When you buy excavator engine parts, you need an excavator engine parts exporter you can trust. The right excavator engine parts exporter provides quality parts and quick delivery, keeping your excavator running smoothly and saving you money. This also helps you avoid costly downtime on the job. Importing excavators from China requires careful planning before you buy. Choosing the wrong excavator engine parts exporter can lead to delays and damaged equipment, potentially holding up your entire project. Buying and shipping excavators from China isn’t always easy, especially if you need many parts. Selecting an excavator engine parts exporter with a strong track record makes the process much simpler. Every decision you make impacts how smoothly your buying and shipping experience will go.

Key Takeaways

-

Check if the exporter has the right certificates and a good reputation. This helps you get good parts and avoid waiting too long.

-

Make sure the parts match your excavator model exactly. This keeps your machine working well and stops it from breaking.

-

Pick exporters who sell strong and long-lasting parts. These parts should be tested for quality, whether they are OEM or trusted aftermarket.

-

Choose exporters who ship quickly and are reliable. Good customer support helps your projects stay on track.

-

Look for value, not just low prices. Pick exporters who give good quality, helpful service, and clear return rules for long-term success.

Exporter Credentials

When you look for excavator engine parts, you need to check if your exporter is real and trustworthy. Good credentials help you avoid big mistakes and make sure you get high-quality parts that fit your excavator. Let’s look at the main things you should check before you import.

Certifications

Certifications show that an excavator engine parts exporter follows important industry rules. You should pick exporters who have well-known certifications. These prove the exporter cares about safety, quality, and following the law. Here are some key things to look for:

-

The Bureau of Indian Standards (BIS) Standard Mark is needed for excavator engine parts.

-

Exporters must follow Quality Control Orders and the Machinery and Electrical Equipment Safety Order (2024).

-

The 2023 Fasteners Order says high-tensile bolts and nuts must meet strict rules.

-

BIS rules now include plastic seals and new alloy fasteners.

-

Exporters should use official testing, licenses, and batch checks.

-

Digital certification management and working with licensed makers help prove they are real.

Tip: Always ask for digital copies of certifications before you import. This step helps you avoid fake or poor-quality parts.

Reputation

A good excavator engine parts exporter earns trust by having happy customers and a strong history. You should read online reviews, visit industry forums, and ask for references from past buyers. Reliable exporters often work with big brands and importers for many years.

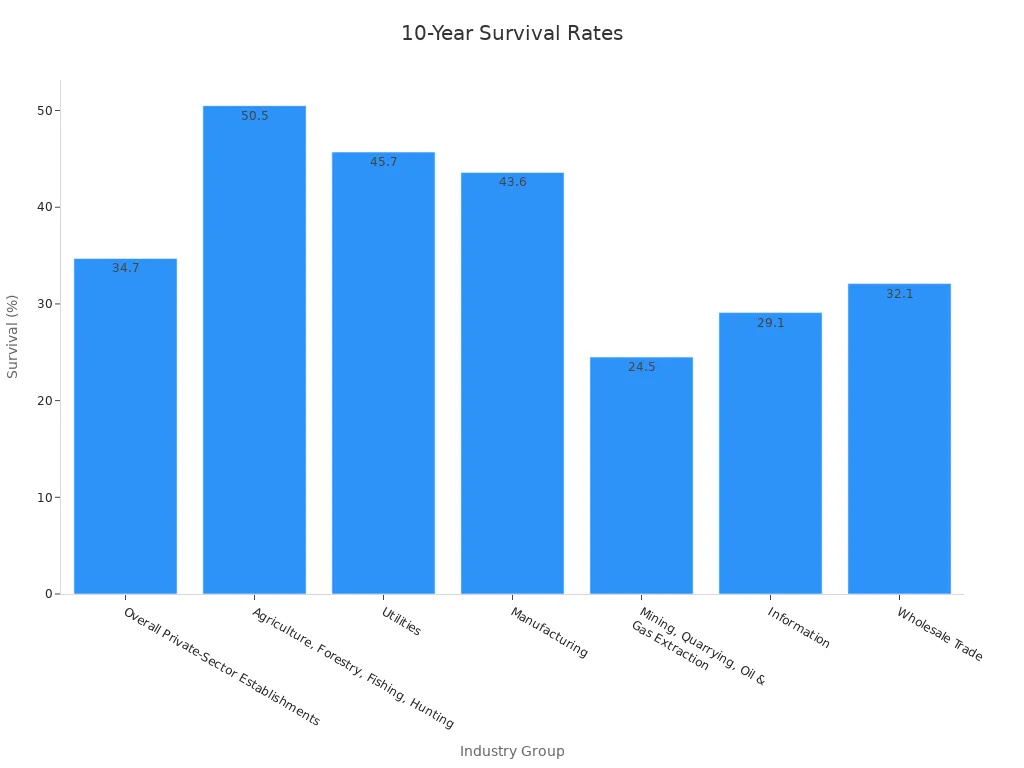

|

Industry Group |

10-Year Survival Rate (2013-2023) |

|---|---|

|

Overall Private-Sector Establishments |

34.7% |

|

Agriculture, Forestry, Fishing, Hunting |

50.5% |

|

Utilities |

45.7% |

|

Manufacturing |

43.6% |

|

Mining, Quarrying, Oil & Gas Extraction |

24.5% |

|

Information |

29.1% |

|

Wholesale Trade |

32.1% |

You can see that manufacturing and wholesale trade exporters with over ten years in business last longer. This means they are more likely to be honest and dependable. Companies with long export records are 60-70% more likely to keep their customers, so you get steady parts and fewer problems.

Track Record

A good track record means the exporter always gives you quality and helps your excavator work well. You should find exporters who can show real results and share case studies. Here are some facts and examples:

-

Fuel efficiency went up by 7% after using OEM-compatible fuel injectors.

-

Maintenance downtime dropped by 15%, which means better durability.

-

Procurement costs went down by 20% without losing quality.

-

Flow rate stayed within ±2%, so fuel delivery was exact.

-

Injectors worked at pressures up to 30,000 PSI, great for tough CAT C15 engines.

-

Emissions dropped by 10% NOx compared to regular parts.

-

Injector lifespan was over 10,000 hours in field tests.

-

Over 15 years of experience and partnerships with OEMs like CNH, CAT, and Volvo.

-

They follow ISO 9001 quality standards and give full technical documents.

Perkins engines are trusted by top excavator makers in China. The Perkins 2206D engine in SEM680D wheel loaders gives long-lasting use, low noise, and lower costs. Perkins technology also helped Kaiser make Stage V walking excavators with better emissions, efficiency, and movement.

Note: A strong track record helps you feel sure about your choices and keeps you from making expensive mistakes when you import.

Product Quality

When you pick an exporter, you should care about product quality. Good excavator engine parts help your machine last longer. They also stop you from paying for repairs. You need to make sure each part meets high standards before using it.

OEM vs Aftermarket

You have two main choices for excavator engine parts. One is OEM, which means Original Equipment Manufacturer. These parts are made by the same company as your excavator. OEM parts fit just right and match the first design. You can trust their quality because the maker tests them for safety and how well they work.

Aftermarket parts are made by other companies. Some aftermarket parts are good and cost less money. Trusted aftermarket brands test their parts and follow the rules. You should check if aftermarket parts are as good as OEM. Bad aftermarket parts can hurt your excavator or make it break down.

Tip: Always ask your exporter if they have OEM or certified aftermarket parts. Good exporters will show you proof that both are good quality.

Material Testing

Material testing helps you know if the parts will last. You want parts that can handle wear, heat, and pressure. Good exporters test how hard and strong each part is. They use machines to see if the metal can take heavy loads. Wear tests show how long the parts will last in your excavator.

Here are some tests exporters use:

-

Hardness Test: Checks how tough the metal is.

-

Tensile Strength Test: Sees if the part can stretch without breaking.

-

Fatigue Test: Shows how many times the part can be used before it breaks.

-

Corrosion Test: Checks if the part can fight rust and chemicals.

|

Test Type |

What It Checks |

Why It Matters for Excavators |

|---|---|---|

|

Hardness |

Metal toughness |

Stops cracks and dents |

|

Wear Resistance |

Surface durability |

Lowers how often you change parts |

|

Fatigue |

Long-term strength |

Handles big jobs for excavators |

|

Corrosion |

Rust and chemical resistance |

Makes parts last longer |

You should always ask for test reports from your exporter. These reports show the excavator engine parts are good quality.

Quality Standards

Quality standards help protect your money. Exporters must follow strict rules so every part works well. Look for exporters who have ISO 9001 or similar certifications. These show the company checks every step for quality.

You should also see if the exporter uses batch testing and digital tracking. Batch testing means they test some parts from each shipment. Digital tracking lets you see where each part came from. This helps you avoid fake or bad parts.

Note: Never forget to check quality certifications. Good exporters will give you these papers before you buy.

Good excavator engine parts keep your machine safe and working well. When you care about quality, you save money and stop project delays. Always pick exporters who show they care about quality at every step.

Compatibility & Range

Model Fit

You must match each part to your excavator’s make and model. Every excavator has its own special details. If you use the wrong part, your machine may not work well. It could wear out faster or even break down. Always look at the manufacturer’s manual before buying parts. OEM codes and serial numbers help you pick the right part. Two parts might look alike, but only the correct one will work well in your excavator.

-

Using original manufacturer parts lowers the chance of failure by 20%.

-

Certified aftermarket parts can cut equipment failures by 15%. They also help your excavator stay strong when lifting heavy things.

-

Always check part models, batch numbers, and machine details.

-

Parts with ISO or CE standards are safe and high quality.

-

Special testing tools and advice from the maker help you avoid mistakes.

When you pick parts made for your excavator, it works better. Good materials and careful building help parts last longer. Upgrades like tough buckets or smart controls make your machine more efficient. Matching hydraulic parts and using digital tools also help your excavator last longer.

Tip: Write down your excavator’s brand, model, and serial number before you order. This step helps you avoid compatibility issues.

Wide Parts Selection

A good exporter has many excavator engine parts to choose from. This makes it easy to find what you need for any brand or model. Exporters with big stocks have parts for Caterpillar, Komatsu, Hitachi, Hyundai, Kobelco, and more. You save time and avoid waiting when you can get many parts in one place.

|

Statistic/Metric |

Value/Description |

|---|---|

|

Number of pieces in stock |

Over 20,000 pieces |

|

Number of SKUs available |

More than 100,000 SKUs |

|

Brands covered |

Caterpillar, Komatsu, Hitachi, Hyundai, Kobelco, and others |

|

Annual sales volume of excavator parts |

Approximately $100 billion |

|

Advantage highlighted |

Broad selection meets diverse customer needs and supports online research and purchasing behavior |

Most people look up excavator parts online before buying. Exporters with lots of choices help you compare and pick the best part. This way, you always get the right part. Your excavator stays in good shape and your projects finish on time.

Delivery & Value

Prompt Shipping

Getting parts fast helps your excavator jobs stay on track. When you order engine parts, you need a freight forwarder you can trust. They should move your order quickly and keep it safe. If shipping is late, your work might stop and cost you money. Always check how your exporter ships parts. Here are some important delivery facts:

|

Metric |

Description |

Impact on Project Continuity |

|---|---|---|

|

Order Accuracy |

Shows if you get the right parts and amounts. |

Stops mistakes and keeps your excavator working without waiting. |

|

Lead Time |

Tells how many days from order to delivery. |

Shorter times help you act fast and need less extra stock. |

|

On-Time Delivery |

Shows if orders arrive when promised. |

Proves your supplier is reliable and helps you avoid job delays. |

|

Supplier Responsiveness |

Tells how fast your exporter answers questions or fixes problems. |

Fast replies solve issues quickly and keep your import smooth. |

Tip: Pick a good freight forwarder so you can track your shipment and fix problems before they slow you down.

Pricing

You want a good deal when buying excavator engine parts. The cheapest price is not always the best choice. Smart buyers compare prices from different exporters before buying. Try these steps to save money and get good value:

-

Check prices from many suppliers so you do not pick the first one.

-

Think about aftermarket parts that meet the rules for a cheaper option.

-

Make friends with exporters to get discounts and better deals.

-

Take care of your parts so they last longer and save money.

-

Buy lots of parts at once if you need them to pay less for each.

Prices can change depending on brand, place, and how many people want the parts. Look at import and export numbers for your country to see what prices are like now. Compare brands like Caterpillar, Komatsu, and Volvo to find the best value for your needs.

Value Over Price

Picking value instead of just price gives better results for your excavator jobs. If you care about quality and service, you will have fewer breakdowns and delays. A big company found that spending more on value, like better customer help and supply chain, made customers happier and helped their business grow. Experts say value-based buying builds trust and helps you succeed for a long time. If you only look for the lowest price, you might get bad parts and need to buy more often.

Remember: Value is more than just price. Choose exporters who give good after-sales help, clear return rules, and work with trusted freight forwarders. This way, you can import with confidence and keep your excavator working well.

Customer Support

Picking an exporter with good customer support really matters. You need answers that are easy to understand and quick help. Support should not stop after you buy your parts. Good customer support helps you avoid mistakes. It also keeps your excavator working without long waits.

Responsiveness

You want an exporter who replies fast when you ask questions. Quick answers help you fix problems before they get worse. When you ask for help, you should get updates and clear answers. Exporters who use direct contact and focused messages reply faster. This can make response rates go up by 500% or more. Some exporters even answer every question from Komatsu Hydraulic Excavator buyers. These facts show that fast and personal replies keep you happy and interested.

A fast exporter helps you avoid waiting and keeps your excavator on track.

After-Sales Service

You still need help after you buy your engine parts. Good after-sales service means you get help with setup, fixing problems, and sending things back. Exporters should have easy return rules and give you technical help. You want to know you can get help quickly if something is wrong.

-

Service numbers like Customer Satisfaction Score and Repeat Purchase Rate show how well exporters help after you buy.

-

Fast fixes, clear answers, and easy returns make you want to buy again.

-

Many exporters now use AI tools to give you quick and personal help.

-

Support in many languages and ways to contact the exporter make it easier for you to get answers.

Pick exporters who help in your language and on different apps or websites. This way, you always have help for your excavator when you need it.

Good customer support helps you feel calm. You can work on your excavator projects, knowing help is always there.

To find a good excavator engine parts exporter, check their credentials. Look at the quality of their parts. Make sure the parts fit your excavator. The exporter should ship parts fast. They also need to give good customer support. These steps help your excavator work well and stop expensive delays.

Remember: Pick exporters who are reliable and give you good value. This helps protect your excavator and keeps your projects on time.

FAQ

What certifications should you check before buying excavator engine parts?

Look for ISO 9001, BIS, and CE certifications. These certificates mean the exporter follows important safety and quality rules. Always ask for digital copies before you order anything.

How do you know if a part will fit your excavator?

Check your excavator’s brand, model, and serial number. Make sure these match the part’s details. You can ask the exporter for help or use the manual to check.

Why is OEM better than aftermarket for engine parts?

OEM parts are made by the original company. They fit right and last longer. Some aftermarket parts work well, but you need to check their quality. OEM parts give you better performance and less worry.

What should you do if a part arrives damaged or does not work?

Tell the exporter as soon as you can.

Send photos and your order information.

Good exporters let you return parts easily and get replacements fast.

Always read the return policy before you buy.