the excavator hydraulic pump to change engine power into strong hydraulic pressure. This pressure pushes hydraulic oil through the system. It lets you move the boom, arm, and attachments easily. Excavator hydraulics can be very powerful. Even small machines sometimes work at relief pressures close to 4000 PSI. The lifting strength depends on the pressure and the cylinder size. So, a small excavator can lift heavy things if the hydraulic pump makes enough pressure.

Key Takeaways

Excavator hydraulic pumps change engine power into hydraulic pressure. This lets the boom, arm, and attachments move easily.

Important parts like the pump housing, drive shaft, and control valves help the pump work well and last longer.

Doing regular maintenance, like looking for leaks and changing dirty fluid, helps the hydraulic system work safely and well.

Knowing how open-centre and closed-centre hydraulic systems are different helps you pick the best excavator for your job.

Using good hydraulic fluid and parts can make the excavator work better, use less fuel, and last longer.

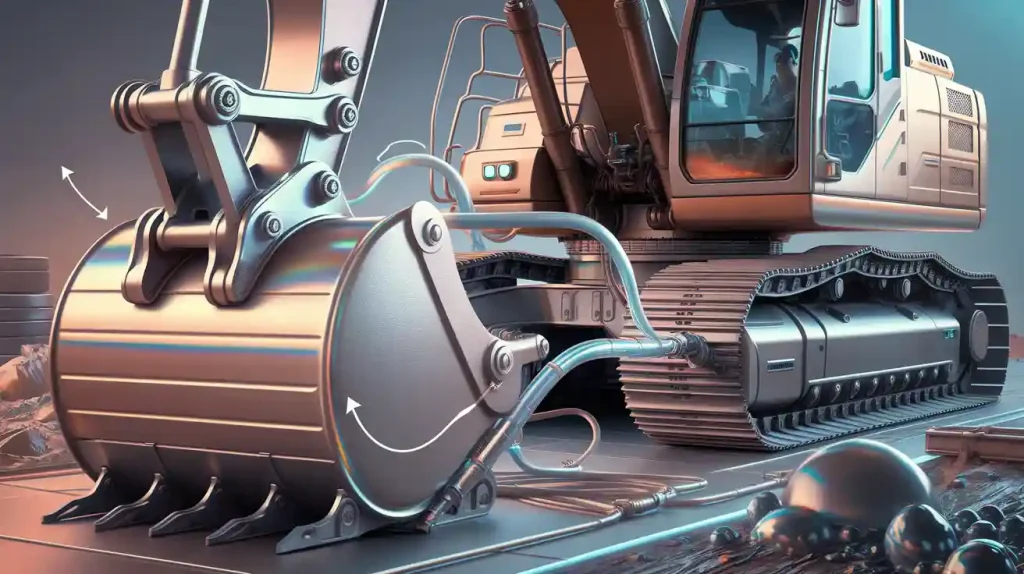

Excavator Hydraulic Pump Components

Knowing the main parts of an excavator hydraulic pump helps you understand how the system works. Every part has its own job to keep the excavator working well.

Pump Housing

The pump housing holds all the inside parts of the hydraulic pump. It keeps the moving parts safe from dirt and damage. The housing must be strong to handle high pressure and keep the hydraulic oil inside. Good housing helps the pump last longer, even if you use your excavator a lot.

Drive Shaft

The drive shaft links the engine to the hydraulic pump. When the engine turns, the drive shaft spins and makes the pump work. If you take care of your hydraulic pump, the drive shaft can last for years.

A hydraulic pump in a heavy excavator can last 5,000 to 10,000 hours if you maintain it well.

Plunger and Swash Plate

The plunger and swash plate work together to move hydraulic oil. The swash plate tilts at different angles. This angle decides how much oil the pump moves.

The swash plate’s angle is important because it sets the pump’s displacement.

Changing the swash plate’s angle changes the plunger stroke length, which helps the parts fit better and work more efficiently.

The shape of the plunger hole can help the movement and lower pressure loss.

When these parts fit well, the pump works better and runs smoother.

Inlet and Outlet Ports

The inlet port lets hydraulic oil go into the pump. The outlet port sends pressurized oil out to the rest of the excavator. Clean ports help the pump work without leaks or clogs. You should check these ports often to keep your excavator working well.

Control Valves

Control valves control the flow and pressure of hydraulic oil. They help you move the excavator arm, boom, and attachments exactly how you want.

Pressure is like the “muscle” of the excavator, so it can lift heavy things.

Flow controls how fast the hydraulic parts move, so it affects the speed of the excavator.

Control valves are needed to control fluid flow, so you can do precise jobs and handle heavy loads.

Tip: Pressure compensating valves change the flow rate of hydraulic fluid to keep the pressure steady. If you need more flow, the valve opens to keep the pressure up. If you need less flow, the valve closes to keep the pressure at the set level.

If you want good excavator hydraulic pump parts, YNF Machinery has quality parts for many models.

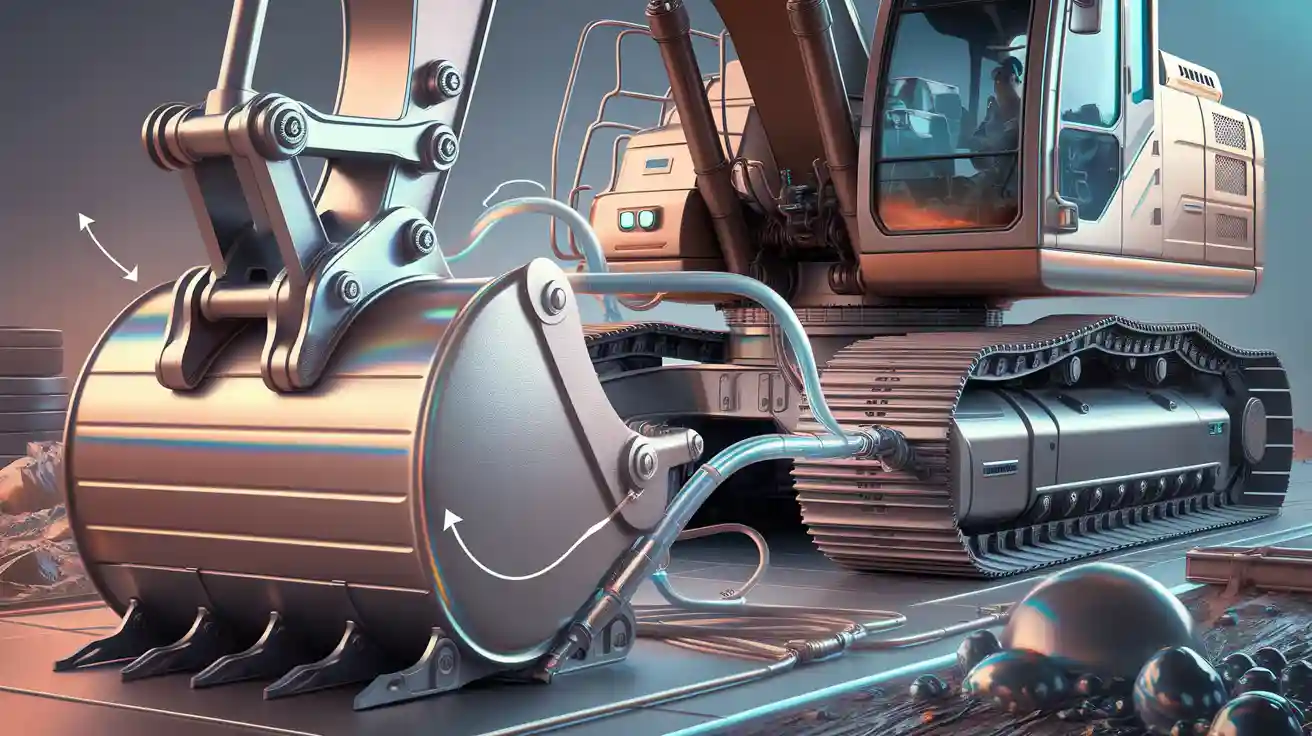

How Excavator Hydraulics Work

Power from the Engine

When you start the excavator, the engine turns on. The engine makes mechanical energy. The hydraulic pump connects to the engine with a drive shaft. As the engine spins, the hydraulic pump also spins. This changes mechanical energy into fluid power. The controller gets signals from your joystick and sensors. It checks pressure, flow, and speed. The controller sends voltage signals to the hydraulic pump, converter motor, and valves. These signals help match the power to your job. The controller manages the load and changes the hydraulic pump output. This gives you smooth and strong movements.

Pressurizing Hydraulic Oil

The hydraulic pump takes oil from the reservoir. The pump pushes oil into the system at high pressure. Pressure builds up inside the pump and moves through hoses and pipes. High-pressure oil makes the excavator hydraulics work. The hoses carry oil to different parts of the excavator. If hoses are strong, you get full power and fast response. If a hose breaks, you lose pressure and power. Broken hoses can also cause safety problems by spraying hydraulic fluid.

High-pressure hoses move hydraulic fluid everywhere in the excavator.

Good hoses help the excavator hydraulic pump work at full strength.

Damaged hoses lower efficiency and cause power loss.

A broken hose can spray oil and make things unsafe for you and others.

Tip: Always check hoses for leaks or cracks before using the excavator. Clean hoses help the excavator hydraulic pump work better and keep you safe.

Moving Cylinders and Motors

Pressurized oil goes from the hydraulic pump to the cylinders and motors. The oil enters the cylinder and pushes the piston. This lifts the boom, moves the arm, or tilts the bucket. Motors use oil to spin and move attachments. You control speed and direction with levers and pedals. Control valves send oil to the right place. You can lift, dig, or swing the excavator smoothly. Power and speed depend on pressure and flow from the hydraulic pump. Excavator hydraulics let you do heavy work with little effort. You count on the excavator hydraulic pump and system to move big loads and handle tough jobs.

Note: Hydraulic pressure is the key to strong lifting and fast movement. If you keep the excavator hydraulic system clean and well-maintained, you get better performance and longer life from your excavator.

Types of Excavator Hydraulic Systems

Open-Centre Load Sensing (OLSS)

You will find the open-centre load sensing system in many older excavators. This hydraulic system uses a simple design. When you move the control lever, the hydraulic pump sends oil through open paths. Oil flows back to the tank when you do not use the controls. The pump always moves oil, even if you do not need power. This design makes the system easy to fix and understand. However, it can waste energy because the hydraulic pump works all the time.

Tip: If you want a system that is easy to repair, OLSS can be a good choice. You may notice more heat and noise because the pump never stops moving oil.

Closed-Centre Load Sensing (CLSS)

Many modern excavators use the closed-centre load sensing system. In this system, the hydraulic pump only works when you need power. When you move the joystick, the pump senses the load and sends oil where you need it. The pump stops or slows down when you do not use the controls. This saves energy and keeps the excavator cool. You get smooth and fast movements with less fuel use. The closed-centre design helps the excavator hydraulic system last longer.

You can control many functions at once.

The hydraulic pump does not run all the time.

You save fuel and reduce wear on the hydraulics.

Variable Plunger Pumps

Variable plunger pumps play a key role in both OLSS and CLSS systems. These pumps change the amount of oil they move based on your needs. When you need more power, the pump increases its output. When you need less, it reduces flow. This makes the excavator hydraulic pump very efficient. You get strong lifting and smooth control. The variable plunger design helps the hydraulic pump last longer and use less energy.

Pump Type | Energy Use | Control Level | Common Use |

|---|---|---|---|

Fixed Displacement | High | Basic | Small excavators |

Variable Plunger | Low | Advanced | Most excavators |

Note: If you want the best performance from your excavator hydraulics, choose a machine with a variable plunger hydraulic pump.

Excavator Hydraulic System Performance

Efficiency Factors

You can make your excavator hydraulic pump work better if you know what affects how well it runs. The way the hydraulic pump is made is very important. Good materials help the pump last longer and not break as fast. Oil type and keeping the oil at the right temperature also matter a lot. If you keep the hydraulic fluid clean and not too hot or cold, the pump works better. How well you use the excavator matters too. Training helps you use the hydraulic system the right way. The ground and weather can change how your excavator works. You might need to change how you use the machine in hard places or bad weather.

Efficiency Factor | Description |

|---|---|

Design and manufacturing quality | Good design and strong materials help the pump last longer and work better. |

Dynamic performance of hydraulic system | The kind of oil and its temperature are important for the pump to work well. |

Operator technology and training | Knowing how to use the excavator helps you get the best results. |

Environmental factors and working conditions | The ground and weather can change how well the excavator works, so you may need to do things differently. |

New hydraulic pump technology, like digital displacement pumps, gives you more control and saves energy. New materials and designs help pumps last longer and work better under high pressure.

Common Issues

If you do not check your excavator often, you might see problems with the hydraulics. Some common problems are:

Low hydraulic pressure

Hydraulic fluid gets too hot

Hydraulics move slow or do not respond

Hydraulic fluid leaks out

Movements are jerky

Pump makes noise or shakes

If the pump gets too hot, seals can break and the fluid can go bad. If it is too cold, the fluid gets thick and the pump has to work harder. Leaking hydraulic fluid is bad for the environment and can be dangerous for people nearby. If the hydraulics do not work right, the machine can move in ways you do not expect, which is not safe.

Maintenance Tips

You can keep your excavator hydraulic pump working well if you follow some easy steps:

Check the hydraulic pump and system often for damage.

Look at fluid levels and change dirty fluid when needed.

Watch for leaks around seals, hoses, and connections.

Change filters that are clogged to keep dirt out.

Use good hydraulic fluid that fits your pump.

Check the pump temperature and make sure the cooling system works.

Doing regular maintenance helps you avoid big repairs and keeps your excavator working. Dirt, heat, and time can wear out the hydraulic pump. If you do not take care of it, the arm may move slower and not lift as much. Checking and fixing things on time keeps your hydraulic system strong and reliable. Training also helps you find problems early and use the excavator safely.

Tip: A good maintenance plan can save you a lot of money every year and keep your excavator working well.

You saw how the excavator hydraulic pump turns engine power into hydraulic force. This force helps the machine move with strength and accuracy. If you know the main parts and system types, you can use your excavator better and stay safe. New technology makes pumps work better and easier to fix.

Benefit | Description |

|---|---|

Powerful Performance | Hydraulic systems give lots of power for lifting and digging. |

Accuracy and Control | You can control the machine well for good results in grading and excavation. |

Versatility | You can use different attachments for many jobs in different industries. |

Fuel Efficiency | These systems help you spend less on fuel and work in a greener way. |

Improved Safety | The machine is more stable, so accidents are less likely and work is safer. |

Durability and Longevity | Strong materials help the excavator last a long time in tough places. |

Increased Productivity | Fast work and less waiting means you get more done. |

Environmental Benefits | New excavators pollute less and use fuel better, so they are better for the environment. |

Doing regular maintenance keeps your excavator working well.

Taking care of your machine helps you sell it for more money.

People want to buy machines that have a good maintenance record.

Feature | Description |

|---|---|

Independent Metering Valve Tech | Smart electronic controls help the excavator work better and save energy. |

Fuel Efficiency Improvement | You can save up to 25% more fuel than with old systems. |

Closed-Center Valve Control | The system uses less hydraulic flow when you do not need it, so you save fuel. |

Precise Control | The system can sense and control each side of the cylinder chamber without using old spools. |

Reduced Pressure Losses | It uses poppet and electro-hydraulic valves instead of spools, so valve control works better. |

Maintenance Simplification | No hydraulic pilot lines means fewer leaks and easier repairs. |

Tip: If you know how your hydraulic system works and take care of it, you will get better results and save money.

FAQ

How often should you check your excavator hydraulic pump?

You should check your hydraulic pump before each use. Look for leaks, strange noises, or low fluid levels. Regular checks help you find problems early and keep your excavator running well.

What hydraulic fluid should you use in your excavator?

Always use the hydraulic fluid recommended in your excavator’s manual. Using the right fluid keeps your pump safe and working smoothly. If you need help, ask YNF Machinery for advice.

Why does your excavator hydraulic pump make noise?

A noisy pump can mean air in the system, low fluid, or worn parts. You should stop and check for leaks or damage. Fixing problems early helps you avoid bigger repairs.

Can you repair a hydraulic pump yourself?

You can do simple checks and replace filters. For big repairs, you should call a trained technician. Using the wrong tools or parts can damage your pump.

Where can you buy quality hydraulic pump parts?

You can buy quality hydraulic pump parts from YNF Machinery. They offer parts for many excavator models and provide support if you have questions.