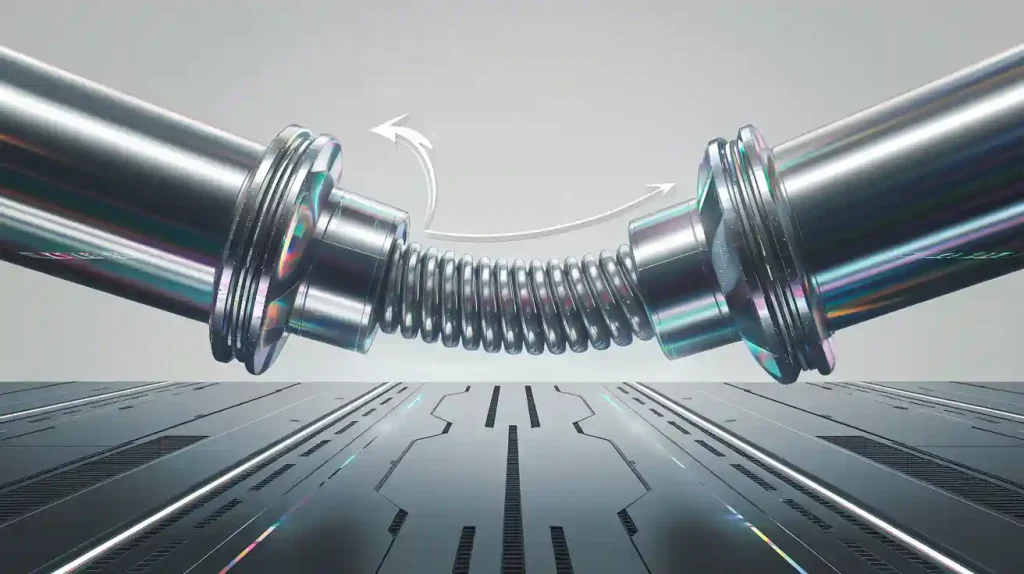

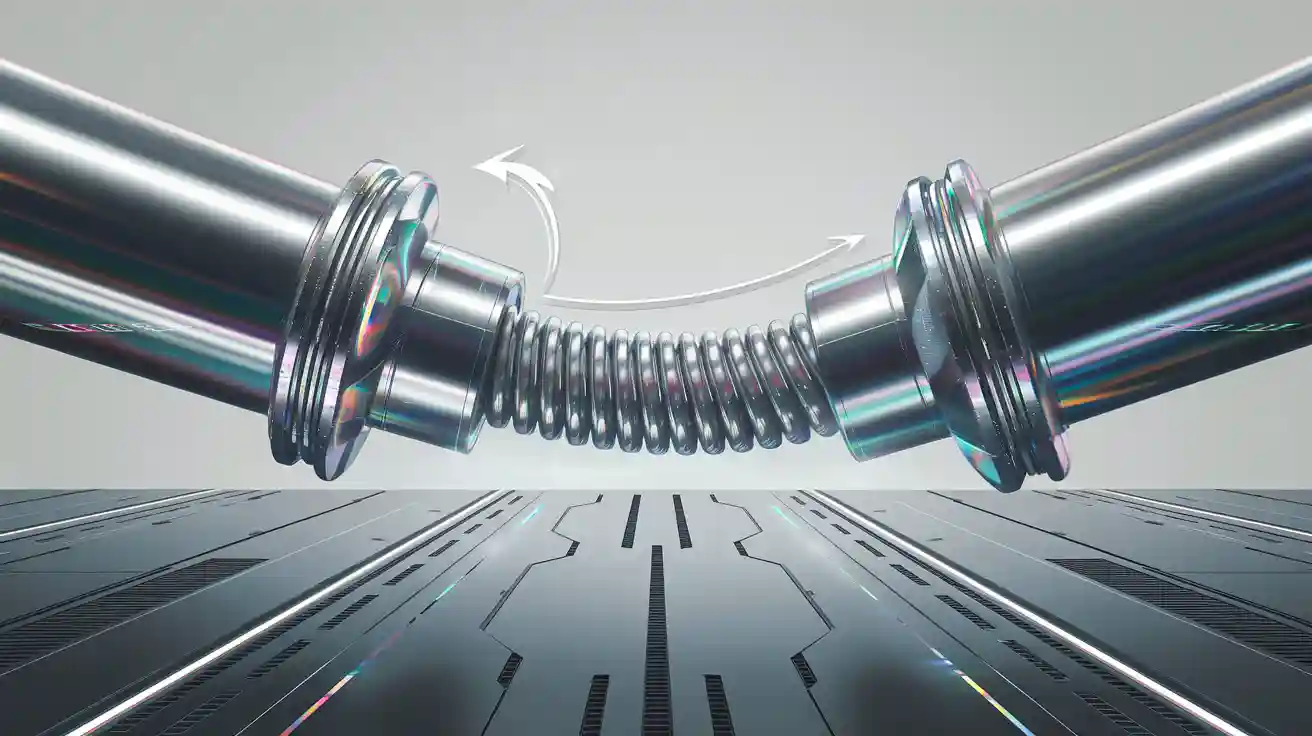

A torsional coupling joins two spinning shafts. It lets them send torque to each other. It also helps lower bad vibrations. You use this device to keep your equipment safe from sudden shocks. It helps machines work without problems. Knowing how torsional couplings work helps you stop breakdowns. It keeps your machines working well.

Here’s why torsional couplings are important in your daily work:

Role of Torsional Couplings | Description |

|---|---|

Transmitting power | Couplings send power from the motor to the equipment. This helps things work well and fast. |

Absorbing shock and vibration | They take in shocks and vibrations. This keeps equipment safe and lowers the chance of breaking. |

Compensation for misalignment | Couplings handle misalignment. This stops early wear and keeps equipment from breaking. |

Enabling maintenance and repairs | They make it easy to take things apart for fixing. This saves time and keeps things working well. |

Key Takeaways

Torsional couplings join two spinning shafts. They let the shafts share torque. They help lower bad vibrations.

These couplings keep machines safe from shocks. This stops breakdowns and helps machines last longer.

Picking the right elastomer type and hardness is very important. It helps control vibrations well in torsional couplings.

Checking torsional couplings often helps find wear early. This lowers repair costs and stops surprise failures.

Torsional couplings are needed in many industries. They are used in cars and building work. They help machines work well in hard situations.

Torsional Coupling Basics

Definition

A torsional coupling is a tool that links two spinning shafts. It moves torque from one shaft to the other. This tool lets both shafts spin together but allows some twisting. The main job is to handle twisting forces when machines work.

Torsional rigidity means how much a shaft or coupling resists twisting when torque is used. There is a formula: θ = TL/GJ. θ is the angle of twist. T is the torque. L is the shaft length. G is the material’s modulus of rigidity. J is the polar moment of inertia. If G and J are bigger, the shaft twists less with the same torque. This idea helps engineers pick the right materials and shapes for torsional couplings.

Think of a torsional coupling like a spring between two spinning rods. It lets the rods turn together but also takes in some twisting energy. This keeps the system safe and steady.

Purpose

A torsional coupling fixes many problems in spinning machines. Its main job is to stop torsional vibrations. These are back-and-forth twists along the shaft. If you do not control them, parts can wear out fast or break.

Torsional couplings help you:

Lower bad vibrations that hurt your equipment.

Stop drivetrain parts from failing early.

Prevent sudden breakdowns from stiff connections.

Studies show special torsional couplings, like magnetorheological dampers, can cut vibration by over 15%. They also lower angular acceleration by more than 22% at certain speeds. Laminated couplings help control vibration and lower damage risk.

Torsional couplings also help you adjust your system. You can set critical speeds away from normal working speeds. This makes machines last longer and work better.

Using a torsional coupling protects machines from shocks and twisting forces. This means less time fixing things and fewer repairs.

How Torsional Coupling Works

Operating Principle

A torsional coupling acts like a shock absorber. It uses springs and damping parts to control twisting. When the machine spins, vibrations move along the shaft. The spring pushes back against these vibrations. The damping part takes in energy and turns it into heat. This helps stop the shaking.

Torsional vibration dampers lower vibrational energy.

Springs push back to fight vibrations.

Damping parts soak up energy and release heat.

These features help stop early wear and damage.

Think about jumping on a trampoline. The springs let you bounce but also slow you down. They keep you safe. A torsional coupling lets shafts twist a little. It stops them from shaking too much.

You must watch out for critical speeds. Critical speed is when your machine spins at its natural frequency. If you reach this speed, the machine can shake a lot. It might break. Torsional couplings help you avoid these dangerous speeds.

Every shaft has a natural frequency.

If you run at this speed, resonance happens.

Vibrations get worse.

Couplings change the natural frequencies.

They help you avoid resonance.

This keeps your equipment safe and working longer.

Key Components

A torsional coupling has important parts. Each part helps control vibration and protect your machine.

Springs: These let the shafts twist a little.

Damping elements: These soak up energy and lower vibration.

Elastomeric elements: These rubber-like parts help with vibration dampening.

Elastomeric elements come in different types. Their material affects how well they dampen vibrations. Here is a table showing some common elastomer types:

Elastomer Type | Shore Hardness | Torsional Rigidity | Damping Capacity |

|---|---|---|---|

Type B, D, E | 64-65 Sh D | High | Low |

Type D | 65 Sh D | High | Limited |

Type E (HYTREL) | Varies | Varies | Varies |

If you pick a harder elastomer, you get more rigidity. You get less vibration dampening. Softer elastomers soak up more vibration. They may twist more. You need to choose the right type for your machine.

Tip: Always check the elastomer type and hardness before you install a torsional coupling. This helps you get the best vibration control.

Types

There are many types of torsional couplings. Each type has a special design. Each works best in certain jobs. Here is a table to help you compare them:

Type of Coupling | Design Characteristics | Applications |

|---|---|---|

Beam Couplings | Helical cuts, handles parallel misalignments up to 0.025 inch, angular up to 7° | Motion control, low torque |

Bellows Couplings | Many metal folds, high torsional stiffness | Motion control |

Chain Couplings | Uses chain sprockets, allows 2° angular and 0.015 inch parallel misalignment | Power transmission |

Jaw Couplings | Multi-jawed hubs with elastomeric spiders, no backlash | Motion control, light power |

Diaphragm Couplings | Flexible metal discs, high torque transmission | High power transmission |

Disc Couplings | Thin metal discs, handles angular misalignment | Power transmission |

Gear Couplings | Needs lubricant, allows 0.01-0.02 inch parallel and 2° angular misalignment | High torque applications |

Grid Couplings | Spring-like parts, absorbs shock, no lubricant needed | Power transmission |

Oldham Couplings | Sliding part design, handles high parallel misalignment | Various applications |

Schmidt Couplings | Made for offset shafts, compact design | Papermaking, printing |

Clamping Couplings | Rigid, no misalignment help, cheap | Slow or off-and-on shafting |

Some couplings, like flexible disc pack couplings, are great for lowering shaft vibration. They protect bearings. These couplings do not need lubrication. They last a long time. They can handle many load cycles. They help your equipment stay reliable.

Note: When you pick a torsional coupling, look at the type, design, and job. This helps you match the coupling to your machine’s needs.

Applications

Industrial

Torsional couplings are used in many industries. They help machines work better and last longer. These devices can handle hard jobs. They work well even in tough places. You can trust torsional couplings to be strong and flexible.

Industrial Sector | Typical Applications |

|---|---|

Marine | Propulsion, auxiliary drives |

Compressors | Various industrial applications |

Generator Sets | Power generation |

Pumps | Fluid transfer and management |

Rail Traction | Train propulsion systems |

Steel Mills | Processing and manufacturing |

Cranes | Lifting and material handling |

Conveyors | Material transport |

Mining | Extraction and processing |

Paper Machinery | Production processes in paper manufacturing |

Construction | Heavy machinery and equipment |

In a gas pipeline compressor, engineers used the right torsional coupling. This stopped vibration problems. You can avoid torsional resonance. Your machines stay safe and work well. If you pick a coupling with the right stiffness, you protect your equipment from harm.

Automotive

Cars and trucks use torsional couplings to keep driveline parts safe. These couplings take in shocks and lower vibrations. They help your car run quietly and smoothly.

Spring couplings lower torsional vibrations and stop resonance.

Gears and bearings are safe from too much force and shock.

Cellasto® materials help give smoother power and less noise.

You can change damping for a better ride.

Geislinger Couplings last long and dampen vibration well.

HYGUARD® torque limiting couplings stop overload and give flexible protection.

Torsional couplings in cars and trucks help them stay reliable. You get less noise, longer part life, and better performance.

Agriculture & Construction

Tractors, harvesters, and construction machines use torsional couplings. These couplings handle high torque and tough jobs. They keep your equipment working in hard places.

Benefit | Description |

|---|---|

High Torque Capacity | Handles heavy loads in power transmission |

Zero-Backlash | Keeps connections accurate and repeatable |

Excellent Torsional Stiffness | Prevents twisting under load |

Misalignment Compensation | Reduces stress and extends component life |

High Speed/Low Inertia | Improves motion control and system tuning |

Corrosion Resistance | Works well in wet, dirty, or corrosive places |

Simple Installation | Makes setup easy and lowers maintenance costs |

You need a coupling that lasts and works with changing loads. New designs limit elastic energy and keep your machines safe during starts and stops.

If you want strong torsional couplings for these jobs, you can pick YNF Machinery. Their products work well and last a long time.

Torsional Coupling Benefits

Vibration Dampening

Torsional couplings help control vibration in machines. The right coupling lowers the chance of bad vibrations. These vibrations can hurt machine parts. Elastomeric couplings are good for stopping vibration. They do not need much care and cost less than other types. Metallic couplings last longer and can handle more torque. But they do not stop vibration as well as elastomeric ones.

Coupling Type | Advantages | Limitations |

|---|---|---|

Elastomeric Couplings | Needs little care, saves money | Wears out in tough places |

Metallic Couplings | Handles lots of torque, lasts long | Does not dampen vibration much |

Jaw Couplings | Fixes misalignment, lowers shock | N/A |

Torsional Couplings | Very accurate, works with high torque and speed | N/A |

Magnetic Couplings | Stops vibration well | Can’t handle much torque |

Torsional couplings also lower sudden force spikes. If you use a coupling with good damping, your machine runs smoother. It lasts longer. You avoid quick jumps in force that wear out parts.

Shock Absorption

You need a coupling that can take shocks and keep equipment safe. Most torsional couplings have two metal hubs and a soft part. The soft part is made from rubber or plastic. It takes the force and turns it into heat. This helps cushion each shock and keeps machines safe.

Most elastomers soak up a little energy with each torque pulse. The energy becomes heat. This cushions shocks and lowers vibration.

Common soft parts are:

Elastomeric polymers like rubber

Plastic materials

This design helps machines handle sudden loads. It stops damage. Machines run smoother and make less noise.

Equipment Protection

Torsional couplings keep equipment safe and help it last longer. High-gain rubber couplings use strong aluminum hubs and special rubber. This rubber lowers vibration. It gives better torsional rigidity and damping. Tests show this rubber does not break down over time. Your system stays reliable.

High-gain rubber couplings help equipment recover faster after shocks.

These couplings make machines last longer and lower the chance of breakdowns.

You also save money on maintenance. Torsional couplings let you plan checks and replacements. You can find wear early and fix problems before they stop your machine. This saves money and keeps machines working well.

Tip: Check your couplings often. This helps you avoid surprise failures and keeps costs low.

Torsional couplings join spinning shafts together. They help absorb shock and lower vibration. You find them in cars, factories, and big machines. These couplings help machines last longer and work safer.

You do less maintenance because couplings fix misalignment. They also lower vibration, so systems work better.

New designs use smart materials and sensors. This helps machines perform better.

Some problems are heat in flexible couplings. You also need to avoid vibration at certain speeds.

Future Trend | Description |

|---|---|

Smart Integration | Sensors check couplings for health while working. |

Sustainability | Green, strong materials are used more often. |

For more information, look at “Couplings and Joints: Design, Selection & Application” or read about how spinning machines work.

FAQ

What does a torsional coupling do in a machine?

A torsional coupling links two spinning shafts. It moves torque from one shaft to another. It also helps lower bad vibrations. This makes your machine work better. It keeps important parts safe.

How do you choose the right torsional coupling?

Check your machine’s torque and speed needs. Think about how much misalignment you have. Look at the elastomer type and how hard it is. YNF Machinery has many choices for you.

Can torsional couplings fix misalignment?

Yes, torsional couplings can handle small misalignments. They help protect your shafts. Your equipment wears out less.

How often should you inspect torsional couplings?

Check your couplings every few months. Look for any damage or wear. Regular checks help stop sudden problems. Your machines keep working well.

Where can you buy reliable torsional couplings?

You can get strong torsional couplings from YNF Machinery. They sell products for many jobs and industries.