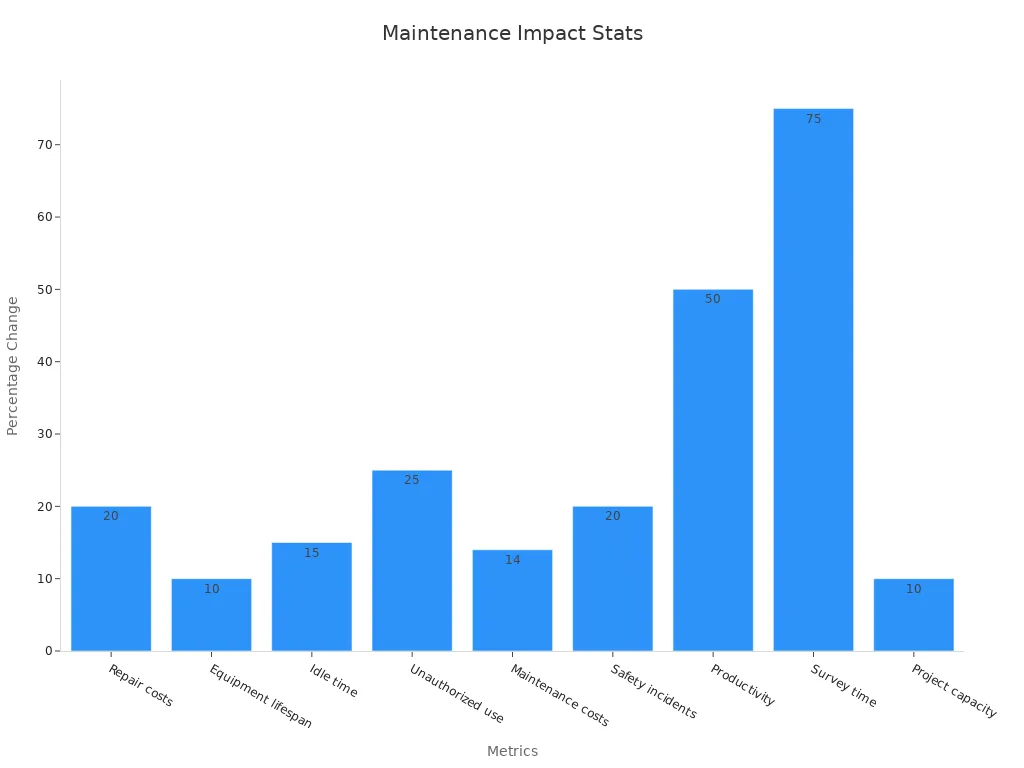

Following a daily maintenance checklist for your excavating machinery parts gives quick results. You spend less money, make things safer, and help your equipment last longer. Studies show that important maintenance steps, like regular excavator maintenance and checks, can lower repair costs by 20%. They can also cut down idle time by 15% and make equipment last 10% longer.

Metric | Improvement/Reduction |

|---|---|

Repair costs | 20% reduction |

Equipment lifespan | 10% extension |

Idle time | 15% reduction |

You keep your team safe and stop expensive breakdowns with regular heavy equipment maintenance. Tips like checking fluid levels and looking at undercarriage parts can stop up to 30% of equipment failures.

Using important maintenance steps keeps excavator maintenance easy and works well.

Machines with regular maintenance work up to 25% better.

Almost 80% of hydraulic failures happen because of dirty fluid, which you can prevent with daily checks.

Not taking care of the undercarriage can make costs go up by 40%.

By following good maintenance tips and routines, you help your excavating machinery parts last longer and keep your projects safe.

Key Takeaways

Check fluid levels, hoses, seals, and undercarriage every day. This helps you find small problems early. It also stops big repairs that cost a lot.

Put grease on moving parts like pins, bushings, and bearings often. This helps stop them from wearing out fast. It also keeps your excavator working well.

Clean tracks, rollers, engine, and filters many times. This stops extra wear and helps your machine work longer. It also means less time fixing it.

Change worn parts right away. This stops bigger damage and saves money. It also keeps your machine safe to use.

Use a maintenance checklist and keep good records. Follow a service schedule and train operators well. This helps your excavator last longer and work better.

Daily Checks

Doing daily checks is very important for excavator maintenance. When you use a checklist every day, you find small problems early. This stops them from turning into big, costly repairs. Daily checks help your excavator parts stay in good condition. They also help your machine work well.

Fluid Levels

Begin each day by checking all fluid levels. Look at the engine oil, hydraulic fluid, coolant, and fuel system water separator. These fluids help your excavator parts work right. If you see low or dirty fluids, refill or change them fast. Oil tests show that a small change in thickness can mean there is a problem. Acid and base number tests help you find issues early. Watching these fluids stops engine damage and helps lubricants last longer. Always make this step part of your daily routine.

Tip: Use a checklist so you do not forget to check fluids.

Hoses and Seals

Now, look at all hoses and seals for leaks or damage. Check for cracks, color changes, or bulges. These signs mean a hose could break soon. If you see leaks, fix them before they get worse. Checking hoses and seals often helps you find loose fittings or worn seals. Sometimes, one loose hose fitting has caused injuries and stopped work for days. By checking hoses and seals every day, you lower the chance of leaks and save money.

Look for cracks, bulges, or faded spots.

Watch for leaks near fittings and seals.

Change worn hoses before they break.

Undercarriage

The undercarriage holds up your excavator and wears out the most. Dirt, rocks, and mud can pile up and cause harm. Clean the undercarriage after every use. Look for loose bolts, broken pins, or oil leaks. Track chains, rollers, and idlers can last a long time with good care. If you skip checks, dirt can jam rollers or loosen bolts, which costs a lot to fix. Always check track tension, because wrong tension can make tracks slip and make the machine less stable.

Take off dirt and mud every day.

Check for loose or broken parts.

Fix track tension if needed.

Doing these tasks every day helps your excavator parts last longer. Regular checks keep your equipment safe and working well.

Lubrication

Lubrication is a very important part of daily maintenance. You must keep all moving parts oiled to stop early damage. This helps you avoid expensive repairs. Good lubrication makes your excavator parts last longer. It also keeps your machine working well.

Pins and Bushings

Pins and bushings move against each other all day long. If you forget to add grease, they will wear out fast. Friction and rust can hurt these parts quickly. Grease makes a layer that protects pins and bushings. This stops problems like galling and scuffing. Always use the right grease for your machine. Follow a schedule to grease these parts often. This helps pins and bushings last longer and work better.

Tip: Grease pins and bushings at the start and end of each shift. This keeps them from wearing out too soon and keeps your machine in good shape.

Bearings

Bearings hold heavy loads and help things move smoothly. If you do not oil them, they will break early. Using better grease and greasing on time helps bearings last longer. This can save you many hours of repair work each year. Some machines use systems that add grease when needed. This gives the right amount of grease for the job. It helps stop early wear, cuts down on repairs, and makes your machine more reliable.

Grease bearings on time.

Listen for dry or noisy bearings.

Use a checklist to remember to grease.

Recommended Lubricants

The right lubricants are important for good care. The best ones lower friction, control heat, and keep dirt out. Using special hydraulic fluids can make your machine work better. It can save energy and fuel costs by up to 20%. For a medium fleet, this can save about $50,000 each year. Always use the lubricants your manufacturer suggests. Stick to your maintenance plan to stop early wear.

Lubricant Type | Benefit | Maintenance Tip |

|---|---|---|

High-performance grease | Lowers friction and wear | Add grease often |

MEHF oils | Makes machines work better | Use for hydraulic systems |

Lubricating your machine often helps stop early wear. It saves money and keeps your excavator safe and running well.

Cleaning Excavator Parts

Tracks and Rollers

It is important to keep tracks and rollers clean. Dirt, mud, and rocks can pile up quickly. If you do not clean them, these parts wear out faster. Cleaning tracks and rollers every day is very important. When you take away debris, you stop extra rubbing. This helps prevent breakdowns.

A study says regular cleaning and checking tracks and rollers can cut downtime by half. Less downtime means your machine works more and costs less to fix. Another report says cleaning, checking, and oiling rollers and bearings helps stop wear. It also makes your equipment last longer. Cleaning often gives you smoother work and better results.

Tip: Use a stiff brush or a pressure washer to clean tracks and rollers after each use. This easy step helps your machine last longer and keeps maintenance simple.

Take mud and rocks off tracks every day.

Look at rollers for stuck dirt.

Oil rollers after you clean them.

Engine and Filters

The engine must stay clean to work well. Dust and dirt can block air and make it overheat. You should clean the engine area often. Change filters on time to keep dirt out of the engine and hydraulic system.

Hydraulic filters take out bad stuff from the fluid. If you forget to change filters, pumps and valves can break. Changing filters when the manufacturer says keeps the hydraulic system clean. This step saves money on repairs and helps your excavator work better.

Cleaning the engine and changing filters stops sludge from building up. Sludge can block oil and cause more rubbing. Clean oil and new filters help the engine last longer and use less fuel. Always follow the schedule for oil and filter changes.

Wipe the engine area to get rid of dust.

Change air and hydraulic filters when needed.

Check for leaks or loose parts while cleaning.

Note: Good filters protect your machine and help stop sudden breakdowns.

Wear Part Replacement

Identifying Wear

It is important to find wear early. This helps your excavator parts work well. Look for cracks, chips, or changes in shape. Check bucket teeth and cutting edges for thinning. Shiny spots or uneven surfaces can mean wear. Loose bolts are also a sign. If you see these things, fix them fast. This stops bigger problems and early wear.

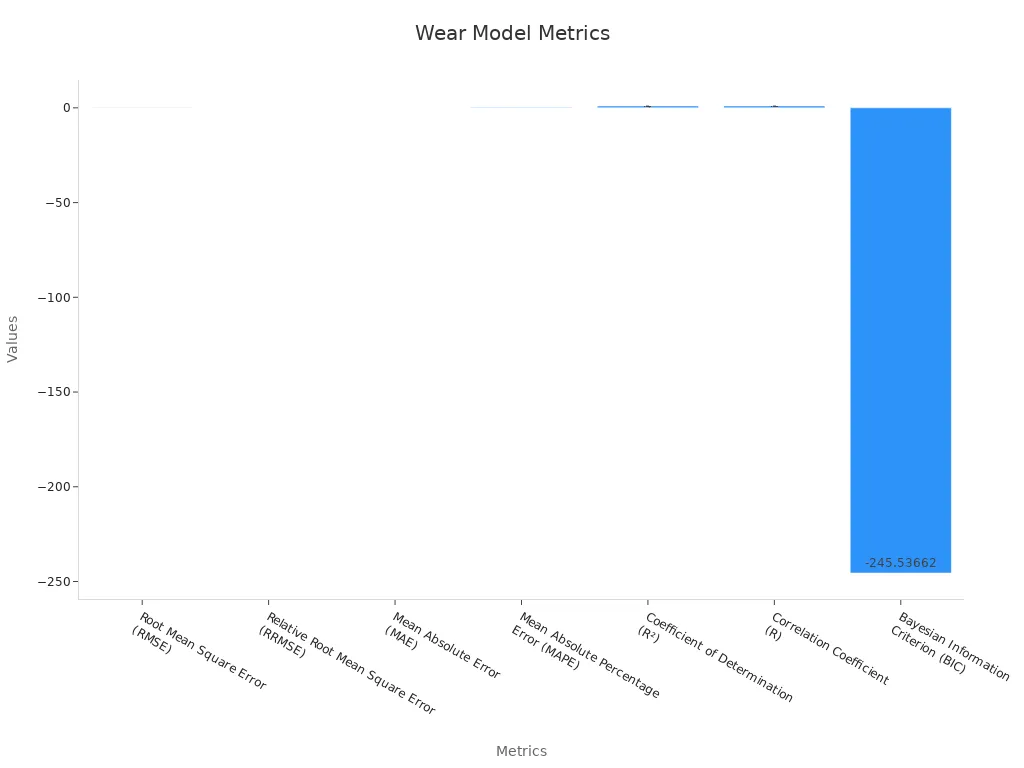

New technology can help you spot wear. AI models can find worn parts before they break. The ALO-MLPNN hybrid model uses real mine data. It is almost perfect at predicting abrasive wear. You can trust these systems to plan maintenance. They help stop early wear and keep your machine safe.

Metric | ALO-MLPNN Model Result |

|---|---|

Root Mean Square Error (RMSE) | 0.22007 |

Relative Root Mean Square Error (RRMSE) | 0.00597 |

Mean Absolute Error (MAE) | 0.10014 |

Mean Absolute Percentage Error (MAPE) | 0.26704 |

Coefficient of Determination (R²) | 0.99962 |

Correlation Coefficient (R) | 0.99981 |

Bayesian Information Criterion (BIC) | -245.53662 |

Tip: Look for wear every day. Use a flashlight to check hidden spots. Write down what you find in a log.

Timely Replacement

When you see worn parts, change them right away. Waiting too long can cause more damage. It can also cost more money. Replacing parts on time keeps your machine safe. It also stops early wear on other parts.

Places that use preventive maintenance have less downtime. They finish more work orders. If you change a $50 bearing on time, you can avoid a $5,000 pump failure. This shows how smart maintenance saves money. It also stops early wear.

Evidence Type | Details |

|---|---|

Preventive Maintenance Data | Facilities using preventive maintenance report 32% less unplanned downtime and 53% more completed work orders (MaintainX 2024 report). |

Cost Avoidance Example | Replacing a $50 bearing timely can prevent a $5,000 pump replacement, illustrating direct cost savings. |

Maintenance Efficiency | Preventive maintenance enables planned downtime instead of costly unplanned stoppages, improving productivity and budgeting predictability. |

Reactive maintenance means more downtime and higher costs.

Preventive maintenance uses checks and quick replacement to stop failures.

Predictive maintenance uses sensors and AI to find wear early.

Well-trained operators can spot worn parts and stop bad products.

A case study shows preventive maintenance can cut early failures by half. It can make parts last over a year longer. You get more uptime and lower costs. Your machine is safer when you replace worn parts on time. Make timely replacement part of your regular plan. This keeps your excavator parts in good shape.

Maintenance Checklist

Prestart and Shutdown

Always use a maintenance checklist before and after using your excavator. This habit helps you find problems early. It keeps your machine working well. A checklist makes sure you do not forget anything. Here are some main benefits:

Doing daily and preventive maintenance helps your excavator last longer.

Finding problems early makes your machine more reliable. It also keeps your work on track.

Regular care keeps your equipment clean and repairs up to date. This helps keep its value high.

Checking for worn or broken parts keeps operators safe. It can stop accidents before they happen.

Taking care of your machine lowers costs and saves fuel.

Tip: Walk around your machine before each shift. Look for leaks, loose bolts, and worn parts. After work, clean the cab and check the undercarriage. Write down any problems in your log.

A good checklist includes these steps:

Check fluid levels and add more if needed.

Look at hoses, seals, and undercarriage for damage.

Test lights, alarms, and controls.

Clean dirt and debris from important spots.

Write down any problems to fix later.

Service Intervals

Following the right service times is important for your excavator. Always use the schedule from the manufacturer for all care tasks. This helps you stop sudden breakdowns and big repair bills. Studies show that regular checks for wear and tear stop sudden failures. You can find loose bolts, oil leaks, and rust early.

Use the manufacturer’s service schedule for all care tasks.

Check, fill fluids, and change parts on time. This helps you find small problems before they get worse.

Use tools or software to track service needs. This helps your equipment last longer.

Teach operators to know machine limits and spot warning signs.

Take care of problems early to work better and spend less on repairs.

Preventive care means less downtime, better safety, and fewer big repairs.

Note: A good maintenance plan keeps your excavator working well and safely. You save money and avoid surprise problems.

A strong routine, with a checklist and regular service, helps you get the most from your machine.

Record Keeping

Maintenance Logs

You should keep good maintenance logs for your excavating machinery. These logs help you remember every service, repair, and check. When you write down each job, you make a clear history for your machine. This record shows what you did and when you did it. You can notice patterns, like parts that break often or repairs that happen a lot.

Maintenance logs help you plan for the future. You can set up preventive maintenance before problems start. Farms and building companies that use these logs have fewer emergency repairs. They save up to 30% on emergency repair costs and have up to 60% fewer urgent fixes. By tracking each job, you find small problems early and stop big breakdowns. This habit can add three to five years to your machine’s life and delay costly replacements.

A good maintenance log should have:

Date of service

Jobs finished

Parts changed

Name of the person who did the work

Tip: Use a notebook, spreadsheet, or app to keep your records neat and easy to find.

Tracking Repairs

Tracking repairs helps you make smart choices about your excavator parts. When you write down every repair, you see which parts break the most. This helps you plan for new parts and order them before you need them. You also save money by fixing problems before they get worse.

Good tracking helps with predictive maintenance. You use data to see patterns and guess when a part might break. Companies that track repairs have 25% fewer fleet breakdowns and up to 50% less unplanned downtime. Maintenance cost savings are between 10% and 40%. You also make your machine last longer by fixing things before big damage happens.

Benefit | Result/Impact |

|---|---|

Fewer unexpected breakdowns | 25% decrease |

Less unplanned downtime | Up to 50% reduction |

Lower maintenance costs | 10-40% savings |

Longer equipment lifespan | Achieved with proactive care |

Better prediction of part wear | Over 90% accuracy |

Keeping good maintenance and repair records helps you avoid costly surprises. You make your machine safer, save money, and keep your excavator working longer.

Choosing Excavating Machinery Parts

OEM vs Aftermarket

When picking excavating machinery parts, you have two choices. You can buy OEM parts or aftermarket parts. OEM parts are made by the company that built your machine. These parts fit well and work like the originals. They give strong performance and last a long time. OEM parts also protect your warranty. They meet high quality rules, so you avoid problems.

Aftermarket parts usually cost less and are easy to get. Some brands have special features or upgrades. You might save money, but quality is not always the same. Some aftermarket parts work as well as OEM parts. Others may wear out faster or not fit right. Using aftermarket parts can risk your warranty. You might get a part that does not fit. For new machines or big jobs, OEM parts are best. For old machines or small repairs, aftermarket parts can help you save.

Tip: Always check if a part will change your warranty before buying.

Supplier Reliability

You need a supplier you can trust for excavating machinery parts. A good supplier gives real parts and ships them fast. They answer your questions and help you choose the right part. Trusted suppliers have good reviews and happy customers.

Look for these signs of a good supplier:

Clear return and warranty rules

Fast and safe shipping

Good reviews from buyers

Helpful customer service

A strong supplier helps you avoid fake or bad parts. You get the right parts on time. This keeps your machine working and your projects on track.

Preventive Excavator Maintenance

Scheduling

A good maintenance plan starts with a clear schedule. You should pick regular times for checks, cleaning, and repairs. When you follow a schedule, you find problems early. This helps you stop bigger issues before they start. Regular checks help you see leaks, worn parts, or low fluids. You can fix these before they cause damage. Keeping your excavator clean also stops wear from dirt and debris.

Here are some important tips for scheduling:

Check fluid levels and add more if needed.

Oil all moving parts to stop friction.

Look at hoses, seals, and undercarriage for wear.

Change worn parts before they break.

Follow the manufacturer’s schedule for your machine.

Sticking to a set schedule for heavy equipment maintenance can make your excavator last up to 30% longer. You also have less downtime and save money on repairs.

Modern tools like apps or calendars help you remember each job. These tools make it easy to track what you did and what is next. Following your schedule keeps your excavator in good shape and running well.

Operator Training

Operator training is just as important as scheduling. Well-trained operators know how to spot early warning signs. They also follow maintenance tips every day. Training helps your team use the right ways to clean, check, and oil parts. When everyone knows the steps, you avoid mistakes that can cause damage.

Training your staff can lower operator-caused downtime by 18%. It also helps make sure maintenance gets done often. Teach your team to use checklists and report problems fast. Make sure they know why preventive maintenance is important for your equipment.

Hold training sessions for all operators often.

Go over maintenance tips and safety rules many times.

Let people ask questions and give feedback to help your process.

A trained operator helps keep your heavy equipment maintenance strong. You get fewer breakdowns, safer job sites, and longer-lasting excavator parts.

If you use a maintenance checklist each day, your excavator lasts longer. Cleaning and checking your machine often helps stop breakdowns. Changing parts when needed keeps your machine safe. These steps help you spend less money and make your jobsite safer. Clean machines let you see better and have more grip. Checklists help you find problems before they get worse. Start these habits now to help your excavator work well for a long time.

FAQ

How often should you check fluid levels in your excavator?

You should check fluid levels every day before you start your machine. This helps you spot leaks or low fluids early. Daily checks keep your excavator running well and help you avoid costly repairs.

What is the best way to clean excavator tracks?

Use a stiff brush or a pressure washer to remove dirt and rocks after each use. Cleaning tracks daily helps prevent extra wear and keeps your machine safe. You also make it easier to spot damage.

When should you replace worn parts on your excavator?

Replace worn parts as soon as you notice damage or wear. Waiting can cause more problems and higher repair costs. Quick replacement keeps your machine safe and working longer.

Do you need to use OEM parts for repairs?

OEM parts fit your machine best and protect your warranty. You can use aftermarket parts for older machines or small repairs. Always check if using non-OEM parts affects your warranty.

Why is operator training important for excavator maintenance?

Operator training helps you spot problems early and follow the right steps for care. Trained operators reduce downtime and keep machines safe. You get better performance and longer part life with good training.