Selecting reputable aftermarket excavator parts manufacturers directly impacts your machine’s performance, reliability, and cost-effectiveness. You get the most value by choosing the right excavator parts, which ensures quality and compatibility. Consider these proven factors:

-

Total Cost of Ownership combines purchase price, installation, maintenance, and downtime to show true savings.

-

High-quality aftermarket hydraulic cylinders last over 3,000 hours, reducing repairs.

-

Leading aftermarket brands like Caterpillar and Komatsu hold strong market shares due to their consistent reliability.

A careful approach to aftermarket parts protects your equipment and investment.

Key Takeaways

-

Always confirm your excavator’s exact make, model, and serial numbers to ensure parts fit perfectly and avoid costly mistakes.

-

Choose reputable aftermarket parts manufacturers with strong reputations, industry certifications, and proven experience with major brands like Caterpillar and Komatsu.

-

Focus on high-quality, certified parts that meet industry standards to protect your equipment and extend its service life.

-

Compare value by considering total cost, warranty coverage, and supplier support rather than just the lowest price.

-

Avoid counterfeit parts by buying only from trusted suppliers who offer clear product information and strong warranties.

Identify Your Excavator Parts Needs

Confirm Make and Model

Before you start buying heavy equipment parts, you need to confirm the exact make and model of your excavator. Each excavator model uses specific types and sizes of accessories. If you choose the wrong accessories, you risk poor performance or even damage to your machine. You also want to avoid safety hazards that come from using incompatible accessories.

Tip: Always check your official manual or ask a professional technician to verify which excavator parts and accessories fit your machine.

Accessory number query systems and matching apps, such as “Mechanical Accessories Assistant,” can help you scan your equipment’s nameplate. These tools make it easier to match the right accessories to your excavator. Confirming the make and model helps you avoid waste and financial loss. You also extend your equipment’s service life by ensuring every part and accessory works as intended.

-

Different excavator models require specific types and sizes of parts, making it essential to know the exact model to avoid mismatched accessories.

-

Using incompatible parts can cause performance degradation, equipment damage, or safety hazards.

-

Official manuals and professional technicians are recommended sources to verify the correct parts for a given excavator model.

-

Accessory number query systems and matching apps (e.g., “Mechanical Accessories Assistant”) help ensure compatibility by scanning equipment nameplates.

-

Confirming make and model helps prevent waste, financial losses, and extends equipment service life by ensuring optimal part performance.

Use Serial Numbers and OEM Codes

When you buy excavator parts or accessories, always check the serial numbers and OEM codes. These numbers help you identify the exact accessories your excavator needs. The case study of E.K. Services shows how accurate equipment data, including serial numbers, make, model, and history, improves fleet management. When you track serial numbers, you can quickly find equipment issues and order the right accessories. This process reduces downtime and supports better cost tracking. Maintenance becomes more efficient because you can schedule and dispatch the right accessories at the right time.

If you want to succeed in buying heavy equipment parts, you must use serial numbers and OEM codes. This step ensures you get the correct excavator parts and accessories every time. You protect your investment and keep your excavator running smoothly.

Compare OEM and Aftermarket Parts

Key Differences

You face a choice between OEM and aftermarket parts when you need new excavator accessories. OEM parts come directly from the original manufacturer. These accessories match your excavator model exactly. Aftermarket parts, on the other hand, come from third-party manufacturers. These accessories fit many brands and models. You often find more options with aftermarket accessories.

OEM accessories usually guarantee a perfect fit and consistent quality. You pay a premium for this assurance. Aftermarket accessories offer a wider selection and can match or even exceed OEM quality in some cases. Many aftermarket brands invest in research to improve durability and performance. You should always check if the aftermarket accessories meet or surpass the standards set by the original brand.

Note: Not all aftermarket accessories are equal. You need to choose reputable brands that focus on quality and compatibility with your excavator.

Value and Cost Considerations

When you compare value, you see that aftermarket parts often provide significant savings. OEM excavator parts have low profit margins for manufacturers because of high production costs and volume sales. Aftermarket parts, however, deliver higher profitability for suppliers and more choices for you. Many aftermarket accessories cost less than OEM options, but still offer high quality and reliability.

You should also consider the total cost of ownership. Aftermarket accessories can reduce downtime and maintenance costs if you select the right brand. Some aftermarket parts even come with better warranties than OEM accessories. You get more flexibility to choose accessories that fit your budget and your excavator’s needs.

A smart approach involves comparing the quality, price, and reputation of each brand. You protect your investment by choosing aftermarket accessories that deliver both value and performance. Always match the accessories to your excavator model and job requirements for the best results.

Research Aftermarket Excavator Parts Manufacturers

Reputation and Track Record

You want to work with aftermarket excavator parts manufacturers that have a proven reputation and a strong track record. Start by checking customer reviews and testimonials. These give you real feedback from other buyers who have used the accessories and services. Look for consistent praise about product quality, delivery speed, and customer support.

Industry certifications also show a manufacturer’s commitment to quality. Certifications like ISO 9001 or CE mark mean the company follows strict standards. Reliable parts supplier companies often display these certifications on their websites. You can also ask for copies before you buy.

Many top aftermarket parts manufacturers use advanced monitoring and data-driven practices to prove their reliability. Here are some best practices for purchasing and evaluating a manufacturer’s reputation:

-

Wear rate monitoring, such as Komatsu crawler wear rates below 0.04mm/h, helps extend service life.

-

Vibration measurement, infrared detection, and IoT monitoring collect real-time data on temperature, vibration, and friction rates.

-

Data-driven maintenance decisions reduce downtime and maintenance costs by providing early warnings and timely part replacements.

-

Life cycle cost analysis and downtime rate comparisons between Komatsu and Caterpillar parts give you a clear, quantitative way to compare brands.

-

Regular quarterly equipment data reports and professional analysis software help guide your maintenance and replacement strategies.

These practices show that quality suppliers focus on measurable performance indicators. You can trust them to deliver accessories that last and perform well.

Experience with Major Brands

When you choose aftermarket excavator parts manufacturers, always check their experience with major brands. The best suppliers have a long history of working with leading names like Komatsu, Caterpillar, Volvo, and Hitachi. This experience means they understand the unique requirements of each excavator model and can offer accessories that fit perfectly.

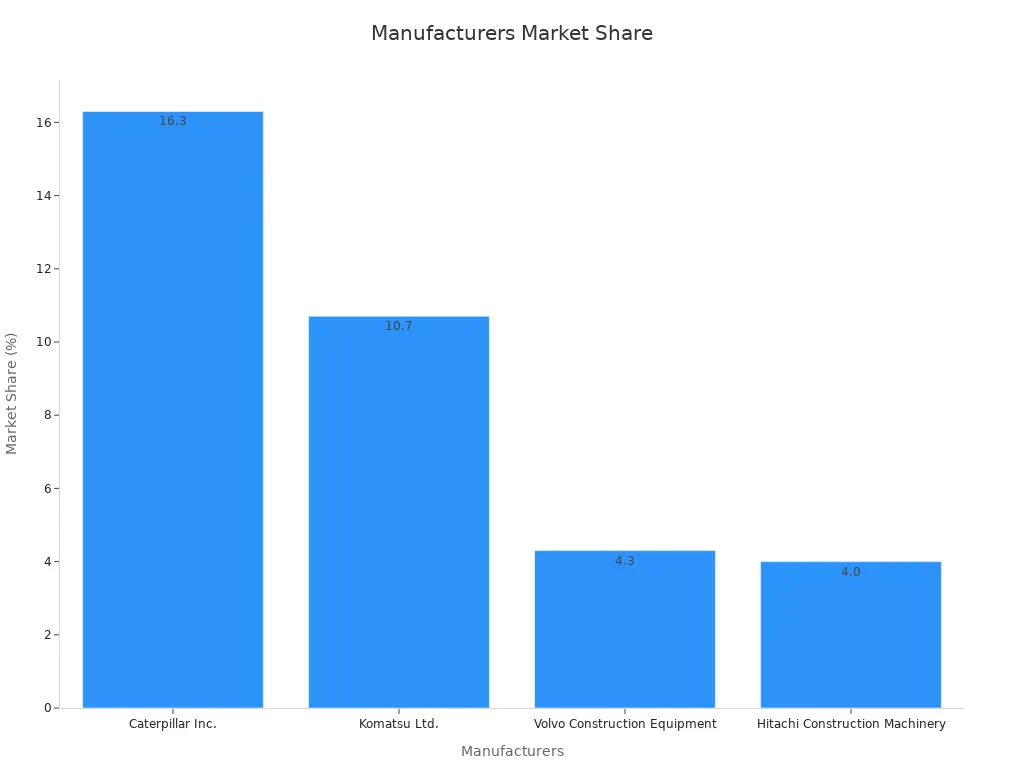

The table below highlights the historical performance and market share of top brands in the excavator industry:

|

Manufacturer |

Founded |

2022 Global Market Share |

Key Historical Success Indicators |

|---|---|---|---|

|

Caterpillar Inc. |

1925 |

16.3% |

Long history, hybrid technology, fuel efficiency, innovation leadership |

|

Komatsu Ltd. |

1921 |

10.7% |

Intelligent machine control, hybrid excavators, strong Asia presence |

|

Volvo Construction Equipment |

1832 (Volvo Group) |

4.3% |

Sustainability focus, operator comfort, fuel efficiency |

|

Hitachi Construction Machinery |

1970 |

4.0% |

Reliability, advanced hydraulic technology, Asia-Pacific strength |

Caterpillar leads the industry with a wide product range and strong research and development. You get excellent resale value, but you may pay more upfront. Komatsu stands out for fuel-efficient machinery and advanced monitoring technology like KOMTRAX. Volvo focuses on safety, sustainability, and operator comfort. Hitachi is known for reliability and advanced hydraulic systems.

Manufacturers with experience in these brands can supply accessories that meet strict quality standards. You get aftermarket parts that match or exceed OEM performance. This expertise supports your excavator parts brand selection and ensures you receive accessories that fit your equipment and job needs.

You should always ask suppliers about their history with these brands. A reliable parts supplier will provide references, case studies, or data showing successful deliveries and satisfied customers. This step helps you avoid costly mistakes and ensures you choose the right accessories for your excavator.

Tip: Choose aftermarket excavator parts manufacturers with a strong reputation, industry certifications, and proven experience with major brands. This approach gives you confidence in your excavator parts brand selection and helps you find accessories that deliver long-term value.

Check High-Quality Excavator Parts

Material Standards

You need to focus on material standards when you select high-quality excavator parts. Manufacturers who follow strict industry standards produce parts that last longer and perform better. Many leading companies use ISO standards to guide their production. These standards set clear rules for safety, material strength, and design.

|

Standard Number |

Title and Scope |

Relevance to Excavator Parts Manufacturing |

|---|---|---|

|

ISO 20474-5:2008 |

Safety requirements for hydraulic excavators |

Confirms safety and material standards for hydraulic parts |

|

ISO 7852:1983 |

Shapes and dimensions of plough bolt heads |

Sets material and dimensional standards for bolt heads |

|

ISO 8643:2017 & 2024 |

Requirements and tests for hydraulic excavator lowering control |

Validates performance and safety for control devices |

You should always ask your supplier if their products meet these ISO standards. This step helps you avoid low-quality parts that may fail during tough jobs. High-quality excavator parts built to these standards give you peace of mind and better value over time.

Certified and Genuine Parts

You want certified and genuine parts for your excavator. These parts go through strict quality control checks before reaching you. Companies like KyoTechs use advanced diagnostic tools and software to test engine assemblies, hydraulic pumps, and electric parts. They also provide warranty coverage, which shows confidence in their high-quality components.

Look for these signs when you buy high-quality excavator parts:

-

Certification labels or documents from the manufacturer

-

Warranty coverage for each part

-

Expert support and clear product information

Tip: Certified parts often come with safety features like proper ventilation, secure storage for manuals, and protection against accidental contact with moving parts. These features show that the manufacturer cares about both safety and quality.

You protect your equipment and your investment when you choose genuine, high-quality excavator parts. Reliable suppliers follow strict inspection standards and use the best materials. This approach keeps your machines running smoothly and safely.

Ensure Compatibility of Aftermarket Parts

Fit for Your Model

You need to make sure every aftermarket part and accessory fits your excavator model. Compatibility protects your machine from costly repair and downtime. Start by checking the exact model and serial numbers for your excavator. Cross-reference these with the specifications and part numbers listed in the manufacturer’s manual. This step helps you avoid mismatched replacement excavator parts and ensures your hydraulic system accessories work as intended.

Many reputable aftermarket brands and suppliers use professional testing tools to compare new and old accessories. They also rely on third-party testing agency reports to confirm stable operation under high load. Certified aftermarket parts that meet ISO or CE standards can reduce failure rates by about 15%. You should always ask if the replacement parts have passed these tests before you buy.

-

Check part models, production batches, and equipment parameters against manuals and parts lists.

-

Use professional installation by trained technicians to ensure system compatibility.

-

Keep detailed records of all replacement excavator parts and accessories for future fault prediction and prevention.

-

Choose rebuilt and remanufactured accessories only if they have passed thorough inspection and performance testing.

-

Rely on warranty and return policies for extra assurance of compatibility.

Tip: Proper installation by certified technicians following manufacturer instructions is critical for the safe use of hydraulic system accessories and other excavator accessories.

Avoid Counterfeit Parts

Counterfeit aftermarket parts and accessories pose a serious risk to your excavator. These fake replacement parts often look like genuine excavator accessories but use poor materials and fail to meet OEM standards. They can cause equipment malfunctions, safety hazards, and even legal problems. The construction machinery market faces many challenges from counterfeit and low-quality accessories.

You may see counterfeit replacement parts sold at lower prices, making them seem attractive. However, these accessories can damage your hydraulic system accessories and shorten the life of your excavator. A real-world case involved counterfeit fuel injectors installed in 15 engines, leading to costly repair and downtime. Using counterfeit excavator parts undermines customer confidence and distorts the market.

-

Counterfeit and substandard aftermarket parts are widespread in the construction machinery market.

-

These accessories often fail quickly and compromise machinery performance and safety.

-

High costs of genuine accessories sometimes push companies to buy cheaper counterfeit alternatives, increasing risks.

-

Industry leaders call for stricter regulations, better product authentication, and more awareness to fight counterfeit accessories.

Note: Always buy aftermarket parts and excavator accessories from reputable suppliers with strong warranties and clear product information. This step protects your investment and keeps your excavator running safely.

Evaluate Warranty and Support

Warranty Coverage

You should always check the warranty coverage before you buy aftermarket excavator parts. A strong warranty shows the manufacturer’s confidence in the quality of their products. Most original parts come with a manufacturer’s warranty, which can last from one to two years. This warranty often covers both parts and labor for defects in manufacturing. Major components like engines, hydraulic systems, and drive parts usually fall under this protection.

Note: Using aftermarket parts while your machine is still under warranty can sometimes void the original warranty. Always read the warranty terms carefully to avoid problems.

Here are some important points to remember about warranty coverage:

-

Warranty terms can differ between suppliers, so review documents closely.

-

Understanding warranty conditions helps you avoid unexpected costs.

-

Warranty coverage can reduce your worries about product reliability.

-

Recognizing exclusions and requirements helps you keep your equipment value high.

You can see how leading brands compare in the table below:

|

Manufacturer |

Product Type |

Base Warranty Duration |

Hour Limit |

Extended Warranty |

Notes |

|---|---|---|---|---|---|

|

CASE |

Excavators |

12 months |

Unlimited |

N/A |

Requires proper maintenance and use |

|

Caterpillar |

Excavators |

12-24 months |

Varies |

Available |

Extended plans for extra coverage |

Standard warranties protect you from defects, but you must follow maintenance schedules and use the equipment properly. Extended warranties may cover more parts, such as powertrain or hydraulics, but require a special contract.

Customer Service

You need reliable customer service when you buy aftermarket excavator parts. Good support helps you solve problems fast and keeps your equipment running. Suppliers with strong reputations often have high customer satisfaction rates and positive reviews. They respond quickly to questions and offer technical help when you need it.

Key customer service metrics include:

-

Fast response times and knowledgeable support teams

-

Clear warranty and return policies

-

Wide range of parts in stock to reduce downtime

-

Timely delivery and rapid shipping options

-

Ability to maintain inventory even during supply chain disruptions

Tip: Choose suppliers who offer both OEM and reputable aftermarket parts. This gives you more options and helps you find the right fit for your needs.

You should look for suppliers who value quality in both their products and their service. A supplier who manages inventory well and delivers on time helps you avoid costly delays. Responsive customer service ensures you get the support you need, whether you have a technical question or need to return a part.

Assess Pricing and Availability

Value for Money

When you compare aftermarket parts to OEM options, you see clear differences in value for money. Many buyers choose aftermarket parts because they offer significant cost savings. Remanufactured accessories often cost 20-40% less than new OEM parts. Some programs even price reman accessories at just 35-45% of the cost of a new machine. You do not sacrifice quality for price. Remanufactured accessories meet or exceed OEM standards. Some even include product improvements that boost power and durability.

You also get strong warranty coverage with many aftermarket accessories. Some remanufactured parts come with warranties that match or surpass those from OEMs, such as three-year or 5,000-hour coverage. This gives you peace of mind when buying heavy equipment parts. Extended warranties help you manage risk and protect your investment.

Tip: Remanufactured accessories can extend the life of your excavator and maximize your equipment’s value. This is especially important for rental businesses that need to keep machines running longer.

You should always weigh the total cost, warranty, and performance when choosing between aftermarket and OEM accessories. This approach ensures you get the best value for your money.

Delivery and Inventory

You need to consider delivery speed and inventory levels when buying heavy equipment parts. Aftermarket parts suppliers often provide wider availability than OEM channels. E-commerce platforms and digital procurement services make it easier to find the accessories you need. This helps you reduce downtime and keep your projects on schedule.

Aftermarket parts pricing can change based on region, demand, and supply chain factors. For example, high rental market utilization in Southeast Asia leads to faster replacement cycles and higher demand for accessories. In Brazil, rental companies sometimes pay $1,200 more for reinforced track links. Middle Eastern contractors invest in sealed lubrication systems due to harsh climates. These factors affect both the price and availability of aftermarket accessories.

-

OEMs like Caterpillar and Komatsu use vertical integration to stabilize prices, but aftermarket suppliers adjust prices based on local conditions.

-

Digital platforms and subscription services create new ways to buy accessories and manage inventory.

-

Regional demand and climate can cause price and availability differences for the same accessories.

You should always check stock levels and delivery times before placing an order. Reliable aftermarket suppliers keep a large inventory of accessories and offer fast shipping. This ensures you get the excavator parts you need without long delays. When you plan ahead and choose suppliers with strong availability, you avoid costly downtime and keep your equipment running smoothly.

Bucket and Breaker Selection

Choosing the Right Attachments

You face many options when selecting excavator accessories for your project. The right bucket and breaker selection can boost your productivity and protect your investment. You should always match the attachment to the job. For example, a trenching bucket works best for digging narrow trenches, while a grading bucket helps with leveling and finishing. When you choose a breaker, look at the impact energy and frequency. These factors help you break concrete or rock faster and with less wear on your machine.

-

Customized bucket attachments for tasks like trenching, grading, or rock breaking improve efficiency and reduce waste.

-

Case studies show that using the right accessories, such as root rakes, can speed up projects by 30% and improve site restoration.

-

You should match the size, weight, and design of each accessory to your project and soil conditions. This step increases safety and precision.

-

Watch for signs like vibrations or hydraulic noise. These signals tell you when to replace or adjust your breaker or bucket.

-

Switching between different accessories, such as trenching buckets and hydraulic thumbs, gives you more flexibility and higher productivity.

-

High-grade steel and reinforced edges in your accessories lower maintenance costs and extend service life.

-

Your input and project needs play a key role in the selection process. Always consider soil type, topography, and application.

Tip: Epiroc’s hydraulic breaker uses advanced technology to improve efficiency and durability. You can use these excavator accessories for demolition, mining, or recycling, expanding your machine’s capabilities.

Matching Attachments to Tasks

You need to match your excavator accessories to each task for the best results. Studies show that using the right bucket size can cut cycle time and increase productivity in earthmoving. Many contractors rely on experience, but real-time monitoring now helps you make better choices. You can track bucket trajectory, digging energy, and force. This data helps you select the right accessories and reduce costs.

-

Comparing buckets with different cutting-edge shapes shows that adapting the design to soil conditions improves performance and lowers energy use.

-

Research proves that the length of working movements affects cycle time and productivity. You should always consider these factors when choosing accessories.

-

Monitoring key parameters, such as impact energy and pressure pulsation, ensures your breaker works safely and efficiently.

You can use prototype testing and sensitivity analysis to find the best breaker for your hydraulic system. This process helps you balance performance and stability. When you match your bucket and breaker selection to your project, you get better results, safer operations, and longer equipment life.

Common Mistakes to Avoid

Focusing Only on Price

Many buyers look for the lowest price when choosing aftermarket excavator parts. You might think saving money upfront is the smartest move. However, this approach often leads to bigger problems later. Low-cost parts can lack the durability and quality you need for heavy equipment. You may face frequent breakdowns or even a complete failure of your excavator. When you choose cheap parts, you often spend more on repair and downtime.

Tip: Always balance price with quality. Reliable parts last longer and help you avoid unexpected repair costs.

You should follow best practices for purchasing. Check the supplier’s reputation and ask about their testing standards. A trusted supplier will provide clear information about their products. They will also offer support if you have questions or concerns.

Ignoring Compatibility

Some buyers ignore compatibility when selecting excavator parts. You might see a part that looks right and fits your budget. If you skip checking the model or serial number, you risk buying the wrong part. Incompatible parts can damage your machine or cause safety issues. You may need to repair your equipment more often, which increases costs and reduces productivity.

Always match each part to your specific excavator model. Use the manual or consult with a professional if you feel unsure. This step protects your investment and keeps your equipment running smoothly.

Remember: Compatibility and quality matter as much as price. Careful selection prevents costly mistakes and keeps your projects on track.

Choosing the right aftermarket excavator parts manufacturer protects your equipment and investment. You should:

-

Select reputable suppliers with a strong history of meeting OEM standards.

-

Confirm that every part matches your machine for perfect compatibility.

-

Work with professional installers to ensure proper fit and performance.

Stay alert for common mistakes. Use these steps to make confident, value-driven decisions. Focus on long-term reliability and keep your excavator running at its best.

FAQ

What are the main benefits of choosing aftermarket excavator parts?

You save money and get more options. Many aftermarket parts match or exceed OEM quality. You can find parts faster and keep your equipment running longer. Aftermarket suppliers often offer strong warranties and support.

How do I know if an aftermarket part will fit my excavator?

Check your excavator’s model and serial number. Compare these with the part’s specifications. Always ask the supplier for compatibility confirmation. Use your equipment manual for reference.

Are aftermarket parts safe to use?

Yes, reputable aftermarket parts meet strict safety and quality standards.

You should buy from certified suppliers. Avoid counterfeit products. Always check for industry certifications and warranty coverage.

What should I look for in a reliable aftermarket parts manufacturer?

-

Strong reputation and positive customer reviews

-

Industry certifications (like ISO 9001)

-

Experience with major brands

-

Clear warranty and support policies

These factors help you choose a trustworthy supplier.