Low MOQ Excavator Coupling China Manufacturer

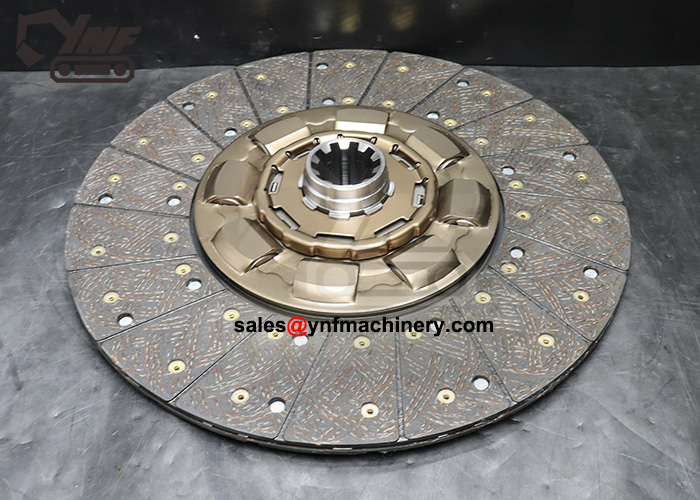

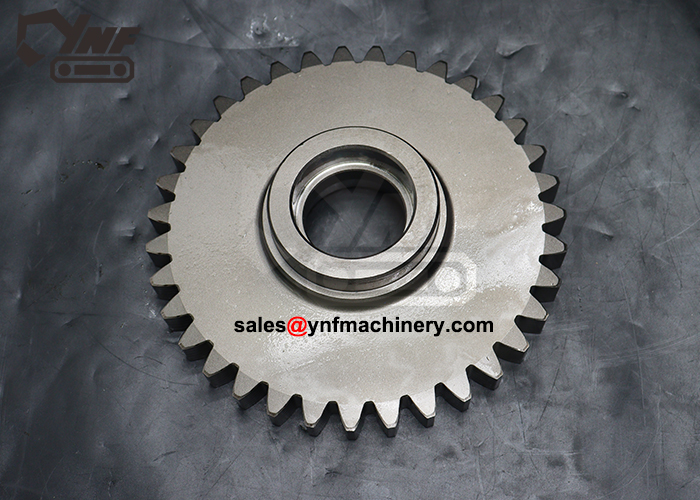

Excavator couplings are essential components that connect the engine to the hydraulic pump, ensuring efficient power transmission. Designed to absorb shock and vibration, they protect the machinery from excessive wear and tear, extending its lifespan.

At YNF, we specialize in high-quality flexible couplings for various excavator brands, offering:

- Durability – Made from premium rubber and metal for long service life.

- High Precision – Ensuring perfect fit and optimal performance.

- Wide Compatibility – Suitable for most mini to medium excavators.

- Low MOQ – Available with no strict quantity limits.

Choose Hydraulic Pump Coupling Product For Excavator Hydraulic Systems

Product Features of Excavator Coupling

1. High Durability & Strength – Made from premium rubber and metal materials, our couplings ensure long-lasting performance under extreme working conditions.

2. Excellent Shock Absorption – Effectively reduces vibration and impact, protecting hydraulic pumps and engines from excessive stress.

3. Precision Fit for Various Excavator Brands – We supply accurately machined couplings compatible with leading brands such as Komatsu, Caterpillar, Hitachi, Volvo, Kobelco, Hyundai, JCB, and more.

4. Efficient Power Transmission – Designed for maximum torque transfer, ensuring stable and smooth operation of excavators.

5. Easy Installation & Maintenance – Our couplings are engineered for a hassle-free replacement process, minimizing downtime.

What Value Does YNF Machinery Bring to Customers?

✅ Reliable Quality Control – We conduct strict quality inspections to ensure every coupling meets OEM standards.

✅ Low MOQ, Flexible Orders – Whether you need one piece or bulk orders, we accommodate all business sizes.

✅ Comprehensive Model Coverage – We supply couplings for mini, medium, and large excavators, ensuring a one-stop solution for our clients.

✅ Competitive Pricing – Get high-quality excavator couplings at factory-direct prices, helping you reduce costs.

✅ Fast Global Shipping – Our efficient logistics ensure timely delivery, avoiding project delays.

✅ Technical Support & Consultation – Not sure about the right coupling? We assist in part number identification to ensure a perfect fit for your machine.

At YNF Machinery, we are committed to providing high-quality excavator couplings with professional service and seamless purchasing experience. Whether you are a wholesaler or an excavator repair business, we ensure you get the right parts with efficiency, reliability, and affordability.

Key Advantages of YNF Excavator Couplings

At YNF Machinery, we prioritize quality, reliability, and customer satisfaction. Whether you’re a wholesaler, distributor, or repair business, our excavator couplings provide cost-effective solutions to enhance your machine’s performance.

Our couplings are made with high-quality rubber and metal components that effectively absorb shocks and minimize vibrations. This protects critical components like the hydraulic pump, engine, and transmission, reducing wear and extending equipment lifespan.

✅ Benefit: Prevents damage to key parts, reducing maintenance costs.

Designed for heavy-duty applications, our couplings withstand high torque loads, extreme temperatures, and continuous operation. We use premium rubber formulations and reinforced metal structures to ensure long service life even under harsh working conditions.

✅ Benefit: Ensures long-lasting performance, reducing downtime and replacement costs.

We provide accurately machined couplings that match the specifications of leading excavator brands such as Komatsu, Caterpillar, Volvo, Hitachi, Hyundai, JCB, Kobelco, and more. With a wide range of models, finding the right fit is hassle-free.

✅Benefit: Ensures seamless installation and optimal power transmission.

Unlike many suppliers with high minimum order quantities (MOQs), we support small and bulk orders, making it easier for businesses of all sizes to source quality excavator couplings. We also offer part number identification services, helping customers find the exact parts they need.

✅ Benefit: Saves time, reduces procurement stress, and improves purchasing efficiency.

Reliable Excavator Couplings for Smooth Power Transmission – Get Yours Today!

At YNF Machinery, we provide high-quality excavator couplings designed for durability, precision fit, and maximum performance. Our couplings effectively reduce vibration, protect hydraulic pumps and engines, and ensure smooth power transmission, extending your machine’s lifespan.

✅ Premium Materials – Strong wear resistance for long service life

✅ Perfect Fit – Compatible with major brands like Komatsu, Caterpillar, Hitachi, Volvo, and more

✅ Low MOQ & Fast Shipping – Order one piece or bulk with quick global delivery

✅ Technical Support – We help identify the right coupling using part numbers

With factory-direct pricing and strict quality control, we ensure cost-effective solutions for excavator repair businesses, wholesalers, and contractors. Order now and keep your machines running efficiently!

Excavator Coupling FAQs

Here are some commonly asked questions about excavator couplings, including excavator hydraulic pump coupling, digger rotary coupling, excavator rotating coupler, flexible coupling, rubber coupling, shock-absorbing coupling, hydraulic pump coupling, engine drive coupling, and rubber-flex coupling.

1. What is an excavator hydraulic pump coupling?

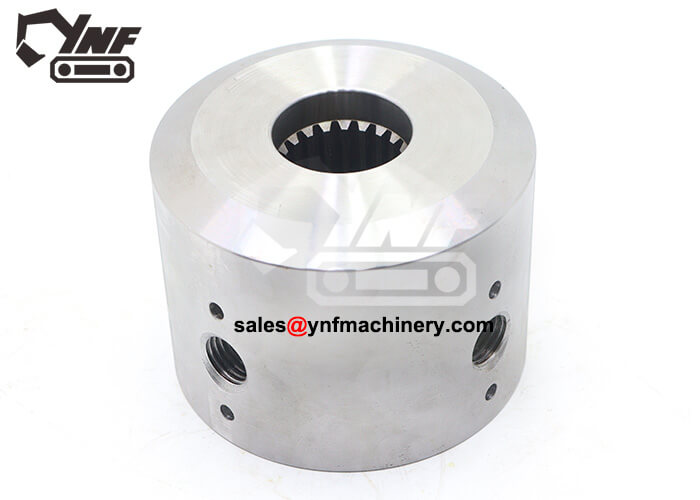

An excavator hydraulic pump coupling connects the engine to the hydraulic pump, transferring power efficiently. It helps absorb shocks and vibrations, preventing damage to critical components and ensuring smooth hydraulic operation.

2. What is a digger rotary coupling, and how does it work?

A digger rotary coupling (also known as a slew ring coupling) allows hydraulic flow between the fixed and rotating parts of an excavator. This component is essential for 360-degree rotation, enabling uninterrupted hydraulic power for attachments like grapples, breakers, and tilt buckets.

3. What is an excavator rotating coupler?

An excavator rotating coupler enables attachments to rotate freely while maintaining hydraulic flow. It increases the flexibility and versatility of your excavator, making operations like material handling and precision digging more efficient.

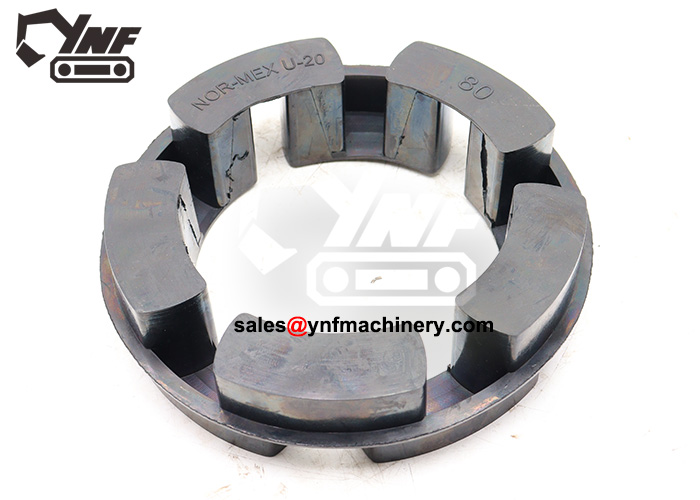

4. What is a flexible coupling in an excavator?

A flexible coupling connects rotating shafts, compensating for misalignment and reducing vibration. In excavators, it is commonly used between the engine and hydraulic pump to enhance power transmission and extend component lifespan.

5. What is a rubber coupling, and why is it important?

A rubber coupling is designed to absorb shocks, reduce noise, and prevent excessive wear on connected components. It provides smooth torque transfer and helps protect the hydraulic system from sudden impacts.

6. What are the benefits of a shock-absorbing coupling in excavators?

A shock-absorbing coupling reduces the impact of sudden load changes, preventing damage to engine, hydraulic pumps, and transmissions. It improves the longevity and performance of excavator components.

7. How does a hydraulic pump coupling improve excavator performance?

A hydraulic pump coupling ensures efficient power transfer from the engine to the hydraulic pump, allowing the excavator’s hydraulic system to function smoothly. High-quality couplings help prevent slippage, misalignment, and mechanical failures.

8. What is an engine drive coupling in an excavator?

An engine drive coupling connects the engine to other drivetrain components, ensuring consistent power transmission while minimizing vibration and wear. It plays a crucial role in maintaining stable excavator operation.

9. What is a rubber-flex coupling, and where is it used?

A rubber-flex coupling is a highly flexible coupling designed to handle torque fluctuations and absorb shocks. It is widely used in excavator hydraulic systems, ensuring smooth operation and longer service life.

10. How do I choose the right excavator coupling for my machine?

To select the right excavator coupling, consider:

✅ Machine brand and model – Ensure compatibility with Komatsu, Caterpillar, Volvo, Hitachi, Hyundai, JCB, Kobelco, and more.

✅ Part number identification – Use OEM part numbers to find an exact match.

✅ Application type – Hydraulic pump, engine drive, or rotary function.

✅ Material and durability – Choose high-quality rubber and metal for long-lasting performance.

At YNF Machinery, we provide a wide range of excavator couplings with low MOQ, fast delivery, and expert support. Need help? Contact us today!

A Guide to Excavator Couplings and Their Uses

Excavator couplings are key parts of construction machines. They connect tools to the excavator’s hydraulic system for smooth work. These couplings help tools like buckets, hammers, and grapples work well. They control hydraulic flow and pressure to keep things running.

Why does this matter? Each tool needs specific hydraulic power. High-pressure lines run tools like hammers. Medium-pressure lines control rotation or tilt. Using the wrong coupling can cause problems like pressure loss or overheating. This can slow down your work. From simple quick couplers to advanced ISO 16028 systems, each type has a special job. They are used for general building, forestry, or high-pressure tasks.

Key Takeaways

- Excavator couplings link tools to hydraulic systems for smooth work. Picking the right coupling stops problems like pressure drops or overheating.

- Quick couplers help switch tools fast, often in minutes. This increases work speed on job sites and cuts waiting time.

- Different couplers fit different tasks. Mechanical ones are cheap and good for simple jobs. Hydraulic ones are easy to use for frequent tool changes.

- Flat face couplers work well in dirty places. They stop leaks and keep systems clean, great for forestry and similar work.

- Multi-coupling systems connect many lines at once. They save time and make advanced hydraulic setups more efficient.

Overview of Excavator Couplings

What is an Excavator Coupling?

An excavator coupling connects tools to the machine’s hydraulic system. It moves hydraulic power to attachments like buckets, hammers, and grapples. These couplings follow standards like ISO 16028 for compatibility. This lets you switch tools easily without worrying about connection issues.

Some couplers, like the FSH series, handle tough jobs. They stay strong under high pressure and frequent use. This makes them perfect for heavy-duty tasks. Whether on construction sites or in forests, the right excavator coupling keeps tools working well.

How Excavator Couplings Enhance Efficiency

Excavator couplings save time and effort. Quick couplers let you change tools fast, often in minutes. Hydraulic quick couplers don’t need manual adjustments, reducing delays. This keeps your work moving smoothly.

Tiltable couplers add even more flexibility. They let tools rotate or tilt for tricky tasks. These features help you finish jobs faster and with better accuracy. Whether digging or breaking concrete, couplers make excavators more useful and efficient.

Key Benefits of Using Excavator Quick Couplers

Excavator quick couplers offer many benefits for modern projects:

- Time Savings: Tiltable couplers cut downtime by up to 30%.

- Cost Efficiency: Renting excavators with quick couplers saves money on tools.

- Versatility: Quick couplers work with many attachments, like buckets or hammers.

- Durability: ISO 16028 couplers handle high pressure and last a long time.

With more infrastructure projects, excavator quick couplers are becoming essential. They improve efficiency and make work easier.

Types of Excavator Quick Couplers

Picking the right excavator quick coupler makes work faster and safer. Let’s explore three main types and how they help.

Mechanical Quick Couplers

Mechanical quick couplers are simple and cost-effective. You attach or remove tools by hand, so you must leave the cab. This takes more time but is easy to maintain and very reliable.

A big benefit of mechanical couplers is their toughness. They don’t use hydraulics, so there’s less chance of leaks or pressure problems. They’re great for small excavators or jobs with fewer tool changes.

Tip: On a tight budget or doing light tasks? Mechanical couplers are a smart pick.

Hydraulic Quick Couplers

Hydraulic quick couplers make switching tools easier. You can change attachments without leaving the cab. They use the excavator’s hydraulics to lock and unlock tools, saving time.

These couplers are ideal for jobs needing frequent tool changes, like digging or demolition. They also have safety features like automatic locks to stop tools from falling off.

Here’s how hydraulic couplers are tested for safety:

| Testing Method | Purpose | Importance |

|---|---|---|

| Burst Testing | Checks maximum pressure before failure. | Prevents accidents and ensures safety. |

| Flex Impulse Testing | Tests strength under bending and pressure. | Improves design for tough jobs. |

Hydraulic couplers cost more than mechanical ones but are worth it for their efficiency and safety.

Did you know? Hydraulic tilt couplers let tools tilt or spin. They’re great for precise tasks like landscaping.

Flat Face Couplers

Flat face couplers are made for heavy-duty jobs needing cleanliness. Their flat design stops fluid leaks and keeps dirt out. This makes them perfect for forestry and hydraulic excavators.

These couplers seal tightly to prevent leaks, even under high pressure. This boosts safety and reduces downtime, helping you finish work faster.

Here’s how flat face couplers compare to others:

| Type of Quick Coupler | Advantages | Limitations | Applications |

|---|---|---|---|

| Flat Face | Stops leaks, keeps dirt out | Bigger, more expensive | Forestry, hydraulic excavators, skid steer loaders |

| Screw-to-Connect | Handles high pressure, secure connection | Slower to connect, needs alignment | Mining, offshore drilling, injection molding |

| Multi-Coupling | Connects many lines at once | Costly, harder to install | Industrial automation, plastic injection molding |

Flat face couplers are heavier and pricier but work well in tough conditions.

Pro Tip: Working in forestry or areas with dirt risks? Flat face couplers are the best choice.

ISO A and ISO B Couplers

ISO A and ISO B couplers are very common in excavators. They follow global standards, making them fit many machines and tools. For general construction work, these couplers are often the best choice.

How Are ISO A and ISO B Couplers Different?

The main difference is in their design and use:

- ISO A Couplers: Made for low-pressure jobs. They are simple and easy to use. These couplers work well for light tasks like basic construction.

- ISO B Couplers: Built for high-pressure systems. They are stronger and better for tough jobs like demolition or heavy digging.

Tip: Not sure which to pick? Check your machine’s pressure needs. Use ISO A for lighter tasks and ISO B for harder ones.

ISO A and ISO B couplers are popular because they are flexible and easy to find. They are a reliable choice for connecting excavator tools.

Screw-to-Connect Couplers

Screw-to-connect couplers are made for strength and safety. They handle high-pressure tasks, making them great for mining, drilling, and molding.

Why Pick Screw-to-Connect Couplers?

These couplers have many benefits:

- High Pressure: They don’t leak, even under extreme pressure.

- Secure Fit: The screw design keeps the connection tight and safe.

- Long-Lasting: They stay strong in tough conditions.

But they take longer to connect and need careful alignment. For high-pressure jobs, the extra effort is worth it.

Here’s a quick look at reports about screw-to-connect couplers:

| Report Title | Date | Focus Area |

|---|---|---|

| BSEE QC-FIT Update – API Winter Standards Meeting | June 2016 | Fastener evaluations overview |

| 2016 Update on BSEE QC-FIT Evaluation of Connectors and Bolt Failures | February 2016 | Connector and bolt failure analysis |

| QC-FIT Evaluation of Connector and Bolt Failures | August 2014 | Detailed study of connector issues |

Note: For high-pressure tasks, screw-to-connect couplers are dependable. They are perfect for jobs needing safety and durability.

Multi-Coupling Systems

Multi-coupling systems are great for complex hydraulic setups. They let you connect many hydraulic lines at once, saving time and effort. These systems are ideal for advanced tools and attachments.

Why Use Multi-Coupling Systems?

- Time-Saving: Connect several lines in one step, reducing delays.

- Leak Prevention: They seal all connections tightly, stopping leaks.

- Wide Use: They work with many tools, making them useful for industries like automation and molding.

Here’s how multi-coupling systems perform in tests:

| Study | Findings | Fuel Efficiency Improvement |

|---|---|---|

| Heybroek, 2017 | Tested hydraulic transformers in wheel loaders | 9% fuel reduction per load |

| Heybroek and Sahlman, 2018 | Used multi-chamber cylinders in excavators | 34%-50% fuel savings |

| Opgenoorth et al., 2022 | Adapted STEAM system with better metering | 28.3% energy savings |

Pro Tip: Working with complex hydraulic tools? Multi-coupling systems save time and boost precision. They’re great for big projects where every detail matters.

Applications of Different Types of Excavator Quick Couplers

Picking the right excavator quick coupler is important for safety and speed. Each type works best in certain jobs. Knowing their strengths helps you use your tools better. Let’s see how these couplers are used in different industries.

General Construction and ISO A Couplers

ISO A couplers are great for basic construction work. They are made for low-pressure systems and lighter tasks. Jobs like digging, grading, or moving materials are perfect for these couplers. If you use simple tools like buckets, ISO A couplers are a good fit.

Their easy design makes switching tools fast and simple. This saves time on small projects like home building or small business sites. ISO A couplers help keep your work smooth and efficient.

Tip: Don’t need high-pressure tools? ISO A couplers are affordable and reliable.

Forestry and Flat Face Couplers

Forestry jobs need couplers that handle tough conditions and stay clean. Flat face couplers are the best choice for this kind of work. Their design stops leaks and keeps dirt out of your hydraulic system. This is very helpful in muddy or dusty areas.

Here’s why flat face couplers are great for forestry:

| Feature | Benefit |

|---|---|

| Leak-free performance | Stops fluid loss, protecting the environment |

| Minimal air and contaminant inclusion | Keeps the system clean, reducing damage risks |

| Easy to clean flat faces | Makes maintenance faster and easier |

| Safety locking sleeve | Prevents accidental disconnection, improving safety |

Flat face couplers also save time by making cleaning simple. You can focus more on work and less on maintenance. Whether using a skid steer loader or an excavator in the forest, these couplers keep things safe and smooth.

Pro Tip: Working in dirty areas like forests? Flat face couplers protect your equipment and keep it running well.

High-Pressure Tasks and Screw-to-Connect Couplers

For high-pressure jobs, screw-to-connect couplers are the strongest option. They are built for tough tasks like mining, drilling, or crane work.

Here’s why screw-to-connect couplers are perfect for high-pressure jobs:

- WEO 420 Plug-in fittings handle up to 6091 PSI (420 bar).

- They are made for extreme conditions and work reliably.

- Zinc-nickel coating stops rust, making them last longer.

- HNBR seals let them work in very hot environments.

These couplers stay secure and don’t leak, even under heavy pressure. They take longer to connect because of their screw design, but the safety and strength are worth it. For heavy-duty tools, screw-to-connect couplers keep everything firmly in place.

Note: Doing high-pressure work? Screw-to-connect couplers are safe and long-lasting.

Complex Hydraulic Tools and Multi-Coupling Systems

Using complex hydraulic tools can be tricky and time-consuming. Multi-coupling systems make this easier. They connect many hydraulic lines at once. This is great for advanced excavator setups. Tools like hydraulic breakers, augers, or grapples work better with these systems. They save time and improve efficiency.

Why Multi-Coupling Systems Are Important

Multi-coupling systems are made for modern excavators. They have many benefits:

- Time Efficiency: Connect several hydraulic lines quickly. This reduces delays.

- Leak Prevention: Tight seals stop fluid leaks and protect equipment.

- Versatility: They work with many tools in industries like construction and forestry.

Pro Tip: Use multi-coupling systems to save hours on tool changes.

How Multi-Coupling Systems Handle Tough Jobs

These systems work well in hard conditions. They keep tools running smoothly. Here’s why they’re effective:

- They unify input indices for steady tool performance.

- They check static and dynamic factors for changing conditions.

- They focus on key metrics for reliable results every time.

Switching tools like hydraulic hammers and tilt buckets is easy with these systems. They ensure smooth transitions without losing performance.

Benefits of Multi-Coupling Systems

Imagine switching between a breaker and a grapple on-site. Without multi-coupling systems, this takes time. With them, it’s done in seconds.

Here’s a comparison:

| Feature | Multi-Coupling Systems | Standard Couplers |

|---|---|---|

| Connection Speed | Connects multiple lines fast | Needs separate connections |

| Leak Prevention | Strong sealing | Moderate sealing |

| Tool Compatibility | Works with complex tools | Limited to simple tools |

This saves time and reduces wear on your excavator. It also lowers maintenance costs and extends the machine’s life.

Note: Multi-coupling systems are ideal for tools needing precise pressure control.

Should You Use Multi-Coupling Systems?

If you often change tools or use complex setups, these systems are helpful. They’re great for industries needing accuracy, like mining or automation.

Investing in multi-coupling systems boosts efficiency. It also ensures your excavator works well, even in tough tasks.

Comparing Types of Excavator Quick Couplers

Mechanical vs. Hydraulic Quick Couplers

Choosing between mechanical and hydraulic couplers depends on your work. Mechanical couplers are simple and cost less. You attach tools by hand, which takes extra time. They are strong and work well for small jobs or fewer tool changes.

Hydraulic couplers are easier to use. You can switch tools without leaving the cab. This saves time and keeps work moving quickly. They are great for tasks like demolition or landscaping. Hydraulic couplers also have safety locks to keep tools secure.

If you want something cheap and tough, pick mechanical couplers. If speed and ease are more important, go with hydraulic couplers.

Flat Face vs. Screw-to-Connect Couplers

Flat face and screw-to-connect couplers are good for different jobs. Flat face couplers stop leaks and block dirt. They are perfect for forestry or dirty places. Cleaning them is easy, saving you time.

Screw-to-connect couplers are made for strength. They handle high-pressure jobs like mining or drilling. Their screw design keeps them tightly connected. But they take longer to attach and need careful alignment.

For dirty areas, flat face couplers are the best choice. For high-pressure tasks, screw-to-connect couplers are safer and stronger.

Multi-Coupling Systems vs. Standard Couplers

Multi-coupling systems are great for complex setups. They connect many hydraulic lines at once, saving time. These systems work well with advanced tools like grapples or breakers. They also stop leaks and control pressure better.

Standard couplers are simpler but slower. You must connect each line one by one. This can cause leaks if not done right. They are better for basic jobs with fewer lines.

If you use advanced tools or switch attachments often, multi-coupling systems are a smart choice. They save time and make your excavator more useful.

Factors to Think About When Picking an Excavator Coupling

Matching with Tools and Excavator Models

Make sure the coupler fits your excavator and tools. Not all couplers work with every machine or attachment. For example, ISO 13031 sets rules for universal quick couplers. This makes it easier to use tools like buckets or grapples from different brands. These standards ensure tools connect safely and work well.

Safety rules are also important. Attachments must follow laws like OSHA for safety or EU rules for low emissions. Here’s how compatibility and rules connect:

| Aspect | Evidence |

|---|---|

| Safety Rules | Attachments must meet safety and environmental standards. |

| Compatibility Standards | ISO 13031 ensures couplers work across different brands. |

| Buyer Preferences | 60% of buyers want tools that meet industry rules. |

Tip: Check your excavator’s manual and tool details to avoid mismatches.

Pressure and Flow Needs

Hydraulic systems need the right pressure and flow to work well. A wrong coupler can cause problems or damage. Look at things like working pressure, burst pressure, and flow rate.

Key points to check:

- Size: The coupler should match your system’s flow needs.

- Pressure: Make sure the coupler’s pressure ratings fit your system.

- Flow Rate: Use formulas to calculate flow rate based on pressure and fluid type.

For tough jobs like mining, screw-to-connect couplers are a good pick. They handle high pressure without leaking, keeping your excavator safe and efficient.

Pro Tip: Not sure about pressure or flow? Ask a hydraulic expert to avoid mistakes.

Worksite and Operating Conditions

Your work environment affects the coupler you need. Dusty or muddy places need couplers that block dirt. Flat face couplers are great for forestry because they seal tightly and keep systems clean.

Temperature also matters. Couplers should handle both the fluid and outside temperatures. For very hot or cold places, use couplers with strong seals like HNBR.

If you switch tools often, multi-coupling systems save time and reduce wear. They’re perfect for frequent tool changes.

Note: Pick a coupler that fits your worksite’s challenges for better performance and durability.

Maintenance, Durability, and Cost

When picking a coupler, think about upkeep, strength, and price. These factors affect how well your excavator works and your overall costs. Let’s look at the details.

Manual quick couplers are cheaper to buy. They are easy to use and need little care. This makes them great for jobs with fewer tool changes. Hydraulic quick couplers cost more at first but save time later. You can control them from the cab, which speeds up work and reduces delays.

Here’s a simple comparison:

| Coupler Type | Cost | Ease of Use | Maintenance |

|---|---|---|---|

| Manual Quick Coupler | Lower | Needs manual handling | Simple upkeep |

| Hydraulic Quick Coupler | Higher | Operated from cab | More upkeep |

Durability is also important. Manual couplers are strong and last in tough conditions. Hydraulic couplers are advanced but need regular checks. This ensures seals and locks stay in good shape. For heavy tools like buckets or grapples, durability matters even more.

Maintenance affects costs too. Manual couplers are cheaper to maintain. Hydraulic couplers, while complex, boost productivity over time. When choosing a coupler, balance the upfront cost with long-term benefits.

Tip: On a budget and don’t change tools often? Pick a manual coupler. For frequent changes or advanced tools, a hydraulic coupler is worth it.

Picking the right excavator coupling makes work quicker and safer. Whether in building, forestry, or tough jobs, there’s a coupler for you. Quick couplers let you switch tools fast, saving time. Multi-coupling systems are great for handling advanced hydraulic tools.

Here’s a summary of the advantages:

| Benefit/Application | Description |

|---|---|

| Fast Tool Switching | Quick couplers help change tools quickly without extra tools, cutting delays. |

| Better Work Efficiency | Less time switching tools means more tasks get done faster. |

| Multi-Tool Use | Attachments like buckets, hammers, and grapples make excavators useful for many tasks. |

When choosing a coupler, consider your machine, tools, and job needs. Picking the right one ensures smooth work and lasting performance.

Pro Tip: Always check your machine’s manual and pressure limits before deciding.

FAQ

What is the main purpose of an excavator coupling?

Excavator couplings link tools to the machine’s hydraulic system. They send power to attachments like buckets or hammers for smooth use. Without the right coupling, tools won’t work well or safely.

How do I know which coupling fits my excavator?

Check your excavator’s manual for compatibility details. Look for pressure ratings, flow needs, and attachment types. If unsure, ask your equipment dealer or a hydraulic expert.

Tip: Match the coupling to your machine’s specs to prevent damage.

Are hydraulic quick couplers worth the extra cost?

Yes, if you change tools often. Hydraulic quick couplers save time by letting you switch attachments without leaving the cab. They also improve safety with automatic locks. For frequent tool changes, they’re a smart choice.

Can I use the same coupling for all attachments?

Not always. Different tools need specific couplings based on pressure, flow, or connection type. Forestry tools often use flat face couplers. High-pressure tasks need screw-to-connect couplers.

How do I maintain my excavator couplings?

Clean couplings often to stop dirt buildup. Check seals and connections for leaks or wear. Replace damaged parts quickly to avoid hydraulic problems.

Pro Tip: Use a soft cloth and hydraulic fluid to clean couplings gently.

How to Replace Your Excavator Coupling with YNF Machinery for Reliable Results

You want your excavator to work well and be safe. Changing the excavator coupling can help it work better. It can also stop expensive breakdowns. Picking the right part is important. YNF Machinery gives good parts that experts trust. Many workers worry about if the part fits, if it lasts, and making mistakes when putting it in.

“One thing they need to think about is who will connect the parts. They also need to know how to train them. The OSHA bulletin tells bosses to check quick couplers. They should do things to stop buckets from coming off by accident. This can cause bad injuries or even death. But some people say the best way is to make sure workers know how to use the equipment right. There is no one type of coupling device. Each machine can use two or three attachments. Mistakes can happen, some people say.”

YNF Machinery helps you stop these problems by giving good couplings and help.

Key Takeaways

- Upgrading your excavator coupling makes it work better. You get more control and fewer breakdowns. This helps you finish jobs faster.

- Picking good couplings from YNF Machinery makes your machine more reliable. You will have fewer accidents and less time when work stops.

- Choose the right coupling type for what you need. Manual, hydraulic, and tiltrotator couplings do different jobs. Pick the one that fits your work.

- Follow the right steps to install the coupling. Clean the parts and check if they line up. Test the system to make sure it is safe and works well.

- Take care of your coupling and test it often. This can stop expensive repairs. Stay ahead to keep your excavator working smoothly.

Why Upgrade Excavator Coupling

Performance Benefits

Upgrading your excavator coupling helps your machine do better work. The power moves smoothly from the engine to the hydraulic pump. This lets your excavator dig, lift, and move with more control. Using a good coupling from YNF Machinery helps your equipment work its best.

Here are some changes you might see after upgrading:

| Performance Metric | Observations |

|---|---|

| Breakout Force Reduction | Making the stick longer and tip bigger lowers breakout force by 3% to 5%. |

| Equipment Utilization | Contractors try to use their equipment as much as possible. |

| Lifting Characteristics Improvement | Taking off the bucket or attachment helps the excavator lift better. |

A better excavator coupling helps your machine work harder and smarter. You finish more jobs in less time. Your excavator can handle tough work with less trouble.

Tip: Upgrading your coupling can help you spend less on repairs. A strong coupling keeps other parts from wearing out fast.

Reliability Improvements

Picking a high-quality excavator coupling makes your machine safer and more reliable. YNF Machinery makes couplings that last longer and work in every direction. You do not need to move your excavator as much, so you save fuel and time.

Here are ways reliability gets better:

- Your excavator moves and works in any direction.

- You spend less time moving the machine, so you get more done and use less fuel.

- You make the job site safer.

- Smart couplings watch for problems and lower accident risks by almost 30%.

- Automatic locking makes new couplings safer and more reliable in more than half of them.

A reliable excavator coupling means fewer breakdowns and less waiting. You keep your projects going and your workers safe. YNF Machinery gives you couplings that meet high standards, so you can trust your equipment every day.

Select Excavator Coupling from YNF Machinery

Picking the right excavator coupling helps your machine last longer. It also helps your excavator work better. YNF Machinery has many choices. You can find the one that fits your job.

Coupling Types

YNF Machinery sells different couplings for many jobs and machines. Each type has special things it can do. Some couplings are good for certain tasks. The table below shows the main types and what they do:

| Type of Coupling | Application Description | Performance Characteristics |

|---|---|---|

| Manual Couplings | Suitable for smaller excavators and projects with infrequent attachment changes. | Cost-effective and low maintenance, ideal for simple tasks. |

| Hydraulic Couplings | Designed for larger excavators needing frequent attachment changes. | Allows quick switching from the cab, enhancing efficiency. |

| Tiltrotator Couplings | Best for complex tasks requiring rotation and tilting of attachments. | Increases productivity and precision, reducing repositioning time. |

YNF Machinery also has Centaflex, Bowex, and Monolastic couplings. Centaflex-A couplings help stop torque changes. They work in many excavators. Centaflex-H couplings are strong and good for hard jobs. Bowex couplings are best for fast jobs. Monolastic couplings use rubber to lower shaking.

Tip: Pick a coupling that fits your job. If you change tools a lot, hydraulic couplings save time. For hard digging, Centaflex-H or Bowex couplings give more power.

Compatibility Factors

You must make sure your coupling fits your machine and tools. YNF Machinery makes couplings for many brands and models. The table below shows what to check:

| Compatibility Factor | Description |

|---|---|

| Matching Couplings to Excavator Models | Couplings must fit specific excavator models to ensure a secure and efficient connection. |

| Ensuring Compatibility with Various Attachments | Couplings should work seamlessly with different attachments like buckets and breakers for optimal performance. |

| Assessing Durability and Material Quality | The quality of materials used in couplings affects their longevity and performance under various conditions. |

YNF Machinery builds couplings for tough work in building, mining, and factories. These couplings lower shaking and move power smoothly. You get a strong link that keeps your excavator safe.

Selection Tips

You want your coupling to last and help your machine run well. Use these tips to pick the best one from YNF Machinery:

- Check often: Look for cracks or parts that are not straight.

- Add oil if needed: Follow YNF Machinery’s guide to keep parts moving.

- Watch for shaking: Listen for noise or feel for shaking. This helps you find problems early.

- Change when needed: Use good couplings from YNF Machinery to keep your machine safe.

The right coupling helps your machine work better and last longer. YNF Machinery has many choices. You can find one that fits your excavator and your job.

| Benefit | Description |

|---|---|

| Enhanced Efficiency | Reliable couplings ensure seamless power transmission, reducing energy loss. |

| Reduced Downtime | Durable couplings minimize the risk of mechanical failures. |

| Extended Equipment Lifespan | Couplings protect critical components from premature wear. |

| Versatility | Various types available for specific excavator and application needs. |

Note: Always pick couplings that fit your excavator and job. YNF Machinery can help you choose the right part.

Replace Excavator Coupling Step-by-Step

Changing your excavator coupling helps your machine work better. It also makes it safer to use. You can follow these steps to do the job right. YNF Machinery makes couplings that are easy to put in. This means you spend less time fixing and more time working.

Preparation

You need to get ready before you start. Good planning keeps you safe and helps you avoid mistakes.

- Stay alert and watch what is around you to stay safe.

- Follow the instructions from the manufacturer for each step.

- Check quick coupler devices to make sure safety parts work.

- Never stand under or close to the excavator bucket or tool.

- Talk with your team about using quick coupler devices.

- Train workers to use quick coupler systems the right way.

- Check quick couplers before you use them each time.

- Do regular maintenance as the manufacturer says.

Tip: Always clean your work area and tools before you start. This helps you find problems early and keeps dirt out.

Removal

You need to take off the old coupling without breaking other parts. You can use different ways depending on your tools.

| Method | Description | Advantages/Disadvantages |

|---|---|---|

| Hydraulic Removal | Use a hydraulic tool to push the hub off the shaft. | Fast and accurate. You need special tools, but it saves time and money. |

| Mechanical Removal | Use a manual tool with a piston to remove the hub. | Costs less at first. It takes longer and needs more effort. You need to be strong. |

| Destructive Removal | Use a plasma torch to cut the hub off. | Only use this if nothing else works. It can hurt the shaft and ruins the hub. |

Note: Try hydraulic or mechanical removal first. Only use destructive removal if you have no other choice.

Installation

You need to put in the new coupling the right way. YNF Machinery makes it simple if you follow each step.

- Clean all parts before you start. Dirt can cause leaks.

- Line up the male and female halves of the coupling.

- Push the halves together until you hear a click or feel them lock. Do not force them.

- Use the right tools to tighten. Do not over-tighten or you might break the seals. Do not under-tighten or you might get leaks.

- Change any seals that look worn or cracked before you finish.

- After you install the coupling, run the system at low pressure. Check for leaks or loose parts.

| Common Mistake | Description | Prevention Tip |

|---|---|---|

| Misalignment | Shafts that do not line up can cause failure. | Always check alignment before you put in the coupling. |

| Not following manufacturer’s instructions | Skipping steps can cause problems. | Read and follow the instructions from YNF Machinery closely. |

| Incorrect coupling specification | Using the wrong coupling can lead to failure. | Make sure you have the right coupling for your excavator. |

| Insufficient lubrication | Not enough lubrication causes wear. | Use the right type and amount of lubricant as recommended. |

| Poor system maintenance | Skipping maintenance lowers efficiency. | Set up a regular schedule for checks and replacements. |

Alert: Always use couplings from YNF Machinery for the best fit and performance.

Testing

You need to test the new coupling to make sure it works well and does not leak.

- Turn on the excavator. Let the hydraulic system build pressure. Watch for warning signs.

- Use the controls to work the quick coupler. Open, close, and lock onto tools. Make sure movements are smooth.

- Check the hydraulic pressure. It should match the manufacturer’s range.

- Look at all connections while you use the coupler. Watch for leaks, drips, or hissing sounds.

- If you find leaks, turn off the excavator and let out the pressure. Tighten any loose parts. Use hydraulic sealant if you need to.

- Test the system again to make sure leaks are gone and the coupler works right.

- Repeat these checks during the first hours of use to make sure everything stays tight.

Tip: Regular testing helps you find problems early and keeps your excavator safe.

YNF Machinery makes couplings that are easy to put in and take care of. You can trust their products to help your excavator work better and last longer.

YNF Machinery Coupling Advantages

Durability

You want a coupling that can handle hard work. YNF Machinery makes couplings with strong materials. These couplings can stand up to oil, heat, and bad weather. They last longer and do not need much fixing. Many people see less downtime and fewer repairs after using YNF Machinery.

Here is how YNF CF-H couplings stack up against others:

| Feature | YNF CF-H Couplings | Competitors |

|---|---|---|

| Environmental Resistance | High resistance to extreme temperatures and oils | Varies, often lower resistance |

| Vibration Dampening | Exceptional shock absorption and noise reduction | Generally less effective |

| Service Life and Maintenance | Long service life with minimal maintenance | Often requires more frequent maintenance |

These couplings can hold heavy loads and keep working. The special rubber parts help stop shaking and take in shocks. This helps your excavator run smoothly and keeps other parts safe.

Support & Warranty

When you buy from YNF Machinery, you get more than just a part. You get help from a team that wants you to do well. If you have questions or need help, you can contact them in many ways:

- 📞 Call them at +86 189 2425 0310

- 📧 Email them at [email protected]

- 📝 Check the FAQ page for quick answers

- 📦 Find out about payment, shipping, and warranty

- 👷 Get help from skilled engineers and support staff

YNF Machinery gives a clear warranty for every coupling. You can feel safe knowing help is always there.

Customer Satisfaction

People who use YNF Machinery couplings often say good things. They notice their machines work better. Here are some top benefits customers talk about:

| Benefit | Description |

|---|---|

| Durability | Made to last long and need little fixing, so you save time and money. |

| Operational Efficiency | Cuts down on shaking and noise, making machines work better. |

| Material Strength | Built with tough materials that fight oil, heat, and stress. |

| Torsional Flexibility | Special rubber parts soak up shocks and stop shaking. |

| Misalignment Accommodation | Handles parts that do not line up, keeping equipment from wearing out too fast. |

You get a coupling that works hard every day. YNF Machinery helps your excavator keep running well, so you can finish your work.

Common Mistakes

Sizing Errors

Some people think any coupling will fit. But picking the wrong size happens a lot. If you choose the wrong size, your excavator can break. It might not work well. Always look at the manufacturer’s guide before buying. You need to measure the space between coupling hubs. This space changes how much power your excavator uses. If you forget these things, you can hurt your machine.

Here are sizing mistakes you should not make:

- Picking a coupling that does not fit your excavator.

- Not checking the space between coupling hubs.

- Using a coupling with the wrong spline count or shaft size.

- Forgetting to check for misalignment, which can break parts.

- Not following YNF Machinery’s instructions when installing.

If you make a sizing mistake, you might see overheating. You could hear loud noises or feel more shaking. These problems can get worse over time.

| Consequence | Description |

|---|---|

| Premature Failure | The wrong coupling can break early or damage other parts. |

| Increased Maintenance | Bad sizing means more fixing and less work time. |

| Cost Implications | Buying a cheap coupling can cost more later. |

Tip: Use YNF Machinery’s sizing guide to pick the right coupling.

Installation Issues

You need to put in the coupling the right way. Some people skip steps or hurry. This can cause leaks or misalignment. It can even break the coupling. Always clean all parts before you start. Make sure the shafts line up. Use the right amount of lubricant. If you miss these steps, your coupling can break early.

Common installation mistakes are:

- Not cleaning parts before putting them in.

- Shafts that do not line up.

- Using too little or too much lubricant.

- Skipping steps in the instructions.

- Not changing old seals.

You can stop these problems by reading and following YNF Machinery’s instructions. Take your time and check your work as you go.

Alert: Good installation keeps your excavator safe and working longer.

Skipped Testing

After you put in a new coupling, you need to test it. Some people forget this step. If you skip testing, you might miss leaks or loose parts. You could miss other problems too. Testing helps you find issues before they get worse.

You should:

- Run the excavator at low pressure first.

- Look for leaks, drips, or strange sounds.

- Watch for overheating or shaking.

- Tighten any loose parts right away.

Testing often keeps your machine safe. It helps you avoid expensive repairs. YNF Machinery says to test after every installation and during regular checks.

Note: Testing is the last step, but it is very important for good results.

If you upgrade your excavator coupling with YNF Machinery, your machine works better and lasts longer. The parts are easy to put in. They are made from strong materials. You will have less time when your machine is not working. Picking the right coupling and putting it in the right way helps your excavator run smoothly. This also saves you money as time goes on.

| Benefit | Description |

|---|---|

| Reliable Performance | YNF couplings move power well, even during hard jobs. |

| Easy Installation | You fix things faster and spend more time working. |

| High Flexibility | The design lets parts line up wrong but keeps things safe. |

| Durable and Cost-Effective | Strong parts mean you do not need many repairs or new parts. |

Choose YNF Machinery for good quality, helpful support, and value that lasts a long time.

FAQ

How do you know which excavator coupling fits your machine?

First, look at your excavator’s model number and shaft size. YNF Machinery can help you find the right coupling. If you are not sure, you can ask their team for help.

How often should you replace your excavator coupling?

Check your coupling every few months to stay safe. If you see cracks, wear, or shaking, change it. YNF Machinery says to follow your machine’s maintenance plan for the best results.

Can you install a YNF Machinery coupling by yourself?

You can put it in by yourself if you follow the steps. YNF Machinery makes couplings that are simple to install. Always read the manual and use the right tools to stay safe.

What makes YNF Machinery couplings last longer?

YNF Machinery uses tough materials and smart designs. Their couplings can handle oil, heat, and heavy work. This helps you work more hours and fix things less often.

Where can you buy genuine YNF Machinery excavator couplings?

You can buy from the official YNF Machinery website: https://ynfmachinery.com/excavator-couplings. You can also talk to their support team if you need help with your order.

Tip: Buy from YNF Machinery to get real parts and good support.