Modern excavators rely heavily on various excavator electric parts. These essential components include the electronic control unit (ECU), sensors, wiring harnesses, electric motors, alternators, batteries, relays, fuses, and display panels. All these excavator electric parts work in unison to control and power the main functions of an excavator. They also support advanced excavator attachments. A reliable electric system helps operators avoid costly downtime and ensures the excavator’s main parts operate smoothly. Reliability analysis models, such as those used for the Komatsu PC-1250, demonstrate that durable excavator electric parts lead to improved excavator performance and fewer unexpected failures.

Key Takeaways

Modern excavators have important electric parts. These include the ECU, sensors, wiring harnesses, batteries, and motors. These parts help the machine work well and stay safe. The ECU is like the brain of the machine. It controls the excavator by using data from sensors. It changes engine and hydraulic actions to fit the job. Electric motors and batteries help save fuel and make less noise. They also help the excavator do hard work with less pollution. It is important to check display panels, wiring, batteries, relays, and fuses often. This stops problems and keeps the excavator working well. New electric systems make the machine safer and more productive. They also help save money by connecting parts and using smart technology.

Excavator Electric Parts

Electronic Control Unit (ECU)

The Electronic Control Unit, or ECU, is like the excavator’s brain. It controls and manages many other electric parts. The ECU gets signals from sensors. Then, it sends commands to systems like the engine and hydraulic pumps. This helps the excavator work well and smoothly. For example, D-ECOPOWER uses the ECU to change hydraulic flow. This saves fuel and helps the machine do more work. The ECU also helps lower emissions by matching power to the job.

Sensors

Sensors gather important data from different parts of the excavator. They measure things like temperature, pressure, speed, and position. The ECU uses this data to make quick decisions. If a sensor finds the engine is too hot, the ECU can cool it down. Sensors help keep the excavator safe and stop damage. They also help with features like automatic grade control and fuel management.

Wiring Harnesses

Wiring harnesses link all the electrical parts in the excavator. These bundles of wires carry power and signals between the ECU, sensors, motors, and other parts. A strong wiring harness makes sure every electric part talks to each other. Good wiring also keeps out water, dust, and shaking, which are common on job sites.

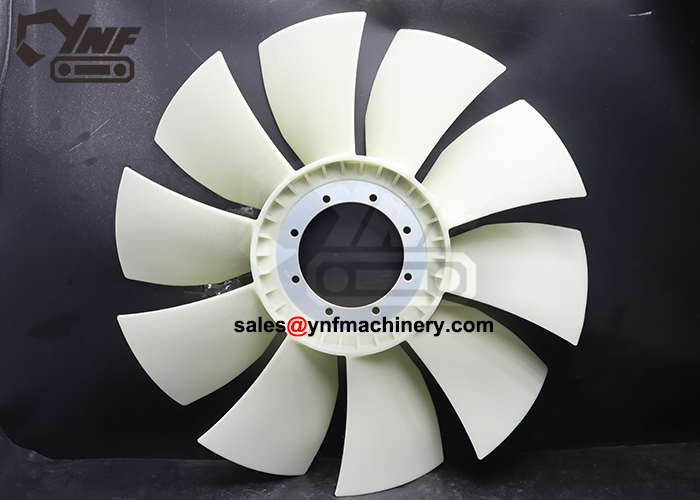

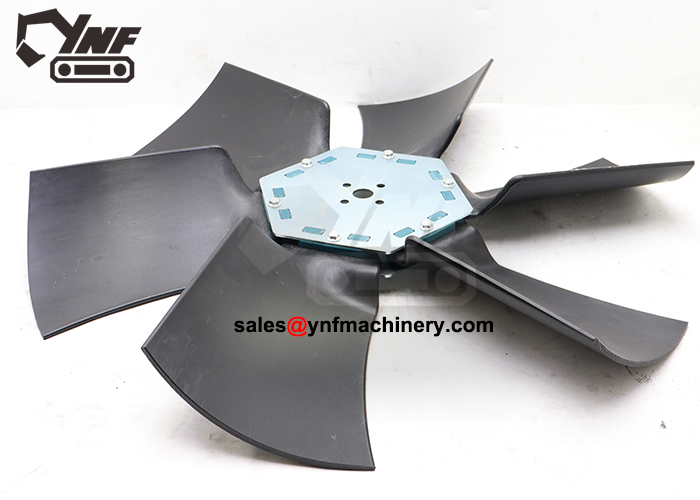

Electric Motor

The electric motor gives power for many jobs in modern excavators. Some machines use electric motors to run the main hydraulic pumps. Others use them for attachments or extra systems. Electric motors give a lot of power and react fast to the ECU. Studies show electric motors can match or beat diesel engines. For example, electric excavators can reach 215 kW of power, while diesel ones reach 135 kW. This means electric motors help the excavator do tough jobs with less energy and less noise.

Alternator

The alternator makes electricity when the excavator is running. It changes engine power into electrical power. This power charges the batteries and gives energy to other electric parts. The alternator keeps the system steady and makes sure lights, sensors, and controls always have power.

Batteries

Batteries store energy for the excavator. They give power when the engine is off or when more energy is needed. Many excavators use lithium iron phosphate batteries. These last longer and work well in hard conditions. Some new models, like the CASE CX210ZQ, use battery systems that can be swapped quickly. Batteries are important in electric and hybrid excavators. They help with main jobs and backup power. But batteries need charging and care to last long and work well.

Relays and Fuses

Relays and fuses keep the excavator’s electrical system safe. Relays work like switches, turning circuits on or off. Fuses break the circuit if too much current flows. This stops damage to important parts. These small parts help stop fires and expensive repairs. They also make it easier to find problems.

Display Panels

Display panels show key information to the operator. These screens show engine status, fuel levels, error codes, and sensor data. Some panels have touch controls for special features. Clear display panels help operators make fast choices and keep the excavator safe. They also help with new tech, like remote monitoring and self-driving features.

Tip: Always check display panels for warning lights or error messages. Acting fast can stop bigger problems and keep the excavator working well.

Recent data shows the good points of advanced excavator electric parts. For example, hybrid systems with electric motors and energy management can cut energy use by over 9%. They can also boost energy regeneration by more than 10%. Electric excavators cost less to run and are quieter. This makes work more efficient and the site nicer. Battery replacement costs are still high, but the savings and cleaner environment make electric systems a smart pick for many jobs.

Key Electric Part | Electric Equipment Performance | Diesel Equipment Performance | Efficiency and Durability Implication |

|---|---|---|---|

Electric Motor | 215 kW output power | 135 kW output power | Higher efficiency for heavy tasks |

Battery | 6 hours endurance | 20 hours endurance | Needs charging strategy |

Energy Cost | 49.58 CNY/h | 160 CNY/h | Lower operational cost |

Emissions | Zero emissions | Diesel exhaust | Cleaner and healthier environment |

Noise | 20-30 dB lower | Higher noise | Less stress on equipment and workers |

These facts show that the main parts of an excavator, especially the electric ones, are very important in today’s construction. By knowing how each part works, operators and technicians can keep the excavator working its best.

How Parts Work in Excavator

Power Generation and Distribution

The excavator needs electricity to work. The alternator makes power when the engine is on. This power charges the batteries. It also gives energy to all electric parts. Batteries keep extra energy for later use. They help when the engine is off or more power is needed. Wiring harnesses link the alternator, batteries, and other parts. This makes sure power goes to the right places. Relays and fuses stop too much current from flowing. This keeps the excavator safe from electrical harm.

Control and Monitoring

The electronic control unit, or ECU, runs the main systems. It gets live data from sensors in the machine. These sensors check temperature, pressure, and position. The ECU uses this data to change engine speed and hydraulic flow. It also controls other functions. Display panels show things like engine heat, fuel, and error codes. Operators use this info to make quick choices and keep the excavator working well.

Online monitoring systems watch for vibration, temperature, and pressure. These systems help find problems early and cut downtime by 20%.

Real-time remote monitoring helps fix issues faster and cuts emergency repair time in half.

Automatic scheduling systems make work faster by 18% and lower waiting time.

Diagnostic alerts and reminders help stop big breakdowns and save money on repairs.

Safety and Protection

Safety is very important for every excavator. Relays and fuses protect against too much electricity. The ECU can turn off systems if it finds danger. Sensors warn the operator about problems early. Display panels show warning lights and error messages for fast action. IoT sensors and smart tools spot wear and predict failures. This helps the excavator last longer and have less surprise downtime. All these features work together to keep the machine and people safe.

System Integration

Advanced Features

Modern excavators use electric parts for many new features. These features help operators work faster and stay safe. Electrohydraulic control systems mix sensors, actuators, and hydraulic parts. This setup gives better control and smoother movement. GPS lets the machine change slope and height right away. This makes digging more exact and cuts down on manual work.

Many excavators have telematics systems now. These let people check fuel, maintenance, and machine use from far away. Safety is better with rearview and 360-degree cameras. Operators can see all around and avoid danger. Tiltrotator accessories let the arm and attachments move together. This helps in small spaces and saves time.

Note: Advanced features like E-fencing use sensors and software to make safe zones. The excavator will stop if it gets too close to danger.

Manufacturer | Advanced Feature(s) Enabled by Electric System Integration | Benchmark / Contribution |

|---|---|---|

XCMG | Electric intelligent excavators | 40% reduction in energy consumption; used in smart city and green infrastructure projects |

Caterpillar | AI-driven excavators with autonomous capabilities | 30% reduction in operational errors; 20% increase in fuel efficiency; enhanced precision and safety |

Hyundai | IoT-integrated intelligent excavators | 25% reduction in downtime; real-time monitoring and operational cost optimization |

Komatsu | Hybrid intelligent excavators | Over 35% reduction in fuel consumption; eco-friendly operations suitable for urban projects |

CASE | Fully autonomous intelligent excavators for mining | 30% improvement in operational efficiency; enhanced safety by removing operator from hazardous environments |

Efficiency and Productivity

System integration links all electric parts together. This teamwork makes the excavator work better and faster. When sensors, ECUs, and motors work as one, the machine uses less fuel and does more. The Dextreme system uses a digital pump and controller. This setup saves up to 15% fuel and makes the machine react faster. Bosch Rexroth’s eLION platform mixes electric motors, inverters, and smart software for top performance.

Automation uses sensors, software, and electrohydraulic parts for digging and other jobs. This means the operator does less and the job goes faster.

Digitalization with IoT sensors checks wear and oil. This helps plan repairs and stops surprise breakdowns.

Steer-by-wire and electrohydraulic systems help with semi-autonomous work. These make the excavator easier and safer to use.

AI and IoT let the machine watch itself and plan repairs before big problems happen. Hybrid and electric models are quieter and cleaner, so they are good for cities. When all electric parts work together, the excavator and its tools do even better.

Maintenance and Issues

Common Problems

Excavators sometimes have electrical problems that hurt how they work. Operators might see warning lights or error codes on the display panel. If sensors are not working, they can give wrong information. This can make the machine hard to control. Broken wiring harnesses can stop signals from getting to the right parts. Batteries may lose power fast or not start the machine. Relays and fuses can blow and make some systems stop. Electric motors might get too hot or make weird sounds if there is a problem. When these things happen, the excavator can slow down, use more fuel, or stop working.

Tip: Look for things like blinking lights, slow controls, or the machine turning off suddenly. These signs usually mean there is an electrical problem.

Maintenance Tips

Taking care of the excavator’s electric parts helps them last longer. Operators should look at display panels every day for alerts or error messages. Cleaning sensors and keeping them dry stops bad readings. Check wiring harnesses for cracks or loose wires. Change broken wires right away. Batteries need to be checked for rust and tight wires. Most batteries last three to five years, but hard work can make them wear out faster. Relays and fuses should be checked during regular service. Change any that look old or are blown.

Sensors and monitoring tools help watch the health of electric parts. These tools can find high heat or strange shaking early. Predictive maintenance uses this data to warn about problems. For example, finding a hydraulic leak early can stop shutdowns and keep the excavator working. Keeping electric parts safe from dust, water, and heat helps them last longer. Using good replacement parts also keeps the machine working well.

Regular checks help find damage or worn parts early.

Real-time monitoring and alerts help lower downtime and repair costs.

Keeping digital records of maintenance makes the excavator more reliable.

Note: Good care keeps the excavator safe, working well, and ready for jobs.

Modern excavators need electric parts such as the ECU, sensors, wiring harnesses, and batteries. These parts help the excavator work well, stay safe, and use new features. When all the systems work together, the machine is more reliable and efficient. Checking and caring for electric parts often keeps them working their best. One study found that excavators with full maintenance records sold for 15% more. This shows that taking care of the machine is important. Operators should learn about new electric technology to keep their excavator ready for future work.

FAQ

What happens if an excavator’s battery fails on the job?

If the battery fails, the excavator might not start or run. Operators need to look at the display panel for warning signs. Changing or charging the battery quickly can stop long delays.

How do sensors help with the excavator’s hydraulic system?

Sensors watch pressure and temperature in the hydraulic system. They send this data to the ECU. The ECU uses it to keep the system safe and working right.

Why are wiring harnesses important for hydraulic system parts?

Wiring harnesses link sensors and controls to hydraulic system parts. They move signals and power between these parts. Good harnesses stop signal loss and help the excavator work smoothly.

How often should operators check relays and fuses?

Operators should check relays and fuses at every scheduled maintenance. Checking early helps find problems before they get worse.

Can electric parts affect fuel efficiency?

Yes. Electric parts like the ECU and sensors help control fuel use. They change engine and hydraulic actions to save more fuel.