When you need to buy excavator hydraulic pump, making the right choice is crucial. The hydraulic pump’s pressure, flow rate, and displacement must match your excavator to prevent breakdowns and costly repairs. Using the wrong pump can damage your equipment and cause work delays for several days.

Tip: Always review your machine’s requirements before you buy excavator hydraulic pump.

Key Takeaways

-

Always look at your excavator’s make, model, and OEM codes before you buy a hydraulic pump. This helps you get the right part and stops expensive mistakes.

-

Learn about the three main types of hydraulic pumps: gear, vane, and piston. Each type does different jobs, so pick one that matches your excavator’s work.

-

Pay attention to important specs like pressure rating, flow rate, and pump size. These things decide how well your excavator works and how long it will last.

-

Think about the supplier’s reputation and warranty when you buy a hydraulic pump. A good supplier gives better help and keeps your money safe.

-

Check your hydraulic pump often for leaks and damage. This lets you find problems early and keeps your excavator working well.

Check Machine Specs

Find Make, Model, and OEM Codes

To pick the right hydraulic pump, you must know your excavator’s details. First, check the make, model, and OEM codes. These codes help you find the correct pump. Each excavator series uses certain hydraulic pump models. These models must match things like displacement volume, pressure rating, and flow rate. You also need to see if the pump meets ISO standards and emissions rules. Good pumps have high efficiency, low noise, and last a long time. Quality checks include ISO certification and checking materials. After you buy, support should include a warranty, technical help, and spare parts.

Tip: Use the right codes so you do not get the wrong part.

Confirm Hydraulic Pump Requirements

You can find the manufacturer number on the pump’s nameplate. This number helps you order the right pump for your excavator. Here are steps to find and read the nameplate:

-

Look for the nameplate on the pump’s main body.

-

Find the model number on the nameplate. This number shows the pump’s details.

-

If you cannot read the nameplate, ask a hydraulic pump technician for help.

The hydraulic pump size must fit your excavator’s system. Power is important because it helps the pump make the pressure and flow you need for different jobs. The job you do decides the flow rate and pressure you need for best results.

Note: Size, power, and what you use it for are important. Always check these before you buy.

Compare Hydraulic Pump Types

Gear, Vane, and Piston Pumps

When you choose a hydraulic pump for your excavator, you need to know the main types. Each type works best in different situations. Here is a quick look at the three most common hydraulic pumps:

-

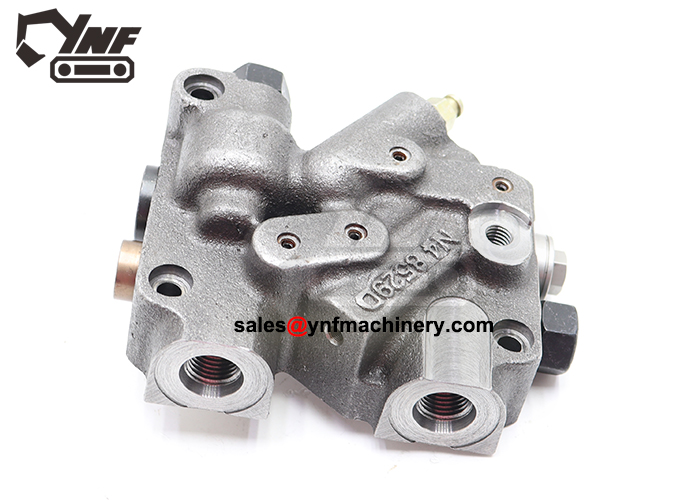

Gear Pumps

Gear pumps use rotating gears to move hydraulic fluid. They have high volumetric efficiency and run quietly. You can maintain them easily, and they cost less than other types. Gear pumps do not handle high-pressure jobs well. Dirt or wear can lower their performance. -

Vane Pumps

Vane pumps use sliding vanes to push fluid. They give smooth operation and can handle higher pressure than gear pumps. You can also maintain them without much trouble. Vane pumps are less efficient than gear pumps. Like gear pumps, dirt and wear can affect how well they work. -

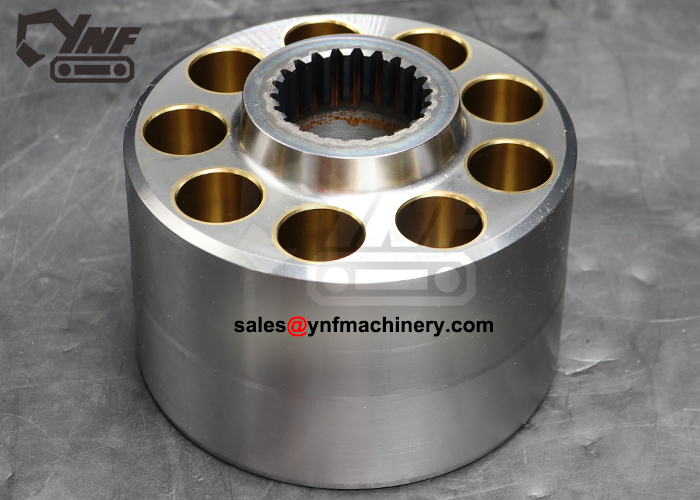

Piston Pumps

Piston pumps use moving pistons to create pressure. They work well for high-pressure tasks and have high efficiency. These pumps last a long time and suit tough jobs. Piston pumps cost more and need clean hydraulic fluid to avoid damage.

Note: The lifespan of each pump depends on quality and care. For example, a well-maintained vane pump can last up to 18,000 hours. Regular oil changes and part replacements help pumps last longer.

|

Pump Type |

Efficiency |

Pressure Capability |

Maintenance |

Cost |

Best Use Case |

|---|---|---|---|---|---|

|

Gear |

High |

Low |

Easy |

Low |

General, low pressure |

|

Vane |

Medium |

Medium-High |

Easy |

Medium |

Smooth, steady flow |

|

Piston |

High |

High |

Moderate |

High |

Heavy-duty, high pressure |

Match Pump Type to Application

You must match the pump type to your excavator’s needs. Think about the job, the flow rate, and the pressure you need.

-

Use gear pumps for basic digging or lifting. They work well in most excavators that do not need high pressure.

-

Choose vane pumps if you want smooth operation and steady flow rate. They fit medium-duty excavator tasks.

-

Pick piston pumps for heavy-duty excavator work. These pumps handle high pressure and variable flow rate. You see them in machines that lift heavy loads or work long hours.

Tip: Always check the manufacturer’s life rating for each pump. This rating tells you how many hours the pump should last at certain pressures and speeds.

You can get the best performance from your excavator by choosing the right hydraulic pump. The right match helps you avoid breakdowns and keeps your machine running strong.

Key Specs for Hydraulic Pump Selection

Pressure, Flow Rate, and Displacement

When you pick a hydraulic pump, focus on three things. These are pressure rating, flow rate, and pump size. These details decide how well your excavator works and how long it lasts.

Pick a pump with a pressure rating above your excavator’s needs. This keeps your system safe from sudden pressure jumps. For example, big excavators need pumps that handle up to 4,500 psi. They also need a flow rate of 150 gallons per minute (GPM). Medium excavators may need up to 234 liters per minute. Their system pressure is about 32.4 to 34.3 MPa.

|

Equipment Type |

Flow Rate (GPM) |

Pressure (psi) |

|---|---|---|

|

Large Excavator |

150 |

4500 |

Tip: Write down your flow rate and pressure needs before shopping. This helps you compare pumps easily.

A good hydraulic system with the right flow rate makes your excavator work well. When the pump size matches your machine, you get steady work and fewer problems. If the pump is too small, your excavator moves slowly or struggles with heavy loads. If the pump is too big, you waste energy and might break parts.

To find the right pump size, use this easy method:

-

Find the heaviest load your excavator will lift.

-

Double this weight for safety.

-

Divide by the cylinder size to get the smallest pump size you need.

Think about how fast your actuators move and how long each stroke takes. Figure out the volume needed for both sides of the cylinder. Make sure your pump gives enough flow for the job.

Safety Margins and Environmental Factors

Safety margins matter when you choose a hydraulic pump. The safety margin is the gap between the pump’s pressure rating and the highest pressure your excavator faces. Most machines use a safety factor of 3 to 4 times the working pressure. This helps your system handle sudden pressure spikes and keeps your machine safe.

The environment also affects your pump choice. Hot weather can make hydraulic fluid thin. This causes more wear and leaks. Cold weather makes fluid thick. This slows starts and lowers efficiency. Fluid compatibility is important. Always use fluids that fit your pump and the temperature range.

Contamination is a big problem. Dirt, water, and other stuff can hurt your pump and shorten its life. Good filters and regular care help stop these issues. In tough places, you need pumps with strong seals and better filters. This keeps dust, mud, and water out of your excavator.

Note: Fast speeds, heavy loads, and extreme temperatures stress your hydraulic system. You may only get 60-70% working time if you ignore these things when picking a pump.

To sum up, always check the pressure rating, flow rate, and pump size for your excavator. Write down your flow rate and pressure needs. Think about fluid compatibility and where your machine will work. These steps help you pick the right hydraulic pump and keep your excavator working well.

Buy Excavator Hydraulic Pump: Options and Support

OEM vs Aftermarket

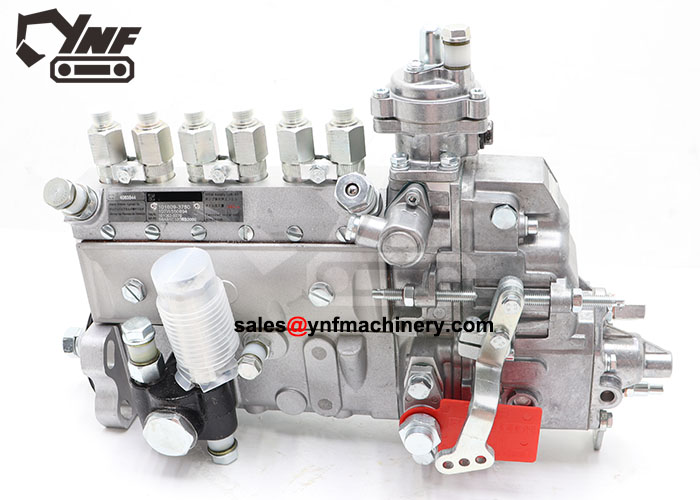

When you buy excavator hydraulic pump, you have two main choices. You can pick OEM or aftermarket pumps. OEM hydraulic pumps come from the original maker of your machine. These pumps fit your excavator very well. They meet high quality standards. OEM pumps work well and are very reliable. But they usually cost more money. Sometimes, it is hard to find OEM pumps for old machines.

Aftermarket hydraulic pumps give you more options and lower prices. Some aftermarket pumps are as good as OEM ones. Others may not be as good. You might find pumps with new features or better efficiency. Many aftermarket sellers let you change flow rate or other specs. This helps you get what you need for your excavator. You must check each pump carefully. Quality and fit are not always the same.

Here is a simple comparison:

|

Aspect |

OEM Hydraulic Pumps |

Aftermarket Hydraulic Pumps |

|---|---|---|

|

Compatibility |

High |

Varies |

|

Quality |

Consistent |

Varies widely |

|

Cost |

Higher |

Lower |

|

Availability |

Limited |

Wide |

|

Performance |

Reliable |

Can vary |

|

Innovation |

Less |

More |

|

Warranty |

Manufacturer-backed |

Often included, but coverage varies |

|

Customization |

Limited |

More options |

Tip: OEM pumps are best if you want a perfect fit and trust. If you want to save money or try new features, aftermarket pumps might be better for you.

Supplier Reputation and Warranty

Picking the right pump also means picking a good supplier. Always buy excavator hydraulic pump from someone you trust. YNF Machinery is a good choice for these pumps. They have strong quality checks and ISO certificates. Many customers say good things about them. They also help with spare parts and technical support.

Check these things before you buy excavator hydraulic pump:

-

Find a supplier with good reviews and a strong history.

-

Make sure the supplier gives a warranty to protect you.

-

Ask if they help after you buy and have spare parts.

-

Check that the pump fits your excavator’s flow rate and needs.

Warranty is important. OEM warranties last longer and help keep your machine’s warranty safe. Aftermarket warranties may be shorter. But some sellers, like YNF Machinery, still give good support and protection.

Note: Good customer service and warranty help keep your excavator working. Always pick a supplier who supports their products.

Picking the right hydraulic pump for your excavator takes some steps. First, you need to look at the specs. Next, match the pump type to your job. Think about where you will use your machine. Compare the features of each pump. Choose the one that fits your needs best.

|

Selection Factor |

Gear Pump |

Piston Pump |

Amphibious Use |

|---|---|---|---|

|

Pressure Requirements |

Low-Medium |

High |

High |

|

Flow & Speed Needs |

Fixed |

Variable |

Variable |

|

Operational Efficiency |

Lower |

Higher |

Higher |

|

Cost & Complexity |

Lower |

Higher |

Higher |

|

Durability & Environment |

Lower |

Higher |

Highest |

Taking care of your hydraulic pump helps your excavator work well:

-

Your machine works better.

-

You do not spend a lot on repairs.

-

You keep other parts safe from harm.

If you are not sure what to do, ask YNF Machinery for advice. Picking carefully helps you avoid problems. It keeps your excavator strong and working well.

FAQ

How do you know when your excavator hydraulic pump needs replacement?

You notice slow movement, strange noises, or leaks. The pump may not build enough pressure. If you see these signs, check your hydraulic system. Replace the pump to keep your excavator working safely.

Can you install a hydraulic pump by yourself?

You can install a hydraulic pump if you have basic tools and follow the manual. Always turn off the machine first. If you feel unsure, ask a technician for help. Safety comes first.

What is the best way to choose a reliable hydraulic pump supplier?

You should look for suppliers with good reviews and strong support. YNF Machinery offers quality hydraulic pumps, technical help, and spare parts. This makes them a trusted choice for your excavator.

How often should you check your hydraulic pump?

You should check your hydraulic pump every month. Look for leaks, wear, and pressure changes. Regular checks help you find problems early and keep your excavator running well.

What happens if you use the wrong hydraulic pump?

You risk damaging your excavator. The wrong pump can cause poor performance, leaks, or system failure. Always match the pump to your machine’s specs to avoid costly repairs.