Maintaining your Hitachi excavator in optimal condition involves paying attention to essential components, as outlined in the Hitachi excavator parts list. Key parts include the engine, hydraulics, undercarriage, swing mechanism, frame, and electrical system. Each of these components plays a crucial role in ensuring the machine operates smoothly and minimizes the risk of breakdowns. Regular inspections and prompt repairs can help prevent significant issues and save you money in the long run. Utilizing high-quality parts, such as genuine Hitachi excavator parts, enhances reliability and extends the lifespan of your equipment. A well-maintained excavator not only performs better but also lasts for many years.

Key Takeaways

Check your excavator often. Daily, weekly, and monthly checks find problems early and save money on repairs.

Use real Hitachi parts for better performance. These parts fit well and last longer in your machine.

Replace important parts like filters and hoses on time. This keeps your excavator working smoothly and efficiently.

Take care of the hydraulic system. Regular checks stop leaks and help with digging and lifting.

Spot damage early. Look for cracks or strange noises to avoid big problems later.

Overview of Hitachi Excavators and Their Importance

Role of Hitachi excavators in construction and maintenance

Hitachi excavators are important for building and repair projects. They are used for digging, leveling, and tearing down structures. These machines are flexible and popular with builders for mining, roads, and gardens. The need for earthmoving machines is growing worldwide. By 2025, the wheeled excavator market may reach $20.38 billion. This shows how much these machines are needed in countries like India and China.

Here are reasons why Hitachi excavators matter:

Demand for large hydraulic excavators in 2019 was twice that of 2011.

More money is being spent on copper mining, needing strong machines.

Hitachi sells equipment and offers maintenance, ensuring they last longer.

These machines help workers do more while spending less. Their smart technology, like hybrid engines, saves fuel and cuts pollution. This makes them a greener choice for the planet.

Key features contributing to reliability and efficiency

Hitachi excavators are tough and work well. They are made to perform in hard conditions. Important features show how dependable they are:

Feature | Value |

|---|---|

Fuel Efficiency | Average |

Lifting Capacity | 13 tons |

Speed | 5 km/h |

Reliability | High |

These features make them great for heavy jobs. They have strong engines and hydraulic systems to lift heavy things easily. Their easy-to-use controls and smart systems make work simpler. Picking Hitachi excavators means getting machines that are strong, accurate, and efficient. They help keep your projects on track.

Hitachi Excavator Parts List by System

Engine Components

The engine is like the heart of your excavator. It powers all the machine’s functions. Taking care of engine parts keeps it running well. Hitachi excavators, like the Hitachi EX60, use strong engines for power and fuel savings. Important engine parts include air filters, fuel injectors, pistons, and turbochargers. Checking these parts often avoids big repairs and keeps the machine working.

Good engine care improves how well it works. For example, Hitachi engines, such as those by Cummins or MTU, save fuel while staying productive. The table below shows some engine details:

Feature | Details |

|---|---|

Engine Rated Power (kW) | Cummins: 2 x 1 119 kW (1 520 PS, 1 500 HP) |

MTU: 2 x 1 150 kW (1 563 PS, 1 542 HP) | |

Fuel Efficiency | Uses less fuel but keeps high performance |

Maintenance Features | Easier maintenance lowers costs and improves reliability |

By servicing the engine regularly and using real Hitachi parts, you can make it last longer and work better.

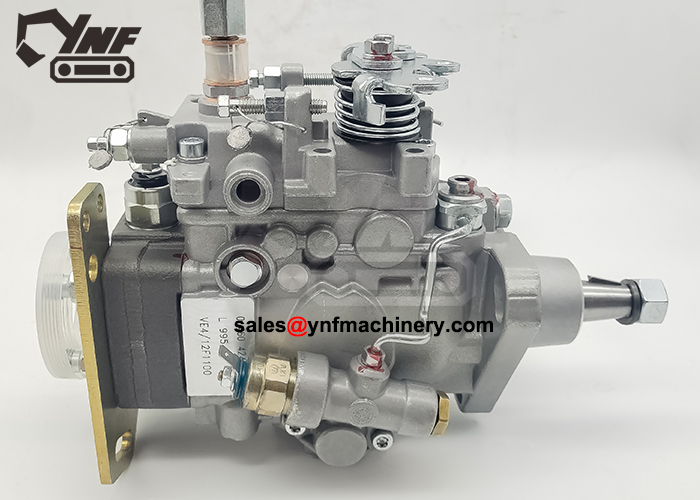

Hydraulic System Parts

The hydraulic system is the main part of your excavator. It helps with digging, lifting, and moving. Hitachi hydraulic systems are built to be strong and accurate. Key parts include hydraulic pumps, cylinders, hoses, and valves. These parts work together for smooth and efficient operations.

Hitachi excavators have advanced features like Solution Linkage® Assist. This semi-automatic system stops over-digging, making work safer and faster. Hybrid technology in the hydraulic system also saves fuel and cuts costs. It’s better for the environment too. Checking and replacing worn hydraulic parts keeps the machine working its best.

Undercarriage Parts

The undercarriage holds up the excavator and keeps it steady. It includes tracks, rollers, idlers, and sprockets. These parts wear out quickly, especially in tough conditions. Regular care is needed to avoid expensive fixes and delays.

Strong undercarriage parts, like those in Hitachi EX60 machines, last longer and work better. Tracks made from good materials resist damage and extend the machine’s life. Well-kept rollers and idlers help it move smoothly. Sprockets keep the tracks tight. The table below explains key parts by system:

Category | Description |

|---|---|

Electronic System | Parts for the excavator’s electronic functions. |

Hydraulic System | Parts for the machine’s hydraulic work. |

Structure | Steel parts that form the excavator’s body. |

To keep the undercarriage in good shape, inspect it often. Replace worn parts quickly and use real Hitachi parts to keep your excavator working well.

Swing Mechanism Parts

The swing mechanism helps the excavator turn smoothly and easily. It is important for jobs like digging or loading materials. Key parts include the swing motor, swing bearing, and swing gear. These parts work together to make sure the excavator rotates without problems.

The swing motor makes the upper part of the excavator turn. It changes hydraulic power into movement. Check the motor often for leaks or strange sounds to catch issues early. The swing bearing holds the upper part and lets it rotate. Lubricating the bearing regularly stops damage and makes it last longer. The swing gear moves power from the motor to the bearing. Broken gears can cause jerky movements and lower efficiency.

Taking care of the swing mechanism avoids expensive repairs. Replace worn parts with strong ones, like real Hitachi EX60 parts, for better performance. Lubricate and inspect the swing system often to keep your excavator working well.

Structural and Electrical Components

Structural and electrical parts are the main support of the excavator. They give strength, power, and control for safe and smooth operation. Structural parts include the boom, arm, and frame. Electrical parts include wires, sensors, and control panels.

The boom and arm are used for lifting and digging. These parts must handle heavy loads and tough conditions. Cracks or bends in them can hurt the excavator’s performance. Check the boom and arm for damage to keep them dependable. The frame holds the machine together, including the tracks and hydraulic systems. A strong frame stops failures and keeps the excavator steady.

Electrical parts control how the excavator works. Sensors check the machine’s performance, and wires connect its systems. Bad electrical parts can cause problems and slow down work. Inspect wires and sensors often to fix issues early.

Using real Hitachi parts ensures they fit and work well. Good-quality parts lower the chance of breakdowns and make the machine last longer. By caring for both structural and electrical parts, you can keep your excavator running efficiently and avoid delays.

Common Replacement Parts and Identification

Frequently replaced parts (e.g., filters, hoses, bucket teeth)

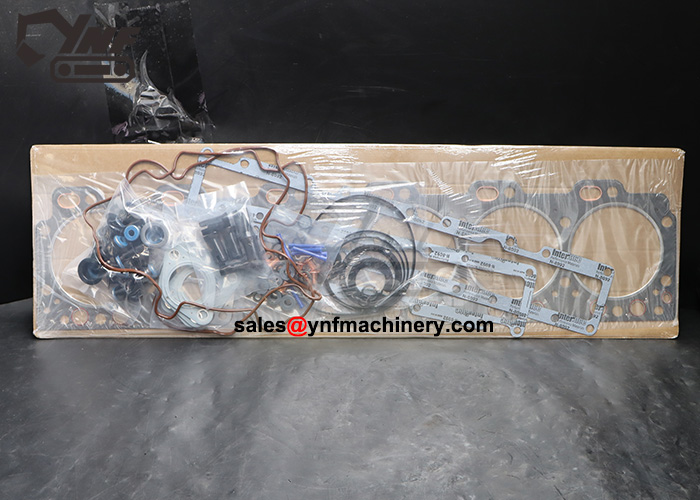

Some parts of a Hitachi excavator wear out quickly. These are called common replacement parts. Filters, hoses, and bucket teeth are replaced often. Filters, like air and fuel filters, keep systems clean. Changing them on time stops dirt from causing damage.

Hoses carry hydraulic fluid under pressure. Over time, they may crack or leak. This can lower the machine’s efficiency. Replacing old hoses keeps the excavator working smoothly. Bucket teeth, used for digging, wear down fast. New teeth improve digging and reduce machine strain.

Taking care of these parts helps the excavator run well. It also reduces work delays.

How to identify parts using catalog numbers

Finding the right part is easier with catalog numbers. Each part has a unique number in the equipment manual. This number ensures you get the correct part for your machine.

Check the parts manual that came with your excavator. You can also find catalog numbers online or by contacting Hitachi support. Using these numbers avoids mistakes and speeds up repairs.

New technology, like telematics, makes this process faster. These tools help track your machine, predict repairs, and manage parts better.

Benefits of using genuine Hitachi parts

Using real Hitachi parts has many benefits. These parts are made for your excavator, so they work better and last longer. Cheaper, non-original parts may cause more problems and break faster.

Genuine parts also support smart features like predictive maintenance. This reduces downtime and improves how the machine works. While they cost more upfront, they save money over time. Repairs are less frequent, and the machine lasts longer.

Choosing real Hitachi parts keeps your excavator running its best, even in tough jobs.

Maintenance and Servicing Tips

Regular inspection schedules

Keeping your excavator in good shape starts with regular checks. Daily, weekly, and monthly inspections help avoid problems and keep it working well. Use this checklist to stay on track:

Frequency | Purpose |

|---|---|

Daily Inspections | Check fluids, leaks, and safety tools every morning. |

Weekly Checks | Look at hydraulics, tracks, and attachments. Add grease to moving parts. |

Monthly Inspections | Inspect the engine, hydraulic pump, wires, and frame for hidden damage. |

These checks catch problems early and save money on repairs. Always check fluids and filters to keep your excavator running smoothly.

Identifying wear and tear in critical parts

Finding worn-out parts early stops bigger problems later. Focus on important parts like hoses, bucket teeth, and tracks. Look for cracks, leaks, or strange sounds while using the machine. Worn bucket teeth make digging harder, and broken hoses can harm the hydraulic system.

Use tools like sensors or tracking systems to watch your excavator’s condition. These tools show problems before they get worse. Fixing issues early keeps your machine working longer and lowers costs.

Best practices for selecting replacement parts

Picking the right parts helps your excavator last longer. Follow these tips to choose wisely:

Pick strong materials like hardened steel for durable parts.

Measure carefully to ensure the part fits your machine.

Choose parts made with advanced methods like heat treatment.

Look for safety labels like ISO9001 for trusted quality.

Ask experts or read reviews to find good recommendations.

Using these steps avoids breakdowns and keeps your excavator working well. Always choose real parts to protect your machine’s performance.

Taking care of your Hitachi excavator keeps it working well. Regular checks help find problems early and avoid big repairs. Replacing worn parts on time makes the machine last longer. Using real Hitachi parts boosts efficiency and helps it work better.

The table below shows ways to maintain your excavator:

Maintenance Tip | Why It Matters | How It Helps |

|---|---|---|

Finds problems before they get worse | Saves money on repairs | |

Replace Worn Parts | Keeps the machine strong and working longer | Improves reliability |

Choose Genuine Parts | Makes maintenance easier and better | Increases productivity |

Following these tips protects your machine and keeps it reliable for years.

FAQ

What are the benefits of using genuine Hitachi parts?

Real Hitachi parts fit your excavator perfectly. They are made to last longer and work better. Using them lowers the chance of breakdowns and saves money on replacements.

How often should you inspect your Hitachi excavator?

Check your excavator every day, week, and month. Daily checks look for leaks and check fluids. Weekly checks include tracks and hydraulics. Monthly checks cover the engine, frame, and wires. Regular checks stop big problems.

How do you identify the correct replacement part?

Find the catalog number in your manual. This number helps you get the right part. You can also ask Hitachi support or use online tools to confirm it.

Why is hydraulic system maintenance important?

The hydraulic system helps with digging and lifting. Regular care stops leaks and keeps it working well. It also makes parts like pumps and hoses last longer. A good system saves time and money.

What should you do if you notice unusual sounds during operation?

Strange sounds mean something might be broken. Stop the machine and check parts like the engine or hydraulics. Fixing it early avoids bigger problems and costly repairs.