Fluid coupling, also called hydraulic coupling, is a device. It moves spinning force between shafts with transmission fluid. It uses an impeller and a runner to move the fluid. This helps send rotation from one part to another. In today’s power systems, fluid coupling is important. It helps lower damage to parts. It keeps machines safe from sudden hits. It makes starting up smoother and easier.

-

It lowers damage on moving parts

-

It keeps machines safe from quick shocks

-

It makes speeding up and slowing down easier

-

It helps machines last longer, even in hard places

Key Takeaways

-

Fluid coupling moves power gently between shafts with hydraulic fluid. This helps protect machines from quick shocks.

-

Picking the right working fluid is very important for good work. The fluid should have good thickness, stay stable with heat, and stop rust.

-

There are different fluid coupling types. Constant-fill works for steady loads. Variable-fill works for loads that change. These types help control and make things work better.

-

Using fluid coupling makes parts last longer. It also lowers the cost to fix machines.

-

Fluid coupling is used a lot in mining, power plants, and cars. It helps machines work better and keeps people safe.

Fluid Coupling Basics

Definition

Fluid coupling is a device that helps machines move spinning force from one shaft to another. People call it hydraulic coupling too. Many machines use fluid coupling to make power transfer smooth and safe. This device uses a liquid called fluid to move energy between its parts. Using fluid coupling protects machines from sudden shocks. It also makes starting and stopping easier.

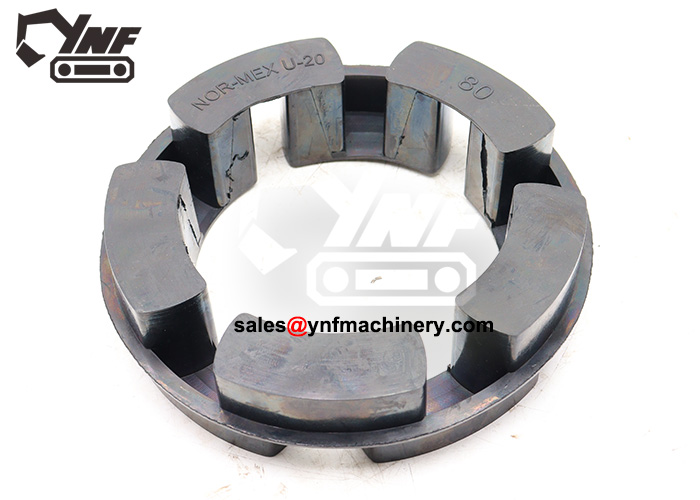

Key Parts

Fluid coupling works because it has important parts. Each part helps the device move power smoothly. Here is a table that lists the main parts and what they do:

|

Component |

Description |

|---|---|

|

Housing (Casing) |

The outside shell holds all the inside parts. It keeps the fluid in place. |

|

Impeller (Pump) |

This part connects to the input shaft. It spins and pushes fluid toward the runner. |

|

Turbine (Runner) |

The runner connects to the output shaft. It gets energy from the fluid and helps move the load. |

|

Working Fluid |

The fluid moves between the impeller and runner. It carries energy and affects how well the device works. |

The impeller acts like a pump. When you turn on the machine, the impeller spins and throws fluid outward. The fluid moves toward the runner, which acts like a turbine. The runner catches the moving fluid and starts to spin. This lets the runner send torque and speed to the output shaft.

Here is another table that shows how the impeller, fluid, and runner work together:

|

Component |

Function |

|---|---|

|

Impeller |

Spins and pushes fluid outward, giving it motion. |

|

Hydraulic Fluid |

Moves from the impeller to the runner, creating force and torque. |

|

Output Turbine |

Spins because the fluid hits it, passing energy to the next part. |

The runner is very important. It gets fluid from the impeller and helps send force to the output shaft. The impeller and runner work together to keep power moving smoothly.

The working fluid matters a lot. You need to pick the right fluid for your fluid coupling. The fluid must have special features to work well:

-

Viscosity: The fluid should flow easily but not too fast. Most fluids have a viscosity between 2.5 and 72 cSt at 40°C. For cars, the fluid usually has 3 to 7 cSt at 100°C.

-

Thermal Stability: The fluid must handle high heat, sometimes over 200°F.

-

Oxidation Resistance: The fluid should not break down when it gets hot.

-

Viscosity Index (VI): A high VI helps the fluid keep its thickness when temperatures change.

-

Low Viscosity: Fluids with low viscosity help lower heat loss.

-

Foam Resistance: The fluid should not foam up when the impeller stirs it.

-

Rust Protection: Most fluids use hydrocarbon bases with additives to stop rust.

-

Seal Compatibility: The fluid must not hurt the seals inside the coupling.

Tip: To help your fluid coupling last longer, always use the right fluid and check it often.

Fluid coupling uses these parts and features to make machines safer and more reliable. Many industries use fluid coupling because it helps machines run smoothly and protects them from damage.

Fluid Coupling Operation

Working Principle

The Föttinger principle shows how fluid coupling works. Power moves from one shaft to another using fluid motion. When you start the machine, the impeller spins fast. It pushes fluid outward. The fluid goes to the runner. The runner starts spinning too. The impeller and runner never touch each other. The fluid carries energy between them. The impeller changes mechanical energy into kinetic energy. The runner takes this kinetic energy and makes it mechanical again. The impeller and runner spin at different speeds. This speed difference creates centrifugal force. Centrifugal force helps move torque without touching. The fluid acts like a cushion. This makes power transmission smooth.

Efficiency and Stator Role

Fluid coupling uses slip to make power transfer smooth. Slip happens when the input shaft spins faster than the output shaft. Controlled slip limits torque when you start the machine. It lets the input turbine build pressure slowly. Slow pressure stops sudden jolts. This protects the drive source. You can change the slip rate to match your equipment speed. Most fluid couplings keep slip between 1.5% and 6.0%. You can find slip percentage with this formula: 100 × (n1 – n2) / n1 where n1 is the driver speed and n2 is the driven impeller speed.

-

Controlled slip limits torque at startup.

-

Gradual engagement stops shocks or overloads.

-

You can change slip rates to control speed.

-

Slip usually stays between 1.5% and 6.0%.

Adding a stator makes fluid coupling work better. The stator sits between the impeller and runner. It changes the direction of the returning fluid. This helps the impeller spin better. The stator has angled and curved blades. These blades guide the fluid. This design boosts torque and makes the system more efficient. Some stators have a one-way clutch. The clutch lets the stator hold or freewheel. This depends on the load. You get better torque multiplication and smoother operation.

|

Evidence Description |

Explanation |

|---|---|

|

Stator redirects fluid flow |

The stator changes the direction of the returning fluid. This helps the impeller spin and boosts torque and efficiency. |

|

Blade design |

Angled and curved blades guide fluid better. This improves performance compared to straight blades. |

|

One-way clutch functionality |

The clutch lets the stator hold or freewheel. This helps multiply torque under different conditions. |

Fluid coupling gives reliable power transmission. You get smooth starts and less wear. Your machines stay protected. Choosing fluid coupling makes your equipment safer and more efficient.

Fluid Coupling Types

There are two main types of fluid coupling. Each type works best for different jobs. Knowing how they work helps you choose the right one.

Constant-Fill

Constant-fill fluid coupling holds a set amount of fluid. The fluid level does not change. This gives steady power to your machine. It works well when the load stays the same. You do not need to add or remove fluid often. The design is simple and easy to care for. Many factories use constant-fill for conveyor belts and pumps. It is good for jobs that do not change much.

Tip: If your machine runs at the same speed and load, constant-fill fluid coupling works smoothly.

Variable-Fill

Variable-fill fluid coupling lets you change the fluid inside. You can add or take out fluid as needed. This helps control power when the load changes. If your machine faces different loads, you can adjust the fluid. This keeps things running well. Variable-fill works best where loads change a lot, like in mining or big fans.

Variable-fill fluid coupling changes with the load by changing the oil amount. You can meet more power needs this way. This helps keep your machine efficient, even if the load shifts. Engineers use special models to make it work better. These models look at oil flow, oil heat, and blade size. You get more control and save energy.

Here is a table that shows how constant-fill and variable-fill are different:

|

Type |

Characteristics |

Applications |

|---|---|---|

|

Constant-Fill Fluid Couplings |

Give steady power; best for loads that do not change; simple and reliable. |

Good for steady load jobs. |

|

Variable-Fill Fluid Couplings |

Let you adjust power; best for changing loads; give better control and save energy. |

Good for jobs with changing loads. |

Pick the right fluid coupling for your job. Use constant-fill for steady loads. Use variable-fill for loads that change.

Advantages

Smooth Transfer

Fluid coupling helps power move smoothly. The fluid inside acts like a soft cushion. It sits between the input and output shafts. This cushion takes in shocks and stops quick jerks. Your machines shake less and make less noise. Big machines get the most help because the fluid lets them start slowly. The engine does not have trouble when starting heavy loads. There is no direct contact between moving parts. This means power moves in a steady way.

-

The fluid lowers shocks and vibrations.

-

The system stops engine trouble by letting the fluid slip and pick up the load slowly.

-

You get steady power flow, which keeps your equipment safe.

-

Shock loads are taken in, so both machines stay safe.

-

Engine vibrations are softened, which helps your transmission last longer.

Here is a table that shows how fluid coupling and mechanical clutches are different:

|

Advantage |

Description |

|---|---|

|

Smooth Power Transmission |

No quick jerks or shocks. |

|

Vibration Damping |

Lowers stress on machines. |

|

Improved Efficiency |

Works well when loads change. |

Overload Protection

Fluid coupling gives strong protection from overloads. If your machine gets a sudden heavy load, the fluid takes in the shock. This stops your equipment from getting hurt. Some couplings use a shear pin for extra safety. The pin breaks if the load is too high, which keeps the drive safe. Hydraulic couplings also have special parts that take in shocks during high pressure. You can trust fluid coupling to keep your machines safe when things go wrong.

-

The fluid takes in shock and stops damage during heavy loads.

-

Shear pins give good protection for slow, strong drives.

-

Overload protection works well when pressure is high.

Reduced Wear

Fluid coupling helps lower wear and tear. The fluid lets the input and output slip without touching. This means there is almost no rubbing between moving parts. The pump and turbine inside do not wear out fast. You do not need to change parts often, so you save money. Hydrodynamic couplings send power with almost no wear, so your equipment lasts longer.

|

Evidence Description |

Key Benefit |

|---|---|

|

Fluid couplings let input and output slip without touching. |

Very little wear on the parts. |

|

The pump and turbine do not wear out and need little care. |

More durability and less maintenance needed. |

|

Hydrodynamic couplings send power with almost no wear. |

Better efficiency and longer life for parts. |

Note: Using the right fluid and checking it often helps your fluid coupling last longer.

Applications

Industry

Fluid coupling is used in many factories and plants. It helps machines work better and keeps them safe from sudden hits. You can find fluid coupling in mining, power plants, and ships. In mining, it protects big machines like conveyors and crushers from getting overloaded. Power plants use fluid coupling for pumps and fans that need strong force. Ships use fluid coupling to help engines run smoothly and protect other machines.

|

Sector |

Application Description |

|---|---|

|

Mining |

Used in big machines like conveyors and crushers. It helps move force smoothly and keeps machines safe from shocks. |

|

Power Generation |

Used in pumps and fans. It works well when strong force is needed in power plants. |

|

Marine |

Used in ship engines and other machines. It helps move force smoothly and keeps machines safe from shocks. |

Note: Fluid coupling helps machines last longer and work better in tough places.

Automotive

Fluid coupling is found in many cars and trucks. It helps the car change gears smoothly and makes driving easier. Buses and other public vehicles use fluid coupling to give smoother rides. This technology helps save fuel and makes driving more comfortable.

|

Benefit |

Description |

|---|---|

|

Improved Fuel Efficiency |

Fluid coupling helps cars use less fuel by moving power better. |

|

Smoother Power Delivery |

It helps cars speed up smoothly and lowers shocks in the engine. |

|

Enhanced Vehicle Performance |

It helps control force, so cars and buses work better and last longer. |

Fluid coupling makes cars and buses safer and more reliable for everyone.

Other Uses

Fluid coupling is now used in clean energy systems. You can find it in wind turbines, water power plants, and biomass stations. These places need steady force and protection from too much load. Fluid coupling helps control changing speeds and keeps generators safe. In wind turbines, it moves power well, lowers wear, and handles different speeds. This helps machines last longer and work better.

-

Fluid coupling moves power between the wind turbine and generator.

-

It lowers wear and helps machines last longer.

-

It controls changing speeds, which makes things work better.

As clean energy grows, fluid coupling becomes more important. You can count on it for smooth power and protection in these systems. If you need fluid coupling, YNF Machinery has good choices for all these uses.

Fluid coupling helps move power between shafts without touching. It uses fluid motion to make power transfer smooth and safe. Many machines use fluid coupling, like cars and wind turbines. It gives overload protection, less wear, and steady running. In 2025, fluid coupling will still be important. Industries want solutions that are reliable and save energy.

FAQ

What is the main job of a fluid coupling?

You use a fluid coupling to move spinning force from one shaft to another. It helps your machines start smoothly and protects them from sudden shocks.

How does a hydraulic coupling help with overloads?

A hydraulic coupling takes in extra force when your machine faces a heavy load. You avoid damage because the fluid inside absorbs the shock and keeps your equipment safe.

Can you use fluid coupling in cars?

Yes, you find fluid coupling in many cars and buses. It helps your vehicle change gears smoothly and gives you a better driving experience.

How do you keep a fluid coupling working well?

You should check the fluid level often and use the right type of fluid. Clean the parts and follow the care tips from your supplier, like YNF Machinery.

What is the difference between constant-fill and variable-fill fluid couplings?

Constant-fill fluid couplings hold the same amount of fluid all the time. Variable-fill types let you change the fluid level to match different loads.