You want your excavator to deliver top performance with less downtime. You know that choosing aftermarket excavator parts for sale helps you save money, but you need to trust the quality and reliability. Every excavator runs best when you select parts that match your model and meet strict quality standards. Reliable suppliers reduce downtime and give you peace of mind. When you pay attention to compatibility and reliability, you protect your excavator from unexpected downtime and costly repairs.

Key Takeaways

Choose aftermarket excavator parts that match your machine’s model and meet quality standards to avoid costly downtime and repairs.

Buy from reliable suppliers who provide clear product info, warranties, and technical support to ensure part compatibility and durability.

Regularly inspect and maintain key components like undercarriage, boom, arm, and hydraulic systems to extend your excavator’s life and performance.

Use diagrams and schematics to confirm part fit and avoid mistakes when selecting aftermarket parts for major brands like Caterpillar, Komatsu, and Hitachi.

Balance cost savings with quality by prioritizing high-quality parts and following maintenance schedules to reduce breakdowns and improve safety.

Aftermarket Excavator Parts Overview

What Are Aftermarket Excavator Parts?

You can find many aftermarket excavator parts for sale that fit different brands and models. Aftermarket parts are made by companies other than the original equipment manufacturer (OEM). These parts help you keep your excavator running without always paying the higher price for OEM parts. Many aftermarket excavator parts for sale include items like filters, tracks, buckets, and other excavator accessories. You can use aftermarket replacement parts to repair or upgrade your machine. These parts often match the size and function of OEM parts, but you need to check for compatibility with your specific excavator.

Benefits and Drawbacks

You get several benefits when you choose aftermarket parts for your excavator.

Aftermarket excavator parts for sale usually cost less than OEM parts.

You have a wider selection and can often find parts faster.

Some aftermarket parts offer more customization for your excavator accessories.

However, you should know the drawbacks:

Quality can vary between manufacturers.

Some aftermarket parts may not fit as well as OEM parts.

Limited warranty coverage is common.

Using aftermarket parts might lower your excavator’s resale value.

Tip: Always buy from reputable suppliers and ask for professional installation. Routine inspection and maintenance help you spot leaks, low fluids, or unusual noises before they cause bigger problems.

Common Spare Parts for Excavators

You need to keep essential spare parts on hand to reduce downtime. The most common spare parts for excavators include:

Hydraulic filters

Track rollers

Buckets

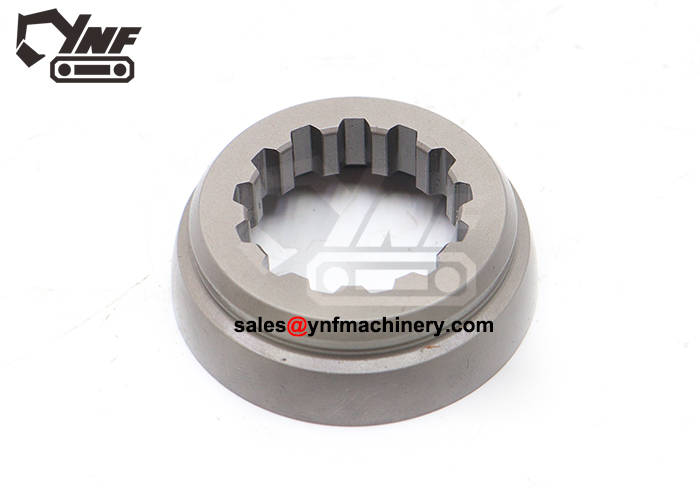

Sprockets

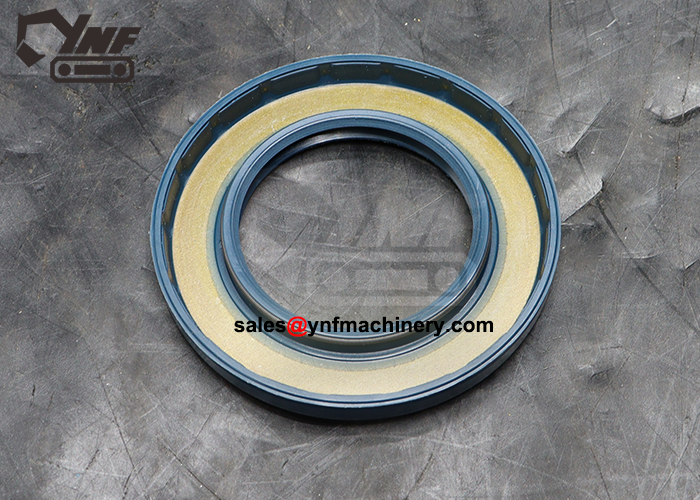

Seals and gaskets

Pins and bushings

Engine components

Electrical excavator accessories

A table can help you see which essential spare parts match different excavator types and their spare parts needs:

Excavator Accessories | Common Spare Parts for Excavators |

|---|---|

Hydraulic System | Filters, seals, hoses |

Undercarriage | Track rollers, sprockets |

Boom and Arm | Pins, bushings |

Engine | Filters, gaskets |

You should always check the quality of aftermarket parts before buying. High-quality aftermarket excavator parts for sale help your machine last longer and work better.

Key Excavator Components

Undercarriage Parts

You depend on the undercarriage to support your excavator and keep it moving. The undercarriage includes tracks, rollers, sprockets, and idlers. These parts carry the weight of your machine and face constant wear. If you want to extend the durability of your excavator, you must inspect the undercarriage often. Tracks and undercarriage parts need regular cleaning and tension checks. Field surveys show that almost 40% of crawler system failures happen because of skipped tensioning and poor daily care. You should adjust track tension weekly and check reducer oil every 100 hours. When you use high-quality components for your undercarriage, you reduce breakdowns and keep your excavator running longer.

Tip: Always keep essential spare parts for excavators like track rollers and sprockets in your shop. This helps you avoid long delays when repairs are needed.

Boom and Arm Parts

The boom and arm give your excavator its reach and digging power. These parts handle heavy loads and constant movement. Maintenance records show that you should inspect boom, arm, and bucket cylinders every 250 hours. Lubricate all pivot points and service pins every 50 hours. By tracking wear patterns in your logs, you can spot problems early and replace worn excavator parts before they fail. Using high-quality components for the boom and arm increases durability and keeps your excavator safe and strong. Good bucket and breaker selection also helps you match the right tool to the job, reducing stress on these parts.

Hydraulic and Track System Parts

Hydraulic system components power your excavator’s movement and attachments. You need to clean filters and refill hydraulic oil every 250 hours. Tracks and undercarriage parts, such as track plates, need replacement every 500 hours if they show severe wear. Common causes of failure include oil seal leaks, blocked oil circuits, and worn tracks. A technical guide explains that engine and hydraulic systems cause nearly 80% of excavator failures. You can lower this risk by using high-quality components and following the manufacturer’s manual. Keep detailed records and always choose essential spare parts that match your model for the best durability and performance.

Inspection Item | Frequency | Maintenance Action |

|---|---|---|

Track tensioning | Weekly | Adjust tension (re-inject or release grease) |

Reducer lubricating oil | Every 100 hours | Check and change oil |

Hydraulic system | Every 250 hours | Clean filter and replenish hydraulic oil |

Track plate | Every 500 hours | Replace severely worn parts |

Major Brands and Compatibility

Choosing the right aftermarket parts for your excavator depends on the brand and model you own. Each brand has unique features, so you need to pay close attention to compatibility and quality. Using diagrams and schematics helps you match the correct excavator accessories and replacement parts to your machine. Below, you will find key information for each major excavator parts brand selection.

Caterpillar Excavator Parts

Caterpillar stands out as a leading brand in the excavator industry. You often look for aftermarket parts like undercarriage components, track parts, and work tool attachments. These parts offer cost savings and quality that can match OEM standards. Caterpillar organizes its excavators into mini, small, medium, and large categories. You should always check your model’s specifications before buying aftermarket replacement parts. This ensures the parts fit and perform well. Many aftermarket manufacturers offer warranty options, giving you extra peace of mind. Regular inspections, cleaning, and correct track tension help you get the most from your excavator accessories. Always use the official parts reference guides or diagrams to confirm compatibility.

Komatsu Excavator Parts

Komatsu is another popular brand for excavators. You can find many aftermarket parts for Komatsu machines, including reinforced booms, arms, and track frames. Factory-made upgrade kits let you add new features, such as iMC 3.0 machine control. These kits help you keep your excavator up to date and compatible with modern technology. Komatsu’s heavy-duty components increase durability and reliability. You benefit from longer service intervals, such as engine oil changes every 1,000 hours and hydraulic filter changes every 3,000 hours. The Komatsu Care program supports you with genuine parts and long-term maintenance. When you choose aftermarket excavator parts for Komatsu, always match the part to your model and check for compatibility with advanced safety systems.

Hitachi Excavator Parts

Hitachi excavators are known for their strong hydraulic systems and efficient designs. You can find aftermarket parts for Hitachi, such as hydraulic pumps, filters, and track rollers. Always check the part number and compare it with your machine’s manual. Hitachi often updates its models, so you need to use diagrams and schematics to avoid mistakes. Many aftermarket suppliers offer high-quality excavator parts that meet or exceed OEM standards. You should inspect seals, hoses, and electrical excavator accessories regularly to prevent leaks and downtime.

Volvo Excavator Parts

Volvo is a trusted brand for reliability and safety. You can buy aftermarket parts like buckets, pins, bushings, and hydraulic components for Volvo excavators. Always check the compatibility of each part with your specific model. Volvo uses advanced technology in its machines, so you need to match the electronics and sensors carefully. Use the official diagrams to guide your excavator parts brand selection. Regular maintenance and using high-quality aftermarket parts help you keep your Volvo excavator running smoothly.

John Deere Excavator Parts

John Deere offers a wide range of excavators for different jobs. You can choose between OEM and aftermarket parts for your John Deere machine. OEM parts cost more but offer higher quality, reliability, and better fit. They also come with warranties and help maintain your equipment’s resale value. Aftermarket parts are more affordable and work well for older excavators or when OEM parts are hard to find. However, some aftermarket parts may need adjustments and might not last as long. Poorly fitted parts can reduce your excavator’s lifespan and safety. Always weigh the cost savings against the possible risks. Use diagrams and schematics to make sure you select the right excavator accessories and replacement parts.

Note: Using aftermarket parts on John Deere excavators may void your warranty. Always check your warranty status before making a purchase.

Kobelco Excavator Parts

Kobelco excavators are popular for their fuel efficiency and smooth operation. You can find many aftermarket parts, such as hydraulic cylinders, filters, and undercarriage components. Always match the part number and check the compatibility with your model. Kobelco often updates its technology, so you should use diagrams and schematics to avoid errors. Regular maintenance and using high-quality aftermarket parts help you get the best performance from your Kobelco excavator.

Doosan Excavator Parts

Doosan is a growing brand in the excavator market. You can buy aftermarket parts like track chains, sprockets, and engine filters for Doosan machines. Always check the compatibility of each part with your excavator’s model and year. Doosan uses advanced hydraulic systems, so you need to match the parts carefully. Use diagrams and official guides to help with your excavator parts brand selection. Routine inspections and timely replacement of worn excavator accessories keep your Doosan excavator in top shape.

Case Excavator Parts

Case excavators are known for their rugged design and easy maintenance. You can find aftermarket parts such as pins, bushings, hydraulic pumps, and track rollers. Always check the part number and compare it with your Case model. Case machines often share parts across different models, but you should still use diagrams to confirm compatibility. Regular maintenance and using high-quality aftermarket parts help you extend the life of your Case excavator.

Other High-Quality Excavator Parts Brands

Many other brands offer reliable excavator accessories and aftermarket parts. Brands like Hyundai, JCB, and SANY provide a wide range of options for different excavator models. Always check the compatibility of each part with your machine. Use diagrams, schematics, and official guides to avoid mistakes. Choosing high-quality excavator parts from trusted brands helps you reduce downtime and improve performance.

Tip: Always use diagrams and schematics when selecting aftermarket parts. This helps you avoid costly errors and ensures the best fit for your excavator.

How to Choose Aftermarket Excavator Parts for Sale

Ensuring Compatibility

You need to make sure every aftermarket excavator part fits your machine. Start by checking your excavator’s model number and year. Look at the part number on your old component. Compare it with the new aftermarket part. Use diagrams and schematics to match the size and shape. If you skip this step, you risk buying parts that do not fit or work well. Some aftermarket excavator parts for sale may look similar but have small differences. Always ask your supplier for detailed specifications. This helps you avoid costly mistakes and keeps your excavator running smoothly.

Evaluating Supplier Reliability

You want to buy from suppliers who value quality and reliability. Reliable suppliers provide clear product information and answer your questions quickly. They offer support if you have problems with your aftermarket parts. Look for suppliers with good reviews and a strong reputation. Ask if they test their aftermarket excavator parts for sale before shipping. Reliable suppliers often provide tracking numbers and fast delivery. You can also check if they offer a return policy. This shows they stand behind the quality of their excavator parts. A trustworthy supplier helps you avoid delays and keeps your excavator working.

Tip: Choose suppliers who offer technical support and have experience with your excavator brand. This increases your chances of getting the right replacement parts.

Cost vs. Quality Considerations

You may want to save money, but you should never ignore quality. Aftermarket parts usually cost less than OEM parts. However, the quality of aftermarket excavator parts can vary a lot. Some aftermarket parts use lower-quality materials or less precise manufacturing. This can lead to faster wear and more breakdowns. A market analysis shows that genuine OEM parts cost more because they use better materials and strict quality checks. They also come with warranties, which support long-term use. Aftermarket parts may not include a warranty or may have limited coverage. This increases your risk of equipment failure and safety issues. For example, counterfeit fuel injectors caused engine failures in several excavators. You must balance the lower price of aftermarket excavator parts for sale with the need for reliability and safety. Always consider the importance of warranty coverage when making your choice.

Factor | Genuine OEM Parts | Aftermarket Parts |

|---|---|---|

Price | Higher | Lower, but varies |

Quality | High, reliable, durable | Variable; sometimes lower |

Warranty | Usually included | Often limited or none |

Reliability | High | Can be lower |

Compatibility | Exact fit | May have issues |

Practical Tips for Buying and Maintaining Excavator Parts

Pre-Purchase Checklist

Before you buy any excavator part, you should follow a clear checklist. This helps you avoid mistakes and keeps your machine running well. Many heavy equipment inspection apps now offer digital checklists. These tools let you check every part, report problems, and store records for future use. Here is a simple checklist you can use before buying:

Check all lights, including headlights and warning lights.

Inspect steps, handrails, and grab irons for safety.

Look at the undercarriage for rust or damage.

Test brakes, fluid levels, and parking brake.

Examine electrical lines for damage.

Check hydraulic lines for leaks and oil condition.

Inspect the fuel tank and cap.

Look at lift arms for rust or leaks.

Inspect the body for damage.

Check grease lines and look for leaks.

Inspect coolant and fuel lines.

Examine work tools for wear.

For tracked excavators, check rollers, sprockets, and tracks. For wheeled machines, inspect tires and axles. Always finish by checking the engine compartment. Using this checklist helps you reduce downtime and improve reliability.

Installation and Maintenance Tips

Proper installation of aftermarket parts is key to quality and durability. Always follow the manufacturer’s instructions. Use high-quality components to make sure each part fits well and lasts longer. After installation, test the excavator for performance and durability. Regular maintenance keeps your machine safe and strong. Here is a table of important checks:

Maintenance Area | Key Tasks and Checks |

|---|---|

Hydraulic System | Inspect oil, check for leaks, examine hoses and seals |

Boom and Arm | Check for cracks or damage in welds and joints |

Undercarriage | Examine tracks, rollers, sprockets, moving parts |

Engine | Change oil, replace filters, check coolant |

Electrical System | Test battery, lights, and control panel |

You should schedule preventive maintenance based on machine hours, not just fixed dates. Real-time monitoring and automated diagnostics help you spot problems early. This approach can cut downtime by 50% and reduce repair costs.

Tip: Assign clear roles for maintenance and keep a detailed inventory of spare parts. This helps you reduce downtime and improve reliability.

Maximizing Performance with High-Quality Excavator Parts

You can boost excavator performance by choosing high-quality excavator parts. These parts offer better quality, reliability, and durability. Studies show that high-quality components increase wear resistance by up to 25% and extend service life by 30%. Precision manufacturing also improves working efficiency and lowers fuel use. When you use high-quality excavator parts, you reduce downtime and save money on repairs. Preventive maintenance and regular inspections help you catch issues before they cause failures. Always buy from reputable suppliers who test their parts for performance and durability. This ensures your excavator works at its best and lasts longer.

Note: Set clear goals for your maintenance program, such as reducing downtime and repair costs. Use digital tools to track performance and schedule tasks.

You can reduce downtime by choosing the right aftermarket parts and checking compatibility before you buy. Research suppliers to avoid downtime from poor-quality parts. Use the checklists in this guide to prevent downtime and keep your machine running. Regular maintenance helps you spot issues early and avoid downtime. Consult diagrams and schematics to make sure you select the correct part and avoid unnecessary downtime.

FAQ

What are aftermarket parts?

Aftermarket parts come from companies other than the original manufacturer. You can use them to replace worn or broken parts. Many people choose them because they often cost less and are easy to find.

How do I know if a part will fit my machine?

You should check your machine’s model number and the part number. Compare these with the new part. Use diagrams or ask your supplier for help. This step helps you avoid buying the wrong part.

Are aftermarket parts as good as original parts?

Some aftermarket parts match the quality of original parts. Others may not last as long. You should buy from trusted suppliers and check reviews. Always look for warranty information before you decide.

Will using aftermarket parts affect my warranty?

Using aftermarket parts can sometimes void your warranty. You need to read your warranty terms or ask your dealer. Always check before you install any new part.

How often should I replace key parts?

You should follow the maintenance schedule in your manual. Replace filters, hoses, and other wear parts as recommended. Regular checks help you spot problems early and keep your machine running well.