Choosing the right excavator hydraulic pump, especially considering the excavator hydraulic pump price, helps your machine work well. You need a pump that matches your excavator’s needs. This helps you do more work and use less fuel. It also makes your job site run better. Your engine will have enough power for hard jobs. Picking the right pump can lower costs. You get more value for the price you pay.

Key Takeaways

Write down what your project needs. List the jobs your excavator will do. This helps you pick a pump with the right power and speed for your work.

Look at your excavator’s details. Check the flow rate, pressure, and if the pump fits your model. This makes sure the pump works well and fits right.

Think about how much the pump costs over time. A pump that costs more at first may save money later. You might spend less on repairs and fixing it.

Pick between OEM and aftermarket pumps with care. OEM pumps are dependable. Aftermarket pumps can cost less but may not be as good.

Take care of your pump often. Follow the care plan for your pump. This helps your pump last longer and keeps your excavator working well.

Project Needs

Type of Work

You need to look at the type of work your excavator will handle. If you plan to dig trenches, lift heavy rocks, or break concrete, each task puts different demands on your hydraulic pump. For example, demolition jobs need strong force, while grading or backfilling requires fast movement. Make a list of your main tasks. This helps you match the pump’s power and speed to your job site excavation needs.

Operating Conditions

Your job site can change how your hydraulic pump works. Several factors affect pump selection:

The hydraulic fluid’s viscosity and chemical makeup change how the pump performs.

Extreme temperatures can make pumps work harder or wear out faster.

High-vibration areas need pumps built for tough conditions.

The pump must draw fluid and create pressure that fits your system. If it cannot, problems like cavitation can happen.

Tip: Always check your job site’s temperature range and vibration levels before choosing a pump.

Flow and Pressure

Every excavator uses hydraulic circuits for different tasks. The bucket circuit moves material, the boom circuit lifts, and the dipper arm digs. Each circuit needs the right flow and pressure to work well. A medium-sized excavator often uses up to 150 gallons per minute and reaches 4,500 psi. This lets you finish many tasks quickly and safely.

Pressure controls how much force your excavator uses. You need high pressure for breaking concrete or lifting heavy loads.

Flow controls how fast your machine moves. Higher flow means quicker boom, arm, and bucket movements.

Use high pressure for tough jobs like demolition.

Use high flow for tasks like grading or backfilling.

You must know your required flow rate before you choose a pump. This ensures your excavator works at its best and avoids costly delays.

Check Excavator Specs

Model Compatibility

You must make sure the hydraulic pump fits your excavator. Each manufacturer makes pumps for certain machines. Using the wrong pump can hurt your excavator or make it work badly. Look at this table to see which brands have pumps for different models:

Manufacturer | Compatible Models |

|---|---|

Caterpillar | Various Models |

Hitachi | Various Models |

JCB | Various Models |

Doosan | Various Models |

Volvo | Various Models |

Hyundai | Various Models |

John Deere | Various Models |

Kobelco | Various Models |

Komatsu | Various Models |

Tip: Always use the pump that matches your excavator’s model number. This helps you install it right and keeps your machine working well.

Hydraulic System

Your excavator’s hydraulic system controls how the pump works. You need to know the flow rate, pressure, and port sizes. These numbers help you pick a pump that fits and works well. If you get a pump with the wrong flow or pressure, your excavator may not lift or dig right. Check your owner’s manual for these numbers. Write them down before you buy a pump.

Flow rate tells how much fluid moves in the system.

Pressure shows how much force the pump makes.

Port size must match the pump and hoses.

OEM vs. Aftermarket

You can pick between OEM and aftermarket hydraulic pumps. OEM pumps match your excavator’s specs. They work well and last long. Aftermarket pumps cost less, but quality is not always the same. Some aftermarket pumps work as well as OEM, but some do not last as long.

Criteria | OEM Hydraulic Parts | Aftermarket Hydraulic Parts |

|---|---|---|

Purchase Price | Highest; baseline (100%) | Usually 20–50% less; depends on brand |

Material & Manufacturing | Made to OEM specs; factory checked | Can be equal or lower; best ones match OEM |

Fit & Compatibility | Always fits | Usually fits; check sizes and ports |

Warranty & Support | Factory warranty and parts help | Varies; good brands give strong warranties |

Reliability | High and steady | Changes; good aftermarket can match OEM |

OEM pumps give you confidence. They last longer and fit right. Aftermarket pumps save money, but you should read reviews and check specs. Always look at warranty and support before you choose.

Choose the Right Pump

Picking the best hydraulic pump takes some planning. You need to make sure the pump fits your project and machine. This helps your equipment work safely every day.

Pump Type

There are three main types of hydraulic pumps. These are gear, vane, and piston. Each one has good and bad points. The best pump depends on what you need to do at your job site.

Pump Type | Advantages | Disadvantages |

|---|---|---|

Gear Pump | High volumetric efficiency, low noise, inexpensive, easy maintenance | Not suitable for high-pressure, affected by wear |

Vane Pump | Smooth operation, handles high pressure, works with many fluids | Less efficient, sensitive to contamination |

Piston Pump | Handles high pressure, very efficient, durable | More expensive, needs clean fluid |

Gear pumps are good for simple jobs and cost less.

Vane pumps give a smooth flow and help with careful work.

Piston pumps are strong and last a long time.

Some models, like the Rexroth-Uchida AP2D, work well for big jobs. The Kawasaki K3V and K5V series last long, make little noise, and are easy to care for. When you pick a pump, think about your work, the pressure needed, and how much you use your excavator.

Efficiency

Efficiency is how well the pump uses engine power. Good pumps save fuel and keep cool. This helps your excavator work longer. Piston pumps are usually the most efficient for big jobs. Gear and vane pumps are good for smaller jobs.

Tip: Pick pumps with high efficiency if you want to save fuel and keep your machine cool.

Durability

Durability means how long the pump lasts. You want a pump that can handle hard work every day. Piston pumps are made from strong materials and work well under high pressure. Gear pumps are simple and do not wear out fast. Vane pumps are in the middle.

Factor | Description |

|---|---|

Job Requirements | Think about material type, flow rate, pressure, and distance for effective pumping. |

Excavator Compatibility | Make sure the pump fits your machine’s hydraulic system and mounting points. |

Durability & Maintenance | Choose pumps made from strong materials and easy to service. |

Cost vs. ROI | Weigh the upfront price against long-term value and efficiency. |

Always check if the pump fits your excavator. This helps stop breakdowns and keeps your project moving.

Maintenance

Maintenance keeps your hydraulic pump working well. Each pump type needs different care.

Pump Type | Maintenance Complexity | Sensitivity to Fluid Cleanliness | Frequency of Maintenance |

|---|---|---|---|

Gear Pumps | Simple | Low | Less frequent |

Piston Pumps | Complex | High | More rigorous |

Vane Pumps | Moderate | Moderate | Regular checks needed |

Gear pumps are easy to care for and can handle dirty fluid. Piston pumps need clean fluid and more checks. Vane pumps need regular care. Always follow the care schedule for your pump. Clean fluid and regular checks help your excavator last longer.

Note: Pick pumps for your daily work, not just the hardest jobs. This stops your pump from getting overworked and keeps your machine running well.

Choosing the right pump means looking at all these things. You need to match the pump to your excavator and your job. The right pump gives you better work, saves money, and keeps your job site safe.

Quality and Support

Brand Reputation

You want a hydraulic pump that works well and lasts long. Trusted brands make pumps that help your excavator do its best. Many companies are known for making good and reliable pumps.

Tip: Pick a brand that is known for being strong and reliable. This helps you stop breakdowns and saves you from big repair bills.

Warranty

A good warranty keeps your money safe. Always check the warranty before you buy a hydraulic pump. Some brands give a full warranty for the main hydraulic pump and all repair parts if there are problems. Other brands have special rules for hydraulic motors.

Component | Warranty Terms |

|---|---|

Hydraulic Motors | 6-months parts warranty |

Taking apart the motor ends the warranty | |

Broken seals are not covered | |

Motors must be sent back to check |

Some brands give a 5 Year or 5,000 Hour Full Machine Warranty.

This covers all repair parts and work if there are problems.

The main hydraulic pump is included in this warranty.

Note: Always read the warranty rules. Make sure you know what is covered and what is not.

Service

Good service after you buy helps your excavator last longer. Good support saves you money and keeps your machine working. Companies with strong service can help you save up to 30% on fixing costs each year. Taking care of your pump can help your machine work almost 35% more. This means your excavator works more and breaks less.

Ask about service choices before you buy.

Pick brands that give fast help and easy-to-find parts.

Regular care and support keep your pump working well.

Callout: Good service and support help you get the most from your hydraulic pump. You spend less time fixing and more time working.

Excavator Hydraulic Pump Price

Initial Cost

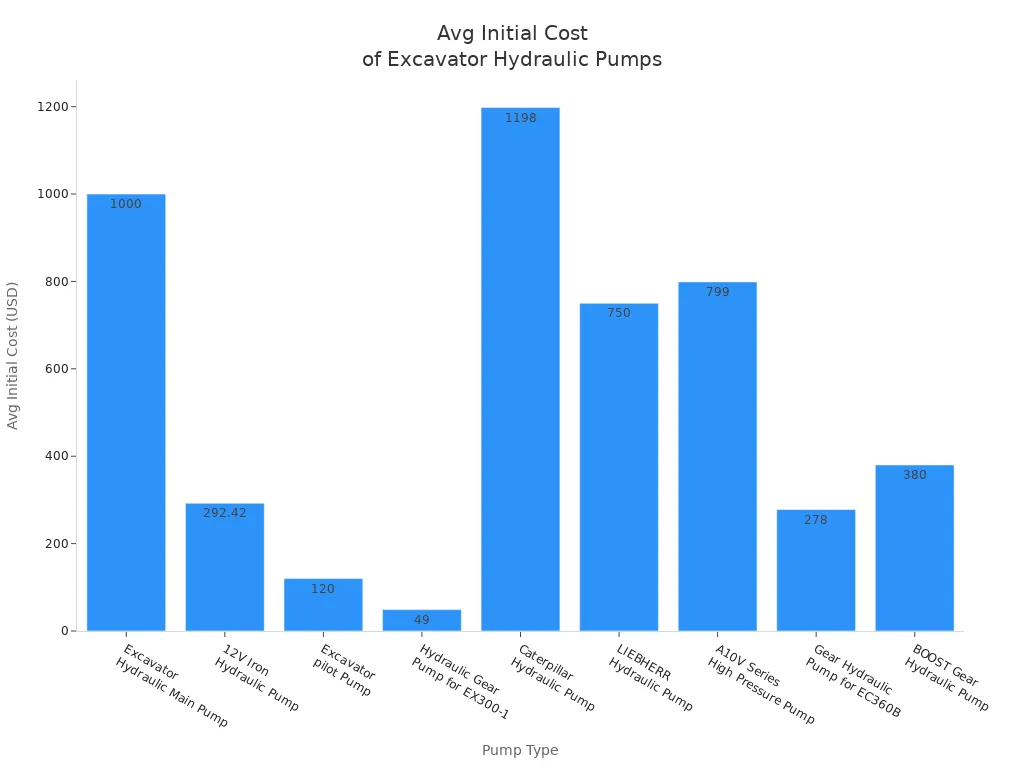

Excavator hydraulic pump prices can be very different. The price depends on the pump’s type and size. Here is a table that shows the usual starting cost for each pump:

Type of Pump | Price Range (USD) |

|---|---|

Excavator Hydraulic Main Pump | $1,000 |

12V Iron Hydraulic Pump | $271.45 – $313.39 |

Excavator pilot Pump | $115 – $125 |

Hydraulic Gear Pump for EX300-1 | $45 – $53 |

Caterpillar Hydraulic Pump | $1,198 |

LIEBHERR Hydraulic Pump | $650 – $850 |

A10V Series High Pressure Pump | $499 – $1,099 |

Gear Hydraulic Pump for EC360B | $268 – $288 |

BOOST Gear Hydraulic Pump | $370 – $390 |

The price changes if the pump is bigger or stronger. Pumps with more power or new technology usually cost more.

Long-Term Value

Do not just look at the first price. Sometimes, a pump that costs more at first saves money later. Pumps from good brands last longer and break less. Strong seals, tough materials, and longer warranties make pumps better. If you pick a pump that works well and lasts, you pay less for repairs and lost time.

Tip: Always check the warranty and service after you buy. Good help can stop extra costs later.

Total Cost

Owning a hydraulic pump costs more than just buying it. You need to think about these things:

Maintenance

Repairs

Downtime

Performance

Features

Brand and model

The cost of materials, how hard it is to make, and shipping also change the price. Pumps with special features or long warranties may cost more at first. But they can help you spend less over time.

Note: Look at the total cost, not just the price. A cheap pump might cost more later.

When you pick a pump, think about the first price, long-term value, and total cost. This helps your excavator work well and keeps your spending under control.

Sourcing and Verification

Trusted Suppliers

You need a supplier you can trust when buying a hydraulic pump. A good supplier helps you with support and gives clear warranties. They also sell products you can count on. YNF Machinery is the top supplier for excavator hydraulic pumps. This guide does not suggest any other suppliers.

Here is a table that shows what to look for in a supplier:

Criteria | YNF Machinery |

|---|---|

Warranty | 6-months |

Certification | ISO9001 |

Customer Support | Free replacement parts for 6-months |

Engineering Reputation | Known for precision engineering |

Durability Focus | Optimized for durability and efficiency |

Tip: Pick a supplier with ISO9001 certification and good customer support. This helps you avoid trouble and keeps your excavator running.

Certifications

Certifications prove a hydraulic pump is safe and high quality. ISO9001 is a very important certification. It means the pump was made with strict rules for quality. Always check for this before you buy. Pumps with ISO9001 last longer and work better. Certified pumps help your excavator stay safe and work well.

Check for ISO9001 on the label or supplier’s website.

Ask the supplier for proof if you do not see it.

Installation

Installing your hydraulic pump the right way helps it work well. Follow these steps to put in a new pump:

Put the new pump on the bracket and bolt it down. Make sure the bolts are tight enough.

Hook up all hoses and fittings. Use new O-rings if needed and tighten everything to stop leaks.

Fill the system with the right oil and viscosity.

Bleed the system to get rid of air. Use the service manual to help you.

Start the excavator and test all hydraulic parts for leaks and smooth work.

Note: Careful installation keeps your excavator safe and helps your pump last longer.

You can pick the right excavator hydraulic pump by using a simple plan. First, make sure the pump fits your excavator’s needs and project. Doing this gives you important benefits.

Benefit | Description |

|---|---|

Precision and Accuracy | Makes sure parts are in the right place for hard jobs. |

Enhanced Safety | Helps stop accidents by keeping lifting safe and steady. This makes the work area safer. |

Increased Productivity | Machines do more work with less help from people. This makes jobs faster and better. |

Structural Integrity | Shares heavy loads so no part gets too much stress. This is important for big or odd-shaped loads. |

Think about these things for good quality and value that lasts:

How strong the materials are

What kind of pump it is

How the seals work

How much pressure it can handle

How much care it needs

If the maker is well-known

What kind of warranty you get

If the price is worth it

If you are not sure, ask experts or trusted sellers for help. This way, you can get the best use from your excavator.

FAQ

What is the most important factor when choosing a hydraulic pump?

You need to pick a pump that fits your excavator model and job. Always check the flow and pressure first. Make sure the pump matches your machine. This helps your excavator work safely and well.

How often should I service my excavator hydraulic pump?

Check your pump after every 250 hours of use. Clean the fluid and look for leaks or worn parts. Doing regular checks helps your pump last longer. It also stops your machine from breaking down.

Can I use an aftermarket pump instead of an OEM pump?

You can use an aftermarket pump if you want. Always look at the quality, fit, and warranty. Some aftermarket pumps work just as well as OEM. Read reviews and compare details before you buy one.

Where can I buy a reliable excavator hydraulic pump?

You can buy a good pump from YNF Machinery. They sell certified pumps with strong warranties. Their customer support is helpful. Always pick trusted sellers to avoid problems.

What happens if I install the wrong hydraulic pump?

If you put in the wrong pump, your excavator may not work right. You might see leaks, bad performance, or damage. Always check that the pump fits before you install it.