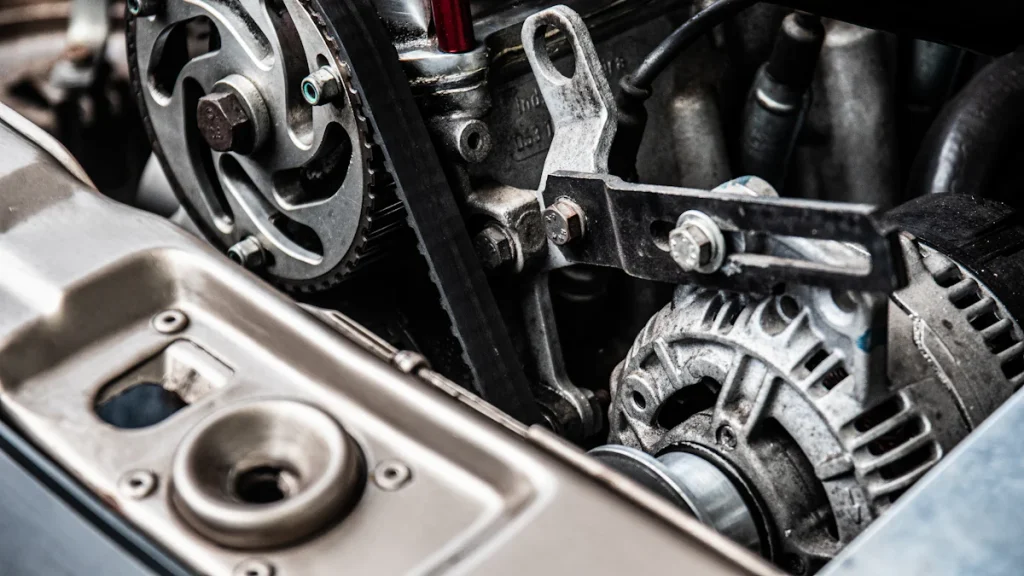

Choosing the right parts for your excavator ensures smooth operation and reduces costly downtime. Isuzu excavator engine parts, known for their durability and precision, play a vital role in maintaining your machine’s efficiency. High-quality components extend the lifespan of your equipment and improve its performance under demanding conditions. A systematic approach to selecting these parts helps you avoid compatibility issues and ensures cost-effective solutions. By focusing on quality and fit, you can keep your excavator running reliably, even in the toughest environments.

Key Takeaways

Identify your excavator’s model and engine specifications to ensure compatibility when selecting parts.

Use your excavator’s manual to find accurate part numbers and descriptions, minimizing the risk of ordering incorrect components.

Research and choose reputable suppliers who specialize in Isuzu engine parts to guarantee quality and authenticity.

Consider the benefits and risks of new, used, and remanufactured parts to make informed purchasing decisions based on your budget.

Regularly inspect and maintain detailed records of part purchases and performance to extend the lifespan of your excavator.

Prioritize quality over low prices to avoid costly repairs and ensure reliable performance in demanding conditions.

Plan for long-term costs by investing in high-quality parts that reduce maintenance frequency and enhance overall efficiency.

Identifying Your Excavator’s Needs

Understanding Your Excavator Model and Specifications

Locate the model number and serial number of your Isuzu excavator.

To begin, you need to identify the model number and serial number of your Isuzu excavator. These details are crucial for finding the right replacement parts. Typically, you can find this information on a metal plate attached to the machine. The plate is often located near the operator’s cabin or on the engine itself. If you cannot locate it, refer to your excavator’s manual for guidance. Knowing these numbers ensures that the parts you select will fit your machine perfectly.

Identify the engine type and its specific requirements.

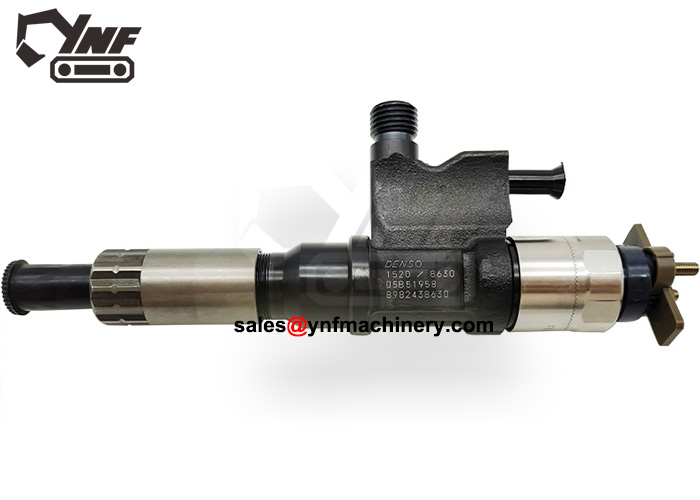

Next, determine the engine type used in your excavator. Isuzu engines are known for their reliability and durability, with popular models like the 6BG1, 4HK1, and 6HK1. Each engine type has unique specifications and requirements. For example, some engines use a Common Rail injection system, which enhances fuel efficiency and reduces emissions. Understanding your engine’s specific needs helps you choose components that maintain optimal performance. Always consult your excavator parts diagram or manual to confirm the engine’s details.

Determining the Required Replacement Parts

Use the machine’s manual to find part numbers and descriptions.

Your excavator’s manual is an invaluable resource when identifying replacement parts. It includes an excavator parts diagram that lists part numbers and descriptions for every component.

Assess whether the part is for repair, replacement, or upgrade.

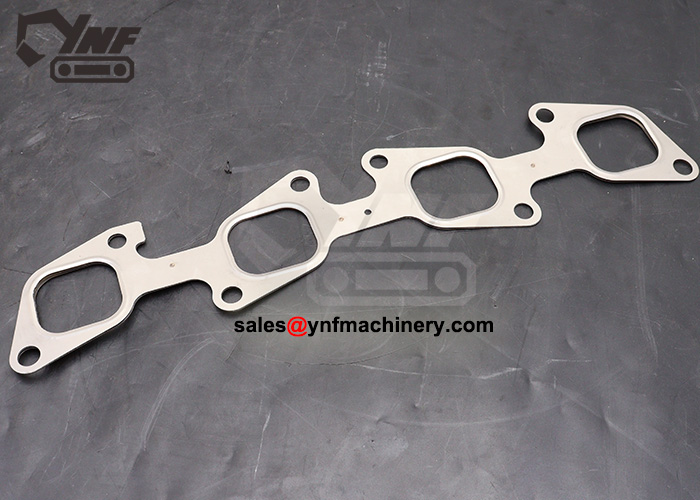

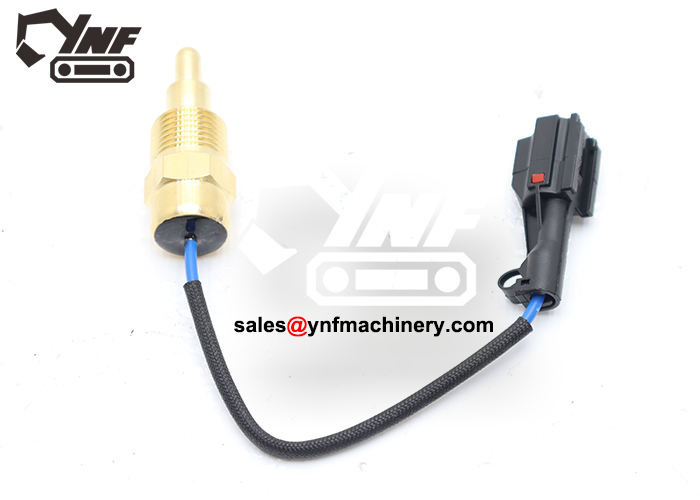

Before purchasing, evaluate the purpose of the part. Are you repairing a damaged component, replacing a worn-out one, or upgrading to improve performance? For repairs, you might need a single component, such as a gasket or injector. Replacements often involve larger parts like turbochargers or water pumps. Upgrades, on the other hand, may include advanced components designed for better efficiency or durability. Understanding the purpose helps you make informed decisions and prioritize your excavator’s needs effectively.

Researching and Verifying Suppliers

Finding a reliable supplier is a critical step when purchasing replacement parts for your Isuzu excavator.

Choosing Reputable Suppliers for Isuzu Excavator Engine Parts

Evaluate online reviews and testimonials for supplier credibility.

Start by researching online reviews and testimonials to assess the credibility of potential suppliers. Look for feedback from other excavator owners who have purchased replacement parts. Positive reviews often highlight timely delivery, excellent customer service, and the quality of the parts provided. For example, Diesel Parts Direct has earned a strong reputation for offering dependable Isuzu engine parts with a 6-month warranty and satisfaction guarantee. Such reviews can give you confidence in your purchasing decision.

Confirm the supplier’s expertise in Isuzu engine parts.

A supplier specializing in Isuzu engine parts is more likely to provide components that fit your excavator perfectly. Companies like Hamilton Power Solutions, known for their extensive inventory of Isuzu diesel engine parts, demonstrate expertise in this field. Their focus on Isuzu products ensures they understand the specific needs of your machine. Always verify that the supplier has experience with Isuzu engines and can guide you in selecting the right parts for your excavator.

Ensuring Authenticity and Certifications

Look for genuine or OEM parts with proper certifications.

When purchasing replacement parts, prioritize genuine or OEM parts with proper certifications.

Verify the supplier’s guarantees of quality and authenticity.

A reputable supplier will stand behind the quality of their products. Look for guarantees or return policies that protect your investment. Suppliers like Diesel Parts Direct and Hamilton Power Solutions emphasize customer satisfaction by offering warranties and guarantees on their Isuzu engine parts. These policies reflect their confidence in the quality and authenticity of the components they provide. Before finalizing your purchase, confirm that the supplier offers similar assurances.

By thoroughly researching and verifying suppliers, you can ensure that the parts you purchase meet the highest standards. This step not only protects your excavator but also saves you time and money in the long run.

Exploring Part Options for Replacement

Understanding these options helps you make informed decisions to keep your excavator running efficiently.

New Isuzu Excavator Engine Parts

Benefits of new parts, including reliability and warranty.

New engine replacement parts provide unmatched reliability and performance. These parts are manufactured to meet the highest standards, ensuring they fit perfectly with your excavator. With new parts, you can expect consistent performance, reduced downtime, and enhanced durability. Most new parts come with warranties, offering peace of mind and protection against defects. For example, a new turbocharger or fuel pump guarantees optimal efficiency, which is critical for heavy equipment replacement parts.

When to prioritize new parts over other options.

You should prioritize new parts when reliability and long-term performance are your top concerns. If your excavator arm or excavator bucket experiences frequent wear and tear, new parts ensure durability under demanding conditions. New parts are also ideal for critical components like the excavator final drive or engine systems, where failure could lead to significant downtime. Investing in new parts minimizes risks and ensures your excavator operates at peak efficiency.

Used Excavator Engine Parts

Cost advantages of used parts.

Used parts offer a cost-effective solution for replacing components in your excavator. These parts are often significantly cheaper than new ones, making them an attractive option for budget-conscious operators. For non-critical components like the excavator cab or excavator boom, used parts can provide adequate performance without breaking the bank. By choosing used parts, you can save money while keeping your machine operational.

Risks and considerations when purchasing used parts.

While used parts are affordable, they come with potential risks. These parts may have unknown wear or damage, which could affect their performance and lifespan. Compatibility issues are another concern, especially if the part’s history is unclear. Always inspect used parts thoroughly before purchasing. Verify their condition and ensure they match your excavator’s specifications. For essential components like the excavator arm or engine systems, consider whether the cost savings outweigh the potential risks.

Remanufactured Parts for Excavators

How remanufactured parts balance cost and quality.

Remanufactured parts strike a balance between affordability and reliability. These parts are rebuilt to meet or exceed OEM standards, ensuring they perform like new. For example, a remanufactured fuel pump or water pump undergoes rigorous testing to guarantee quality. Remanufactured parts offer a cost-effective alternative to new parts while maintaining high performance, making them a popular choice for heavy equipment replacement parts.

Ensuring remanufactured parts meet industry standards.

To ensure quality, always purchase remanufactured parts from reputable suppliers. Look for certifications or guarantees that confirm the parts meet industry standards. For critical components like the excavator final drive or engine systems, verify that the remanufactured parts have undergone thorough testing. By choosing reliable suppliers, you can trust that these parts will deliver the performance and durability your excavator requires.

Exploring these options allows you to choose the best replacement parts for your excavator. Whether you opt for new, used, or remanufactured parts, understanding their benefits and limitations ensures your machine remains efficient and reliable.

Ensuring Compatibility and Quality

replacement parts you choose are compatible with your excavator is essential for maintaining its performance and longevity.

Matching Part Numbers and Specifications

Cross-check part numbers with the excavator’s manual.

Your excavator’s manual is an indispensable tool when verifying compatibility. It contains detailed information about part numbers and specifications for every component. Before purchasing a replacement part, locate its corresponding part number in the manual. Compare this number with the one provided by the supplier to confirm a match. This step eliminates guesswork and ensures that the part will fit seamlessly into your machine. For example, if you need a new fuel pump, the manual will guide you to the exact part number required for your excavator model.

Consult experts or use online tools for compatibility checks.

When in doubt, seek advice from professionals who specialize in Isuzu diesel engines or excavator maintenance. Mechanics who diagnose and repair Isuzu engines can provide valuable insights into selecting the right replacement parts. Their hands-on experience with various components makes them a reliable source of guidance. Additionally, many suppliers offer online tools that allow you to input your excavator’s model and engine details to verify compatibility. These tools simplify the process and reduce the risk of purchasing incorrect parts. Always double-check the results with your manual or consult an expert for added assurance.

Verifying Quality Standards for Excavator Engine Parts

Look for ISO or other industry certifications.

Quality certifications, such as ISO standards, serve as a benchmark for the reliability and durability of replacement parts. When shopping for excavator engine parts, prioritize components that meet these certifications. Certified parts undergo rigorous testing to ensure they meet industry standards for performance and safety. For instance, an ISO-certified turbocharger guarantees optimal efficiency and durability, making it a dependable choice for your excavator. Always ask the supplier for documentation that verifies the part’s compliance with these standards.

Inspect parts for wear or damage (if used or remanufactured).

If you opt for used or remanufactured parts, a thorough inspection is crucial. Examine the part for visible signs of wear, such as cracks, rust, or deformation. Confirm that the dimensions, weight, and other specifications align with your excavator’s requirements. Technicians at your chosen provider can assist with this process. As they recommend, visually inspect the part at the dealer to ensure it is free of damage and meets the necessary criteria. This step helps you avoid potential issues that could arise from installing a substandard component.

By carefully matching part numbers, consulting experts, and verifying quality standards, you can confidently select replacement parts that enhance your excavator’s performance. These measures protect your investment and ensure your machine operates efficiently for years to come.

Budgeting and Cost-Effectiveness

Balancing Quality and Price for Excavator Engine Parts

Avoid overly cheap parts that may compromise quality.

When selecting replacement parts for your excavator, prioritize quality over low prices. Cheap parts might seem like a cost-saving option, but they often lack durability and reliability. Inferior components can lead to frequent breakdowns, increased maintenance costs, and reduced machine efficiency. High-quality parts, on the other hand, ensure better performance and longer service life. For example, original spare parts not only extend engine life but also improve fuel efficiency and reliability. Investing in quality parts minimizes the risk of unexpected failures, saving you money in the long term.

Compare prices across multiple suppliers for the best deal.

To make a cost-effective purchase, compare prices from different suppliers. Research reputable suppliers who specialize in excavator engine parts and evaluate their offerings. Look for competitive pricing without compromising on quality. Some suppliers may offer discounts or bundle deals for bulk purchases, which can further reduce costs. By comparing options, you can find the best deal that meets your budget while ensuring the parts are reliable and compatible with your excavator. Always verify the supplier’s credibility and product authenticity before finalizing your purchase.

Planning for Long-Term Costs

Consider maintenance and potential repair costs.

When budgeting for replacement parts, factor in the long-term costs of maintenance and repairs. High-quality parts may have a higher upfront cost, but they reduce the frequency of repairs and replacements. This translates to lower maintenance expenses over time. Additionally, reliable parts help maintain your excavator’s performance, preventing costly downtime. Scarcity of certain components can also increase repair costs, as sourcing rare parts often requires more time and effort. Planning ahead ensures you allocate resources effectively and avoid unexpected expenses.

Invest in high-quality parts to reduce future expenses.

Investing in high-quality replacement parts is a smart financial decision. These parts offer durability, better performance, and warranty protection, which safeguard your investment. For instance, original components designed for your excavator provide optimal compatibility and efficiency. They also reduce the risk of premature wear and tear, extending the lifespan of your machine. By choosing reliable parts, you minimize the need for frequent replacements and repairs, ultimately lowering your overall operating costs. High-quality parts not only enhance your excavator’s performance but also provide peace of mind.

Maintenance and Record-Keeping

Proper maintenance and accurate record-keeping are essential for ensuring the longevity and efficiency of your excavator. By staying organized and proactive, you can prevent unexpected breakdowns and maintain optimal performance.

Tracking Purchases and Maintenance Logs

Maintain detailed records of part purchases and installation dates.

Keeping a detailed log of all part purchases and installation dates is crucial. Record the part name, supplier, purchase date, and installation date. This information helps you track the lifespan of each component and plan for future replacements. For example, if you replace a fuel pump, noting the installation date allows you to monitor its performance over time. Organized records also make it easier to identify patterns in wear and tear, helping you address recurring issues promptly.

“Technicians recommend maintaining a comprehensive log for every replacement part. This practice ensures you can quickly reference past purchases and avoid unnecessary delays during repairs.”

Use logs to monitor part performance over time.

Regularly reviewing your maintenance logs provides valuable insights into your excavator’s performance. Compare the expected lifespan of parts with their actual performance. If a specific component fails prematurely, investigate the cause and consider alternative suppliers or higher-quality options. Monitoring part performance also helps you identify trends, such as frequent failures in certain areas, allowing you to take preventive measures. This proactive approach minimizes downtime and keeps your excavator running efficiently.

Scheduling Regular Inspections for Excavator Engine Parts

Conduct routine checks to identify wear and tear early.

Routine inspections are vital for detecting wear and tear before it leads to major issues. Examine critical components like the engine, hydraulic systems, and moving parts for signs of damage or deterioration. Look for cracks, leaks, or unusual noises during operation. Technicians at your chosen provider can assist with these inspections, offering expert advice on potential problems. Early detection allows you to address issues promptly, reducing the risk of costly repairs or extended downtime.

Replace parts proactively to avoid unexpected breakdowns.

Proactive replacement of worn-out parts ensures your excavator remains reliable. Waiting for a component to fail can lead to significant disruptions and higher repair costs. For instance, replacing a worn gasket before it leaks prevents damage to surrounding parts. Use your maintenance logs to identify components nearing the end of their lifespan and schedule replacements accordingly. This strategy keeps your excavator in peak condition and minimizes unexpected interruptions to your operations.

By implementing these maintenance and record-keeping practices, you can extend the life of your excavator and maintain its efficiency. Staying organized and proactive not only saves time and money but also ensures your equipment performs reliably under demanding conditions.

For reliable excavator part dealers, consider YNF Machinery as your trusted partner.

Finding the right isuzu excavator engine parts requires a systematic approach. Start by identifying your excavator’s needs, including its model and engine specifications. Research suppliers to ensure you get high-quality components. Explore options like new, used, or remanufactured parts based on your budget and requirements. Verify compatibility and quality to avoid costly mistakes. Maintain detailed records and schedule regular inspections to keep your excavator running efficiently. By following these steps, you can enhance your machine’s performance and longevity. For reliable isuzu excavator engine parts, consider YNF Machinery as your trusted partner.

FAQ

Does AliExpress offer a wide range of Isuzu excavator parts?

Yes, AliExpress provides a broad selection of Isuzu excavator parts. Their detailed product catalog helps you locate the exact part you need for your machine. Whether you are searching for engine components or other essential parts, the platform offers numerous options tailored to your excavator model.

Are Isuzu excavator parts built to last?

Isuzu excavator parts are designed for durability. Manufacturers use high-quality materials and conduct rigorous testing to ensure these parts meet or exceed industry standards. This robust construction extends the lifespan of your excavator and minimizes downtime, making them a reliable choice for heavy machinery.

How can I identify the right part for my excavator?

To identify the correct part, start by checking your excavator’s manual. Locate the part number and specifications listed in the manual. Cross-check this information with the supplier’s catalog to ensure compatibility. If you are unsure, consult an expert or use online tools provided by reputable suppliers to verify the part’s fit for your excavator.

Should I choose OEM parts for my excavator?

OEM (Original Equipment Manufacturer) parts are an excellent choice for your excavator. These parts are specifically designed to match the exact standards of your machine, ensuring optimal performance and compatibility. While they may cost more upfront, their reliability and durability often make them a cost-effective option in the long run.

What are the benefits of remanufactured excavator parts?

Remanufactured parts offer a balance between cost and quality. These components are rebuilt to meet or exceed OEM standards, providing performance similar to new parts. They undergo thorough testing to ensure reliability, making them a budget-friendly yet dependable option for maintaining your excavator.

Can I use used parts for my excavator?

Yes, you can use used parts for your excavator, especially for non-critical components. Used parts are a cost-effective solution, but you should inspect them thoroughly for wear or damage. Ensure they match your machine’s specifications to avoid compatibility issues. For critical systems like the engine, consider whether the cost savings outweigh the potential risks.

How do I ensure the quality of excavator parts?

To ensure quality, look for parts with certifications such as ISO standards. These certifications indicate that the components have undergone rigorous testing and meet industry benchmarks. Additionally, purchase from reputable suppliers who provide guarantees or warranties on their products.

What should I consider when budgeting for excavator parts?

When budgeting, prioritize quality over low prices. High-quality parts reduce the frequency of replacements and repairs, saving you money over time. Compare prices across multiple suppliers to find the best deal without compromising on reliability. Also, factor in long-term costs like maintenance and potential repairs to make informed decisions.

How often should I inspect my excavator parts?

Regular inspections are essential for maintaining your excavator’s efficiency. Conduct routine checks to identify wear and tear early. Inspect critical components like the engine, hydraulic systems, and moving parts. Proactive maintenance helps you address issues before they escalate, reducing downtime and repair costs.

Where can I find reliable Isuzu excavator parts?

You can find reliable Isuzu excavator parts from trusted suppliers like YNF Machinery. With over 35 years of experience, YNF Machinery offers high-quality components that meet the needs of various excavator models. Their expertise ensures you receive durable and compatible parts to keep your machine running efficiently.