Excavator track parts play a crucial role in the operation of an excavator. These components ensure your machine can handle various terrains with ease. Understanding the different parts of an excavator and their functions is vital for maintaining optimal performance. Regular maintenance not only extends the life of these parts but also reduces operating costs. By keeping your excavator in top condition, you ensure it remains productive on the job site. For reliable and high-quality excavator parts, consider YNF Machinery as your go-to supplier.

Key Takeaways

Understanding the different parts of an excavator, such as tracks, sprockets, and rollers, is essential for optimal performance and longevity.

Regular maintenance, including inspections and timely replacements, can prevent costly repairs and extend the life of your excavator.

Choosing the right type of tracks—rubber for flat surfaces and steel for rugged terrains—can significantly impact your machine’s efficiency.

Proper track tension is crucial; both loose and overly tight tracks can lead to operational issues like slippage and uneven wear.

Cleaning and lubricating the undercarriage after use helps reduce wear and ensures smooth operation across various terrains.

Investing in high-quality parts from reliable suppliers like YNF Machinery enhances the performance and reliability of your excavator.

Proactive maintenance not only improves your excavator’s efficiency but also leads to significant cost savings over time.

Different Types of Excavator Track Parts

Understanding the different types of excavator parts is crucial for maintaining the efficiency and longevity of your machine. The excavator undercarriage consists of several key components, each playing a vital role in the operation of the equipment. Let’s explore these main parts of an excavator and their functions.

Excavator Tracks

Excavator tracks are essential for providing mobility and stability to the machine. They come in two primary types:

Rubber Tracks

Rubber tracks offer versatility and are ideal for use on flat surfaces. They are quieter and cause less vibration compared to steel tracks, making them suitable for residential areas. However, they are less durable and can wear out faster, especially on rocky or debris-strewn job sites. Regular maintenance is crucial to extend their lifespan and prevent unexpected downtime.

Steel Tracks

Steel tracks are more durable and suitable for heavy-duty excavations, particularly in muddy or rocky environments. They provide better traction and are less likely to break down. However, they generate more noise and vibrations, which can be uncomfortable for the operator. Steel tracks also leave more marks on the surface, which might not be ideal for all job sites.

Sprockets

Sprockets are another critical component of the undercarriage of heavy equipment. They engage with the track chains to facilitate movement.

Function and Importance

Sprockets drive the tracks and ensure smooth operation. They play a crucial role in synchronizing the movement of the tracks with the engine’s power output.

Common Materials Used

Sprockets are typically made from high-strength steel to withstand the stress and wear they encounter during operation. This material choice ensures durability and longevity.

Rollers

Track rollers support the weight of the excavator and reduce friction as the tracks move. They are divided into two categories:

Top Rollers

Top rollers, also known as carrier rollers, help guide the track and maintain its alignment. They ensure that the track remains in place during operation.

Bottom Rollers

Bottom rollers bear the weight of the excavator and facilitate smooth movement over various terrains. They are crucial for distributing the machine’s weight evenly across the tracks.

By understanding these different parts of an excavator, you can ensure that your machine operates efficiently and effectively. Regular inspection and maintenance of these excavator track parts will help prevent costly repairs and extend the life of your equipment. For high-quality undercarriage parts, consider YNF Machinery as your preferred supplier.

Idlers

Idlers play a crucial role in the functionality of your excavator’s track system. They help guide the track chains and maintain proper tension, ensuring smooth operation.

Front Idlers

Front idlers are located at the front of the track assembly. They help guide the tracks and maintain tension, preventing them from sagging or derailing. By keeping the tracks aligned, front idlers ensure that your excavator moves efficiently across various terrains. Regular inspection of these idlers is essential to avoid unnecessary wear and tear, which can lead to costly repairs.

Rear Idlers

Rear idlers, positioned at the back of the track assembly, also contribute to maintaining track tension. They work in tandem with the front idlers to ensure the tracks remain taut and aligned. This alignment is vital for distributing the machine’s weight evenly, reducing stress on other excavator track parts. Proper maintenance of rear idlers helps prolong the life of your tracks and enhances the overall performance of your excavator.

Track Chains

Track chains are integral to the mobility of your excavator. They consist of individual links connected by pins and bushings, similar to a bicycle chain. These components endure substantial stress, so engineers design them to be robust for longevity and performance.

Link Assemblies

Link assemblies form the backbone of the track chains. They connect the track pads and allow for the smooth movement of the excavator. Each link must be strong enough to withstand the weight and force exerted during operation. Regular checks for wear and damage in the link assemblies can prevent unexpected breakdowns and extend the life of your excavator.

Pins and Bushings

Pins and bushings hold the link assemblies together, allowing for flexibility and movement. They enable the track to bend and flex as the excavator maneuvers over uneven terrain. Over time, these components can wear out due to friction and stress. Replacing worn pins and bushings is crucial to maintaining the efficiency and safety of your excavator.

Understanding these different types of excavator parts and their functions is essential for maintaining your machine’s efficiency and longevity. Regular maintenance and timely replacements of these parts of an excavator can prevent costly repairs and downtime. For high-quality undercarriage parts, consider YNF Machinery as your preferred supplier.

Functions of Different Parts of an Excavator

Understanding the functions of various excavator track parts is essential for maintaining your machine’s efficiency and performance. Each component plays a specific role in ensuring the smooth operation of your excavator.

Excavator Tracks

Excavator tracks are vital for the mobility and stability of your machine. They perform two primary functions:

Provide Traction

Tracks provide the necessary traction for your excavator to move across different terrains. Whether you’re working on muddy, rocky, or uneven surfaces, tracks ensure that your machine maintains grip and stability. This traction is crucial for preventing slippage and ensuring that your excavator can perform tasks efficiently.

Support Weight Distribution

Tracks also play a significant role in distributing the weight of the excavator evenly. By spreading the weight across a larger surface area, tracks help prevent the machine from sinking into soft ground. This weight distribution is essential for maintaining balance and stability during operation.

Sprockets

Sprockets are integral to the movement of the tracks. They have two main functions:

Drive the Track

Sprockets drive the tracks by engaging with the track chains. This engagement ensures that the tracks move in sync with the engine’s power output, allowing your excavator to move forward or backward smoothly.

Synchronize Movement

Sprockets also synchronize the movement of the tracks with the rest of the machine. This synchronization is crucial for maintaining the alignment and tension of the tracks, preventing derailment and ensuring efficient operation.

Rollers

Track rollers support the weight of the excavator and facilitate its movement. They serve two key functions:

Support Track Weight

Rollers bear the weight of the excavator, ensuring that the tracks remain in contact with the ground. This support is vital for maintaining stability and preventing excessive wear on the tracks.

Facilitate Smooth Movement

Rollers also facilitate the smooth movement of the tracks over various terrains. By reducing friction, they ensure that the tracks can move freely, enhancing the overall efficiency of your excavator.

By understanding the functions of these different types of excavator parts, you can ensure that your machine operates at its best. Regular maintenance and inspection of these components will help prevent costly repairs and extend the life of your equipment. For high-quality parts, consider YNF Machinery as your preferred supplier.

Idlers

Idlers play a pivotal role in the efficient operation of your excavator’s track system. These components are essential for maintaining the integrity and functionality of the tracks, ensuring that your machine performs optimally across various terrains.

Maintain Track Tension

Idlers are crucial for maintaining the correct tension in the track system. They work alongside the tensioner to ensure that the tracks remain taut. Proper tension prevents the tracks from sagging or slipping off, which can lead to operational inefficiencies or even damage. By keeping the tracks tight, idlers help distribute the machine’s weight evenly, reducing wear and tear on other parts of an excavator. Regular checks and adjustments of the idlers can prevent costly repairs and extend the lifespan of your equipment.

Guide Track Movement

In addition to maintaining tension, idlers guide the movement of the track chains. They ensure that the tracks stay aligned as the excavator maneuvers over rough and challenging terrain. This alignment is vital for preventing derailment and ensuring smooth operation. Idlers can be single or dual-flanged, with dual-flanged idlers offering enhanced stability and load distribution. This design further reduces the risk of detracking, providing a more reliable performance. By guiding the track movement, idlers contribute to the overall efficiency and safety of your excavator.

Understanding the role of idlers and other parts of an excavator is essential for maintaining your machine’s performance. Regular maintenance and inspection of these components will help you avoid unexpected downtime and costly repairs. For high-quality track idlers and other excavator parts, consider YNF Machinery as your preferred supplier.

Maintenance Practices for Excavator Track Parts

Proper maintenance of your excavator’s undercarriage is essential for ensuring its longevity and efficiency. By following a structured maintenance routine, you can prevent costly repairs and extend the life of your machine. Here are some key practices to keep your excavator in top condition.

Regular Inspection

Regular inspection forms the backbone of preventive maintenance. By routinely checking your excavator, you can identify potential issues before they escalate.

Check for Wear and Tear

Inspect the track components for signs of wear and tear. Look for cracks, breaks, or any unusual wear patterns on the track chains, rollers, and idlers. These parts endure significant stress during operation, so early detection of damage can save you from expensive repairs.

Monitor Track Tension

Maintaining the correct track tension is crucial for optimal performance. Loose tracks can lead to slippage, while overly tight tracks can cause excessive wear. Regularly check the tension and adjust as necessary to ensure smooth operation.

Cleaning and Lubrication

Keeping your excavator clean and well-lubricated is vital for its functionality. Dirt and debris can cause unnecessary wear on the undercarriage parts.

Remove Debris

After each use, remove any debris from the undercarriage. Pay special attention to the track area, as accumulated dirt can affect performance and lead to premature wear.

Apply Lubricants

Lubricate moving parts regularly to reduce friction and wear. Focus on areas like the rollers and idlers, which require consistent lubrication to function smoothly. Proper lubrication also helps in preventing rust and corrosion.

Replacement and Repairs

Timely replacement and repair of worn-out parts are essential for maintaining the efficiency of your excavator.

Identify Signs of Damage

Regularly inspect the undercarriage for signs of damage. Look for worn-out track chains, cracked rollers, or damaged idlers. Identifying these issues early allows you to address them before they lead to more significant problems.

Schedule Timely Replacements

Replace damaged or worn parts promptly. Using high-quality replacement parts ensures that your excavator continues to operate efficiently. For reliable replacement parts, consider YNF Machinery as your preferred supplier.

By adhering to these maintenance practices, you can enhance the performance and lifespan of your excavator. Regular inspections, cleaning, and timely replacements are key to effective heavy equipment maintenance. Keeping your undercarriage in excellent condition ensures that your excavator remains a valuable asset on any job site.

Common Issues and Troubleshooting in Excavator Tracks

Track Slippage

Track slippage can significantly impact the performance of your excavator. Understanding the causes and solutions can help you address this issue effectively.

Causes

Improper Track Tension: Loose tracks often lead to slippage. When the tension is not correctly adjusted, the tracks may not grip the surface adequately.

Worn Sprockets or Idlers: Sprockets and idlers play a crucial role in maintaining track alignment and tension. Worn components can cause the tracks to slip off.

Debris Accumulation: Dirt and debris can accumulate in the undercarriage, affecting the track’s ability to maintain traction.

Solutions

Adjust Track Tension: Regularly check and adjust the track tension to ensure it is neither too loose nor too tight. Proper tension helps maintain traction and prevents slippage.

Inspect and Replace Worn Parts: Regularly inspect sprockets and idlers for wear and replace them as needed. This maintenance ensures that the tracks remain aligned and functional.

Clean the Undercarriage: After each use, clean the undercarriage to remove any accumulated debris. Keeping the area clean helps maintain optimal track performance.

Uneven Wear

Uneven wear on excavator tracks can lead to reduced efficiency and increased maintenance costs. Identifying the causes and implementing solutions can help mitigate this issue.

Causes

Misaligned Tracks: Misalignment can cause one side of the track to wear faster than the other. This issue often arises from improper tension or damaged components.

Uneven Terrain: Operating on uneven or rocky surfaces can lead to uneven wear. The constant pressure on certain parts of the track accelerates wear.

Inadequate Maintenance: Neglecting regular maintenance can result in uneven wear. Components like rollers and idlers need regular checks to ensure they function correctly.

Solutions

Regular Alignment Checks: Conduct regular checks to ensure that the tracks are properly aligned. Adjust the tension and replace any damaged components to maintain alignment.

Operate on Suitable Terrain: Whenever possible, operate the excavator on even terrain. If uneven surfaces are unavoidable, adjust the operation technique to distribute wear evenly.

Implement a Maintenance Routine: Establish a routine maintenance schedule that includes inspecting and servicing rollers, idlers, and other track components. Regular maintenance helps prevent uneven wear and extends the life of your tracks.

By addressing these common issues, you can enhance the performance and longevity of your excavator tracks. Regular maintenance and timely troubleshooting are key to ensuring your machine operates efficiently. For high-quality replacement parts and expert advice, consider YNF Machinery as your preferred supplier.

Benefits of Proper Track Maintenance

Proper maintenance of your excavator’s tracks offers numerous benefits that enhance both performance and cost-efficiency. By investing time in regular upkeep, you ensure that your machine operates at its best, minimizing downtime and extending its lifespan.

Enhanced Performance

Maintaining your excavator’s tracks leads to improved efficiency and reduced downtime. Here’s how:

Improved Efficiency

Regular maintenance ensures that your excavator tracks remain in optimal condition. Clean and well-maintained tracks provide better traction and stability, allowing your machine to move smoothly across various terrains. This efficiency translates into faster job completion and increased productivity on the job site.

Reduced Downtime

By addressing minor issues before they escalate, you significantly reduce the risk of unexpected breakdowns. Regular inspections and timely repairs keep your excavator running smoothly, minimizing the time spent in the shop for repairs. As a result, your machine stays operational, generating rental fees and keeping projects on schedule.

Cost Savings

Proper track maintenance also leads to substantial cost savings over time. Here’s how it impacts your budget:

Lower Repair Costs

Routine maintenance helps identify and fix small problems before they become major issues. By preventing significant damage, you avoid costly repairs and replacements. This proactive approach not only saves money but also ensures that your excavator remains a reliable asset.

Extended Equipment Lifespan

Consistent care and attention to your excavator’s undercarriage extend the life of your equipment. By keeping the tracks and other components in good condition, you maximize the longevity of your machine. This extended lifespan means you get more value from your investment, reducing the need for frequent replacements.

“Proper maintenance will help extend undercarriage life and lower operating costs by keeping the excavator on the jobsite moving material and generating rental fees, not in the shop for repairs.” – Amy Van Hook

Incorporating these maintenance practices into your routine ensures that your excavator remains a valuable and efficient tool. For high-quality parts and expert advice, consider YNF Machinery as your preferred supplier.

YNF Machinery’s Role in Providing Excavator Track Parts

YNF Machinery stands as a reliable partner for those seeking high-quality excavator track parts. With over 35 years of experience, YNF Machinery has built a reputation for delivering durable and efficient components that enhance the performance of your heavy equipment. Let’s explore some of the key products offered by YNF Machinery.

YNF Machinery’s Excavator Couplings

Excavator couplings play a vital role in ensuring efficient power transmission between the engine and hydraulic pump system. YNF Machinery offers a comprehensive range of couplings designed to withstand tough working conditions. These couplings are crafted from high-quality materials, ensuring durability and easy maintenance. By choosing YNF Machinery’s couplings, you can minimize downtime and maximize productivity on the job site.

High-Quality Materials: YNF Machinery uses advanced manufacturing processes to produce couplings that offer exceptional durability and performance.

Easy Installation: The design of these couplings allows for straightforward installation and maintenance, reducing operational interruptions.

Versatility: Available in various types, including Centaflex-A and Bowex, these couplings cater to different applications and provide flexibility and vibration isolation.

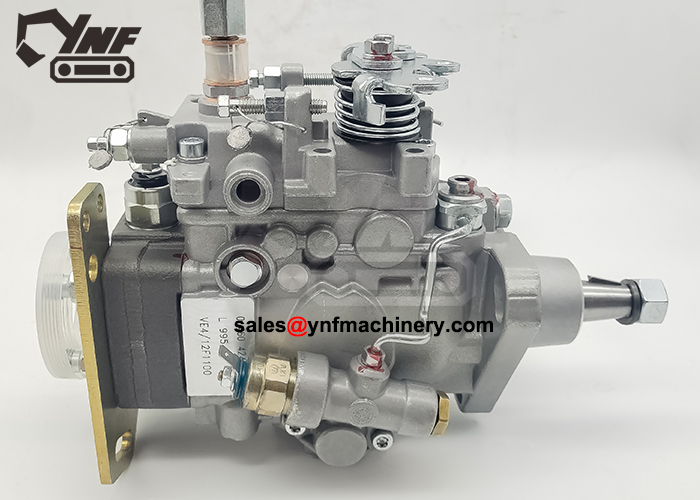

YNF Machinery’s Excavator Engine Parts

The engine is the heart of any excavator, and YNF Machinery provides reliable engine parts to keep your machine running smoothly. These parts are essential for powering heavy-duty construction machines, ensuring they can handle demanding tasks with ease.

Durability and Efficiency: YNF Machinery’s engine parts, such as pistons and crankshafts, are designed to withstand high temperatures and pressure, ensuring long-lasting performance.

OEM and Aftermarket Options: Customers can choose from a wide selection of parts that meet or exceed OEM standards, providing flexibility and choice.

Cost-Effectiveness: By investing in high-quality engine parts, you reduce downtime and repair costs, ultimately saving money in the long run.

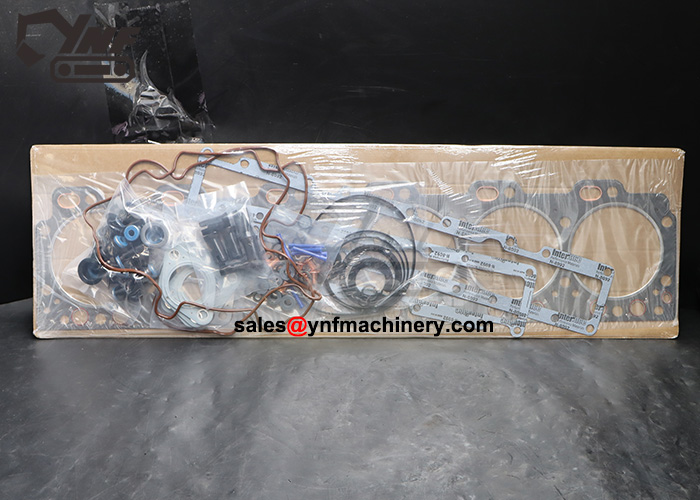

YNF Machinery’s Hydraulic Cylinder Seal Kits

Hydraulic Cylinder Seal Kits are crucial for preventing oil leaks and ensuring smooth operation of excavator cylinders. YNF Machinery offers seal kits that are indispensable for maintaining the efficiency and longevity of your equipment.

High-Grade Materials: These seal kits are made from materials like NBR and FKM, ensuring rigidity and flexibility to withstand shocks and vibrations.

Precision Manufacturing: The kits are available in accurate sizes and thicknesses, allowing for perfect alignment and preventing leakage.

Global Availability: Manufactured to meet international standards, these seal kits are available for worldwide delivery, ensuring customers everywhere can benefit from their quality.

“Proper maintenance will help extend undercarriage life and lower operating costs by keeping the excavator on the jobsite moving material and generating rental fees, not in the shop for repairs.” – Amy Van Hook

By choosing YNF Machinery as your preferred supplier, you gain access to high-quality parts that enhance the efficiency and reliability of your excavator. Whether you need couplings, engine parts, or seal kits, YNF Machinery provides the components you need to keep your operations running smoothly.

Understanding excavator track parts is crucial for maintaining your machine’s efficiency and longevity. Each part of an excavator plays a vital role in ensuring smooth operation across various terrains. Regular maintenance is essential to prevent unexpected downtime and extend the life of your equipment. By proactively inspecting and caring for these components, you enhance traction, stability, and overall performance. Proper upkeep not only improves return on investment but also reduces the total cost of ownership. For high-quality parts and expert advice, consider YNF Machinery as your preferred supplier.

FAQ

What are the key components of an excavator’s track system?

The track system of an excavator includes several essential components. These are excavator tracks, sprockets, rollers, idlers, and track chains. Each part plays a vital role in ensuring the machine’s mobility and stability. Regular maintenance of these components is crucial for optimal performance.

How do I choose between rubber and steel tracks?

Your choice between rubber tracks and steel tracks depends on your work environment. Rubber tracks are ideal for flat, residential areas due to their quieter operation and reduced vibration. Steel tracks, on the other hand, offer durability and better traction on rocky or muddy terrains. Consider the nature of your job site when making a decision.

Why is regular maintenance of excavator tracks important?

Regular maintenance of excavator tracks prevents unexpected downtime and costly repairs. By inspecting and servicing components like rollers and idlers, you ensure that your machine operates efficiently. Proper maintenance also extends the lifespan of your equipment, providing better return on investment.

How can I prevent track slippage?

To prevent track slippage, ensure proper track tension and regularly inspect sprockets and idlers for wear. Clean the undercarriage after each use to remove debris that might affect traction. These practices help maintain optimal track performance.

What causes uneven wear on excavator tracks?

Uneven wear on tracks can result from misaligned tracks, operating on uneven terrain, or inadequate maintenance. Regular alignment checks and a consistent maintenance routine can mitigate this issue. Operating on suitable terrain also helps distribute wear evenly.

How does YNF Machinery support excavator owners?

YNF Machinery provides high-quality excavator parts, including excavator couplings, engine parts, and hydraulic cylinder seal kits. With over 35 years of experience, YNF Machinery offers reliable products and exceptional customer service. Their competitive pricing and fast shipping ensure you receive the parts you need promptly.

What should I look for when inspecting track components?

When inspecting track components, check for signs of wear and tear, such as cracks or breaks in the track chains, rollers, and idlers. Monitor track tension to ensure it is neither too loose nor too tight. Early detection of issues can save you from expensive repairs.

Can YNF Machinery parts fit different excavator brands?

Yes, YNF Machinery offers parts compatible with various excavator brands, including ISUZU, CUMMINS, Yanmar, Komatsu, Kobelco, and Caterpillar. Their wide selection ensures you find the right parts for your specific needs.

How do hydraulic cylinder seal kits benefit my excavator?

Hydraulic cylinder seal kits prevent oil leaks and ensure smooth operation of excavator cylinders. YNF Machinery’s seal kits are made from high-grade materials, providing durability and flexibility. Properly functioning seal kits enhance the efficiency and longevity of your equipment.

Why should I choose YNF Machinery as my supplier?

YNF Machinery stands out for its commitment to quality and customer satisfaction. With a reputation built over 35 years, they offer reliable parts at competitive prices. Their knowledgeable team provides excellent service, ensuring you receive the support you need for your excavator maintenance.