A back up ring helps you keep a seal strong and reliable in your equipment. You place the back up ring next to the seal, and it supports the seal so it does not get pushed out by high pressure. This ring stops gaps from forming, which means you get better leak protection. When you use a back up ring, you help your sealing system last longer and work safely.

Key Takeaways

Back up rings help o-rings stay in place. They stop o-rings from getting pushed out or broken when pressure is high. This helps stop leaks and makes seals last longer.

There are three main kinds of back up rings. These are solid, split, and spiral types. Each type gives different protection. Some are easier to put in than others. They work for different machines.

Back up rings are often made from PTFE or PEEK. PTFE does not react with many chemicals and slides easily. PEEK can handle very high pressure and heat. It is good for hard jobs.

You must pick the right back up ring for your system. Think about pressure, temperature, chemicals, and groove size. This helps the ring fit well and seal right.

Using back up rings the right way helps your equipment work longer. It lowers repair costs and stops seals from breaking. This works for both still and moving systems.

Back Up Ring Basics

What Is a Back Up Ring

A back up ring is a tough, ring-shaped part that you place next to an o-ring or other seal inside a groove. You use it to support the o-ring and keep it from getting squeezed into small gaps when your system faces high pressure. The back up ring fits tightly in the seal housing and acts as a barrier. This stops the softer o-ring from being pushed out or damaged. Most back-up rings are made from strong materials like PTFE, PEEK, or hard rubber. These materials resist deformation and can handle tough conditions. You often see back-up rings in hydraulic and pneumatic systems where pressure can get very high.

Tip: If you want your o-rings to last longer and prevent leaks, always consider adding a backup ring in high-pressure setups.

How Back Up Rings Work

When you use a backup ring, you give your o-ring extra support. The backup ring sits right behind the o-ring in the groove. This setup closes the extrusion gap, which is the small space where the o-ring could get forced out under pressure. The backup ring acts as a physical wall. It keeps the o-ring from stretching or tearing when the pressure rises.

Back-up rings prevent extrusion by fitting tightly in the groove and supporting the o-ring.

They use harder, extrusion-resistant materials to stop the o-ring from being pushed into gaps.

The backup ring can go on one or both sides of the o-ring, depending on where the pressure comes from.

You can choose from solid, split, or spiral back-up rings to match your system’s needs.

Backup rings also help in both static and moving (dynamic) systems. In static systems, the parts do not move, but pressure can still cause problems. In dynamic systems, like moving pistons, the backup ring keeps the o-ring safe from damage caused by movement and pressure changes. This layered approach protects the o-ring from tearing, cutting, or deforming. You keep your sealing system strong and reliable.

Why Use Back Up Rings

You use back up rings for several important reasons:

Back-up rings reduce the extrusion gap between metal parts in cylinders, stopping o-ring extrusion and damage at high pressures.

They let softer o-rings work well under high pressure by giving them strong support.

Back-up rings protect o-rings from damage caused by metal-to-metal contact in moving parts.

The design and material of the backup ring, such as flat or concave shapes and materials like PTFE or Nitrile, affect how well it resists extrusion and how easy it is to install.

For example, if you use a 70A durometer o-ring and your system pressure goes over 1,500 PSI, you need a backup ring to prevent extrusion.

Backup rings play a key role in preventing leaks and reducing leakage. Without a backup ring, o-rings can fail quickly in high-pressure or high-temperature environments. Tests show that seals without backup rings have higher failure rates because of extrusion and wear. When you add a backup ring, you improve the life and reliability of your sealing system. This means less downtime and lower maintenance costs for your equipment.

Back-Up Ring Types

When you pick back-up rings, you should know the types. There are solid, split, and spiral back-up rings. Each type has a special design and way to install it. The right back-up ring keeps your o-rings safe. It also helps your equipment work well.

Solid Back Up Rings

Solid back-up rings are one piece with no cuts. They give the best protection from extrusion. These rings work in high pressure and heat. You see them in hydraulic manifolds and static seals. Solid back-up rings can handle up to 20,000 psi. They also work at temperatures up to 575°F. This is true when made from PTFE or PEEK. They give o-rings strong support and last a long time.

Note: Solid back-up rings are hard to put in small spaces. You cannot bend or stretch them much.

Here is a table that compares solid back-up rings to other types:

Backup Ring Type | Material | Max Working Pressure | Installation Groove Type | Application Notes |

|---|---|---|---|---|

Solid Backup Ring | PTFE | Up to 70 MPa | Split installation groove | Best performance, highest pressure rating |

Split Back Up Rings

Split back-up rings have a cut at an angle. This makes them easier to put in place. You can fit them in grooves without stretching o-rings. You do not need to take apart your equipment. This saves time when you do repairs. Split back-up rings are good when you need fast replacement. They are also good if you cannot reach the parts easily.

Split back-up rings do not stop extrusion as well as solid rings. The split can open and close when under pressure. This may let the o-ring get pinched or hurt. Use split back-up rings when easy installation is more important than strength.

Feature/Aspect | Solid Back-Up Rings | Split Back-Up Rings |

|---|---|---|

Construction | Single, continuous ring | Ring with a precision diagonal cut (split) |

Extrusion Resistance | Superior extrusion resistance and durability | Slightly less extrusion protection |

Installation | Harder to install in tight or restricted spaces | Easier to install without stretching or manipulating o-rings |

Maintenance & Repair | More challenging due to continuous design | Beneficial for maintenance in limited access or tight spaces |

Spiral Back Up Rings

Spiral back-up rings look like a coil or spring. You can put them in without taking things apart. This is helpful for repairs in small spaces. Spiral back-up rings stop o-ring extrusion in both still and moving parts. They work well in high pressure and tough places. You see them in aerospace and oil and gas equipment.

Spiral back-up rings fit around parts easily.

They keep o-rings from being pushed out by pressure.

PTFE spiral rings give chemical resistance and low friction.

Their shape stops overstretching when you install them.

Tip: Pick spiral back-up rings for fast installation and strong protection in hard conditions.

Backup Ring Materials

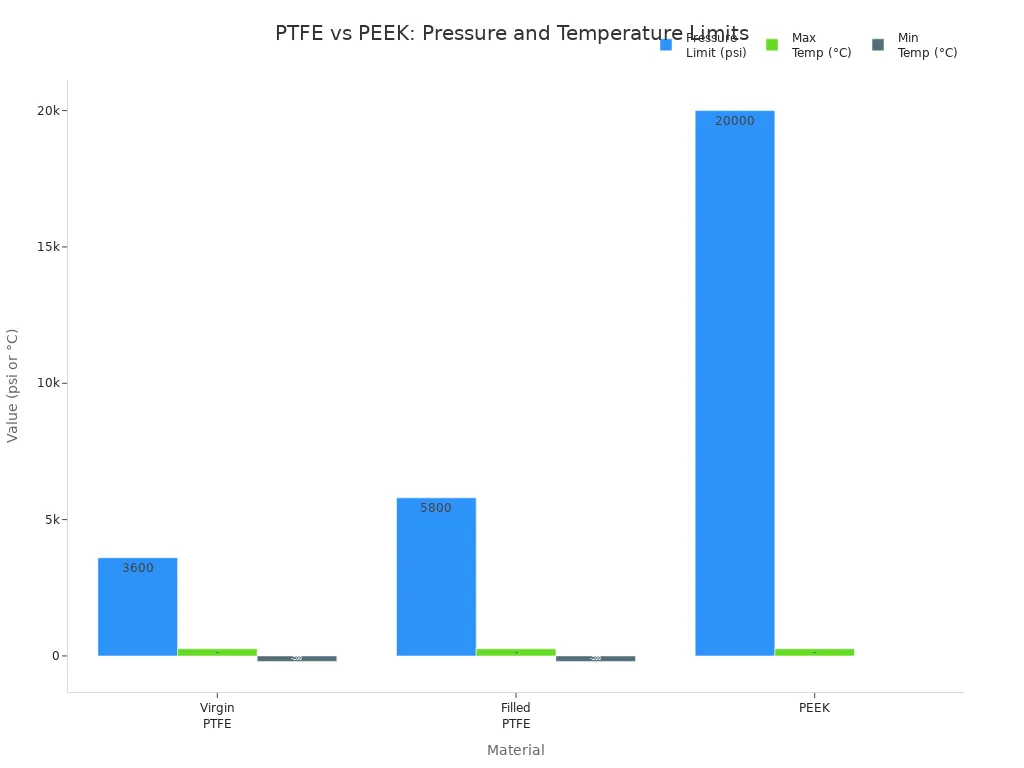

PTFE and PEEK

When you pick backup ring materials, PTFE and PEEK are very common. PTFE is also called Teflon. It stands out because it resists chemicals and has low friction. This means backup rings made from PTFE can handle strong chemicals. They also move smoothly in systems with moving parts. PTFE works well in heat up to 575°F. It can also handle pressure up to 5,800 psi if it has glass or carbon inside. Virgin PTFE is good for lower pressure. Filled PTFE is better for higher loads. PTFE is softer than some other materials. It can change shape under heavy pressure. So, PTFE is best for backup rings that do not face the toughest jobs.

PEEK is much stronger and stiffer than PTFE. You can use PEEK backup rings in very hard jobs. For example, they work in oil and gas drilling. These places have pressure up to 20,000 psi and heat up to 500°F. PEEK does not wear out fast. It keeps its shape even when things get tough. This makes PEEK great for high pressure, high heat, and jobs that last a long time. PEEK costs more than PTFE. But it lasts longer and protects seals better in hard places.

Here is a quick comparison:

Material | Pressure Limit (psi) | Temperature Limit (°F) | Key Features |

|---|---|---|---|

PTFE | 3,600 (virgin), 5,800 (filled) | 575 | Low friction, chemical resistance |

PEEK | 20,000 | 500 | High strength, wear and creep resistance |

Tip: Pick PTFE if you need chemical resistance and low friction. Choose PEEK if you need backup rings for high pressure, high heat, and long-lasting use.

Other Common Materials

There are many other materials for backup rings. Each one has its own strengths. Nylon 6,6 is strong and holds its shape well. But it soaks up water, so do not use it where things get wet. Polyurethane is very strong and does not wear down fast. It is good for moving parts that need to last. FFKM and FKM (Viton) are great at handling chemicals and heat. FFKM can take heat up to 600°F. Silicone, EPDM, and Neoprene are good for special jobs. For example, they work in food, medical, or steam systems.

Here is a table to help you compare:

Material | Mechanical Properties | Temperature Limit | Chemical Resistance | Typical Use Cases |

|---|---|---|---|---|

Nylon 6,6 | Good strength, thermal stability | 186°F | Sensitive to moisture | Automotive, industrial |

Polyurethane | High strength, abrasion resistance | Moderate | Not for acids/ketones | Dynamic seals, hydraulic systems |

FFKM | Highest chemical resistance | 600°F | Excellent | Corrosive, high-temp environments |

FKM (Viton) | Good chemical and temp resistance | 430°F | Not for steam/ketones | Oil, gas, chemical processing |

Silicone | Flexible, UV resistant | High | Limited chemical resistance | Food, medical, static seals |

PTFE | Low friction, chemical resistance | 575°F | Outstanding | Harsh chemicals, high temp |

PEEK | High strength, wear resistance | 500°F | Excellent | Oil & gas, aerospace, severe service |

You can also find backup rings made from new materials like PEK, Arlon 3000XT, and glass-filled PTFE. These choices work even better in very hard jobs. For example, they are used in aerospace or high-voltage systems.

Note: Always pick your backup ring material based on the chemicals, heat, and pressure in your system. The right material keeps your seals safe and helps your equipment last longer.

Choosing Backup O-Rings

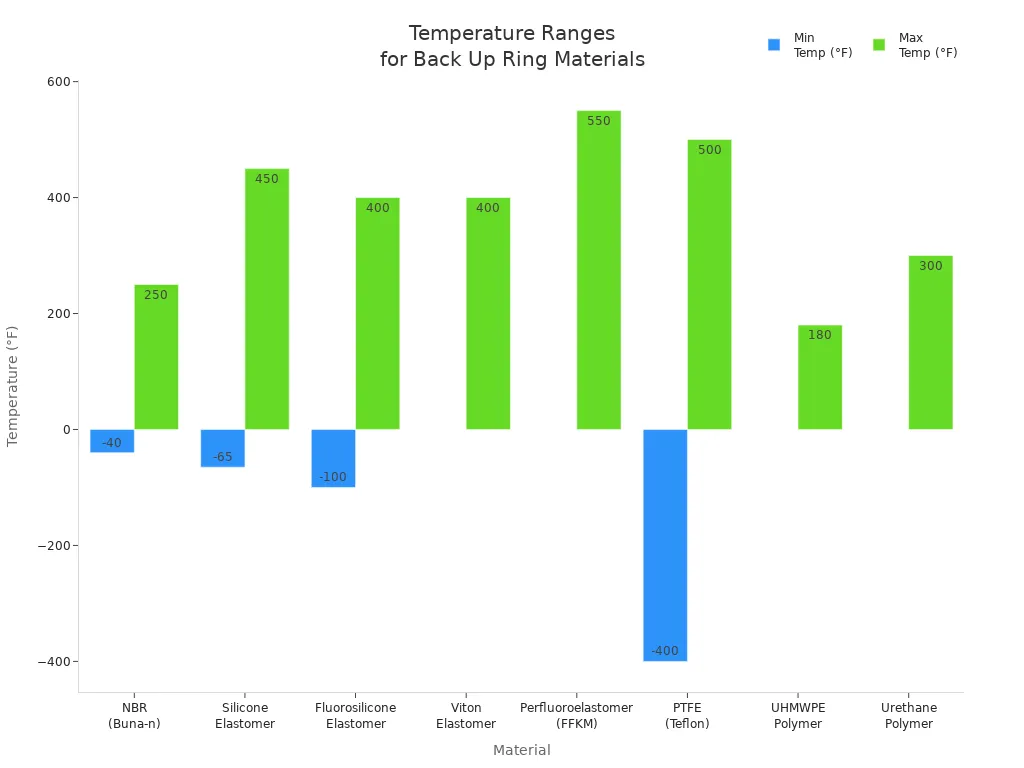

Pressure and Temperature

When you choose backup o-rings, you need to think about the pressure and temperature in your system. High pressure can push o-rings into small gaps. This causes damage and leaks. You can stop this by using back-up rings. These rings act as a barrier and keep the o-ring safe. If your system pressure goes above 1,500 psi, you should always use back-up rings. You also need to check the hardness of your o-ring. Softer o-rings need more support at lower pressures.

Temperature is just as important. Some materials work better in heat or cold. For example, PTFE back-up rings can handle temperatures from -400°F to 500°F. Silicone o-rings work up to 450°F, while Viton o-rings can go up to 400°F. If you use the wrong material, your seal may fail. Always match the material to your system’s temperature range.

Material | Temperature Range (°F) | Notes on Seal Integrity and Application |

|---|---|---|

NBR (Buna-n rubber) | -40 to 250 (up to 300 special) | Good for static seals; check chemical compatibility |

Silicone Elastomer | -65 to 450 (up to 500 special) | Not for hydrocarbon fluids |

Viton Elastomer | Up to 400 | Handles acids, fuels, oils |

PTFE (Teflon) Polymer | -400 to 500 | May get rigid at extremes |

Perfluoroelastomer (FFKM) | Up to 550 (650 special) | Best for high temp and chemicals |

Tip: Always check both pressure and temperature limits before you pick your backup o-rings. This helps you avoid leaks and seal failures.

Compatibility and Sizing

You must also make sure your backup o-rings match the fluids and chemicals in your system. Some materials resist chemicals better than others. PTFE and PEEK are popular for their chemical resistance and temperature strength. In food, medical, or oil and gas industries, you may need special grades that meet strict standards. Always check if your back-up rings can handle the chemicals they will touch.

Sizing is another key step. Backup o-rings need to fit tightly with your o-rings. The groove or gland must be wide enough to hold both the o-ring and the back-up rings. If you use two back-up rings, place one on each side of the o-ring for the best protection. Many industries use standards like MS28774 or AN6244 to guide sizing. These standards help you pick the right size and shape for your application.

Here is a quick checklist for choosing backup o-rings:

Check your system’s pressure and temperature.

Pick materials that resist your fluids and chemicals.

Use industry sizing standards for a proper fit.

Make sure the groove is wide enough for both o-ring and back-up rings.

Use two back-up rings for pressure from both sides.

Note: Always test your seals in real conditions. Lab tests do not always show how seals will work in your equipment.

Backup rings help in high-pressure systems. They stop O-ring extrusion. This keeps your equipment safe. Picking the right type and material is important. It makes your sealing system work better. Here is a simple chart showing how materials help reliability:

Material | Key Properties | Reliability Benefit |

|---|---|---|

PTFE | Low friction, chemical resistance | Less wear, lasts longer |

PEEK | High strength, stable in heat | Handles hard jobs, keeps shape |

Before picking, check your pressure, temperature, and chemicals. If your setup is tricky, ask an expert for help.

FAQ

What is the main job of a back up ring?

A back up ring keeps your o-ring from getting squeezed into gaps. It supports the o-ring so it does not break or leak, even when pressure gets high.

Can you reuse a back up ring?

You should not reuse a back up ring. Once you remove it, the ring may not fit right again. Always use a new one for the best seal and safety.

How do you know which back up ring to pick?

Check your system’s pressure, temperature, and chemicals. Choose a material that matches these needs. Make sure the size fits your groove and o-ring. If you feel unsure, ask an expert.

Do you need a back up ring on both sides of the o-ring?

You need a back up ring on both sides if pressure comes from both directions. If pressure comes from one side, use a back up ring only on that side.

What happens if you skip using a back up ring?

Skipping a back up ring can cause your o-ring to fail. You may see leaks, damage, or even system breakdowns. Using a back up ring helps your equipment last longer and work better.