When you look at China excavator bucket parts, you see a few main materials. These are high manganese steel, Q345B, AISI 4130/4140, high chromium cast iron, and low carbon alloy steel. Each bucket part uses a certain material for a reason. The shell, teeth, pins, and wear plates all need different things. For example, bucket teeth use high manganese steel. This is because it is tough and does not wear out fast. The table below shows how picking a material changes how long it lasts, how well it works, and how much it costs:

Material Type | Durability | Performance | Cost Impact |

|---|---|---|---|

High Manganese Steel | Good toughness and wear resistance | Good for most digging jobs | Medium cost |

Alloy Steel | Harder and resists wear better | Good for rougher places | Higher cost |

Wear-Resistant Alloys | Very high wear resistance | Best for very tough jobs | Highest cost |

Picking the right material for each part helps your bucket last longer. It also helps it work better and saves money on your project.

Key Takeaways

Picking the best material for each bucket part helps it last longer and work better. High manganese steel works well for teeth because it is very strong.

Different jobs need different materials. Use high-strength steel for tough jobs. Use carbon steel for regular jobs to make work easier.

Good materials might cost more at first. They save money later because you fix and replace parts less often.

Wear parts keep your bucket safe from harm. Using strong wear-resistant materials keeps your bucket working well and stops long breaks.

Think about your worksite’s needs. The right material can help your excavator work better and last longer.

Excavator Bucket Parts Overview

Main Components

When you look at an excavator bucket, you see several important parts. Each part has a job that helps the bucket work well in tough conditions. Here are the main components you will find:

Cutting Edge: This is the bottom edge of the bucket. It touches the ground first and cuts into the material. The cutting edge uses hardened steel to last longer.

Teeth: These attach to the cutting edge. Teeth break up and loosen soil, rocks, or other materials. You can find teeth in different shapes and sizes for different jobs.

Wear Plates: These plates protect the sides of the bucket. They stop the bucket from wearing out too fast. You can replace them when they get thin.

Side Cutters: These sit on the sides of the bucket. They help the bucket cut through tough ground and protect the corners.

You need all these parts to keep your excavator bucket strong and ready for work. Each part faces different forces and wear, so they need special materials.

Material Needs

You want your china excavator bucket parts to last as long as possible. The right materials make a big difference. Each part needs a certain hardness and strength. The table below shows some common materials and where you might use them:

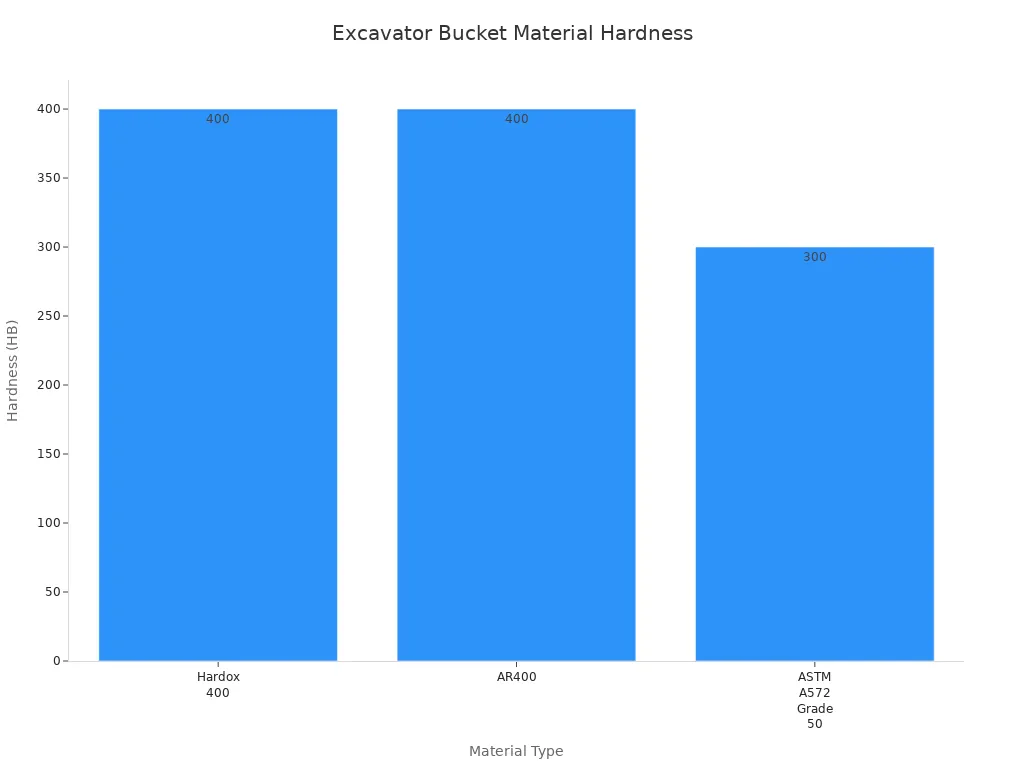

Material Type | Hardness (HB) | Application Area |

|---|---|---|

Hardox 400 | 400 | General construction |

AR400 | 400 | Mining and quarrying |

ASTM A572 Grade 50 | 250-350 | Structural applications |

You should think about what you will dig up. Rocks need tougher parts. Muddy or wet ground may need a different design. The right hardness helps your bucket carry heavy loads without bending. Harder materials mean less downtime and better performance on the job site. When you choose the best materials for each part, your excavator bucket works better and lasts longer.

China Excavator Bucket Parts Materials

Bucket Shell Materials

Excavator bucket shells need to be strong and dependable. Most bucket shells in China use high-strength steels. These steels give a good mix of strength, light weight, and easy welding. The table below lists the main materials and their features:

Material | Properties |

|---|---|

ASTM A572 Grade 50 | High strength, low alloy, lightweight, easy to weld |

AR400 | Abrasion resistant, hardness of 400 HB, excellent wear resistance |

AR500 | Abrasion resistant, hardness of 500 HB, superior wear resistance |

AR400 and AR500 are great at stopping wear. ASTM A572 Grade 50 makes a bucket shell that is lighter but still strong. These materials help buckets do hard jobs without being too heavy. Picking the right shell material helps your bucket work better and need less fixing.

Tip: YNF Machinery makes bucket shells from these strong materials. You get parts that last longer and work well.

Bucket Teeth Materials

Bucket teeth do the hardest work on excavator buckets. You need teeth that can break rocks, dig dirt, and not wear out fast. The most used bucket teeth materials in China are manganese steel and alloy steel. The table below shows why these materials are good:

Material | Properties | Applications |

|---|---|---|

Manganese Steel | Good toughness, work hardening, improved wear resistance under impact loads | Earthmoving, mining, adaptable to various hardness |

Alloy Steel | Enhanced strength, hardness, wear resistance due to alloying elements | Suitable for high hardness, abrasive materials |

Manganese steel is the best pick for bucket teeth. It gets harder as you use it, so it lasts longer. Alloy steel teeth are heat-treated to make them stronger and tougher. This makes them good for digging hard things. Manganese steel teeth are usually 48-52 HRC in hardness and have an impact value over 15 J. These features help bucket teeth last in rough jobs.

YNF Machinery gives you bucket teeth made from strong manganese steel. This keeps your excavator buckets sharp and tough.

Pins and Bushings

Pins and bushings join moving parts in excavator buckets. They must take heavy loads and move all the time. The best materials for these are AISI 4130, AISI 4140, ETD-150, and 45# carbon steel. The table below compares AISI 4130 and AISI 4140:

Property | AISI 4130 | AISI 4140 |

|---|---|---|

Carbon Content | 0.28-0.33 wt.% | 0.38-0.48 wt.% |

Hardness | Lower than 4140 | Higher due to more carbon |

Strength | Good for moderate applications | Superior for high strength |

Weldability | Good | Poor |

Fatigue Resistance | Moderate | Higher due to better strength |

Longevity | Suitable for various uses | Preferred for demanding uses |

AISI 4140 gives better fatigue resistance and lasts longer. ETD-150 and 45# carbon steel are also tough and strong. Makers shape these parts very carefully so they fit well. Some bushings use nitronic steels or Hadfield manganese steel for extra wear resistance.

Note: YNF Machinery has pins and bushings made from these top materials. You get parts that fit right and last longer in your buckets.

Excavator Bucket Wear Parts

Wear parts protect your bucket from getting damaged. These include wear plates, side cutters, and adapters. The main materials for these are high-strength steel, high chromium cast iron, and low carbon alloy steel. The table below shows their features:

Material Type | Properties | Wear Rate Influences |

|---|---|---|

High-strength steel | Hardness, toughness, resistance to abrasion | Type of material being excavated, digging technique, frequency of use in abrasive environments |

Cast iron | Hardness, toughness, resistance to abrasion | Type of material being excavated, digging technique, frequency of use in abrasive environments |

You want wear parts that can handle rocks, sand, and other hard stuff. High chromium cast iron is very hard and resists wear. Low carbon alloy steel is tough and strong. These materials help buckets last longer and stop breakdowns.

YNF Machinery gives you wear parts made from these strong materials. Your bucket gets better protection and you spend less on new parts.

Remember: Picking the right materials for your China excavator bucket parts means your equipment works better and lasts longer. YNF Machinery can help you choose the best parts for your needs.

Why These Materials

Strength and Wear Resistance

You want your excavator bucket to last a long time. The right materials help it stay strong. High-strength steel and wear-resistant alloy steels are very tough. They help your bucket handle rocks, gravel, and hard soil. These materials fight against scratches and damage. They protect the bucket in places that get hit a lot. Using good wear parts keeps the weak spots safe. High chromium cast iron is better at stopping wear than high manganese steel. Q345B is good for easier jobs, like digging clay or loose dirt. Wear-resistant plate steel and high-strength alloy steels keep your bucket strong in hard jobs.

High-strength steel and wear-resistant alloy steels make buckets last longer.

Good wear parts protect the bucket and help it work better.

The type of soil changes what material you should pick.

Tip: Strong materials in your bucket mean less time fixing and more time working.

Cost and Availability

You need to think about price and how well the part works. Carbon steel is cheap and easy to buy. High-strength alloy steels and wear-resistant plate steel cost more. But they last longer, so you do not replace them as much. Good wear parts cost more at first, but you save money later. You can find carbon steel and high-strength steel in many places. This means you get new parts fast when you need them.

Carbon steel is a good choice for price and strength.

High-strength steel and wear-resistant plate steel last longer.

Easy-to-find materials keep your bucket working without waiting.

Task Suitability

Different jobs need different bucket wear parts. You should pick the right material for each job. General-purpose buckets use carbon steel or Q345B for soft dirt. Heavy-duty buckets need high-strength steel or high-strength alloy steels for hard work. Rock buckets use wear-resistant alloy steels and good wear parts for mining and breaking rocks. The table below shows what materials fit each bucket type:

Bucket Type | Material Used | Application Scenario |

|---|---|---|

General-Purpose | Carbon steel, Q345B | Digging, loading, grading in soft soils |

Heavy-Duty | High-strength steel, alloy steels | Digging hard soil, loading crushed rock |

Rock Bucket | Wear-resistant alloy steels, high chromium cast iron | Mining, breaking rocks, extreme abrasion |

You get better strength and work when you pick the right material. Tough materials and good wear parts help your bucket last longer for every job.

Material Comparison for Excavator Buckets

Standard vs. Heavy-Duty

You need to know how standard and heavy-duty buckets are different. Standard buckets use lighter steel and have less extra support. These buckets are good for digging soft dirt or sand. Heavy-duty buckets use thicker steel and more strong parts. They have special things like rock guards to help with hard jobs. These buckets can handle rocks and rough ground better.

Standard buckets have thin steel and less protection.

Heavy-duty buckets have thick steel and more protection.

Heavy-duty buckets have extra strong edges and side guards.

Standard buckets cost less but wear out faster in tough places.

If you dig rocks or work in mines, use a heavy-duty bucket. For easy jobs, a standard bucket saves money and works fine.

Bucket Type | Material Type | Application Suitability |

|---|---|---|

Excavator Rock Buckets | High-strength, wear-resistant steel | Made for hard work and rough ground |

Standard Buckets | Standard-grade steel | Good for soft dirt and light jobs |

Tip: YNF Machinery has both types of buckets. You can pick the best one for your job and get good protection.

Performance Impact

The material you pick changes how your bucket works. Good materials help your bucket last longer and stay strong. The right steel keeps your bucket from breaking when it hits hard things. Wear-resistant parts mean you do not need to change teeth or plates often.

Impact resistance keeps your bucket from breaking.

Wear resistance helps your bucket last longer.

Hard buckets dig well, but tough buckets do not break.

Pick the right material for your job site for better results.

Good parts cost more, but you save money later.

With the right bucket, you finish more work and fix less. Your bucket lasts longer and you do not spend as much on repairs. YNF Machinery can help you choose the best parts for your needs.

You want your excavator bucket to last a long time. Using the right materials helps it last longer. High manganese steel, Q345B, AISI 4130/4140, high chromium cast iron, and low carbon alloy steel all help buckets last longer. Each part uses a special material to work better and last longer. Strong teeth, tough shells, and hard wear plates make buckets last longer. The material you pick changes how long your bucket lasts and how much you fix it. Experts say you should look at quality, price, and custom options to get the longest life. New things like smart sensors and 3D printing also help buckets last longer. YNF Machinery gives you parts that help your bucket last longer and work well.

Pick makers with good quality checks and ISO 9001 certification for longer life.

Think about price and custom choices to fit your job and make buckets last longer.

Look for new materials and smart tools that help buckets last even longer.

Knowing about these materials helps you choose the best bucket and get the longest life.

FAQ

What makes high manganese steel a good choice for bucket teeth?

High manganese steel is a smart pick for bucket teeth. It gets harder as you use it. This means you can dig faster. You do not need to change teeth often. YNF Machinery uses this steel to help you finish jobs quickly.

How does material choice affect excavator bucket efficiency?

The material you pick changes how well your bucket works. Strong materials last longer. You fix your bucket less often. You can dig more in less time. YNF Machinery picks materials that help you work better on every project.

Why should you pick YNF Machinery for excavator bucket parts?

YNF Machinery uses top materials for their parts. You dig faster and stop less for repairs. Their products help you finish jobs quickly. You get better results with every job.

Can better pins and bushings improve efficiency?

Good pins and bushings help your bucket move smoothly. You use less energy when digging. Your bucket works better and faster. YNF Machinery gives you strong pins and bushings for top performance.

How do wear parts impact your excavator’s efficiency?

Wear parts keep your bucket safe from damage. You do not stop often to fix things. This helps you work faster. YNF Machinery gives you wear parts that keep your bucket working well on every site.