You want to fix your excavator quickly and save money. You need to know the main parts to find the right problem. It is important to learn how these parts can break. When you know about 1080 case excavator track parts break down, you can find problems early. This helps your machine work well.

Doing regular maintenance and reading your service manual will help you feel sure every time you work on your machine.

Key Takeaways

Regular checks help you find problems early. Watch for wear, strange sounds, and parts not lining up. This can stop bigger repairs later.

Always think about safety before fixing your excavator. Use the rules in your service manual to stay safe while working.

The right track tension is very important. Check and fix the tension often. This helps stop too much wear and keeps things running well.

Keep your track system clean and oiled. Clean and grease it often to make your excavator parts last longer.

Use the Case 1080 service manual for clear steps. It has important pictures and directions for fixing and taking care of your machine.

Identify Track Problems

Signs of Wear

You can spot early signs of wear if you know what to look for. Worn tracks may show uneven surfaces or thinning metal. You might notice the track links look flat or the shoes have rounded edges. Sometimes, the pins and bushings appear loose or out of place. If you see these changes, your 1080 case excavator track parts break down may be starting. Early detection helps you avoid bigger repairs.

Noise

Strange noises often signal trouble. Listen for clanking, squeaking, or grinding when you move the excavator. These sounds can mean loose or damaged parts. A squeak may come from dry rollers or idlers. A loud clank could point to a broken pin or cracked link. If you hear new or louder noises, stop and check the track system right away.

Tip: Always compare the sound of your machine to how it usually runs. New noises are often the first sign of a problem.

Misalignment

Track misalignment can cause serious damage if you ignore it. You may notice the track drifting to one side or not sitting straight on the rollers. Common causes of misalignment include:

Improper track tension

Operation on hard, rough terrain

Riding over curbs

Demolition debris underfoot

Material buildup in the track system

If you see the track shifting or feel the machine pulling to one side, check the alignment before using the excavator again.

Visible Damage

Regular inspections help you catch visible damage early. Look for these common issues:

Cracks, breakage, or wear on track links and pins

Broken or protruding pins, especially the master pin

Cracks or deformations on bushings near the arms or bucket

Cracks, spalling, or loose hardware on sprockets

Flat spots, broken shafts, or oil leaks on top rollers

Cracks, deformation, or oil leaks on bottom rollers

Spotting these problems early can prevent a full 1080 case excavator track parts break down. Always check each part closely during your routine inspections.

Troubleshooting Steps

Safety First

You must always put safety first before you start any repair or inspection. Park your excavator on level ground. Lower the bucket and blade to the ground. Turn off the engine and remove the key. Use wheel chocks to prevent movement. If you need to lift the machine, use strong jacks and secure stands. Never work under a raised track without proper support. Wear gloves, safety glasses, and steel-toed boots. Always follow the safety guidelines in your Case 1080 service manual.

Tip: Keep a fire extinguisher and first aid kit nearby when working on heavy equipment.

Visual Check

Start with a careful visual inspection. Walk around your excavator and look at the tracks from all sides. Check for dirt, rocks, or debris stuck in the track system. Look for cracks, missing bolts, or bent parts. Pay close attention to the rollers, idlers, and sprockets. If you see oil leaks, broken pieces, or loose hardware, mark these spots for repair. Use a flashlight to see under the track and inside tight spaces.

Track Tension

Proper track tension keeps your excavator running smoothly. Tracks that are too tight or too loose can cause damage. To check tension, measure the sag in the track between the top of the track frame and the bottom of the track chain. Your Case 1080 service manual gives the correct measurement. If you need to adjust the tension, locate the grease-filled tension cylinder. Loosen the cylinder to release grease and reduce tension. Add grease to increase tension. Always make small adjustments and recheck the sag.

Note: Never adjust track tension while the machine is running. Always follow the manual for safe steps.

Rollers & Idlers

Rollers and idlers play a big role in how your track system works. Rollers carry the weight of your excavator and help the track move smoothly. Idlers guide the track and keep it in place. Worn rollers or idlers can cause misalignment, extra ground pressure, and poor performance.

Component | Function | Impact of Wear |

|---|---|---|

Track Roller | Conveys the weight of the excavator to the ground | Worn rollers may not support weight effectively, leading to misalignment. |

Idler | Guides the track links and prevents dislocation | Worn idlers can cause operational inefficiencies and affect track performance. |

The idler guides the track links into smooth operation.

It prevents dislocation of the tracks.

Worn idlers can increase ground pressure and lead to further operational inefficiencies.

If you notice flat spots, oil leaks, or wobbling in these parts, you may have the start of a 1080 case excavator track parts break down. Replace worn rollers and idlers as soon as possible to avoid bigger problems.

Sprockets & Links

Sprockets and links connect the track system and drive the excavator forward. Check the sprocket teeth for sharp points or chips. Worn teeth can slip and cause the track to jump. Inspect the track links for cracks, bent sections, or missing pins. If you see damage, you may need to replace these parts.

To remove or install a track, align the track around the sprocket and idler wheels. Use a pry bar if needed to guide the track into place. Always consult your Case 1080 service manual for step-by-step instructions. Secure all bolts and pins before you finish.

Remember: Careful alignment and proper tension help your track system last longer and work better.

1080 case excavator track parts break down

Understanding the main components of your excavator’s track system helps you spot problems early and keep your machine running smoothly. Each part has a specific job. When you know what to look for, you can prevent a full 1080 case excavator track parts break down.

Here is a table that shows the main parts and their functions:

Component | Function |

|---|---|

Track Chains | Hold track pads together, allow movement around the undercarriage, and keep track alignment. |

Rollers | Support the excavator’s weight and guide the tracks for smooth movement. |

Idlers | Maintain track tension and alignment, helping with stability and smooth operation. |

Sprockets | Drive the tracks, provide traction, and help the machine move over obstacles. |

Track Shoes | Give grip and control on different terrains, stop the excavator from sinking into soft soil. |

Tensioners | Adjust and keep the correct track tension for safe and efficient operation. |

Always check your Case 1080 service manual for diagrams and detailed part information. The manual gives you clear pictures and step-by-step guides for each part.

Track Chains

Track chains connect all the track pads and let the track move around the undercarriage. You need to keep them in good shape to avoid a 1080 case excavator track parts break down. Common failure symptoms include:

Loose or missing pins and bushings

Cracks or visible wear on the links

Chains that sag or do not stay aligned

Many problems come from poor lubrication, wrong chain tension, or too much dirt and moisture. Overloading the machine or driving on rough ground can also cause cracks and breakage. If you see any of these signs, replace the track chains right away.

Failure Symptom | Description |

|---|---|

Insufficient Lubrication | Not enough oil causes friction and fast wear. |

Improper Chain Tension | Wrong tension puts stress on the chain and wears it out faster. |

Environmental Factors | Dust and water can cause rust and shorten the chain’s life. |

Overloading | Too much weight bends or breaks the chain. |

Fatigue Cracks | Heavy use over time causes cracks that can lead to failure. |

Rollers

Rollers carry the weight of your excavator and help the track move smoothly. You find two types: top rollers and bottom rollers. Top rollers support the upper part of the track, while bottom rollers carry the main load.

Watch for these signs of roller failure:

Flat spots or uneven wear

Oil leaks from the roller seals

Wobbling or loose rollers

If you ignore these problems, the track can misalign or even come off. Replace worn rollers quickly to avoid a full 1080 case excavator track parts break down.

Idlers

Idlers keep the track tight and guide it as it moves. They sit at the front of the track frame. If the idler wears out, you may notice:

The track loses tension and sags

The track drifts or misaligns

Unusual noises from the front of the track system

A damaged idler can cause the track to slip or derail. Always check the idler for cracks, bends, or oil leaks during your inspections.

Sprockets

Sprockets drive the track and help the excavator move. You should inspect the sprocket teeth often. Worn or sharp teeth can cause the track to slip or jump. Damaged sprockets also wear out the track pads faster.

Sharp or chipped sprocket teeth

Track pads that show unusual wear

The track jumps or skips during operation

Inspecting sprocket teeth is important. Sharp sprockets and damaged track pads often mean bigger problems. Fix these issues quickly to prevent more wear on your undercarriage.

Track Shoes

Track shoes give your excavator grip and help it move safely on different surfaces. They also stop the machine from sinking into soft ground. You may see damage if you:

Turn too sharply or too often

Drive on rough or uneven ground

Leave debris stuck in the track shoe assembly

Park on uneven surfaces

Common signs of damage include cracks, bent shoes, or missing bolts. Clean the track shoes often and check for loose or broken parts. If you see damage, replace the shoes to avoid a 1080 case excavator track parts break down.

Tensioners

Tensioners keep the track at the right tightness. If the tensioner fails, the track may become too loose or too tight. Signs of tensioner problems include:

The track sags or feels too tight

You hear squeaking or grinding noises

The tensioner leaks grease or oil

A broken tensioner can lead to misalignment and extra wear on other parts. Adjust or replace the tensioner as needed.

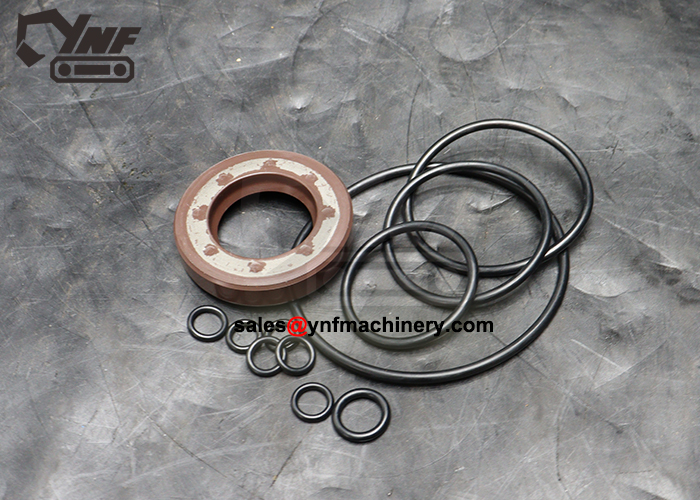

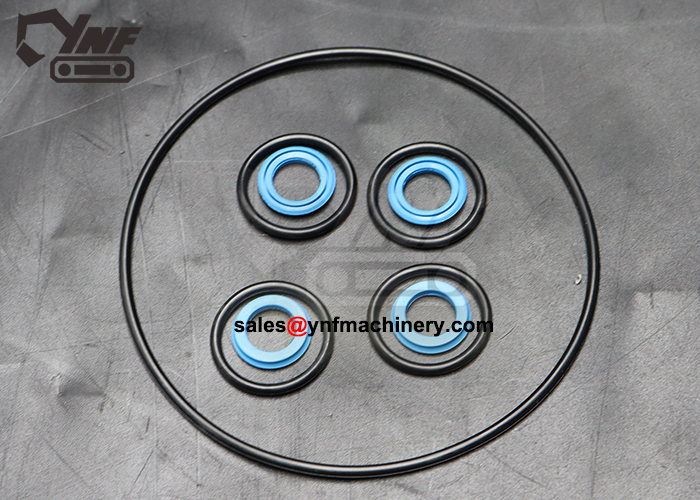

For all replacement track parts, you can trust YNF Machinery. They offer reliable parts that fit your Case 1080 excavator and help prevent future breakdowns.

Always use your Case 1080 service manual for diagrams and detailed instructions. The manual helps you identify each part and shows you how to fix or replace it safely. Regular checks and quick repairs keep your excavator working and help you avoid a full 1080 case excavator track parts break down.

Repair & Replacement

Tools Needed

You need the right tools to repair or replace track parts on your Case 1080 excavator. Gather these before you start:

Heavy-duty wrenches and sockets

Pry bar

Grease gun

Hydraulic jack and secure stands

Safety gloves, goggles, and steel-toed boots

Cleaning brush and rags

Tip: Always check your Case 1080 service manual for any special tools required for your specific model.

Remove Damaged Parts

Start by parking your excavator on flat ground. Lower the bucket and blade for stability. Turn off the engine and remove the key. Use a hydraulic jack to lift the machine and place secure stands under the frame. Release track tension by loosening the grease-filled tension cylinder. Use a pry bar to help remove the old track or damaged parts. Take care not to use too much force, which can cause more damage.

Install New Parts

Before installing new parts, inspect them for any damage or missing pieces. Lay the new track flat and align it with the sprocket and drive wheel. Fix one end of the track on the drive wheel and tighten the bolts. Manually guide the track around the wheels, making sure it sits evenly. Insert and secure the track pin. Always check that the holes line up to avoid misalignment.

Step | Description |

|---|---|

Tool preparation | Gather all needed tools and safety gear. |

Track inspection | Check new parts for damage or missing pieces. |

Positioning adjustment | Park on flat ground and adjust for easy installation. |

Track laying | Lay track flat and align with sprocket and drive wheel. |

Install drive wheel | Attach one end of track and tighten bolts. |

Guide the track | Manually guide track around wheels for proper tension. |

Install track pin | Insert and secure the track pin. |

Check and adjust | Test by driving slowly and checking for smooth operation. |

Note: Never use violent force during installation. Work with a partner for safety.

Adjust Tension

After installing the new parts, use the grease gun to add grease to the tension cylinder. This step tightens the track. Check the sag and adjust until it matches the measurement in your service manual. Proper tension prevents future breakdowns.

Post-Repair Check

Once you finish, inspect all bolts and pins for tightness. Drive the excavator slowly and listen for unusual noises. Watch the track for smooth movement and correct alignment. If you spot any issues, stop and fix them right away.

Always follow your Case 1080 service manual for detailed steps and safety tips. Careful repairs keep your machine running strong.

Maintenance Tips

Inspection Schedule

If you check your Case 1080 excavator often, it will last longer. Regular checks help you find small problems before they get worse. Use this table to help plan when to do maintenance:

Interval (Hours) | |

|---|---|

Daily | Check fluid levels, look for leaks or damage, test safety features |

250 | Change engine oil and filter, check hydraulic system, clean air filters |

500 | Replace hydraulic oil filter, grease moving parts, check undercarriage |

1,000 | Service fuel filter, check electrical system, inspect swing bearing and sprockets |

2,000 | Change hydraulic fluid, service cooling system, check boom, stick, and bucket |

Tip: Write these times on your calendar or in a logbook. Doing regular checks can save you money on repairs.

Lubrication

Grease helps your track parts move without sticking. You need to put grease on all the joints and pivot points. If parts are dry, they wear out and might break. Always use the grease your Case 1080 service manual says to use. Clean off old grease and dirt before adding new grease. This stops dirt from making parts wear out faster.

Cleaning

Mud and dirt can pile up in your track system. Clean the tracks after every use, especially if you work in mud or sand. Use a stiff brush or gentle water spray to get rid of dirt. Look closely at the rollers, sprockets, and track shoes. Clean parts last longer and work better.

Note: Do not use strong water sprays near seals or bearings. Water can push dirt inside and cause damage.

Tension Adjustment

Track tension is important for how long your parts last. You should check and fix the tension often. Wrong tension causes many problems:

Tracks that are not adjusted right wear out faster and do not work well.

Tight tracks can make undercarriage parts wear out four times faster.

Tight tracks put more pressure on parts and can dry out joints.

Loose tracks can rub on the roller frame and wear out parts.

Check the sag in your track and compare it to the number in your manual. Adjust the tension cylinder if you need to. The right tension keeps your track system safe and working well.

Checking tension often helps you stop breakdowns and saves money on repairs.

You can keep your Case 1080 excavator running strong by following these steps. Industry experts highlight a few key points:

Always inspect and maintain your track system.

Troubleshoot track chains, shoes, rollers, and sprockets.

Focus on performance and long life for your machine.

For more help, use the Case 1080 Official Workshop Service Repair Manual. This guide gives you clear instructions for every repair. Stay confident and tackle track issues with the right knowledge and tools.

FAQ

What signs show that my Case 1080 excavator track needs repair?

You may see cracks, loose pins, or sagging tracks. Listen for grinding or clanking noises. Watch for misalignment or uneven movement. Check for oil leaks near rollers or idlers.

How often should I check track tension?

You should check track tension every week. If you use your excavator daily, inspect the tension before each job. Proper tension helps prevent damage and keeps your machine working well.

Can I replace track parts myself?

You can replace track parts if you have the right tools and follow safety steps. Always read your Case 1080 service manual. If you feel unsure, ask a professional for help.

Where can I buy reliable replacement parts for my Case 1080 excavator?

You can buy reliable replacement parts from YNF Machinery. They offer parts that fit your Case 1080 excavator and help prevent future breakdowns.

What tools do I need for basic track repairs?

You need heavy-duty wrenches, a pry bar, a grease gun, a hydraulic jack, and safety gear. Always check your service manual for any special tools your model may need.