When you pick between an excavator skid steer and other equipment, you should think about what your project needs. Excavators are best for big digging jobs and moving lots of dirt, while a skid steer excels in smaller spaces and can handle many different tasks. You often see excavator skid steers at construction sites, roadwork, and large building projects, as well as in cities and suburbs. Many jobs like landscaping, fixing utilities, and building homes use both machines. Consider your main job, the size of your site, the ground conditions, and your budget. Focus on what your project needs to choose the right excavator skid steer or equipment.

Key Takeaways

Excavators work well for deep digging and heavy lifting. They are good on rough or muddy ground. Skid steers are great in small spaces. They have many attachments for different jobs like landscaping and moving materials. Use excavators for big projects that need deep trenches or demolition. Pick skid steers for small jobs where space is tight. Think about your site, project size, and budget before you choose. Regular maintenance keeps both machines running well. It also helps you avoid expensive repairs.

Excavator Skid Steer Overview

Excavator Basics

An excavator is a strong machine made for digging and moving dirt. Most mini excavators have tracks instead of wheels. Tracks help the machine grip the ground and stay steady on rough or muddy areas. Excavators use powerful hydraulic systems. These systems let you dig deep holes, make trenches, and even break down buildings with care. You will see excavators at construction sites that need deep digging. A standard excavator can weigh from about 8,400 kg (18,500 lb) to almost 39,000 kg (85,000 lb). Their horsepower goes from 68 hp up to 271 hp.

Feature | Mini Excavator (Excavator) | Skid Steer Loader |

|---|---|---|

Mobility System | Tracks for stability and traction on rough terrain | Wheels for turning in place and maneuverability |

Primary Specialization | Excavation, digging, trenching, demolition | Material handling, grading, lifting, versatility |

Size and Maneuverability | Larger, less maneuverable in tight spaces | Compact, ideal for confined spaces |

Hydraulic System | Powerful for deep digging and earth-moving | Suited for lifting and attachments |

Terrain Handling | Excellent on uneven or muddy terrain | Best on flat, stable ground |

Attachment Options | Fewer, focused on digging and excavation | Wide variety for many tasks |

Digging Capability | Deep digging | Shallow digging and grading |

Lifting Capacity | Lower than skid steer loader | Higher for material handling |

Skid Steer Basics

A skid steer loader is a small machine that uses wheels, not tracks. Wheels let the machine turn around in one spot. This helps you work in small or tight places. Skid steer loaders are common in landscaping and building jobs. They are easy to move and control. You can pick a small-frame, medium-frame, or large-frame skid steer loader. Small-frame models weigh between 3,000 and 6,000 lbs. Medium-frame models weigh 6,000 to 7,000 lbs. Large-frame models can weigh up to 12,000 lbs. Skid steer loaders are known for being able to do many jobs. You can use different attachments like buckets, forks, augers, and trenchers. These tools help you dig, grade, lift, and even break concrete.

Tip: Skid steer loaders work best on flat, hard ground. If you need to work on rough or muddy ground, a mini excavator might be better.

Best Uses of an Excavator

Use an excavator when you need to dig deep, make trenches, or move a lot of dirt. Excavators are great for big building jobs, roadwork, and tearing down things. They can also lift heavy stuff on bumpy ground. Mini excavators help you dig carefully in small or busy spots. If your job needs to move lots of dirt or dig deep, an excavator will save you time and work. For jobs that need digging and lifting in tough places, excavators work better and faster than skid steer loaders.

Excavator vs Skid Steer: Key Differences

Digging and Lifting

Excavators and skid steers are different when it comes to digging and lifting. Mini excavators have a long boom and arm. This lets them dig deeper and reach farther. They are good for big jobs like digging trenches for pipes or building foundations. Skid steer loaders can dig too, but they cannot dig as deep. Even with a backhoe, their digging depth is less. Mini excavators move more dirt each time because their buckets are bigger.

Here is a table that shows the main differences:

Feature | Skid Steer | Mini Excavator |

|---|---|---|

Maximum Digging Depth | 6.5 to 11 feet (with backhoe) | Greater depth due to long boom and arm |

Lifting Capacity | Limited by single pivot design | Higher, lifts heavier loads efficiently |

Bucket Size | 45 to 102 inches wide | Larger buckets, more material per pass |

Reach | Limited by design | Extended reach, ideal for large projects |

Mini excavators have strong breakout force. For example, a Doosan DX225LC can give a bucket breakout force of 33,510 lbs. Skid steers focus more on how much they can carry and not on lifting power. They do not lift as much as excavators. If you need to dig deep or lift heavy things, pick an excavator.

Terrain and Stability

You should think about the ground and how stable the machine is. Mini excavators use tracks. Tracks help them grip the ground and stay steady on rough or muddy areas. Tracks made from strong rubber or other tough stuff help mini excavators stay safe when digging or grading.

Skid steer loaders use wheels. You can put special tires on them. Lateral tread tires help them move better in mud and on hills. These tires clean themselves, so you do not lose grip in sticky mud. Directional tread tires help you go forward but can make turning less stable. Skid steers with lateral tread tires can turn well and handle bumpy ground. This makes them safer and easier to control on rough sites.

Note: Mini excavators are more stable for digging and lifting on slopes. Skid steers with the right tires can work well in mud or on uneven ground.

Space and Maneuverability

How well a machine moves in small spaces is important. Skid steer loaders are great in tight spots. They can turn almost in one place. This is called zero-radius turning. It helps them work in small yards, busy job sites, or inside buildings. People say skid steers are easier to move in small areas. You can turn quickly and go around things easily.

Mini excavators can also work in small spaces. They use tracks to move. This gives them good balance and control. But they cannot turn as sharply as skid steers. If you need to work in a very small or crowded place, a skid steer is better.

Tip: Skid steers are best for jobs like landscaping in backyards or tearing down things in crowded neighborhoods. Their small size and easy turning are big advantages.

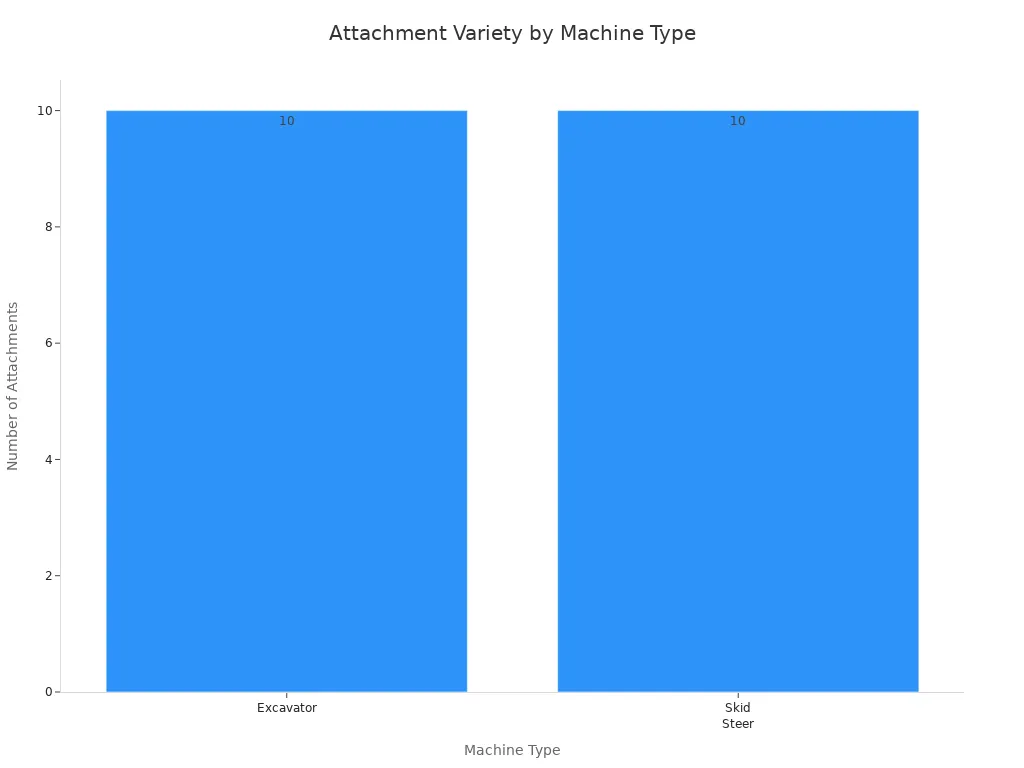

Versatility and Attachments

It is helpful if one machine can do many jobs. Both mini excavators and skid steers can use different attachments. But skid steers have more choices. You can quickly change tools like augers, pallet forks, snow blades, and soil conditioners. This lets you dig, lift, grade, break concrete, and move things with one machine.

Mini excavators also use attachments like dig buckets, hydraulic breakers, compactors, and grapples. These help with digging, breaking, and moving dirt. But skid steers have more types of attachments. This makes them better for jobs that need many tasks.

Attachment Type | Machine Type | Description and Impact on Job Site Versatility |

|---|---|---|

Dig Bucket | Excavator | Digging trenches, holes, and foundations |

Hydraulic Hammer | Excavator | Breaking concrete and rocks |

Auger Drive | Skid Steer | Drilling holes for posts and trees |

Pallet Forks | Skid Steer | Moving pallets and heavy items |

Grapple Bucket | Skid Steer | Sorting and loading debris |

Tilt Bucket | Excavator | Precise grading and ditching |

Laser Grader | Skid Steer | Precision leveling for foundations |

If you want one machine to do many jobs, pick a skid steer loader. They are great for landscaping, snow removal, or moving materials.

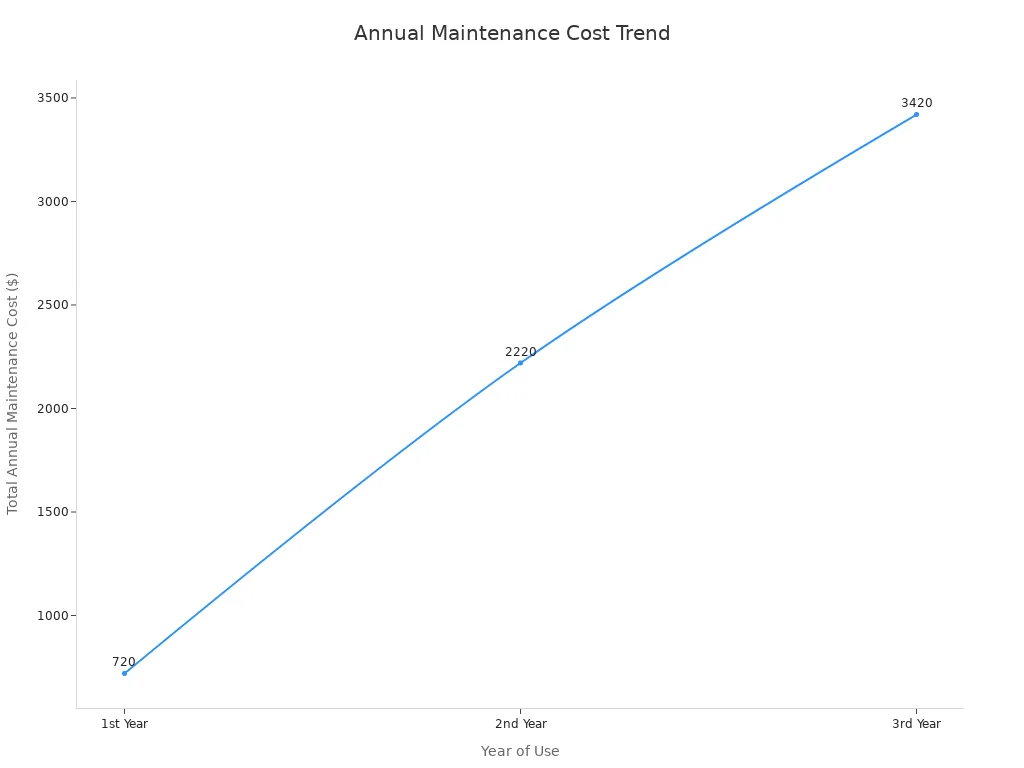

Maintenance and Upkeep

Taking care of your machine is important. Both machines need regular checks, but costs can be different. In the first year, you might spend about $720 on maintenance. By the third year, costs can go over $3,400 as parts wear out and you need new attachments.

Year of Use | Maintenance Frequency | Labor Cost per Maintenance | Additional Costs | Total Annual Maintenance Cost |

|---|---|---|---|---|

1st Year | Every 200 hours (8 times/year) | $90 per maintenance | Parts under warranty (no cost) | $720 |

2nd Year | Same as 1st + major service | $720 (regular) + $1,500 (major service) | $2,220 | |

3rd Year | Same as 2nd + replacements | $720 (regular) + $1,500 (major service) + $700 (attachment) + $500 (tires) | $3,420 |

Common problems include engine trouble, leaks, and worn-out parts. You should check oil, filters, and hydraulic fluid often. Skid steers may have more tire and drive motor problems. Mini excavators can have track and hydraulic issues. Checking your machine often and fixing problems quickly helps you avoid big repairs and keeps your machine working well.

Choosing the Right Machine

Project Size and Scope

When you start a project, pick the right machine for your needs. Think about how big your job is and what work you will do. Here are some things to think about:

Machine size and type: Skid steers come in small, medium, and large sizes. Excavators can be mini or very large for big jobs.

Workspace constraints: Small skid steers fit in tight or small places. Mini excavators with zero tail swing are good for narrow spaces.

Terrain compatibility: Wheeled skid steers work best on flat, hard ground. Tracked excavators are better for rough or muddy areas.

Attachments and versatility: Skid steers have many attachments for different jobs. Excavators have fewer attachments but are great at digging and lifting heavy things.

Project demands: Skid steers are good for small or many different jobs. Excavators are best for big digging, deep trenches, and demolition.

Use a mini excavator for deep trenches, putting in utility lines, or digging pools. Skid steer loaders are good for moving materials, grading, and landscaping.

Site Conditions

Soil and weather can change how well your machine works. Tracked excavators and compact track loaders are best for muddy or bumpy ground. In winter, machines with heated cabs and special fuel help you work safely. Snow and ice may need special tools. On rocky or sloped ground, excavators give you more power and balance. For swampy or soft ground, compact track loaders stop you from sinking.

Machine Type | Best Terrain | Key Advantage |

|---|---|---|

Mini Excavator | Rocky, uneven, muddy | Stability, deep digging |

Skid Steer Loader | Flat, hard, confined | Maneuverability, versatility |

Budget Considerations

Think about your budget before you choose a machine. A new skid steer loader starts at $55,000. Renting one costs $200 to $400 each day. Mini excavators cost at least $20,000 to buy, and renting is $200 to $625 per day. Large excavators can cost up to $600,000. Renting is smart for short jobs. Remember to add money for fuel, delivery, and attachments.

Quick Decision Checklist

Use this checklist to help you decide:

What is your main job? (Digging, lifting, grading, demolition)

How much space do you have?

What is your budget for buying or renting?

What are the soil and weather like?

Do you need lots of attachments for different jobs?

Tip: Picking the right excavator or skid steer loader depends on your project’s size, site, and budget. Think about what each machine does best before you choose.

Now you understand excavators are good for deep digging and trenching. They also move lots of dirt on big jobs. Skid steers are great in small spaces. They can do many jobs with different attachments.

Look at the checklist above to help pick your machine.

If you are still not sure, ask equipment experts for help.

Many companies can give you advice, rent you equipment, and help with maintenance so you can choose the right machine.

FAQ

What is the main difference between an excavator and a skid steer?

You use an excavator for deep digging and heavy lifting. You use a skid steer for working in tight spaces and switching between many tasks. Excavators have tracks. Skid steers have wheels.

Can you use the same attachments on both machines?

Most attachments fit only one type of machine. Skid steers offer more attachment options. Excavators use buckets, breakers, and grapples. Skid steers use augers, pallet forks, and snow blades.

Which machine is easier to operate for beginners?

You may find skid steers easier to learn. They have simple controls and turn in place. Excavators need more skill for digging and lifting. Training helps you use both machines safely.

How do I choose between renting and buying?

If you have short-term or small projects, renting saves money. For long-term or frequent use, buying may cost less over time. Always add costs for fuel, delivery, and maintenance.

Can I use a skid steer on muddy or uneven ground?

You can use a skid steer with special tires on some rough ground. For very muddy or bumpy areas, a mini excavator with tracks gives you better stability and grip.