A simple excavator hydraulic pump diagram helps you find problems fast. If you know each part, you can fix things before they get worse. Operators who know the main parts can spot and solve problems quickly.

Benefit | Explanation |

|---|---|

Knowing key hydraulic pump parts helps you fix problems | If you know the parts, you find issues faster and more correctly. This helps you succeed more often. |

Good maintenance comes from knowing the pump | Operators can take action early. This lowers downtime and makes work better. |

You can improve your skills with these training tools:

Full training about pump use and parts

Practice sessions for checking leaks and strange noises

Checking often to find problems

Review classes to keep skills strong

Stories that show how to find problems early

Talking openly about how well the pump works

You do not need to be an expert to begin. This guide helps you at every step.

Key Takeaways

Knowing the main parts of the hydraulic pump helps you find and fix problems fast.

Doing regular checks, like looking at fluid levels and hoses, stops expensive breakdowns.

Use the excavator hydraulic pump diagram to help you fix problems step by step.

Watch for warning signs like leaks, weird noises, or overheating to spot problems early.

If problems keep happening, call a professional for help so you do not cause more damage.

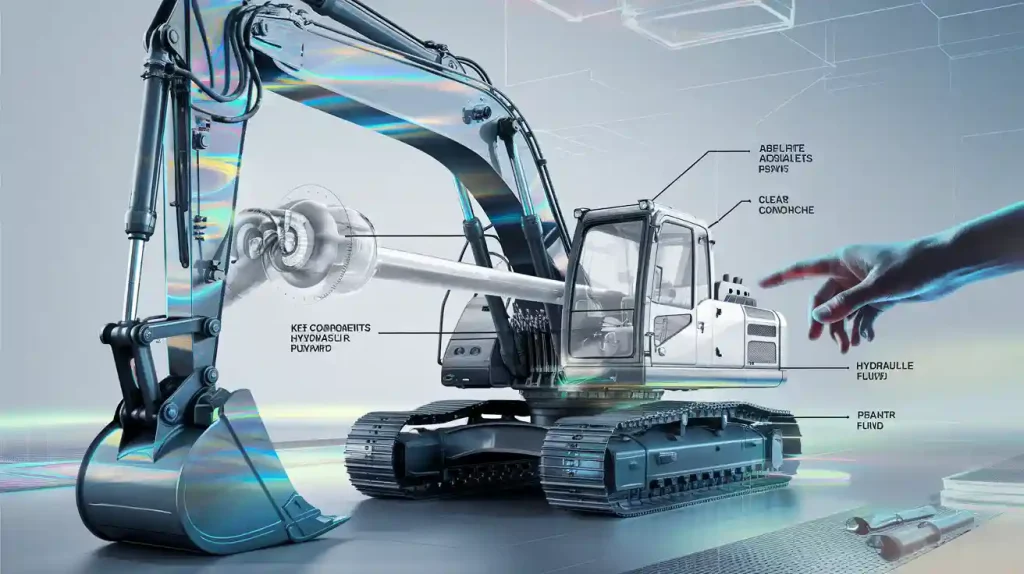

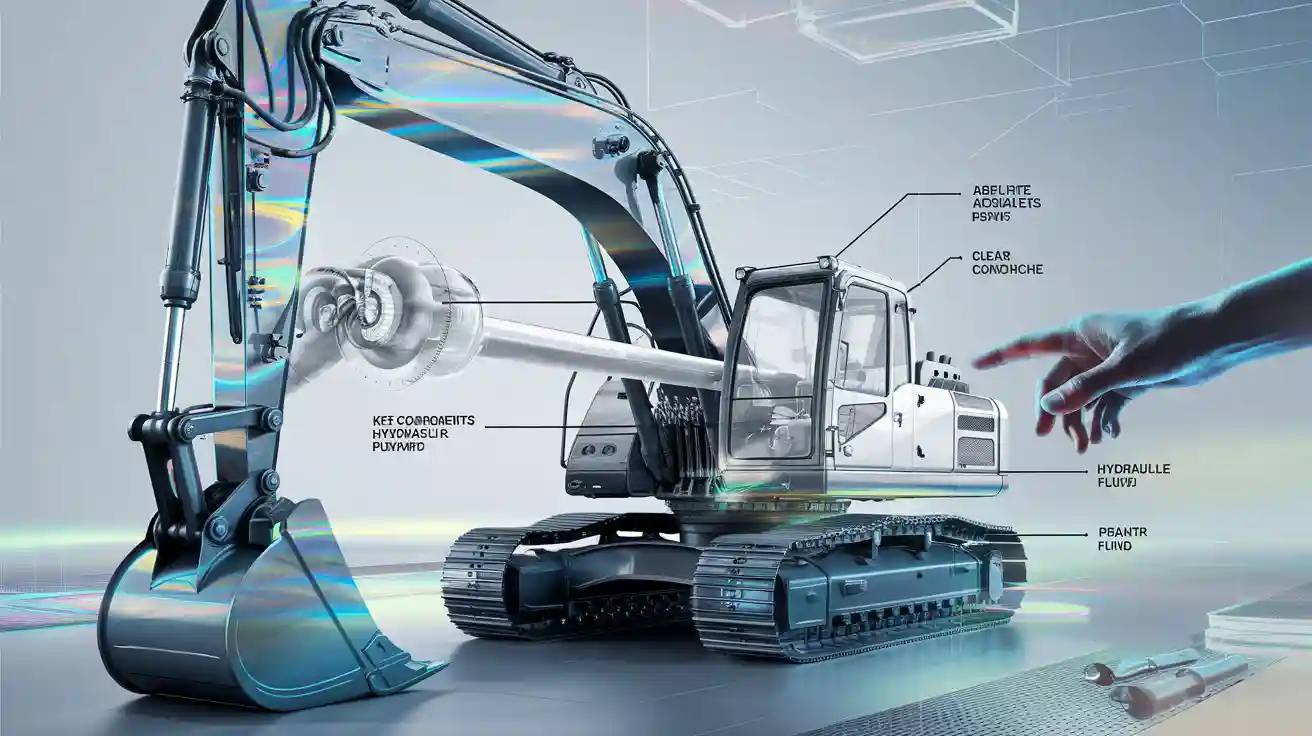

Excavator Hydraulic Pump Diagram

Key Components Overview

When you look at an excavator hydraulic pump diagram, you will see many important parts. Each part helps the machine work well. The main components are:

Pump housing: This keeps all moving parts together.

Drive shaft: This links the engine to the pump.

Control valve: This sends hydraulic fluid where it needs to go.

Hydraulic lines: These move fluid in and out of the pump.

Filters and seals: These keep fluid clean and stop leaks.

Pressure relief valve: This keeps the system safe from too much pressure.

The excavator hydraulic pump diagram helps you find these parts fast. If you know where each part is, you can fix problems quickly. If you see a leak or hear a weird sound, you can check the right spot first.

Tip: Always look at the excavator hydraulic pump diagram before fixing anything. This helps you do repairs right and saves time.

How to Use the Diagram

You can use the excavator hydraulic pump diagram to help you fix problems step by step. First, match the parts on your machine to the diagram. If you see a problem, like less power or a leak, the diagram shows you where to check.

Manufacturers give tips to keep your hydraulic pump working well. The table below lists some important steps:

Maintenance Practice | Description |

|---|---|

Check hydraulic fluid levels | Make sure fluid is at the right level to stop pump failure. |

Inspect hoses and connections for leaks | Look for leaks often to keep the system working well. |

Ensure hydraulic fluid is clean | Use clean fluid to stop dirt and pump problems. |

Follow manufacturer maintenance intervals | Service your pump every 250 to 500 hours as the manual says. |

Inspect and replace worn-out parts | Check seals and filters to stop breakdowns. |

Follow operational guidelines | Do not overload the pump and use the right tools. |

You can use the excavator hydraulic pump diagram for each step. For example, when you look for leaks, the diagram shows you all hose spots. When you change a filter, the diagram tells you where it is. This makes your work faster and easier.

If you want your excavator to work well, always use the excavator hydraulic pump diagram. It helps you know your machine and fix problems before they get worse.

Common Hydraulic Pump Problems

Hydraulic pumps in excavators can have many problems. You can find these problems early if you know what to watch for. If the machine moves slowly or feels jerky, something is wrong. Loud noises are also a warning sign. Checking the pump often helps you stop problems before they get worse.

Fluid Contamination and Leaks

Contamination and leaks are big problems for hydraulic pumps. You might see bubbles or hear sizzling in the oil. This can mean water got into the system. Water can cause rust and change how thick the fluid is. Dirt and dust from outside can also get inside the pump. This makes the pump work harder than it should.

You should look for these signs:

Bubbles or sizzling in the oil

Sludge in the fluid

Leaks around hoses and seals

Lower power or breakdowns

Leaks can happen if seals are old or hoses are broken. Inside the pump, metal bits or rubber pieces can show up when parts wear out. These things make the pump work badly and can cost a lot to fix. Always check for leaks and dirty fluid. Look at fluid levels every day and change filters every 500 hours.

Note: If you see leaks or hear odd noises, check the seals and hoses right away.

Overheating and Cavitation

Overheating is another problem for hydraulic pumps. It happens when the pump cannot cool down. Dirty fluid, not enough fluid, or blocked coolers can cause this. Air getting into the system can also make the pump too hot.

Cause/Warning Sign | Description |

|---|---|

Contaminated hydraulic fluid | Dirt or water can get in if the container is not closed. |

Aeration | Air leaks in the suction line let air inside the system. |

Low reservoir fluid | Not enough fluid means the pump cannot cool off well. |

Blocked heat exchangers | The pump gets too hot if coolers are blocked or broken. |

Unusual noises | Strange sounds can mean the pump is too hot or has other problems. |

Pressure problems | Changes in pressure can show overheating or other trouble. |

Flow problems | Bad fluid flow can mean the pump is too hot or has other issues. |

Cavitation happens when bubbles form in the fluid because of low pressure. These bubbles pop and hurt the metal inside the pump. Over time, cavitation makes the pump work worse and can be expensive to fix. You might notice the machine is slower or louder.

Air in System and Component Wear

Air in the system makes foam or bubbles in the fluid. You might see leaks at seals and connections, which let air in. The pressure gauge might jump up and down. Air pockets mess up fluid flow and make the pump hotter. This makes the pump work harder.

You should watch for these signs:

Foam or bubbles in the fluid

Leaks at seals and connections

Pressure changes on gauges

Higher temperatures than normal

Parts can wear out over time. Hydraulic pumps, control valves, and cylinder seals can get old. Dirt, high pressure, and age make this happen. You might see less power, strange noises, overheating, or leaks.

Affected Parts | Manifestation of Wear |

|---|---|

Hydraulic Pumps | Less power, leaks inside the pump |

Control Valves | Changes in how the part works |

Cylinder Seals | Wear from dirt, pressure, and age |

Tip: Change old seals and check all parts often to stop breakdowns.

Pressure Relief Valve Issues

Problems with the pressure relief valve can be serious. You might see these signs:

Cannot reach pressure: The system does not get enough pressure. The valve might open too soon or be set wrong.

Over maximum pressure: The system goes above safe pressure. The valve might not open when it should.

Relief valve is leaking: Leaks at the valve make the pump work worse and are hard to see.

If you see any of these problems, check the pressure relief valve right away. Trouble with this valve can make the machine unsafe and cost a lot to fix.

Always follow the maker’s maintenance plan. Check fluid levels every day and change filters every 500 hours to stop common problems.

Troubleshooting Steps

If your hydraulic pump has problems, you need a plan. These tips help you find issues fast. They keep your excavator working well. Use the excavator hydraulic pump diagram to help you check and test.

Visual Inspection Points

Begin by looking closely at your excavator. Try to find trouble before it gets worse. Daily checks help you catch problems early.

Look for leaks near hoses, seals, and connections. Leaks mean hydraulic fluid is escaping.

Check the fluid’s color and clarity. Dirty fluid looks dark or has sludge.

See if the pump housing has cracks or damage.

Watch for bubbles or foam in the hydraulic fluid. Air in the system can cause this.

Check filters for dirt or wear. Dirty filters let debris into the pump.

Feel for hot spots on the pump or lines. Overheating can show a problem.

Listen for strange noises. Squealing or knocking sounds mean air or wear inside the pump.

Tip: Always do daily checks. Small leaks or dirty fluid can become big problems fast.

Testing Components

After looking, test important parts. Testing helps you find hidden problems you cannot see.

You need these tools:

Hydraulic pressure gauge

Flow meter

Temperature gauge

Use these tools to check the pump’s health:

Measure pressure at different spots. Low pressure means the pump is weak or leaking inside.

Use a flow meter to test output. Low flow shows wear or blockages.

Check temperature with a gauge. High heat means the pump works too hard or fluid is low.

Do a leak test with a hydraulic leak detector. This tool finds leaks under pressure.

Test efficiency by measuring flow rate at different pressures.

Note: Make sure the intake isolation valve is open before starting the engine. This step protects hydraulic parts from damage.

Common mistakes during troubleshooting are:

Not opening the intake isolation valve

Thinking parts are self-priming and skipping lubrication

Changing oil too often or not enough. Always check the hydraulic fluid before changing it.

Interpreting Results

You need to know what your test results mean. This helps you fix hydraulic pump problems quickly.

Check the work area. Make sure fluid is clean and temperature and pressure are normal.

Look at the hydraulic fluid for contamination. Watch for strange color or metal bits.

Listen for odd sounds. Hissing or knocking can mean air in the system.

Use a pressure gauge to measure system pressure. Low pressure means the pump is weak or leaking.

Look for damage or leaks in hoses and seals.

Do a flow test. Low flow shows wear or blockages inside.

Check for overheating with an infrared thermometer. Hot spots mean the pump works too hard.

If problems remain, open the pump and look for worn parts inside.

Symptom | Possible Cause | What to Check |

|---|---|---|

Not building pressure | Internal leak, worn parts | Pressure gauge, seals |

Jerky operation | Air in system, dirty fluid | Fluid, connections |

Increased noise | Worn parts, air in fluid | Listen, inspect pump |

Overheating | Low fluid, blocked coolers | Temperature, fluid level |

Leaks | Worn seals, damaged hoses | Visual check, leak test |

If fluid is dirty, change it right away. Replace filters and worn seals to keep your pump healthy.

You can fix most hydraulic pump problems with careful checks and tests. Always use the diagram to help you troubleshoot. This keeps your excavator safe and working well.

Essential Maintenance

Preventive Checks

You can keep your excavator working well with regular care. Daily checks help you stop pump problems and save money. Start each morning by walking around your machine. Look for leaks, broken hoses, or loose parts. Check fluid levels and make sure the oil is clean. Dirty or low fluid can cause trouble.

Here is a table that lists the best checks:

Maintenance Check | Description |

|---|---|

Check Fluid Levels | Make sure hydraulic oil, engine oil, and coolant are full. |

Regular Lubrication | Lubricate moving parts to stop friction and wear. |

Watch bucket teeth, track pads, and hydraulic hoses for wear. | |

Scheduled Component Replacements | Change parts before they break to avoid big repairs. |

You should also look at hoses and connections for damage. Tighten all fittings so leaks do not happen. Watch system pressure and temperature to keep things safe. Operators who check fluid every 100-200 hours help stop breakdowns. Daily checks can prevent most failures before they start.

Tip: Keep a log of maintenance. Write down every check, repair, and part change. This helps you see problems early and plan future care.

When to Call a Professional

Some problems need expert help. If you see big leaks, hear loud sounds, or notice less power, call a pro. Get help if you cannot find a leak or if the system will not hold pressure. You can fix small things, like tightening parts or changing filters, but big problems need a technician.

Here are common fixes you can do yourself:

Problem | Common DIY Fixes |

|---|---|

Low Hydraulic Pressure | Clean filters, keep fluid full, check and change worn pumps. |

Overheated Hydraulic Fluid | Use good oil, do not overload, check coolers. |

Hydraulic Fluid Leak | Check hoses, tighten parts, change old seals. |

Jerky Movements | Use clean oil, set right pressure, check cylinders. |

If you have a problem you cannot fix, contact YNF Machinery. They sell good excavator hydraulic pump parts and offer expert service. Getting help from pros can save you money. Emergency repairs cost much more than planned care. Downtime can be very expensive, so quick help protects your machine.

Note: Always follow your maintenance plan. Regular checks and knowing when to get help keep your excavator safe and working well.

Looking at the excavator hydraulic pump diagram helps you spot problems fast. You can fix issues quickly when you use clear steps. This makes your machine work better and last longer. Checking filters and relief valves often keeps the system clean. It also helps the pump work well. The table below shows why maintenance is important:

Benefit | Result |

|---|---|

Regular service | Fewer failures and better reliability |

Early problem detection | Less downtime and lower repair costs |

Check your machine every day and watch for warning signs. Do not wait if you see something wrong. If you find a hard problem, ask an expert for help. This way, your excavator stays strong and works well each day.

FAQ

What are the most common signs of hydraulic pump failure?

Your excavator might move slowly or jerk around. You could hear loud noises from the pump. These signs mean your pump needs help soon. Fixing problems quickly keeps your excavator working well.

How can I prevent costly downtime with my excavator’s hydraulic pump?

Check fluid levels every day. Look at hoses for damage or leaks. Change filters when it is time. Doing these checks helps you find problems early. Taking care of your pump stops big breakdowns.

Why does my excavator lose power during operation?

Leaks, dirty fluid, or old parts can lower power. If you do not fix these, repairs can cost a lot. Always use your hydraulic pump diagram to find problems fast.

When should I call a professional for hydraulic pump issues?

Call a pro if you see big leaks or hear loud sounds. Get help if you cannot fix pressure problems. YNF Machinery can help with expert service and good parts.

Where can I find reliable hydraulic pump parts?

YNF Machinery sells strong hydraulic pump parts. They give good support and products. This helps your excavator work well and avoid downtime.