Understanding the parts of a JCB excavator is essential for operating it efficiently. Each part plays a crucial role in ensuring smooth performance and handling various tasks. Familiarity with the parts of a JCB excavator allows you to operate it more effectively and minimize downtime. For instance, the hydraulic system powers the machine, while the boom and bucket are designed to lift heavy loads. This knowledge not only helps in quickly addressing issues but also in maintaining the excavator’s reliability for construction or other demanding jobs.

Key Takeaways

Knowing JCB excavator parts helps work faster and avoid delays. Understanding what each part does makes fixing problems easier.

Taking care of your excavator with checks and oiling is important. This stops expensive repairs and keeps it working well.

Picking the right tools for jobs makes work quicker. Using the right bucket or tool improves how the machine works and saves time.

Learning about the hydraulic system helps the excavator stay strong. Taking care of these parts stops problems and keeps it running smoothly.

Getting experts to check your excavator is very helpful. Regular inspections find problems early and keep it dependable.

Overview of JCB Excavators

Key Features of JCB Excavators

JCB excavators are known for their smart design and top features. These machines are made to handle tough jobs easily. They offer great performance and are very reliable. Some key features include:

Strong H-frames that are fully welded for stability.

Tracks with sealed parts to last in rough conditions.

Special hydraulic fittings that prevent leaks and work well.

Twin auxiliary lines you can program for different tools.

Big glass windows in the cabin for better visibility.

JCB excavators also use advanced technology. For example, the JCB UX interface has a 10-inch color screen. This makes controlling the machine simple. With a 322-horsepower Cummins diesel engine, they dig better and faster. Longer service times and stronger undercarriages lower repair costs. This helps save money over time.

Importance of Excavators in Construction and Other Industries

Excavators are very important in construction and other industries. They are used for digging, lifting, and moving materials. The demand for excavators shows how useful they are. In 2024, the market was worth $76.72 billion. By 2030, it may grow to $107.81 billion. This shows how much they are needed for building projects.

Special tools make excavators even more useful. The right tool can make work 25% faster. Electric models are also becoming popular. They cut greenhouse gas emissions by 30%. Fleet owners save 15% on costs with better maintenance and less downtime.

Whether on a building site or in a factory, JCB excavators give you the power and flexibility to finish your work efficiently.

Key Parts of JCB Excavator and Their Functions

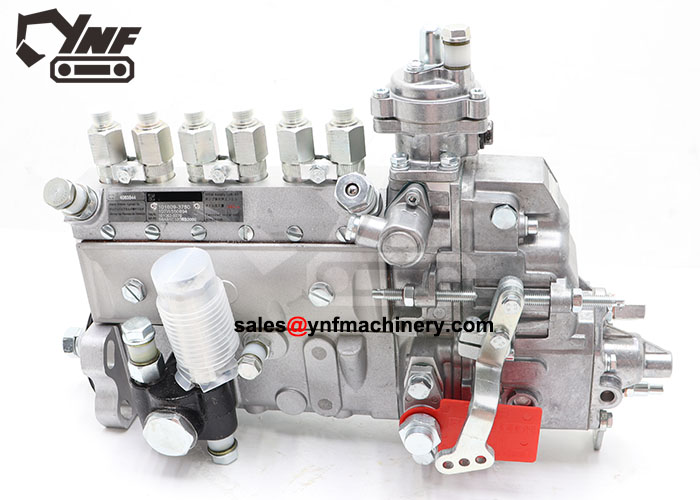

Hydraulic System and Cylinders

The hydraulic system powers your JCB excavator. It moves the boom, arm, and bucket for digging and lifting. This system uses pressurized fluid to create energy. It is key to the machine’s strength and smooth operation. Good hydraulic parts help avoid breakdowns and keep things running well.

JCB excavators have advanced hydraulic systems for better performance. For example, the hydraulic regeneration system reuses oil in the cylinders. This makes the machine more efficient. Bigger bucket cylinders add 11% more force, making tough jobs easier. You can also adjust the machine’s speed and precision with special controls.

Feature | Description |

|---|---|

Hydraulic Pipes and Hoses | Large pipes improve work speed and efficiency. |

Hydraulic Regeneration System | Reuses oil in cylinders for better performance. |

Fuel Savings | Auto-stop and idle features save 5% on fuel. |

Bucket Cylinder | Bigger cylinder adds 11% more digging power. |

Control System | Adjustable controls for speed and accuracy. |

Hydraulic Components | High-quality parts ensure smooth and precise control. |

Power Boost | Adds 9% more pressure for short bursts of power. |

Taking care of the hydraulic system is very important. Skipping maintenance can cause failures and harm other parts. Regular checks and using good parts can prevent problems and make the system last longer.

Boom, Arm, and Bucket

The boom, arm, and bucket are the main digging tools. They work together to dig, lift, and move materials. The boom moves up and down, the arm stretches out, and the bucket scoops or carries items. These parts make the excavator versatile and efficient.

Tests show how important these parts are. For example, timing the boom, arm, and bucket helps check hydraulic performance. Stress tests on the boom ensure it can handle heavy loads. Better designs make these parts stronger and less likely to break.

The bucket’s path is tested for better performance.

Sensors track cylinder lengths for precise movements.

Stress tests confirm the boom’s strength in tough jobs.

Using poor materials or bad designs can cause failures. Cracks in welds or stressed areas can lead to big problems. JCB excavators use strong designs and quality materials to avoid these risks.

Study Title | Findings | Key Issues |

|---|---|---|

Failure assessment of a weld-cracked mining excavator boom | Cracks in welds caused major failure | Weak materials, bad welds, poor design |

Failure analysis of bolts on fatigue test bench for excavator stick | Bolts failed due to stress and bad design | High stress, poor weld quality |

Tracks and Undercarriage

Tracks and the undercarriage keep the excavator stable and moving. Tracks spread the machine’s weight, so it works on soft or uneven ground. The undercarriage has parts like idlers, rollers, and sprockets. These guide and support the tracks for smooth movement.

Tracks and undercarriages must be strong to handle tough jobs. In construction and mining, they face rough surfaces and heavy loads. Strong designs and good lubrication help them last longer. For example, idlers keep the tracks tight and aligned, which extends their life.

Evidence Type | Description |

|---|---|

Mining Industry | Undercarriages handle tough mining conditions. |

Bulldozer Performance | Tracks improve bulldozer efficiency and lifespan. |

Track Stability | Tracks keep machines steady on uneven ground. |

Idler Functionality | Idlers keep tracks tight and aligned for longer use. |

Knowing track problems helps you take care of them. Pin holes in track chains are weak spots that face high stress. Lack of lubrication and rough conditions wear them out faster. Regular checks and maintenance can fix these issues, keeping your excavator reliable.

Operator Cabin and Controls

The operator cabin is where you control the JCB excavator. It is built for comfort, safety, and easy use. This helps you work longer without getting tired. Modern cabins have better layouts, smart controls, and clear views. These features make work easier and safer.

Key Features of the Operator Cabin:

Ergonomic Design: The cabin reduces body strain. Seats, armrests, and controls adjust for comfort.

Advanced Controls: Joysticks and touchscreens make operating simple and precise. They are easy to learn and use.

Enhanced Visibility: Big glass windows and mirrors help you see clearly. This reduces blind spots and improves safety.

Climate Control: Heating and cooling systems keep the cabin comfortable in any weather.

Tip: Clean the windows and mirrors often for better visibility and safety.

Impact of Advanced Cabin Designs:

Studies show good cabin designs improve safety and ease of use. For example, combining hardware and software controls works best:

Interaction Mode | Safety Level | Usability Level | Key Findings |

|---|---|---|---|

Hardware Interaction (HI) | Highest | Moderate | Safest for driving, with fewer distractions. |

Hardware and Software Interaction (HSI) | High | Highest | Fastest task completion and easiest to use. |

Software Interaction (SI) | Lowest | Lowest | Slowest tasks, most errors, and more distractions. |

These results show why a well-designed cabin is important. It boosts productivity and keeps you safe while working.

Ergonomic Insights:

Excavator cabins need smooth interaction between people and machines.

Badly designed controls can cause accidents, showing the need for better ergonomics.

A study on ergonomic design showed how it improves operator performance.

Key Findings | Description |

|---|---|

Human Operation Performance | Highlights the need for designs that help operators work better. |

Ergonomic Design Index System | Lists key factors for operator safety and efficiency. |

Case Study | Proves ergonomic designs work in real-life situations. |

JCB focuses on ergonomics to make cabins comfortable and highly functional. This ensures operators can work efficiently and safely.

Types of JCB Excavators and Their Applications

Mini Excavators

Mini excavators are small machines made for tight spaces. They work well in areas like city construction or home projects. These machines have advanced hydraulics for smooth and precise movements. For example, the KOBELCO SK35SR-7 uses less fuel in ECO mode, saving up to 24%. It also provides strong digging power, making it both efficient and powerful.

A big benefit of mini excavators is their zero tail swing. This feature helps them move easily in cramped areas. Models like the SK25SR-6E have helpful features, such as an LCD screen for important updates. They also save fuel, making them cheaper to use over time. Whether you’re digging, landscaping, or installing utilities, mini excavators are agile and reliable.

Feature | Mini Excavators | Other Models |

|---|---|---|

Size | Small and compact | Bigger and bulkier |

Tail Swing | No tail swing | Larger tail swing |

Maneuverability | Easy to move | Harder to move |

Hydraulic System | Advanced and precise | Basic hydraulics |

Fuel Efficiency | Very fuel-efficient | Uses more fuel |

Standard Excavators

Standard excavators are used in most construction jobs. They are strong and easy to control, making them great for many tasks. These include digging foundations and lifting heavy items. Weighing 11–45 tons, they are perfect for general construction. Their hydraulic systems ensure steady performance for tough jobs.

Tests show how productive standard excavators can be. Medium-sized ones (6 to 10 tons) can move 20 to 40 cubic meters of material per hour. This makes them a favorite for contractors. Adding the right tools can make them even better. For example, attachments for trenching or demolition improve their usefulness.

Excavator Type | Productivity Rate (m3/hour) |

|---|---|

Small Excavators (1 to 5 tons) | 10 to 20 |

Medium Excavators (6 to 10 tons) | 20 to 40 |

Large Excavators (11 to 50 tons) | 40 to 100 |

Heavy-Duty Excavators (Over 50 tons) | 100 |

Long-Reach Excavators

Long-reach excavators are made for jobs needing extra reach. Their long arms and booms help them access hard-to-reach places. These machines are great for dredging rivers or tearing down tall buildings. They are built for tasks where precision and distance are important.

For example, long-reach excavators can clear debris from rivers or demolish high structures. Their hydraulics give them the strength to lift heavy loads. The long arm reduces the need to move the machine often. This saves time and keeps operators safe from dangerous areas. If your job involves tricky locations, these excavators are the best choice.

Excavator Type | Key Features and Applications |

|---|---|

Mini/Compact | Best for small spaces like city or home projects. |

Crawler | Handles big earthmoving jobs with stability and power. |

Wheeled | Moves easily on paved roads or surfaces. |

Long Reach | Perfect for far-reaching tasks like dredging or demolition. |

Tip: Pick the right excavator for your project. The correct choice can save time and money while improving results.

Wheeled Excavators

Wheeled excavators are machines made for speed and flexibility. Unlike tracked excavators, they move on wheels. This makes them great for cities and paved areas. They can travel up to 40 km/h, so moving between sites is fast. This saves time and helps finish projects quicker.

These machines work well in small spaces. Their compact size and easy controls make them simple to use. Wheeled mini excavators are stable and easy to handle. They are perfect for jobs like digging, moving materials, or small demolition tasks.

A big benefit of wheeled excavators is their low ground pressure. This means they won’t damage roads or concrete surfaces. For city jobs, this keeps streets and sidewalks safe during work. They also work well on different types of ground, making them useful for many projects.

Attachments make wheeled excavators even better. Tools like hydraulic breakers or grapples add more ways to use them. These machines also save fuel, which lowers costs. Contractors find them efficient and good for the environment.

Tip: Choose wheeled excavators for city jobs needing mobility and surface care. Their speed and flexibility make them a smart choice for urban construction.

Feature | Benefit |

|---|---|

High Speed | Quick travel between work locations. |

Reduced Ground Pressure | Prevents damage to roads and concrete. |

Compact Design | Fits easily into crowded spaces. |

Versatile Attachments | Adds more ways to use the machine. |

Attachments for JCB Excavators

Buckets for Various Tasks

Buckets are tools that help with many jobs. They are used for digging, trenching, and moving materials. Different buckets work better for specific tasks. For example, trenching buckets make narrow trenches, while heavy-duty buckets handle rocks and debris easily.

Custom buckets can make work faster and safer. Studies show ergonomic designs lower the chance of back injuries. A trenching bucket with the right size improves digging accuracy. This reduces mistakes and saves money. Special tools like root rakes also speed up work by 30%. Picking the right bucket helps save time and get better results.

Tip: Use the correct bucket for your job. This improves performance and protects your excavator from wear.

Hydraulic Breakers and Grapples

Hydraulic breakers and grapples are great for breaking and lifting. Breakers smash concrete, rocks, or asphalt with strong hits. Grapples grab and move items like logs or scrap metal. These tools make excavators useful for tough jobs.

New technology has made these tools better. Breakers now have more power and built-in monitors for reliability. They also make less noise and dust, which is good for city work. Grapples give better control, lowering the chance of accidents when moving materials.

Feature | Advantage |

|---|---|

Versatility | Useful for many construction tasks. |

Advanced Technology | Better performance and reliability. |

Eco-Friendly | Quieter and cleaner for urban projects. |

Safety | Precise handling reduces accidents. |

Speed | Faster than doing the work by hand. |

Note: Adding hydraulic tools like breakers and grapples makes your excavator more flexible for hard jobs.

Augers and Drills

Augers and drills turn excavators into machines for digging holes. They are great for planting trees, setting fence posts, or building foundations. These tools make precise holes quickly, which is helpful for landscaping and construction.

Special designs improve how they work. For example, forestry augers are better for cutting trees and clearing land. These tools also make jobs safer and more accurate. Whether in mining, forestry, or building, augers and drills give your excavator more abilities.

Tip: Check augers and drills often for damage. This keeps them working well and lasting longer.

Specialized Attachments for Specific Applications

Specialized attachments make your excavator more useful for different tasks. These tools are made for specific jobs, helping your machine work better and faster. Picking the right attachment saves time and boosts efficiency on tough projects.

One common attachment is the ripper. It breaks hard soil, frozen ground, or packed materials. This tool is great for preparing land for farming or building. Another helpful tool is the pulverizer. It crushes concrete and separates metal bars. It’s perfect for recycling and tearing down structures.

For forest work, a mulcher is very useful. It clears plants and grinds tree stumps into mulch. This helps prepare land for farming or building. A log grapple is another option. It lifts and moves logs safely and easily during logging jobs.

In mining, rock saws and drum cutters are important. They cut stone and tough materials with accuracy. These tools reduce waste and make cleaner cuts. For underwater work, dredging pumps remove dirt and debris from rivers or reservoirs.

Tip: Use the right tool for the job. The wrong attachment can harm your excavator and slow down work.

Specialized attachments let your excavator handle many tasks. They improve performance and make it useful for industries like construction, forestry, and mining. Choosing the right tools gives better results and keeps your machine working longer.

Maintenance Tips for Excavator Parts

Regular Inspection and Cleaning

Checking and cleaning your excavator often keeps it working well. Inspections help find small problems before they get worse. Cleaning removes dirt that can harm important parts. For example, mud can block the undercarriage or damage hydraulic systems.

Tip: Pay attention to the engine, hydraulics, and electrical parts. These areas wear out faster and need extra care.

Studies show regular checks lower failure chances by 30%. Cleaning also stops hidden risks and keeps the machine safe to use.

Maintenance Task | Benefit |

|---|---|

Cuts failure risk by up to 30%. | |

Cleaning parts | Avoids hidden damage and problems. |

Making inspections and cleaning a habit helps your excavator last longer and work better.

Lubrication and Hydraulic Fluid Monitoring

Lubrication is key for smooth machine movement. It reduces friction and stops parts from overheating. Checking hydraulic fluid levels ensures the system works properly. Low or dirty fluid can cause big problems or even failures.

Note: Use the right oil type and follow the maker’s schedule for lubrication.

Metrics like Oil Cleanliness Level show why lubrication matters. Sticking to schedules improves reliability and reduces downtime.

Metric | Why It Matters |

|---|---|

Overall Lubrication Effectiveness (OLE) | Measures how well lubrication is done. |

Mean Time Between Lubrication (MTBL) | Tracks how often lubrication is needed. |

Lubrication Interval Adherence | Checks if lubrication schedules are followed. |

Oil Cleanliness Level | Shows how clean the oil is, preventing damage from dirt or contamination. |

Proper lubrication and fluid checks keep your excavator running smoothly and efficiently.

Replacing Worn-Out Components

Changing worn-out parts on time keeps your excavator efficient. Parts like tracks, buckets, and hydraulic pumps wear out with use. Replacing them early avoids breakdowns and keeps the machine running well.

Tip: Make a schedule to check parts like the undercarriage and transmission regularly.

Research shows better materials improve part durability and machine life. For example, stronger undercarriage parts last longer in tough conditions.

Part Type | Why It’s Important | New Trends |

|---|---|---|

Transmission Parts | Transfers power; boosts performance and lifespan. | Stronger, more durable designs for heavy use. |

Undercarriage Parts | Provides stability; must handle rough conditions. | Improved materials for better durability and performance. |

Electrical Parts | Runs systems; automation increases their importance. | Focus on reliable, efficient designs for modern machines. |

Replacing old parts on time keeps your excavator safe and dependable.

Importance of Professional Servicing

Getting professional servicing is key to keeping your excavator in great shape. Regular check-ups help the machine work better, reduce downtime, and boost productivity. Fixing small problems early avoids expensive repairs and makes your equipment last longer.

Why Professional Servicing Matters:

Better Performance: Tasks like oiling, changing filters, and checking parts keep the machine working well. This helps you finish jobs faster.

Longer Life: Regular care makes your excavator more reliable and durable over time.

Save Money: Fixing small issues early stops big, costly breakdowns later.

Stay Safe: Professional checks ensure all parts work properly, lowering accident risks.

Tip: Always choose high-quality OEM parts for repairs. These parts fit your excavator perfectly and work best.

Professional servicing also makes maintenance easier. Training and new tools help workers do routine tasks better. For example, diagnostic tools find problems quickly during inspections. This saves time and keeps your machine running longer, helping projects succeed.

Good maintenance includes changing fluids, cleaning, and replacing worn parts. These steps stop damage and keep your excavator dependable. By focusing on professional servicing, you make sure your machine stays safe, efficient, and ready for tough jobs.

Note: Skipping maintenance can cause sudden breakdowns, delay work, and raise costs. Regular servicing is a smart way to avoid these problems.

Knowing excavator parts helps you use it effectively and fix issues fast. Every part is important for smooth operation. Regular care, like checking and oiling, keeps it dependable and lasts longer. Picking the right excavator and tools makes work faster and easier. Taking good care and using proper tools ensures your machine stays strong and works well for your projects.

FAQ

How long does a JCB excavator last?

How long it lasts depends on care and use. With good maintenance, a JCB excavator can work for 10,000 to 15,000 hours or more. Regular check-ups and changing old parts help it last longer.

How often should an excavator be checked?

You should check your excavator every day before using it. Look at the hydraulic system, tracks, engine, and tools for damage or wear. Daily checks stop big problems from happening.

Can all attachments work with a JCB excavator?

Not every attachment fits all models. Always make sure the attachment matches your excavator’s design. Using the wrong tool can harm the machine or make it less effective.

What fuel does a JCB excavator need?

Most JCB excavators use diesel fuel. Always pick high-quality diesel to keep the engine running well and avoid problems.

How do you take care of the hydraulic system?

Check fluid levels, change filters often, and look for leaks. Use the right hydraulic oil for your machine. Good care keeps the system working smoothly and avoids breakdowns.