Premium Hydraulic Seal Kit Supplier for Heavy Machinery

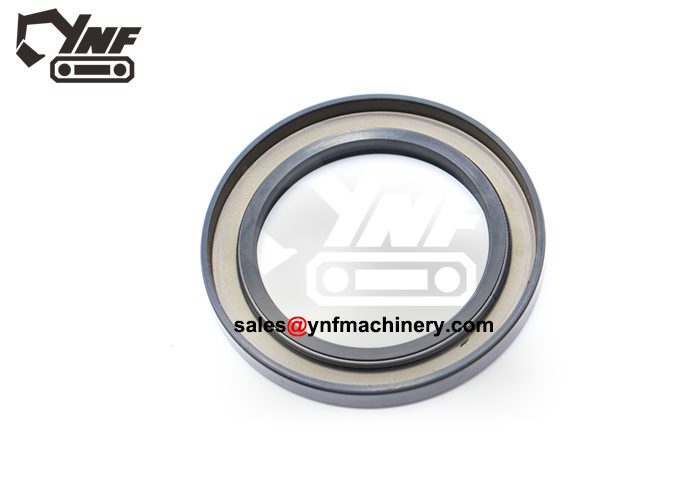

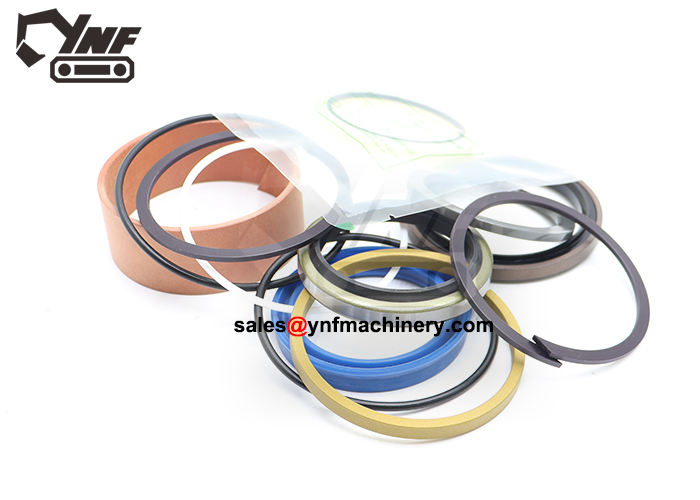

Hydraulic seal kits are manufactured with high-performance rubber and PTFE for demanding excavator applications. YNF Machinery provides reliable, wear-resistant sealing solutions tailored for OEM replacement and aftermarket needs.

Key Features:

-

Compatible with a wide range of excavators and construction equipment

-

High-pressure resistance and excellent sealing performance

-

Durable materials: NBR, PU, PTFE, and custom blends

-

Comprehensive kits for boom, arm, bucket, and track adjusters

-

Strict quality inspection for every kit before shipment

-

OEM & customized options available to match your machinery

Choose Hydraulic Seal Kit Products for Excavator Maintenance

Our hydraulic seal kit range includes complete solutions for various hydraulic cylinders—boom, arm, bucket, track adjusters, and more. Each kit is precision-packed to restore system integrity, prevent leakage, and extend machine life. We support OEM matching and offer flexible customization based on part number or cylinder size.

Why Our Seal Kits Outperform Others

Our seal kits are sourced from top-tier materials and engineered for extreme pressure resistance. Backed by strict QC, they ensure zero-leak performance and extended lifecycle, reducing downtime and repair costs for our global B2B clients.

Why Choose YNF Hydraulic Seal Kit to Support Excavator Repairs

At YNF Machinery, we supply high-quality hydraulic seal kits that reduce failure rates and improve sealing performance. With fast response, OEM compatibility, and global shipping, we help your business stay productive and competitive.

Hydraulic Seal Kit Applications

Excavators

Used for arm, boom, and bucket cylinder repairs in excavators.

Bulldozers

Restore hydraulic blade and ripper control cylinders.

Wheel Loaders

Seals used in lift, tilt, and steering hydraulic systems.

More About Hydraulic Seal Kits

Why Hydraulic Seal Kits Are Crucial for Excavator Efficiency

A hydraulic seal kit helps your excavator work well by stopping leaks and keeping pressure steady. It makes the hydraulic system dependable, so you avoid sudden problems. Without good seals, fluid leaks out, lowering power and damaging important parts. These kits also make your equipment last longer. Using strong seals and replacing them on time protects your machine and keeps it working smoothly.

Key Takeaways

- Hydraulic seal kits stop leaks and keep pressure steady. This helps your excavator work well.

- Changing seals often can save money by avoiding repairs and delays.

- Picking the correct seal kit for your excavator is important for good performance and dependability.

- Check seals regularly to find damage early and avoid expensive fixes.

- Good-quality seals last longer and make your hydraulic system work better.

The Importance of Hydraulic Seal Kits in Excavators

Hydraulic Seal Kit Functions in Excavators

A hydraulic seal kit is very important for excavators. These kits stop fluid from leaking and keep pressure steady. This helps the machine work smoothly without problems. If seals are bad, the system can lose 35% efficiency. This can cause expensive delays and repairs. Each seal has a job, like holding fluid, handling pressure, or resisting heat.

Picking the right seal kit is very important. A wrong kit can hurt performance and cause failures. For example, polyurethane seals last longer and need fewer changes. They can reduce replacements by up to 40%. This saves time and avoids work interruptions.

| Evidence Description | Quantitative Data |

|---|---|

| Fewer replacements needed | 30–40% |

| Longer life for multi-material seals | 25% longer |

| Polyurethane seals extend service intervals | Up to 40% |

| Fewer hydraulic system failures | 22% reduction |

Using good hydraulic seal kits keeps your excavator working well. It also lowers the chance of sudden breakdowns.

Importance of Seals and Gaskets in Hydraulic Systems

Seals and gaskets are very important in hydraulic systems. They stop leaks, keep pressure, and block dirt from getting inside. Without them, the system would not work properly.

| Function | Description |

|---|---|

| Stop Leaks | Seals stop fluid from leaking between parts. |

| Keep Pressure | They hold pressure inside the hydraulic system. |

| Block Dirt | Seals and gaskets keep dirt out of the system. |

Seals like rod seals and piston seals work together to keep pressure. They also allow movement and adjust to metal surface gaps. These features make seals and gaskets very important for excavators.

- Hydraulic seals stop fluid from leaking out.

- They handle high pressure and extreme heat.

- Rod and piston seals keep pressure and allow movement.

Using the right seals and gaskets protects your system. This helps it last longer and work better.

Hydraulic Breaker Seal Kit Applications

Hydraulic breaker seal kits are made for breakers. Breakers break hard materials like concrete and rock. These kits stop oil leaks, which can lower performance and damage parts.

Breakers work in tough conditions, so strong seal kits are needed. Good kits handle hard hits and resist damage from rough materials. This helps breakers work well even in hard jobs.

Using the right seal kit for your breaker makes it work better. It also lasts longer, so you need fewer repairs. This saves time and money over time.

Consequences of Neglecting Hydraulic Seal Kit Maintenance

Preventing Hydraulic Leaks and System Failures

Skipping hydraulic seal kit maintenance can cause big problems. Seals are key to stopping leaks by keeping fluid inside the system. When seals wear out, leaks happen. This lowers the pressure your excavator needs to work. It also raises the chance of system breakdowns. Leaks can cut system efficiency by 35%, making your machine slower and less reliable.

Seals often wear out from regular use. Checking and replacing them often can stop leaks. This keeps your excavator running smoothly. Using strong hydraulic cylinder seal kits makes your machine more dependable. It also reduces the risk of sudden failures.

Tip: Look for cracks or damage on seals. Fix issues early to avoid bigger problems.

Impact on Excavator Efficiency and Productivity

Broken seals hurt your excavator’s performance. Hydraulic systems need steady pressure to lift, dig, or break. Leaks mess up this pressure, making the machine weaker and slower. This means jobs take longer to finish.

Studies show excavators lose 30-40% of working time due to repairs. Bad seals cause frequent stops for fixes, delaying projects. For breakers, damaged seals make it harder to break tough materials like rock or concrete. This lowers productivity even more.

Taking care of seals helps your equipment work better. Stopping leaks keeps your machine running longer and faster.

Cost Implications of Neglected Maintenance

Ignoring seal care can cost a lot of money. Fixing seal problems is one of the highest costs after fuel. If you skip maintenance, total costs can be two to three times higher than the machine’s price. Leaks, weak force, and surprise repairs add to these expenses.

A study found regular seal care cuts repair costs by 20% in two years. Seal issues can cost up to $100,000 yearly in downtime. Using good seal kits can lower this by 40%. Shops that focus on seal care save 15% on repairs and get 25% fewer complaints about bad seals.

Note: Spending on good seals and gaskets saves money over time. It also prevents costly delays.

Not maintaining your hydraulic breaker or excavator seal kit wastes money and time. Regular care avoids these problems and keeps your machine working well.

Benefits of Regular Hydraulic Seal Kit Replacement

Better Excavator Performance and Dependability

Changing your hydraulic seal kit often helps your excavator work its best. Old seals can leak fluid, lowering pressure and slowing the machine. Fresh seals stop leaks and keep everything running smoothly. Strong oil seals also make breakdowns less likely during important jobs.

- One company cut downtime by 30% after using custom seal kits.

- A factory had fewer leaks and worked better with improved seals.

These examples show how replacing seals on time boosts performance. It also keeps your equipment reliable, even in tough situations.

Longer Life for Hydraulic Systems

Replacing seals regularly makes hydraulic systems last longer. Seals like oil seals and cylinder kits handle pressure and stop leaks. But they wear out after 500–800 hours of use. If not replaced, worn seals can cause leaks, jerky movements, or major damage.

Changing seals on time avoids these problems and protects key parts like pistons and cylinders. This care reduces damage and helps the system work well for years. Using strong seals and gaskets keeps hydraulic systems durable and dependable.

Saving Money with Regular Maintenance

Taking care of your hydraulic seal kit saves money over time. Checking and replacing seals stops sudden failures that cost a lot to fix. Good oil seals keep pressure steady, use less fuel, and finish jobs faster.

- Regular maintenance makes machines run better and smoother.

- Fixing issues early lowers downtime and repair costs.

- Strong seals stop leaks, saving money on oil and repairs.

Replacing your seal kit on time avoids big expenses and delays. This saves money and keeps your equipment working efficiently.

Tip: Make a schedule to check and replace seals. This prevents surprises and helps you save more.

Effective Maintenance and Replacement of Hydraulic Seal Kits

Identifying Signs of Seal Kit Wear and Tear

Finding early signs of wear in your seal kit is important. Regular checks help catch problems before they get worse. Start by looking at hoses, fittings, and connections. Check for cracks, leaks, or damage you can see. Testing pressure is another good way to check for issues. It shows if the system can handle pressure without breaking. For hidden problems, ultrasonic testing uses sound waves to find flaws inside parts.

| Diagnostic Method | Description |

|---|---|

| Visual Inspections | Look for cracks, leaks, or damage on hoses and fittings. |

| Pressure Testing | Check if the system can handle normal working pressure. |

| Ultrasonic Testing | Use sound waves to find hidden problems inside parts. |

These methods help you check oil seal wear and make sure seals and gaskets are installed correctly.

Best Practices for Preventing Hydraulic Leaks

Stopping hydraulic leaks starts with keeping fluid clean. Always use certified hydraulic fluid that matches the maker’s rules. Dirty fluid can harm seals and make the system weaker. Before using your excavator, check for leaks or damage. Fix leaks quickly and use tools to spot problems early.

Tip: Keep hydraulic fluid stored safely to avoid dirt. Follow filter cleaning schedules to stop clogs.

| Best Practice | Description |

|---|---|

| Perform Pre-Operational Inspections | Look for leaks or damage before using the machine. |

| Maintain Fluid Quality | Use clean fluid and replace it when the maker recommends. |

| Adhere to Filter Maintenance Schedules | Clean filters regularly to keep the system working well. |

These steps help your hydraulic system work better and make your seal kit last longer.

Steps for Safe and Efficient Seal Kit Replacement

Changing a seal kit needs careful planning. Follow these steps to do it safely:

- Check Manufacturer’s Instructions: Read the guide for your cylinder and seal kit.

- Keep Everything Clean: Clean all parts to stop dirt from ruining the seals.

- Use Lubrication: Add lubrication during installation to protect seals and help them work smoothly.

- Test After Installation: Check for leaks or problems after replacing the seal kit.

Handle seals gently to avoid tearing or bending them. Store seals in cool, dry places to keep them safe from heat and sunlight. Following these steps helps you install seals and gaskets correctly, keeping your excavator running well.

Choosing the Right Hydraulic Seal Kit for Your Equipment

Picking the right hydraulic seal kit is very important. It helps your excavator stay reliable and work well. Focus on three things: quality, fit, and how it works in tough conditions.

First, choose a high-quality seal kit. Good kits are tested to handle hard jobs. Strong seals last longer and stop leaks or breakdowns. This keeps your excavator running smoothly and reduces downtime.

Next, make sure the seal kit fits your excavator model. Each machine needs specific seals to work properly. Using the wrong kit can cause leaks or lower efficiency. Always check the maker’s guide to find the right one.

Finally, think about how the seal works in tough places. Excavators often face heat, cold, or dusty areas. Pick seals made from strong materials like polyurethane. These seals work well in harsh conditions and keep your system dependable.

Take time to pick the best seal kit. A strong, well-fitting, and durable kit improves your excavator’s performance. It also helps the hydraulic system last longer. Choosing wisely saves money and avoids big repairs.

Tip: Keep an extra seal kit ready for quick fixes.

Hydraulic seal kits help excavators stay strong and work well. They stop leaks, keep pressure steady, and protect important parts from damage. Checking seals often and replacing them on time keeps your machine running smoothly. This also lowers repair costs and prevents delays.

A demolition team used special tools to find problems early. Fixing issues quickly saved money, made the equipment safer, and helped it last longer.

- Taking care of seals stops sudden breakdowns and keeps machines working.

- Finding problems early makes equipment more reliable and cheaper to fix.

Spending time on hydraulic system care helps your machine last longer and work better.

FAQ

What is a hydraulic seal kit, and why is it important?

A hydraulic seal kit has seals and gaskets to stop fluid leaks. It helps your excavator keep pressure steady and work well. Without it, your machine could lose power and need expensive repairs.

How often should you replace hydraulic seal kits?

Replace hydraulic seal kits every 500–800 hours of use. Follow the manufacturer’s advice for the best results. Regular replacement stops leaks, keeps the system working, and protects your excavator’s parts.

How can you tell if a hydraulic seal kit needs replacement?

Check for leaks, low pressure, or jerky movements in your machine. Cracks or damage on seals also mean it’s time to replace them. Regular checks help you find these problems early.

Can you use any hydraulic seal kit for your excavator?

No, you need a seal kit made for your excavator model. Using the wrong kit can cause leaks and hurt the system. Always check the manufacturer’s guide to pick the right one.

What are the benefits of proactive hydraulic seal kit maintenance?

Taking care of seals stops leaks and saves money on repairs. It also helps your excavator work better and last longer. Regular maintenance keeps your machine reliable and efficient.

Tip: Keep an extra seal kit ready for quick repairs.

What Is a Hydraulic Seal Kit?

A hydraulic seal kit includes all necessary seals to rebuild hydraulic cylinders in excavators and other machinery. It ensures pressure retention and prevents oil leakage.

Material Options

| Material | Advantages |

|---|---|

| NBR | Excellent oil resistance |

| PU | High wear resistance |

| PTFE | Low friction, high temperature use |

Manufacturing & QC Process

-

Material inspection

-

CNC molding

-

Dimension check

-

Packaging & labeling

FAQ Guide

Q: Can I customize by part number?

A: Yes. Provide your machine model or part number, and we’ll match it.

Q: Do you offer OEM packaging?

A: Yes. Branding customization is available upon request.

Delivery & Shipping

-

Lead time: 5–15 working days depending on quantity

-

Shipping: DHL, FedEx, air/sea freight

-

Incoterms: EXW, FOB, CIF available