You can find common hydraulic pump coupling sizes by looking at measurements like 1/4″, 3/8″, 1/2″, 3/4″, 1″, LH100-LH900, QD bushings 6-16, and IEC motor sizes 63-355. Knowing these sizes helps you pick or change parts easily. Always make sure the coupling fits the pump’s needs. This stops damage and keeps your hydraulic system safe. Check for important things like diameter and thread type. This helps you pick the right fit for your job.

Key Takeaways

Learn common hydraulic pump coupling sizes like 1/4″, 3/8″, and 1/2″. This helps you pick the right parts for your system.

Always measure the hose inner diameter (ID) with a caliper first. This stops leaks and makes sure the fit is tight.

Look at the thread type of your couplings. If the thread type matches, it stops leaks and connects well.

Use tables and charts to find the right hydraulic pump coupling sizes fast. These tools help you choose easier.

Check and take care of your hydraulic couplings often. This lowers downtime and saves money on fixing things.

Hydraulic Pump Coupling Sizes

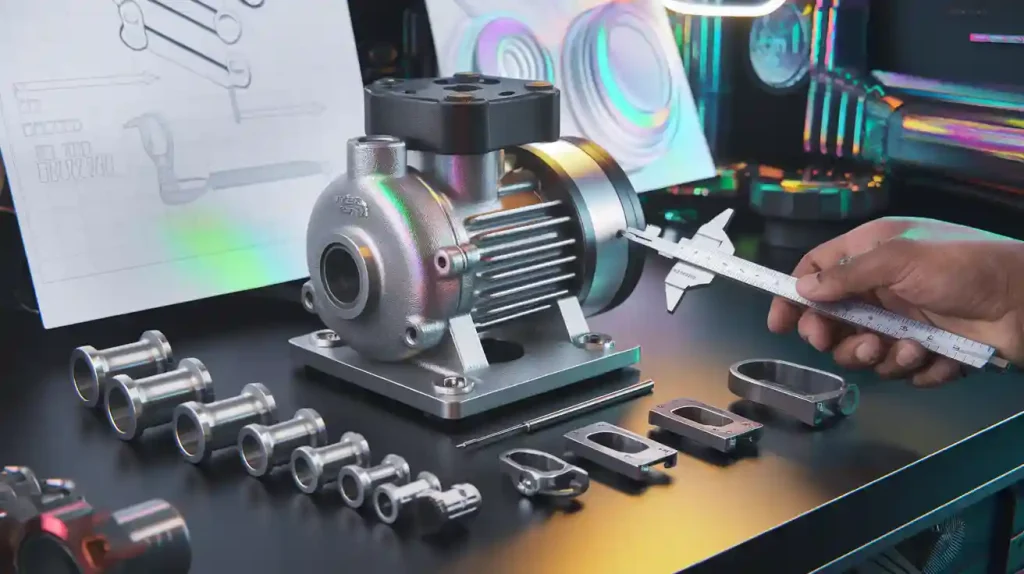

Choosing the right hydraulic pump coupling sizes helps you keep your system running smoothly. You need to know the most common coupling size options and how to measure them. This section gives you a clear overview of the main types and sizes you will find.

Common Inch Sizes

You often see inch-based hydraulic pump coupling sizes in many industries. These sizes include 1/4-inch, 3/8-inch, and 1/2-inch. Each coupling size fits a specific application. For example, 1/4-inch couplings work well in pneumatic systems. You use 3/8-inch couplings in automotive and industrial settings. Heavy-duty jobs need 1/2-inch couplings.

Tip: Always measure the hose inner diameter (ID) with a caliper before choosing a coupling size. This helps you avoid leaks and ensures a secure fit.

Here is a quick reference table for common inch sizes:

Coupling Size | Common Applications | Measurement Method |

|---|---|---|

1/4-inch | Pneumatic systems | Inner diameter (ID) |

3/8-inch | Automotive, industrial | Inner diameter (ID) |

1/2-inch | Heavy-duty applications | Inner diameter (ID) |

To identify the correct hydraulic pump coupling sizes, follow these steps:

Measure the hose inner diameter (ID) using a caliper.

Use a thread gauge to check the thread type.

Test the system’s flow and pressure with a flow meter and pressure gauge.

Match your measurements with standard sizing charts.

LH Line and QD Bushings

LH line couplings and QD bushings offer more options for hydraulic pump coupling sizes. You find these in both metric and inch measurements. LH100 to LH900 are common in hydraulic systems. QD bushings come in types like JA, J, and SH. Each type has its own bore size range and outer diameter.

Here is a table showing some QD bushing features:

Bushing Type | Bore Size Range | Length Through Bore | Outer Diameter |

|---|---|---|---|

JA | Compact | N/A | N/A |

J | Heavy-duty | 1.8125 inches | 3.875 inches |

SH | 15mm to 38mm | 1.3125 inches | 2.687 inches |

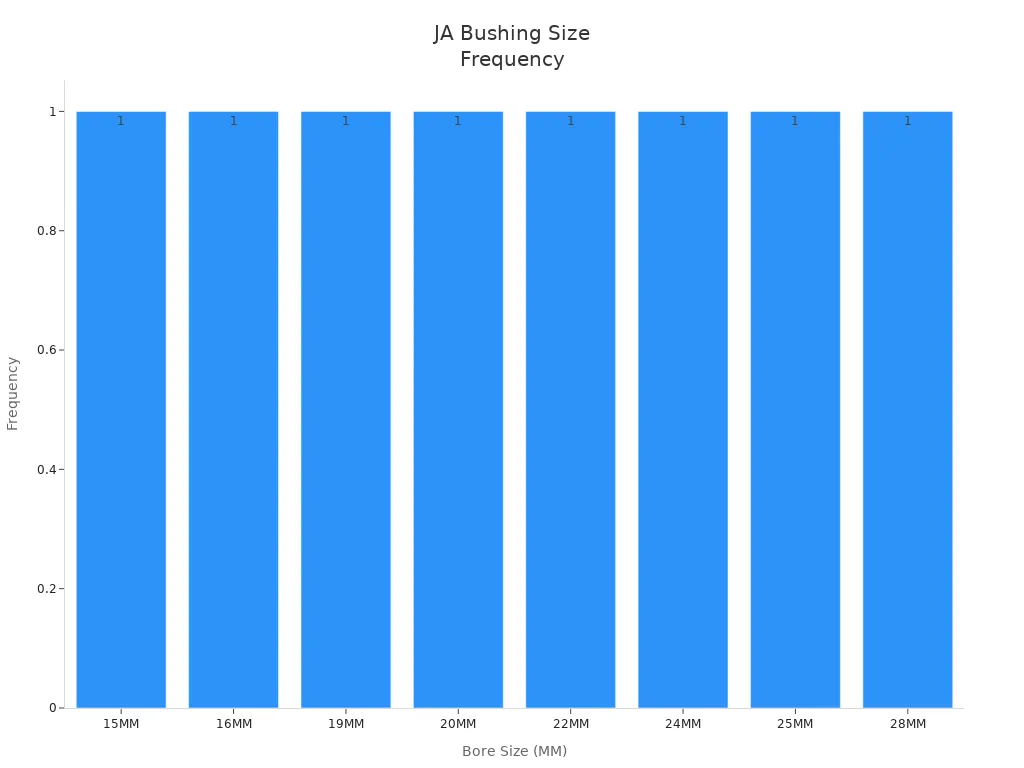

You can see the most frequent JA bushing bore sizes in the chart below:

The SH Metric QD Bushing Size Chart covers bore sizes from 15mm to 38mm. These fit many industrial uses. The J Metric QD Bushing works for bore sizes from 50mm to 100mm. You use these for heavy-duty tasks. The F Metric QD Bushing fits bore sizes from 42mm to 90mm. These are best for high-torque jobs.

IEC Motor Coupling Sizes

IEC motor coupling sizes use a different system. You see sizes like 63, 71, 80, 90, 100, up to 355. These numbers match the motor frame size. You need to match the coupling size to the motor’s shaft diameter and length. This ensures the coupling fits tightly and transfers power without slipping.

Here is a reference table for quick lookup:

Size Category | Thread Size | Flare Seat Angle | Material |

|---|---|---|---|

AN-4 | 7/16-20 | 37° | Aluminum |

AN-6 | 3/8-24 | 37° | Steel |

AN-8 | 1/2-20 | 37° | Stainless Steel |

You should always check the motor’s manual for the correct hydraulic pump coupling sizes. Matching the right coupling size keeps your system safe and efficient.

Note: If you need help finding the right coupling size, use reference tables and sizing charts. These tools make selection faster and more accurate.

Identifying Hydraulic Couplers

Hydraulic couplers join pumps, hoses, and fittings together. Picking the right coupling type keeps your equipment safe. It also helps stop leaks. You need to measure and check each part to find the right one.

Measuring Diameter

First, measure the diameter of your hydraulic couplers. This helps you pick the right coupling for your pump and hose. Use the correct tool to get a good measurement.

Measurement Tool | Description | Accuracy |

|---|---|---|

Calipers | Use for exact measurements of the coupler body. | Very accurate in mm. |

Measuring Tape | Good for measuring the full length. | Not as accurate, line up carefully. |

Clean your hydraulic couplers before you start.

Use calipers to check the outer diameter in a few spots. Calipers give you a very exact number.

If you do not have calipers, use a measuring tape. Make sure the tape is straight across the widest part.

Write down the size in millimeters or inches.

Tip: Measure both the male and female sides of the hydraulic couplers. This helps you avoid picking the wrong coupling type.

Checking Thread Type

Thread type changes how hydraulic couplers connect to pumps and fittings. You need to check the threads to find the right coupling type. Use a thread gauge or look at the threads closely.

Common thread types are:

NPT thread: Used a lot in North America. Needs sealing to stop leaks.

SAE thread / ORB thread: Has an O-ring at the end. Makes a better seal.

BSPP thread: A straight thread. Needs another seal to stop leaks.

JIC thread: Used in fluid power systems. Can be reconnected without leaks.

ORFS thread: Has an O-ring on the face. Stops leaks well.

Look at the thread shape and count the threads per inch. A thread gauge works best for this. If you see an O-ring, it is probably ORB or ORFS. If the thread gets smaller, it is likely NPT.

The thread type affects if your parts fit together. Different places use different threads. Make sure all your parts match. If they do not, you might need an adapter. Buying all your hydraulic couplers and tools from one brand can help you avoid problems.

Determining Fitting Type

You need to know the fitting type to pick the right hydraulic couplers. Each coupling type has its own features. Look for these when you check your coupler.

Main fitting types are:

NPT: Tapered threads seal the connection.

NPTF: Metal-to-metal seal for no leaks.

ORB Fittings: Straight thread with an O-ring for high pressure.

JIC Fittings: Seals with a 37° cone.

ORFS Fittings: Flat surface with an O-ring to stop leaks.

BSP: Tapered or straight threads, uses thread shape or metal contact.

DIN 7631: Metric fitting with a 60° cone.

DIN 3852: Fits many hose sizes and metric threads.

JIS Tapered Pipe (PT): Japanese standard, like BSP.

Check the end of the hydraulic couplers for cones, O-rings, or flat faces. These help you know the coupling type. Use the table below to match your job with the best fitting type.

Application Type | Recommended Fitting Types |

|---|---|

High-Pressure Applications | Heavy DIN Metric Fittings, JIC Fittings |

Corrosive Environments | Stainless Steel BSPP, Stainless Steel ORB |

Precision and Leak-Proof Systems | FACE SEAL Fittings |

General Industrial and Pneumatic Systems | NPT Fittings |

Agricultural and Outdoor Equipment | JIC Fittings, ORB Fittings |

European and Asian Markets | BSPP Fittings |

Mobile Machinery and Moderate Pressure | Light DIN Metric Fittings |

Note: Always match the fitting type to your pump and job. This stops leaks and keeps your hydraulic couplers working well.

You can figure out hydraulic couplers by measuring diameter, checking thread type, and knowing the fitting type. Use calipers and thread gauges for the best results. Look for special things like O-rings or cones. Picking the right coupling type keeps your system safe and working well.

Selecting Hydraulic Fittings

Picking the right hydraulic fittings keeps your pump safe. It also helps your system work well. You need to use good steps and not make mistakes. This stops leaks, breakdowns, and costly fixes.

Best Practices

When you pick hydraulic fittings, measure the thread size first. Also, check the fitting’s size. Use a caliper to get the right number. Always match the fitting’s material to where you use it. Stainless steel and brass are good in places with lots of rust. Look at the pressure ratings on the hydraulic fittings. Make sure they can handle your system’s highest pressure. Think about the temperature and stress in your work area. Pick hydraulic fittings that work in very hot or cold places.

Tip: Check if the hydraulic fittings match your pump and hose. This means looking at the thread type, size, and material.

You should also think about how strong the hydraulic fittings are. Strong fittings stop leaks and blowouts. Find fittings with high burst pressure numbers. Look at the maker’s charts for how heat changes the fittings. High heat can make hydraulic fittings weaker and break.

Aspect | Description |

|---|---|

Pressure Ratings | The most pressure hydraulic fittings can take safely. |

Material Strength | Strong materials help hydraulic fittings keep the system safe. |

Temperature Effects | Very hot or cold can change hydraulic fittings and how well they hold pressure. |

YNF Machinery sells good hydraulic pump couplings and hydraulic fittings. Their parts meet rules and help you avoid problems.

Common Mistakes

Many people make mistakes when picking hydraulic fittings. These mistakes can cause leaks, breakdowns, and safety problems.

Picking the wrong size makes leaks and bad sealing.

Not matching materials causes rust and fast damage.

Not checking pressure ratings can cause blowouts.

Forgetting about the work area makes fittings weak and short-lived.

Not checking thread type causes bad fits and leaks.

Never use broken hydraulic fittings again. Always put in new ones if they are worn or cracked. Do not mix materials that do not go together. This can cause rust, especially in high-pressure systems. Do not tighten hydraulic fittings too much. Too much force can break threads and cause leaks.

Note: Leaks from hydraulic fittings stop work and can be unsafe. Breakdowns can cost a lot to fix and take time. Leaking fluid can also hurt the environment.

Pick hydraulic fittings that fit your pump and job. Measure well, check pressure ratings, and pick the right material. This keeps your hydraulic system safe and working well.

You can find the right hydraulic pump coupling size by doing a few things. First, measure the shaft diameter. Then, check the thread type to make sure it fits. Think about how much horsepower you need. Also, look at how fast the pump runs. Check if the temperature is okay for your parts. Make sure you have enough space for the coupling. Look at how much load the system will carry. See if the coupling can handle misalignment.

If you measure carefully and know the standard sizes, you can stop leaks. This also helps you avoid problems with your system. Use tables and charts to help you pick the right size. These tools make choosing easier and more accurate.

If you check your couplings often and install them the right way, you will have less downtime. You will also spend less money fixing things. YNF Machinery has good couplings you can trust for your hydraulic system.

Next Steps:

Read and follow the instructions from the manufacturer when you install the coupling.

Make sure the coupling is lined up right and check the torque ratings.

Plan regular checks and add lubrication when needed.

These steps help keep your hydraulic system safe and working well.

FAQ

What is a hydraulic pump coupling?

A hydraulic pump coupling joins the pump to the motor. It moves power from one part to another. The coupling helps lower vibration. It keeps the hydraulic system working well. You need to pick the right size for your equipment.

How do you measure a hydraulic coupling size?

To measure a hydraulic coupling, check the shaft diameter and length. Use calipers to get a good measurement. Always look at standard sizing charts to compare your numbers. This helps you choose the right hydraulic coupling for your system.

Why does the thread type matter in hydraulic couplings?

Thread type changes how hydraulic couplings fit together. If you use the wrong thread, leaks or damage can happen. Always match the thread type to your pump and fittings. This keeps your hydraulic system safe.

Can you reuse old hydraulic couplings?

Do not reuse old hydraulic couplings. Worn or broken couplings can cause leaks or make the system fail. Always put in new hydraulic couplings when you change parts. This keeps your equipment safe and working well.

Where can you buy quality hydraulic pump couplings?

You can buy good hydraulic pump couplings from YNF Machinery. They sell many types of hydraulic couplings and fittings. Their products help your hydraulic system stay safe and work well.