OEM and aftermarket crawler excavator spare parts differ in several ways. Operators notice that OEM parts fit perfectly and work seamlessly with their machines. Aftermarket parts offer more options but may not fit as precisely. The quality of aftermarket parts can vary significantly. Many users report that OEM parts last longer, while some aftermarket parts tend to break sooner. Warranty policies also differ; OEM suppliers provide clear warranty terms. When reviewing the crawler excavator spare parts pricelist, OEM parts generally cost more upfront. However, cheaper aftermarket parts might end up costing more over time if they fail prematurely. Operators prefer parts that are readily available, reasonably priced, and come with reliable support.

Operators often worry about:

The quality of parts and their durability

Proper fit for their excavator

Warranty coverage and hassle-free returns

Fast availability of parts

Price and longevity of the parts

Customer service and supplier reliability

Key Takeaways

OEM parts fit just right and last a long time because the original maker makes them and checks their quality carefully.

Aftermarket parts are cheaper and come quicker, but they might not fit as well and their quality and strength can change.

Picking OEM parts keeps your excavator safe, keeps its warranty, and saves money on repairs later.

Aftermarket parts are good for fast repairs or old machines, but you must check if they fit, how good they are, and if they have a warranty.

Always check the part numbers, read the warranty, and buy from trusted sellers to stop problems and keep your machines working well.

OEM Parts vs Aftermarket Parts

OEM Parts

OEM parts come straight from the company that made the crawler excavator. These parts are made to match the machine exactly. The manufacturer makes oem undercarriage parts and other undercarriage components to fit just right and work well. Each oem part is checked carefully and follows the same rules as the original machine. This makes sure oem undercarriage parts work the same every time and keep the machine safe.

Many operators pick oem parts because they know they will fit. These parts help keep the excavator’s warranty and stop it from breaking down. Oem undercarriage components use strong materials, so they last longer and keep the machine safe from harm. But oem parts usually cost more and do not have many choices for upgrades. Owners might have to wait if the manufacturer does not have the part in stock.

Note: Oem undercarriage parts are known for being the best in quality and accuracy.

Aspect | OEM Parts | Aftermarket Parts |

|---|---|---|

Manufacturer | Made by the original equipment manufacturer (same company that made the machine) | Made by third-party manufacturers |

Design and Fit | Specifically developed for the equipment’s design, ensuring precise compatibility | Designed to fit various makes, not guaranteed to be fully compatible |

Manufacturing Standards | Subject to strict manufacturing and quality control processes | Quality varies widely due to lack of standardized oversight |

Safety and Performance | Meet intended safety and performance standards set by the original manufacturer | Not guaranteed to meet original safety and performance standards |

Warranty | Often come with manufacturer warranty (e.g., 12-month parts/service warranty) | Typically no manufacturer warranty or limited warranty |

Quality and Durability | High-quality, durable materials ensuring longevity and reliability | May use inferior materials, leading to variable quality and lifespan |

Industry Standard Position | Considered the benchmark for manufacturing precision and quality control | Offer more choices and lower upfront cost but with variable quality and compatibility risks |

Aftermarket Parts

Aftermarket parts are made by other companies, not the original one. These companies make aftermarket undercarriage parts and undercarriage components to fit many different machines. The quality of aftermarket parts is not always the same because they do not always follow the same rules as oem parts. Some aftermarket undercarriage parts use weaker materials, so they might not last as long or work as well.

A lot of owners buy aftermarket parts because they are cheaper and there are more choices. Aftermarket undercarriage components can help save money, especially for old excavators. But these parts might not fit perfectly, which can make it hard to put them on or make the machine work right. Some aftermarket parts do not have a good warranty, so owners take a bigger risk.

Oem parts are made by the original company, so they are high quality and fit well.

Aftermarket parts are made by other companies, so quality and fit can change.

Oem undercarriage parts usually last longer and keep the excavator safer.

Aftermarket undercarriage components give more choices but might not be as good.

Owners need to think about saving money or risking lower quality and fit.

Operators should always check if aftermarket undercarriage parts are good and fit right before using them, so they do not have problems later.

Quality & Durability

OEM Quality

OEM parts are known for their strong quality and durability. Makers use tough materials like high-grade steel for each part. They check the parts carefully at every step. Engineers design oem undercarriage parts to fit each excavator model exactly. This helps the parts work well and last a long time.

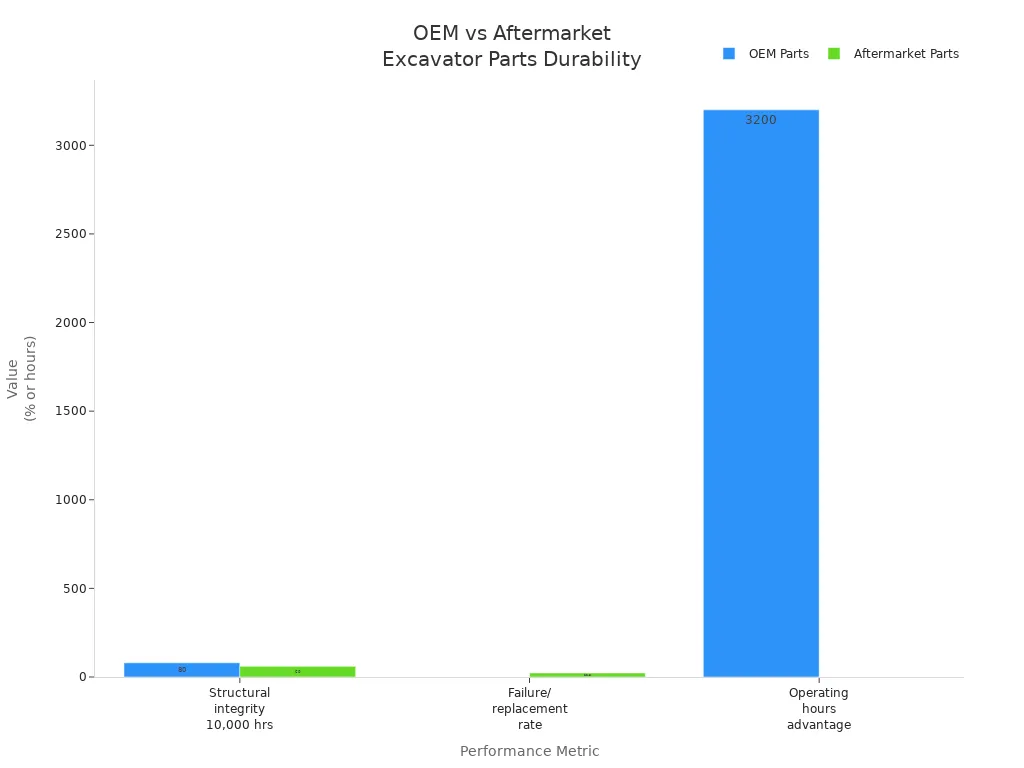

OEM parts go through many tests. These tests include stress checks and wear tests. The tests copy up to 10,000 hours of hard work. OEM undercarriage parts are 40% better at stopping cracks than other parts. Operators see oem parts keep about 80% of their strength after lots of use. In rough places like mines or oil sands, oem undercarriage components last up to 3,200 more hours before needing to be changed.

OEM parts always give good quality and steady performance. Operators trust these parts to keep their excavators safe and working well.

Aspect | OEM Parts | Aftermarket Parts |

|---|---|---|

Material Grade | High-grade steel with strict specs | Often use regular steel with 12-18% less strength |

Testing & Validation | Many stress tests and wear checks for 10,000 hours; 40% better at stopping cracks | Sometimes skip important tests; 34% fail in tests after 6,000 hours |

Failure/Replacement Rates | Fewer failures; keep ~80% strength after 10,000 hours | 15%-30% more replacements in mines; keep 50-70% strength after 10,000 hours |

Operating Hours Before Replacement | Last 3,200 more hours in tough places | Do not last as long, especially in hard jobs |

Performance in Severe Conditions | Very strong and do not bend under stress | Work less well and break faster when hit hard |

Aftermarket Quality

Aftermarket parts give owners more choices, but quality can change a lot. Many aftermarket undercarriage parts use regular steel, which is not as strong as oem parts. Some makers do not do important tests, so these parts break more often. Studies show aftermarket undercarriage components fail 34% of the time after 6,000 hours.

Operators need to change aftermarket parts more often. These parts keep only 50-70% of their strength after 10,000 hours. In mines, owners replace aftermarket undercarriage parts 15%-30% more than oem parts. These parts do not work as well in tough jobs. This means aftermarket parts may not be good for hard work.

Before buying aftermarket undercarriage parts, operators should look at the quality checks and how the parts work in real jobs. Good materials and strong tests make parts last longer, but not all aftermarket parts have these things.

Quality comparison between oem and aftermarket undercarriage parts shows oem parts last longer and work better. Aftermarket parts cost less at first, but owners may pay more later because they need to replace them more often.

OEM parts use strong materials and careful checks.

Aftermarket parts may not always be strong or last long.

Good performance depends on the steel and testing.

Operators should think about how parts work over time before buying undercarriage parts for their excavator.

Crawler Excavator Spare Parts Pricelist & Cost

OEM Parts Pricing

OEM parts usually cost more on the pricelist. They come from the original maker. These parts last a long time and fit well. The higher price means you get strong quality checks and a good warranty. OEM parts often have a warranty from the maker, so you are protected. Using OEM parts helps keep your excavator’s warranty safe. The price also pays for research, testing, and support. OEM parts are a good choice for people who want their machine to last longer and break down less.

Aftermarket Parts Pricing

Aftermarket parts cost less on the pricelist. Many owners buy them to save money. Some aftermarket parts, like Hyundai HCE travel motors, can lower repair costs by half. The low price makes people want to buy them, but quality and strength can change. Warranty rules for aftermarket parts are different, so check before you buy. Using aftermarket parts might cancel your equipment’s warranty. The pricelist does not always show extra costs, like more repairs or longer downtime.

Long-Term Value

The cheapest price does not always mean the best deal. OEM parts last longer, fit better, and can make your machine work up to 30% more. This means less time fixing and less money spent on repairs. Aftermarket parts save money at first, but you might pay more later. You may need more repairs, have more problems, and wait longer for fixes. If you use OEM parts and take care of your machine, you can save up to 25% in total costs. Fixing and caring for your excavator is about 15-20% of its total cost, so picking good parts is important. You should think about price, how long parts last, and how much you will save in the end.

Tip: Always look at the pricelist and think about both the costs you see and the ones you do not before you choose.

Warranty & Support

OEM Warranty

OEM parts usually have a strong warranty. The warranty can last from 12 months or 12,000 miles up to 36 months or 36,000 miles. Some oem parts have even longer protection. The warranty covers problems with materials and how the part was made. Most companies want to see maintenance records before they say yes to a claim. This helps them know the machine was taken care of. Operators like oem warranties because the rules are clear and support is strong. If something goes wrong, the manufacturer gives fast help and sends new parts. The support team knows the equipment well and answers questions quickly.

Part Type | Common Warranty Duration | Coverage | Notes on Warranty Conditions |

|---|---|---|---|

OEM Parts | 12-36 months or 12,000-36,000 miles | Defects in materials and workmanship | Stricter claim rules; may require detailed maintenance records |

Note: OEM warranty coverage helps keep the machine’s value and protects the original warranty.

Aftermarket Warranty

Aftermarket parts have different warranty lengths. Most last from 90 days up to 2 years. The warranty covers problems with materials and how the part was made, but the rules change with each brand. Some aftermarket parts are easy to claim, but others have more steps. The quality of the warranty depends on the company. Some aftermarket companies give good help, but others may not answer fast or give clear support. Operators should always check the warranty before buying aftermarket parts. Reading the details helps avoid problems later.

Part Type | Common Warranty Duration | Coverage | Notes on Warranty Conditions |

|---|---|---|---|

Aftermarket Parts | 90 days to 2 years | Defects in materials and workmanship | Warranty terms vary widely by manufacturer; quality and reputation dependent |

OEM parts have longer and more trusted warranty coverage.

Aftermarket parts have shorter and less certain support.

Good warranty coverage saves money and helps avoid long repairs.

Tip: Always keep maintenance records and read warranty details before picking oem or aftermarket parts.

Availability & Compatibility

OEM Availability

OEM parts come from the company that made the excavator or their trusted dealers. These parts match the machine’s design and have strong warranty protection. Big brands have dealer networks around the world. This helps operators in large areas get oem parts fast. Sometimes, local dealers do not have every oem undercarriage part in stock. Dealers may need to order parts from the factory. This can make operators wait longer, especially for rare parts or models. Operators with only a few machines might wait more because dealers help bigger customers first. When oem parts arrive, they fit well and keep the machine working right.

OEM undercarriage parts often need special orders, so wait times can be longer.

Dealers may not have every oem part, which can mean more downtime if a machine breaks.

Aftermarket Availability

Aftermarket parts give more choices for crawler excavators. Many sellers keep aftermarket undercarriage parts ready to ship fast. Quick shipping helps machines get fixed sooner. Aftermarket parts are good for buyers who want to save money or need a fast repair. More people buy aftermarket parts because they cost less. But some aftermarket parts are not as strong or tough as oem parts. Problems with shipping can happen for both oem and aftermarket parts. Aftermarket sellers often have more flexible stock.

Aftermarket undercarriage parts are usually ready faster than oem parts.

Buyers should be careful of fake or weak aftermarket parts, which can cause safety or machine problems.

Fit & Installation

Making sure parts fit is very important when picking oem or aftermarket parts. OEM undercarriage parts always fit and are easy to put on. Aftermarket parts might not match the machine’s size or shape. Reports say 41% of problems with excavator attachments come from fit issues. These problems can mean more work, delays, or even damage. Operators should check if aftermarket undercarriage parts will fit before buying. Reading product details, checking part numbers, and asking experts can help stop fit problems.

Tip: Always check part numbers and machine models before ordering undercarriage parts. This helps stop fit problems and keeps machines working well.

OEM parts fit best and are easy to install.

Aftermarket parts may need changes or extra checks to fit right.

Careful research and talking to suppliers can fix most fit problems.

Choosing OEM or Aftermarket

Decision Factors

Fleet managers and operators have many choices for crawler excavator spare parts. They think about what is best for their machines and business. The most important things they look at are:

Cost: Managers look at the price now and later.

Quality: They want parts that last and work well.

Performance: Good parts help machines run without stopping.

Durability: Strong parts mean less fixing and fewer changes.

Warranty: A good warranty helps if something goes wrong.

Compatibility: Parts must fit and work with the machine.

Availability: Getting parts fast means less waiting for repairs.

Supplier support: Good suppliers help fix problems quickly.

Safety: Some managers pick OEM parts for important systems to keep things safe.

Managers try to get the most work done and spend less money. They sometimes test aftermarket parts on a few machines first. Suppliers with lots of knowledge and big networks help fleets get parts faster and avoid delays.

Tip: Always think about how you use your equipment before picking OEM or aftermarket parts. This helps you save money and still get good quality and performance.

When to Choose OEM

Experts say OEM parts are best in some cases. OEM parts fit perfectly and work well, which is very important for hydraulic and electronic systems. These parts go through many tests in labs and in the field. OEM parts use strong materials and special welding, so they last longer in hard jobs.

Operators pick OEM parts when they need:

Parts that fit their excavator exactly.

The best quality and long-lasting parts.

A warranty and help from the maker.

To keep their machine’s value high.

To follow safety and emissions rules.

To feel safe on important or special jobs.

Here is a table showing when OEM parts are best:

Scenario | Why Choose OEM Parts |

|---|---|

Critical engine or hydraulic systems | Makes sure the machine works safely |

Equipment under warranty | Keeps the warranty and support |

Regulated industries | Follows the rules |

High-intensity or specialized use | Lasts longer in tough jobs |

Resale value matters | Keeps the machine worth more |

Operators who want the best for their machines often pick OEM parts. They trust these parts to keep their excavators safe and working, even in hard places.

Note: YNF Machinery has many OEM crawler excavator spare parts with good warranty and support.

When to Choose Aftermarket

Aftermarket parts help save money for many operators. Businesses pick aftermarket parts when they want to spend less. These parts cost less than OEM parts. Aftermarket parts can be new, used, rebuilt, or fixed up, so there are more choices for different budgets.

Operators like aftermarket parts when:

They need to do regular fixes or small repairs.

Their machine is old and not under warranty.

OEM parts are not in stock or take too long to get.

They need to fix machines fast to keep working.

They want new features that OEM does not have.

Aftermarket parts help fleets that use their machines a lot and need to save money. These parts are easier to find and can help fix machines faster. But there can be problems like short warranties, fit issues, or lower resale value. Checking and taking care of aftermarket parts often helps them last longer.

Tip: Always check if the supplier is good and what the warranty says before buying aftermarket parts. Try the parts in real jobs to make sure they work well.

Operators who need quick and cheap fixes often pick aftermarket parts. They try to balance price, quality, and how well the parts work to keep their machines running.

Operators notice big differences between OEM and aftermarket crawler excavator spare parts. OEM parts are high quality and fit exactly right. They have strong warranty support. But they cost more and sometimes take longer to get. Aftermarket parts are cheaper and arrive faster. Their quality depends on who makes them.

OEM parts are best for important jobs and when you need a warranty.

Aftermarket parts are good for quick and cheap fixes.

Operators should make sure the parts fit their machine. They should check if the supplier is trusted and read the warranty rules. Picking the right parts helps save money, keeps machines working, and gives good support later.

FAQ

What is the main difference between OEM and aftermarket parts?

OEM parts are made by the original company. They fit the machine just right. Aftermarket parts are made by other companies. These might not fit as well. OEM parts often last longer than aftermarket ones.

Can aftermarket parts void my excavator’s warranty?

Yes, using aftermarket parts can cancel your warranty. Always read the warranty rules before you use non-OEM parts.

How can operators check if a part will fit their excavator?

Operators should check the part number and model. They can ask YNF Machinery for help. Reading product info and talking to experts helps stop mistakes.

Are aftermarket parts always cheaper than OEM parts?

Aftermarket parts usually cost less at first. But they might break sooner or need more repairs. This can make them cost more later.

Where can operators buy reliable crawler excavator spare parts?

Operators can get good parts from YNF Machinery. This company sells both OEM and strong aftermarket parts. They also give good support.