High-Performance Engine Parts Supplier for Excavator Repairs

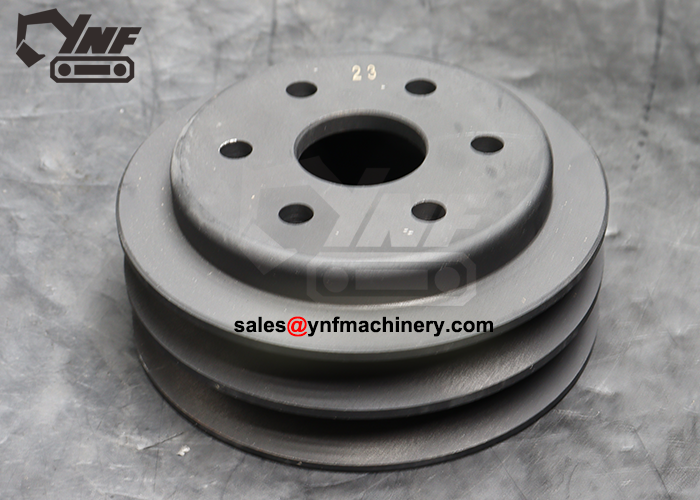

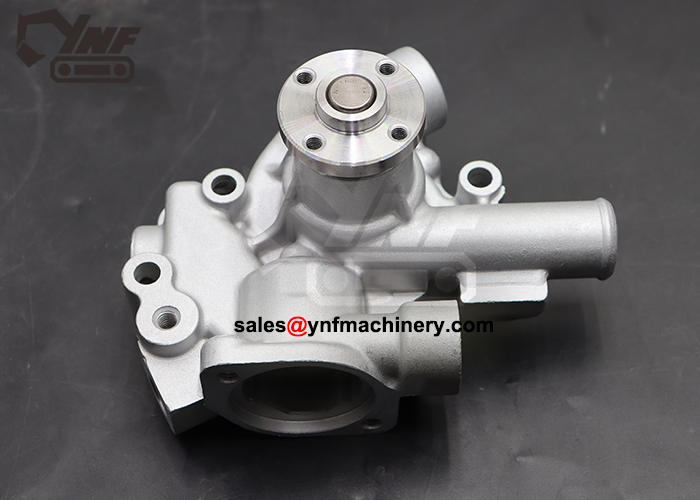

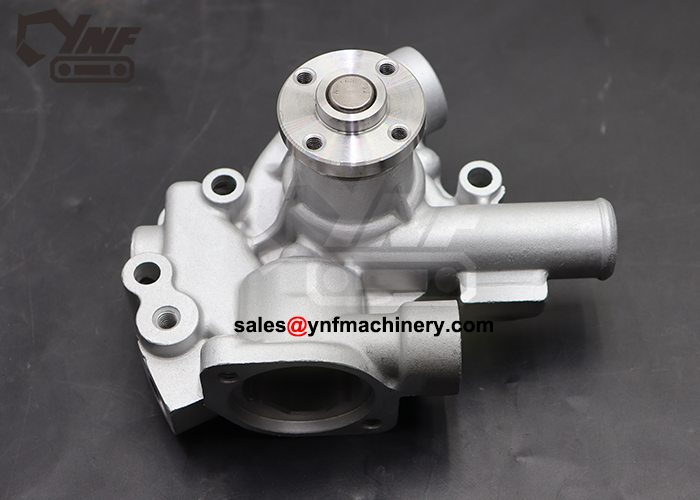

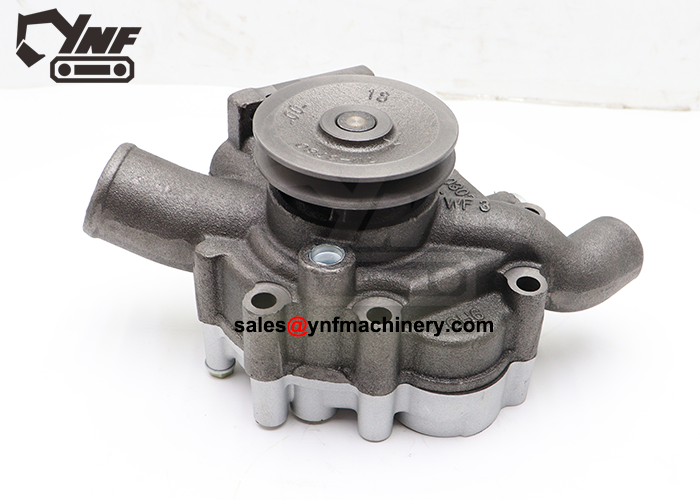

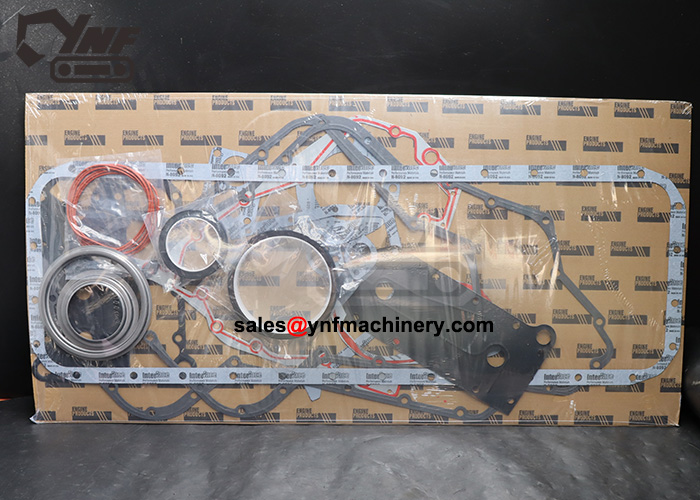

Engine parts are built for precision, durability, and heat resistance. YNF Machinery supplies a wide range of excavator engine components for OEM replacement and aftermarket repair.

Key Features:

-

Compatible with Cummins, Yanmar, Isuzu, Komatsu, and other diesel engines

-

Includes pistons, crankshafts, gaskets, liners, valves, camshafts, and more

-

OEM-quality materials and tolerances for long service life

-

Part number verification and full matching support

-

Supports both partial repairs and complete engine rebuilds

-

Global B2B supply with flexible packaging and shipping options

Engine Parts Series for Diesel-Powered Machinery

Our engine parts catalog covers the essential components for excavator engines, including top-end and bottom-end kits, cylinder heads, cooling systems, fuel components, and sealing kits. We support full compatibility with popular models from Cummins (4BT/6BT/6CTA), Yanmar (3TNV/4TNV), Komatsu (SAA6D102), Isuzu (4HK1/6BG1), and more.

Why Our Engine Parts Are the Smart Choice for Global Buyers

YNF Machinery delivers engine parts with high dimensional accuracy, OEM-grade materials, and strict quality checks. From fast matching to secure packaging and export, we reduce sourcing risk and support long-term equipment performance.

All engine components are manufactured using high-grade steel, aluminum alloys, and graphite gaskets. Tight tolerances and CNC machining ensure optimal fit and long-term engine durability—even in high-temperature, high-load conditions.

We help buyers match parts quickly by engine model, part number, or visual reference. With a technical team experienced in multiple brands and engines, we ensure the parts you receive fit correctly the first time.

Our engine parts are designed to fit a wide range of engine models from Cummins, Yanmar, Isuzu, Komatsu, and more. This allows you to source all key components from one supplier, saving cost and effort.

We support small and large volume orders with the same attention to quality. Custom packaging and labeling are available to support distributors and regional partners building their own aftermarket engine parts line.

Why Choose YNF Engine Parts to Support Diesel Equipment Maintenance

Our engine parts are built to perform under pressure. With full support for part matching, multi-brand compatibility, and efficient logistics, YNF Machinery helps keep your machines running with less downtime and lower cost.

Engine Parts Applications

Excavators

Used to restore power and performance in diesel excavators.

Generators

Applied in industrial diesel generators for stable output.

Wheel Loaders

Maintains engine reliability in material handling equipment.

Agricultural Machinery

Supports small diesel engines used in farming applications.

Technical Guide to Excavator Engine Components

Common Engine Components We Supply

| Part Name | Function |

|---|---|

| Piston Kit | Converts combustion pressure into motion |

| Crankshaft | Transfers power to the drivetrain |

| Gasket Set | Seals engine components to prevent leaks |

| Cylinder Head | Houses valves and combustion chambers |

| Camshaft | Controls valve timing |

| Liner Kit | Rebuilds worn engine cylinders |

Supported Engine Brands

-

Cummins: 4BT, 6BT, QSB, ISF

-

Yanmar: 3TNV, 4TNV

-

Isuzu: 4HK1, 6BG1, 6HK1

-

Komatsu: SAA4D95, SAA6D102

-

Deutz / Kubota / Perkins: On request

How to Ensure Part Fit

-

Provide engine model + machine model

-

Attach part number or clear component photos

-

We’ll confirm within 12–24 hours

Production & Quality Control

-

CNC precision manufacturing

-

Material certification for steel, aluminum, graphite

-

Load simulation testing available on request

-

Custom branding for high-volume buyers

Shipping & Terms

-

Secure packaging for global freight

-

Fast dispatch for standard kits

-

MOQ flexibility and mixed orders accepted

-

Payment: T/T, PayPal, Western Union, Alibaba Assurance

FAQ Section

Q: Do you offer engine rebuild kits?

A: Yes, we offer top-end kits, bottom-end kits, and full rebuild sets.

Q: Can you help with hard-to-find parts?

A: Yes, we support sourcing and production based on samples or drawings.

How to Maintain Excavator Engine Parts for Longevity

Keeping your excavator in good shape helps it work well. It also lowers costs and prevents sudden problems. Taking care of engine parts early makes them last longer. For instance, newer Caterpillar excavators use 20% less fuel. They also cut maintenance costs by 20% compared to older ones. This saves money and makes them more reliable. Regular care improves how your machine works and avoids expensive fixes.

Key Takeaways

- Check fluid levels every day to avoid overheating or damage. Refill fluids right away if they are low.

- Clean engine parts often to stop dirt from building up. Cleaning also helps you find problems early. Use a soft brush or cloth to clean.

- Look closely at the engine to spot leaks or damage early. Check for cracks, tears, or wet areas.

- Change oil and filters on time to keep the engine smooth. This lowers wear and makes the engine last longer.

- Use real replacement parts for the best fit and work. Cheap parts might cost less now but can cause big repairs later.

Daily Maintenance Practices

Taking care of your excavator daily keeps its engine working well. Small tasks done every day can stop big problems later.

Checking Fluid Levels

Begin each day by checking your excavator’s fluid levels. Fluids like engine oil, coolant, and hydraulic fluid are very important. If levels are too low, the engine might overheat or break down. Use a dipstick to check oil and look at the coolant tank. If anything is low, refill it right away.

Keeping fluids at the right levels protects the engine from damage. It also helps your excavator run smoothly all day. Skipping this step could lead to expensive repairs and wasted time.

Cleaning Engine Parts

Cleaning the engine is another key part of daily care. Dirt and debris can build up and cause damage over time. Use a soft brush or cloth to wipe dirt off the engine. Focus on areas near the air intake and cooling system.

A clean engine works better and is easier to check for problems. Cleaning under the machine also stops seals from breaking and keeps it lighter. This simple habit can save money and make your excavator last longer.

Conducting Visual Inspections

Looking over your excavator is quick but very helpful. Walk around it and check for damage, leaks, or worn-out parts. Look at hoses, belts, and seals for cracks or tears. Also, check the engine for any oil or coolant leaks.

Finding problems early stops them from becoming bigger issues. Regular checks keep your excavator reliable and lower repair costs. They also help it work better during the day.

Tip: Clean while inspecting to spot hidden problems more easily.

Watching for Leaks or Damage

Checking for leaks or damage is key to saving money. Small leaks or damage can turn into big problems fast. Spend a few minutes daily to inspect your excavator. This simple step can prevent costly repairs later.

Finding Leaks

Leaks happen where fluids like oil, coolant, or fuel move. Look under your excavator for puddles or stains. Focus on spots below the engine and hydraulic system.

Check the engine closely. Look around seals, gaskets, and connections for fluid leaks. Use a flashlight to see hard-to-reach areas. If you find wet spots or drips, fix them quickly to avoid damage.

Tip: Wipe the engine with a clean cloth before checking. This helps you spot new leaks easily.

Spotting Damage

Broken parts can make the engine work poorly or stop. Look for cracks, dents, or rust on hoses, belts, and the radiator. Check the engine block for wear or damage.

Listen while the engine runs. Strange sounds like knocking or hissing may mean trouble. Vibrations or shaking can also show a problem. If you notice these, stop using the machine and call a mechanic.

Why It’s Important

Ignoring leaks or damage can ruin the engine. For example, a small coolant leak can cause overheating. A broken hose might lower hydraulic pressure. Regular checks catch problems early and keep your excavator working well.

Daily inspections protect your engine and make it last longer. Add leak and damage checks to your routine to keep your excavator in great shape.

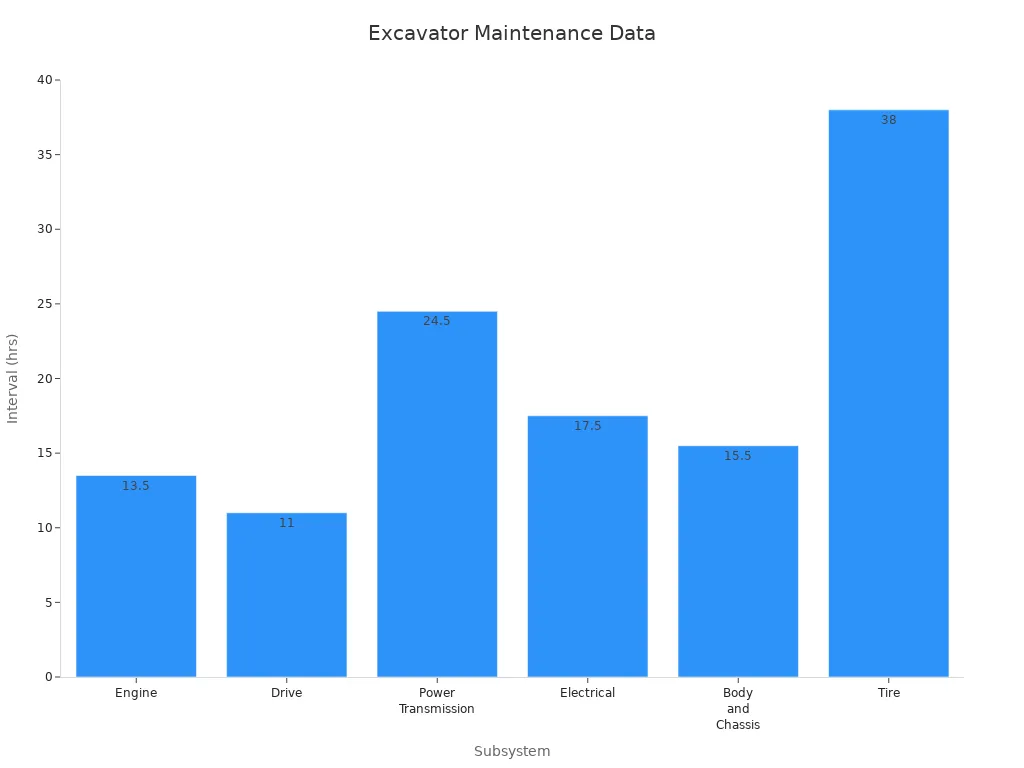

Scheduled Maintenance Intervals

Doing regular maintenance keeps your excavator’s engine working well. It also stops sudden breakdowns and saves money on repairs. Following a schedule helps the engine last longer and reduces wear. Below are tasks to do at specific times.

Maintenance Tasks at 100 Hours

At 100 hours, focus on simple but important tasks. Check the engine oil and change it if needed. Look at the air filter for dirt and clean or replace it. This helps the engine get enough air. Inspect the coolant system for leaks or dirty fluid. Tighten loose bolts to stop damage from shaking.

Also, check the hydraulic system for leaks or broken parts. Keeping these in good shape helps the engine run smoothly. These small steps are the start of a good maintenance plan.

Maintenance Tasks at 250 Hours

At 250 hours, more detailed work is needed. Change the engine oil and replace the oil filter. This keeps the engine lubricated and prevents damage. Look at the fuel filter and replace it if it’s clogged. Clean fuel helps the engine work better.

| Maintenance Task | Hours | Why It’s Important |

|---|---|---|

| Oil and Filter Change | 250 hours | Keeps parts lubricated and stops wear. |

Check belts and hoses for cracks or wear. Replace damaged ones to avoid sudden problems. Clean the radiator and cooling system to stop overheating. These tasks make the engine more reliable and keep it running well.

Maintenance Tasks at 500 Hours

At 500 hours, a full check-up is needed. Replace the air, fuel, and oil filters for better performance. Flush and refill the coolant system to keep the engine cool. Check the power system and grease moving parts to reduce wear.

- Preventive care stops expensive repairs later.

- Most engine problems can be avoided with good maintenance.

- Better care makes the engine last longer and saves money.

Following this schedule keeps your engine in great shape. Regular care lowers wear, stops failures, and boosts productivity.

Maintenance Tasks at 1,000+ Hours

At 1,000 hours, your excavator needs a full check-up. This includes replacing worn parts and fixing any issues.

Key Tasks to Perform:

- Replace All Filters

Air, fuel, and oil filters wear out by now. Changing them keeps air and fuel clean for the engine. Clean filters stop clogs and help the engine work better. Skipping this can harm performance and cause damage. - Flush and Refill Fluids

Replace old coolant, hydraulic fluid, and engine oil. Over time, fluids lose their ability to protect the engine. Fresh fluids keep the engine cool and prevent rust or overheating. - Inspect and Adjust Valves

Valves may shift after long use. Check and adjust them to ensure proper combustion. Well-tuned valves help the engine last longer and run smoothly. - Examine the Cooling System

The cooling system keeps the engine from overheating. Clean the radiator and check hoses for cracks or leaks. Replace damaged parts to avoid heat problems. - Check the Turbocharger (if applicable)

If your excavator has a turbocharger, inspect it for wear. A damaged turbocharger can lower power and make the engine less efficient.

Tip: Write down all maintenance tasks in a log. This helps you track repairs and plan future work.

Doing these tasks keeps your engine strong and reliable. Regular care stops big problems and makes your equipment last longer.

Key Components to Monitor

Filters (Air, Fuel, Oil)

Filters help keep the engine clean and working well. Air filters stop dirt from getting into the engine. Fuel filters make sure only clean fuel reaches the engine. Oil filters remove harmful particles from the oil to protect moving parts.

- Why Regular Maintenance Matters:

- Dirty air filters block airflow and hurt the engine’s performance.

- Hydraulic filters can clog, causing problems for the engine.

Check fuel filters and the water bowl every day. Too much water can harm the engine by up to 80%. This might force it into protect mode.

Inspect filters often and replace them when needed. Clean filters help the engine run better and avoid costly repairs.

Coolant System

The coolant system stops the engine from overheating. It moves coolant through the engine and radiator to keep the temperature steady. A good coolant system prevents heat damage and keeps the engine working well.

Check coolant levels daily and refill if they’re low. Look for leaks around hoses, clamps, or the radiator. Replace worn parts quickly to avoid overheating. Flush the system regularly to remove old fluid and debris that reduce cooling.

A healthy coolant system protects the engine and makes it last longer. Ignoring it can cause overheating and serious damage.

Engine Oil and Lubrication

Engine oil reduces friction and protects moving parts from wear. Changing oil on time and keeping parts lubricated stops overheating and ensures smooth operation.

| Benefit | Explanation |

|---|---|

| Longer Engine Life | Good care helps the engine last longer and work more hours. |

| Less Downtime | Regular maintenance avoids sudden breakdowns, keeping equipment ready to use. |

| Better Performance | Fresh oil and proper lubrication improve how the machine works. |

Check oil levels every day and top off if needed. Change oil and filters on schedule to keep lubrication strong. Use high-quality oil for the best engine performance and durability.

Taking care of oil and lubrication keeps the engine running smoothly. It reduces wear and prevents breakdowns.

Belts and Hoses

Belts and hoses are important for your excavator’s engine. They help move power, air, and fluids. Checking them often can stop sudden problems and expensive fixes.

Checking Belts

Belts link parts like the alternator and cooling fan. Over time, they may crack, loosen, or wear out. Look for cracks, frayed edges, or shiny spots on belts. A shiny belt might mean it’s slipping, which can hurt the engine’s performance.

Press on the belt to check its tightness. If it’s too loose or tight, adjust it using the maker’s instructions. A belt with the right tension helps the engine run smoothly and stay cool.

Looking at Hoses

Hoses move fluids like coolant and hydraulic oil to the engine. Check for bulges, cracks, or leaks, especially near clamps and connections. These spots often wear out first.

Feel the hose with your hand for soft areas. A soft hose might mean it’s damaged inside. Replace bad hoses quickly to stop leaks and keep the engine from overheating or losing power.

Easy Maintenance Tips

- Change Damaged Parts Quickly: Broken belts or hoses can harm the engine and cause breakdowns.

- Keep Extras Nearby: Have spare belts and hoses ready to avoid long delays.

- Clean Around Them: Dirt near belts and hoses can make them wear out faster. Wipe these areas often to make them last longer.

Tip: Use strong, high-quality parts to fit your engine and last longer.

Taking care of belts and hoses reduces stress on the engine. This keeps your excavator working its best.

Preventive Engine Maintenance Measures

Proper Operation Techniques

Using the right techniques helps keep the engine in good shape. How you use your excavator affects its performance and lifespan. Following smart practices lowers wear and avoids expensive repairs.

- Check your machine often to find problems early.

- Stick to a maintenance schedule for better engine health.

- Use high-quality oil to protect the engine from damage.

Operate the excavator gently and avoid sudden stops or starts. Quick movements can strain the engine and other parts. Always follow the maker’s rules for speed and load limits. These habits reduce stress on the engine and make it work better.

Avoiding Harsh Operating Conditions

Tough conditions can harm your engine over time. Extreme heat, dust, and heavy loads make the engine work harder. Preventive care includes staying away from these conditions when possible.

Keep your excavator out of dusty or dirty areas. Dust can block filters and cause overheating. If you must work in such places, clean air filters often.

Don’t overload the excavator. Carrying too much weight makes the engine wear out faster. Watch the temperature gauge to avoid overheating. If it gets too hot, stop and let the machine cool down.

Using Genuine Replacement Parts

Using real replacement parts is very important for your engine. These parts fit perfectly and keep the machine running well. Cheaper, fake parts might save money now but can cause big problems later.

| Fact | Details |

|---|---|

| Emergency repairs cost more | 3-4.7x higher than planned maintenance |

| Daily loss from unexpected downtime | $4,200-$7,800 |

| Performance drop without good maintenance | 10-25% |

Real parts help the engine run smoothly and avoid breakdowns. They also prevent costly delays. Always buy parts from trusted sellers to protect your engine and save money in the long run.

Tip: Write down all part changes to track repairs and plan ahead.

Storing Equipment Correctly

Storing your excavator the right way helps its engine last longer. It also keeps the machine safe from damage caused by weather. Use these simple tips to protect your excavator when it’s not being used.

- Choose a Good Spot

Keep your excavator in a dry, covered place. Rain, snow, or sunlight can harm the engine and other parts. If you don’t have indoor space, cover it with a strong tarp. This stops rust and keeps moisture away from the engine. - Get the Engine Ready

Clean the engine to remove dirt before storing. Check oil and coolant levels and refill them if needed. Run the engine for a few minutes to spread the fluids. This stops rust inside. Add a fuel stabilizer for long storage to protect the fuel system. - Take Out the Battery

Remove the battery to stop it from losing power. Store it in a cool, dry spot to keep it charged. A good battery helps the engine start easily later. - Check Belts and Hoses

Look at belts and hoses for cracks or damage. Replace bad ones before storing the excavator. This keeps the engine safe during storage. - Lift the Machine

Raise the excavator slightly to take pressure off tires or tracks. This stops flat spots and protects the undercarriage. A smooth undercarriage helps the engine work better later.

Tip: Make a checklist for storage steps. This helps you remember everything important for the engine.

These storage tips keep your excavator’s engine and parts in great shape. Good storage saves money on repairs and makes sure your machine is ready to use.

Recognizing Warning Signs in Engine Parts

Knowing early signs of engine trouble can save money. Strange sounds, warning lights, or performance changes show problems. Fixing these early avoids big repairs and keeps your excavator running. Daily checks and regular inspections help the engine last longer.

Unusual Noises or Vibrations

Weird sounds or shaking often mean engine trouble. Grinding or screeching noises might mean parts are worn out. Too much vibration could mean loose belts or broken mounts.

If you hear odd sounds, stop and check right away. For example, knocking noises might mean serious issues like bad pistons. Ignoring these signs can cause major damage and costly repairs.

Tip: Use a listening tool to find where noises come from.

Daily checks help catch these problems early. Fixing them quickly keeps the engine working well and avoids downtime.

Warning Lights on the Dashboard

Dashboard lights warn you about engine problems. They show issues like low oil, overheating, or electrical faults. Ignoring these lights can harm the engine or lower its performance.

Common warning lights include:

- Oil Pressure Light: Shows low oil or a bad oil pump.

- Coolant Temperature Light: Warns of overheating or coolant leaks.

- Check Engine Light: Signals anything from small sensor issues to big engine problems.

When a light comes on, check the manual to know what it means. Fix the problem fast to avoid more damage. Daily checks can help spot issues before lights turn on.

Note: Flashing lights mean urgent problems. Act quickly if you see one.

Changes in Engine Performance

If the engine suddenly works poorly, something is wrong. Problems like hard starts, stalling, or using too much fuel are signs. These often happen because of worn parts or clogged filters.

Other signs of trouble include:

- Oil Sludge: Shows poor lubrication, which can cause overheating.

- Metal Shavings in Oil: Means parts inside are rubbing too much.

- Excessive Exhaust Smoke: Points to burning oil or coolant leaks.

- Rough Idling or Runaway Engine: Shows wear that needs fixing fast.

Daily checks can catch these problems early. For example, checking oil for sludge during maintenance can stop bigger issues. Fixing performance problems quickly keeps the engine running well.

Tip: Write down fuel use and engine smoothness. This helps track changes and find problems early.

Watching for these warning signs protects your engine and saves money. Regular checks and daily care keep your excavator reliable and long-lasting.

Too Much Smoke or Heat

Too much smoke or heat from the engine is a big problem. Ignoring these signs can damage the engine and cost a lot to fix. Knowing the causes and acting fast helps keep the engine working longer.

Types of Smoke and What They Mean

Different smoke colors show different engine problems. Learning what each type means helps you fix issues quickly.

- Black Smoke

Black smoke shows fuel isn’t burning properly. This happens when there’s too much fuel or not enough air. It can be caused by dirty air filters, bad injectors, or low-quality fuel. - Blue Smoke

Blue smoke means the engine is burning oil. This happens when worn-out parts let oil into the combustion area. It lowers performance and wears out the engine faster. - White Smoke

White smoke means coolant is leaking into the engine. This could be from a broken gasket or cracked cylinder head. If ignored, it can cause overheating and serious damage.

Tip: Check the color of smoke during daily inspections. This helps you find problems early and fix them before they get worse.

Why Engines Overheat

Overheating puts stress on the engine and shortens its life. Fixing the causes quickly can stop long-term damage.

- Low Coolant Levels

Not enough coolant makes it hard to control the engine’s temperature. Leaks in hoses or the radiator are common causes. - Clogged Radiator

Dirt and debris can block the radiator, making it harder to cool the engine. Cleaning it often helps prevent overheating. - Broken Thermostat

A bad thermostat stops coolant from flowing properly. This causes uneven cooling and higher temperatures. - Overloading

Carrying too much weight makes the engine work harder. This creates more heat and wears out parts faster.

How to Prevent Smoke and Heat

Simple steps can stop smoke and heat problems. These habits improve how the engine works and help it last longer.

- Check Filters Often

Clean or replace air and fuel filters to keep fuel burning right. This lowers the chance of black smoke and helps the engine run better. - Monitor Coolant Levels Daily

Add coolant if it’s low and check for leaks in hoses. A good cooling system stops overheating and protects the engine. - Use Quality Fuel and Oil

Cheap fuel and oil can harm the engine and cause smoke. Always use products recommended by the maker. - Don’t Overload

Keep the excavator within its weight limits. This reduces stress on the engine and keeps it running smoothly.

Note: Regular maintenance can catch small problems before they cause smoke or heat issues.

When to Call a Mechanic

If smoke or heat problems don’t go away, call a mechanic. Some issues, like a cracked cylinder head or broken turbocharger, need expert help. Fixing these quickly stops more damage and keeps the engine in good shape.

By solving smoke or heat problems early, you protect the engine and avoid expensive repairs. Regular checks and care keep your excavator working well and lasting longer.

Taking care of your excavator every day keeps its engine strong. Sticking to a maintenance plan helps avoid expensive repairs. Regular checks let you find problems early and fix them fast. For example:

- Checking hydraulic oil often stops wear and catches issues early.

- Using real-time tools finds oil problems like dirt or thickness changes.

Fixing warning signs like strange sounds or too much smoke quickly protects your machine. These simple steps save money and help your excavator last longer.

Tip: Try condition-based maintenance for even better performance!

FAQ

What is the most important daily maintenance task for an excavator engine?

Checking fluid levels is very important. Low oil or coolant can overheat or harm the engine. Use a dipstick to check oil and look at the coolant tank. Refill fluids right away if they are low to keep the engine working well.

How often should I replace engine filters?

Follow the maker’s schedule for replacing air, fuel, and oil filters. Air filters usually need changing every 250 hours. Oil and fuel filters should be replaced every 500 hours. Clean filters help the engine run better and avoid damage.

What should I do if I notice unusual engine noises?

Turn off the machine right away and check the engine. Odd sounds like knocking or grinding might mean parts are worn or loose. Fix the problem quickly to stop more damage. If unsure, ask a mechanic for help.

Can I use non-genuine parts for engine repairs?

It’s best to use real parts. They fit properly and keep the engine running well. Fake parts might cost less at first but can cause problems or expensive repairs later. Always buy from trusted sellers for replacements.

How can I prevent my excavator engine from overheating?

Check coolant levels every day and look for leaks. Clean the radiator often to remove dirt. Don’t overload the machine, as it makes the engine work harder. Taking care of the cooling system keeps the engine at a safe temperature.

Tip: Write down maintenance tasks to spot repeated problems easily.