Understanding the parts of an excavator is essential for keeping your machine running efficiently. Each component, from the tracks to the bucket, plays a critical role in its operation. Proper care ensures these parts perform at their best. Regular maintenance helps you identify potential issues early, reducing breakdowns and repair costs. For example, advancements in lubricants and filters can cut engine drain intervals by up to 50%, saving time and money. By focusing on the condition of these essential excavator parts, you can extend the lifespan of your equipment and maintain peak performance.

Key Takeaways

parts of an excavator is crucial for efficient operation and maintenance.

Regular inspections and maintenance of tracks, rollers, and idlers can prevent costly breakdowns and extend equipment lifespan.

Proper lubrication of moving parts, such as the swing drive and hydraulic cylinders, reduces friction and enhances performance.

Choosing high-quality parts from reliable suppliers like YNF Machinery ensures durability and reliability in challenging conditions. Routine maintenance tasks like greasing and oil changes are essential for optimal performance and can save money in the long run.

Attachments significantly increase the versatility of your excavator, allowing it to perform a variety of tasks effectively.

Addressing issues promptly, such as leaks or wear, can prevent further damage and ensure your excavator remains operational.

Lower Structure: The Foundation of Mobility and Stability

The lower structure of an excavator forms the backbone of its mobility and stability. It ensures that your machine can navigate challenging terrains while maintaining balance during operations. Understanding the components of the excavator undercarriage and their maintenance needs is vital for keeping your equipment in top condition.

Tracks and Track Pads

Function:

The tracks and track pads provide the necessary stability and mobility for your excavator. They are designed to handle various terrains, whether rocky, muddy, or uneven. These components are typically made from reinforced steel or steel-reinforced rubber, ensuring durability and strength during heavy-duty operations. Proper traction from the tracks prevents slippage, which enhances safety and efficiency on the job site.

Maintenance:

Regular inspections of your excavator tracks are essential. Look for signs of wear, such as cracks, splits, or thinning rubber on the track pads. If you notice steel showing through the rubber, it’s time to replace the pads. Check for loose bolts, bent shoes, or missing parts, as these can lead to larger issues. Adjust the track tension according to the manufacturer’s guidelines to prevent excessive wear. Cleaning debris from the tracks after each use also helps maintain their performance. Greasing the tracks every 10 to 50 operating hours, depending on usage intensity, ensures smooth operation and reduces friction.

Rollers

Function:

The rollers guide the chains between the sprocket and idler, ensuring smooth movement of the tracks. They play a crucial role in maintaining the alignment and functionality of the track excavator.

Maintenance:

Inspect the rollers regularly for cracks or wear. Damaged rollers can cause uneven track wear and misalignment, reducing productivity. Lubricate the rollers frequently to minimize friction and extend their lifespan. Replacing all rollers simultaneously can help maintain balance and prevent uneven wear on the crawler excavator.

Idlers

Function:

Idlers maintain the tension of the tracks, ensuring smooth operation and preventing derailment. They also help distribute the weight of the excavator evenly across the undercarriage.

Maintenance:

Check the idlers for proper alignment and wear. Misaligned or worn idlers can lead to track damage and reduced efficiency. Regularly inspect these components and replace them if necessary to avoid costly repairs.

Sprockets

Function:

Sprockets play a crucial role in the lower structure of your excavator. They engage directly with the track chain links, propelling the machine forward or backward. This interaction ensures smooth and efficient movement, even on challenging terrains. The sprockets’ teeth grip the chain links firmly, providing the necessary traction for the excavator undercarriage to function effectively.

Maintenance:

Inspect your sprockets regularly to identify signs of wear or damage. Worn-out teeth can lead to poor engagement with the track chain, causing slippage and reducing operational efficiency. Replace damaged sprockets promptly to avoid further harm to the tracks and other components. Cleaning debris from the sprockets after each use helps maintain their performance and prevents premature wear. Proper alignment of the sprockets with the track chain is also essential for smooth operation.

Swing Drive/Slewing Ring

Function:

The swing drive or slewing ring enables the upper structure of your excavator to rotate a full 360 degrees. This rotational capability allows you to perform tasks like digging, lifting, and dumping without repositioning the entire machine. The swing drive ensures precise and controlled movements, enhancing the efficiency of your operations.

Maintenance:

Regular greasing of the swing drive is vital to ensure smooth rotation and prevent friction-related damage. Inspect the slewing ring for cracks, wear, or loose bolts. Tighten any loose bolts immediately to avoid misalignment or operational issues. Check for unusual noises during rotation, as these may indicate internal damage. Addressing these issues early can save you from costly repairs and downtime.

Travel Motor

Function:

The travel motor converts hydraulic fluid pressure into rotational force, driving the tracks and enabling your excavator to move. This component is essential for the mobility of your track excavator, ensuring it can navigate various terrains with ease.

Maintenance:

Inspect the hydraulic connections of the travel motor regularly to ensure there are no leaks or blockages. Proper lubrication is critical for maintaining the motor’s efficiency and preventing overheating. Clean the area around the travel motor to remove dirt and debris that could interfere with its operation. If you notice a decrease in performance or unusual noises, address these issues immediately to prevent further damage.

YNF Machinery’s Contribution to Lower Structure Parts

When it comes to maintaining the lower structure of your excavator, high-quality components are essential for ensuring durability and reliability. YNF Machinery stands out as a trusted provider of premium parts designed to enhance the performance of your machine’s undercarriage.

Why Choose YNF Machinery for Tracks and Track Pads?

YNF Machinery offers tracks and track pads that are built to withstand the toughest working conditions. These components are crafted from reinforced materials, ensuring they can handle the constant wear and tear caused by challenging terrains. Whether you operate on rocky, muddy, or uneven surfaces, YNF Machinery’s products provide the traction and stability you need to keep your excavator running smoothly.

Daily inspections of your excavator tracks are crucial for identifying potential issues early. YNF Machinery’s track pads are designed to resist cracking, splitting, and thinning, reducing the need for frequent replacements. Their products also ensure proper alignment and tension, which minimizes slippage and enhances safety during operations.

Rollers That Deliver Long-Lasting Performance

The rollers in your undercarriage play a vital role in guiding the tracks and maintaining smooth movement. YNF Machinery supplies rollers that are engineered for durability and precision. These rollers reduce friction and wear, ensuring your excavator operates efficiently. Regular lubrication and timely replacement of worn rollers are essential for extending their lifespan, and YNF Machinery provides components that make maintenance straightforward and hassle-free.

A Commitment to Quality and Reliability

YNF Machinery prioritizes quality in every product they offer. Their tracks, track pads, and rollers undergo rigorous testing to meet high-performance standards. This commitment ensures that you receive parts that not only fit perfectly but also last longer, reducing downtime and maintenance costs.

By choosing YNF Machinery, you invest in components that enhance the stability and mobility of your excavator’s lower structure. Their products help you maintain peak performance, even in the most demanding environments.

Upper Structure: The Core of Operation and Control

The upper structure of an excavator serves as the command center, housing critical components that ensure smooth operation and control. Understanding the key parts of this section and their proper care can significantly enhance your machine’s performance and safety.

Cabin

Function:

The cab is the operator’s control hub, designed for comfort and safety. It includes essential features like ROPS (Roll-Over Protective Structure) and FOPS (Falling Object Protective Structure) to protect you during operations. The layout of the controls ensures precision and ease of use, allowing you to manage the excavator’s movements efficiently. A well-designed cab minimizes operator fatigue, improving productivity over long working hours.

Maintenance:

Keep the cab clean to maintain visibility and prevent dust from interfering with the controls. Regularly inspect the safety features, such as seat belts and protective structures, to ensure they function correctly. Test all control systems periodically to confirm they respond accurately. Address any issues immediately to avoid compromising safety or efficiency.

Counterweight

Function:

The counterweight provides balance to the excavator during operation. It prevents tipping when lifting heavy loads or working on uneven terrain. This component is crucial for maintaining stability, especially when the boom and arm extend far from the machine’s center of gravity.

Maintenance:

Inspect the counterweight for secure attachment to the upper structure. Check for cracks, dents, or other signs of damage that could affect its performance. Tighten any loose bolts and replace damaged parts promptly. Regular inspections ensure the counterweight continues to provide the necessary stability for safe operations.

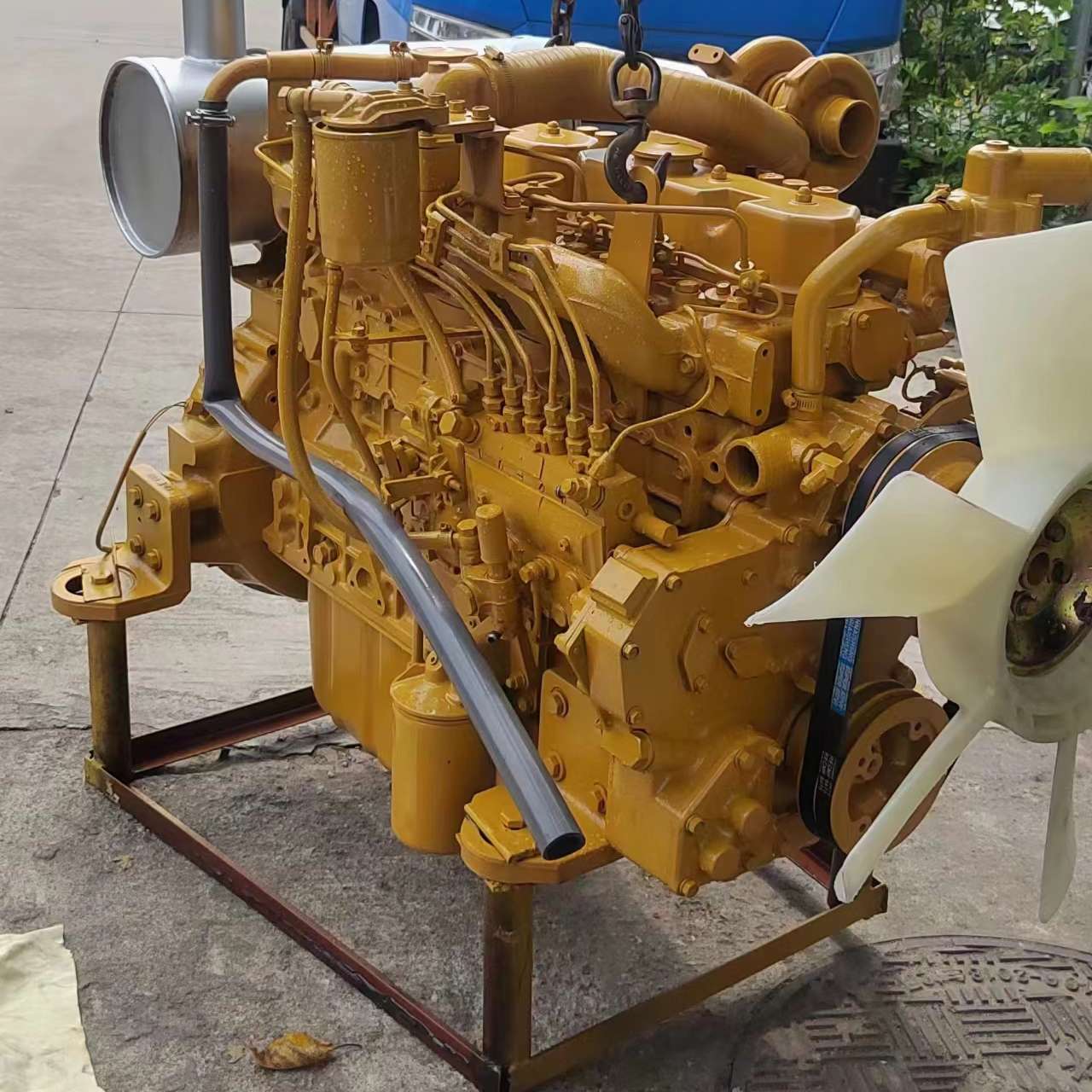

Engine Compartment

Function:

The engine compartment houses vital components, including the diesel engine, fuel tank, hydraulic fluid tank, and main control valve. These parts work together to power the excavator and enable precise movements. The engine generates the torque needed for heavy-duty tasks, while the hydraulic system ensures smooth operation of the boom, arm, and bucket.

Maintenance:

Change the hydraulic oil every 1,000 operating hours to maintain optimal performance. Regularly inspect the fuel and fluid levels to prevent disruptions during operation. Clean the engine compartment to remove dirt and debris that could interfere with the components. Address any leaks or unusual noises immediately to avoid costly repairs.

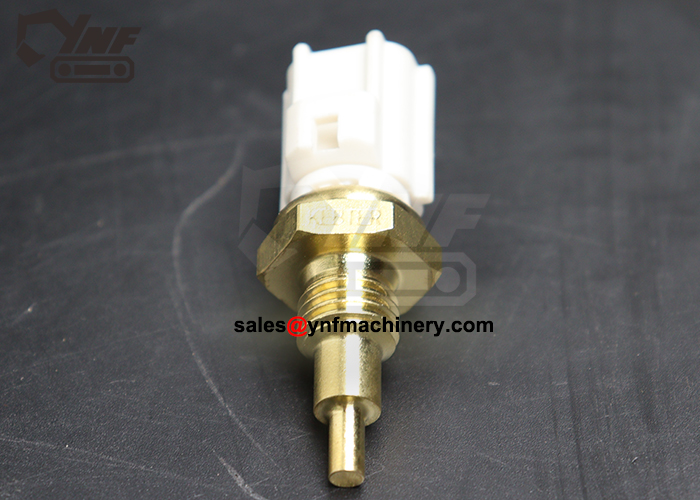

Main Control Valves

Function:

The main control valves play a pivotal role in managing the hydraulic fluid flow within your excavator. These valves direct the fluid to specific components, enabling precise movements of the boom, arm, and bucket. By controlling the flow and pressure, they ensure that your excavator operates smoothly and efficiently. Without properly functioning main controls, achieving accurate and responsive machine movements becomes challenging.

Maintenance:

Regular inspection of the main control valves is essential to maintain their performance. Look for signs of leaks around the valves, as these can indicate worn seals or damaged components. Leaks not only reduce efficiency but also lead to increased wear on other parts of the hydraulic system. Calibration of the valves is equally important. Miscalibrated valves can result in uneven or jerky movements, which may compromise the safety and precision of your operations. Cleaning the valves periodically helps prevent debris buildup, ensuring uninterrupted hydraulic flow. Addressing these maintenance tasks promptly will extend the lifespan of your excavator’s hydraulic system.

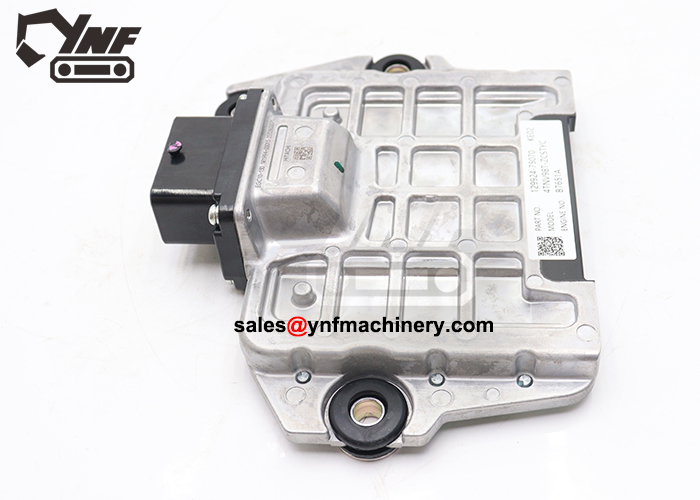

YNF Machinery’s Excavator Engine Parts

Highlight:

When it comes to maintaining the upper structure of your excavator, reliable engine parts are indispensable. YNF Machinery offers a wide range of high-quality components, including injectors and fuel pumps, designed to optimize your machine’s performance. These parts ensure efficient fuel delivery and combustion, which are critical for powering heavy-duty tasks.

YNF Machinery’s engine parts stand out for their durability and precision. The injectors deliver fuel with accuracy, enhancing the engine’s efficiency and reducing emissions. Fuel pumps, on the other hand, maintain consistent pressure, ensuring smooth operation even under demanding conditions. By choosing YNF Machinery, you gain access to components that meet or exceed industry standards, helping you avoid unexpected breakdowns and costly repairs.

“Investing in premium engine parts not only boosts performance but also minimizes downtime, keeping your projects on track.”

With YNF Machinery’s commitment to quality, you can trust their products to support the upper structure of your excavator. Their parts undergo rigorous testing to ensure reliability, making them a preferred choice for operators worldwide. Whether you’re replacing worn components or upgrading for better efficiency, YNF Machinery provides the solutions you need to keep your excavator running at its best.

Front Attachment: The Workhorse of the Excavator

The front attachment of an excavator is where the real work happens. It includes critical components like the boom, arm, and bucket, which perform essential tasks such as digging, lifting, and moving materials. Proper care and maintenance of these parts ensure your excavator operates efficiently and reliably.

Boom and Arm

Function:

The boom and arm mechanism forms the backbone of your excavator’s digging and lifting capabilities. The excavator boom connects to the main body and provides the vertical reach, while the arm extends outward to increase the range of motion. Together, they allow you to handle heavy loads and perform precise movements, making them indispensable for construction and earthmoving tasks.

Maintenance:

Inspect the boom and arm regularly for cracks, dents, or signs of wear. Pay close attention to the hydraulic mechanisms, as leaks or damaged seals can compromise performance. Lubricate the joints and pins to reduce friction and prevent premature wear. Cleaning the excavator arm and boom after each use removes debris that could interfere with their operation. Address any issues promptly to avoid costly repairs and downtime.

Bucket

Function:

The bucket is the primary earthmoving component of your excavator. It comes in various shapes and sizes, tailored for specific tasks such as digging, trenching, or grading. The bucket’s design ensures efficient material handling, whether you’re scooping soil, gravel, or rocks.

Maintenance:

Inspect the bucket frequently for wear, cracks, or damage. Check the teeth for signs of wear, as dull or broken teeth reduce digging efficiency. Replace worn-out teeth to maintain optimal performance. Tighten any loose bolts to ensure the bucket remains securely attached. Cleaning the bucket after each use prevents material buildup, which can lead to corrosion or reduced functionality.

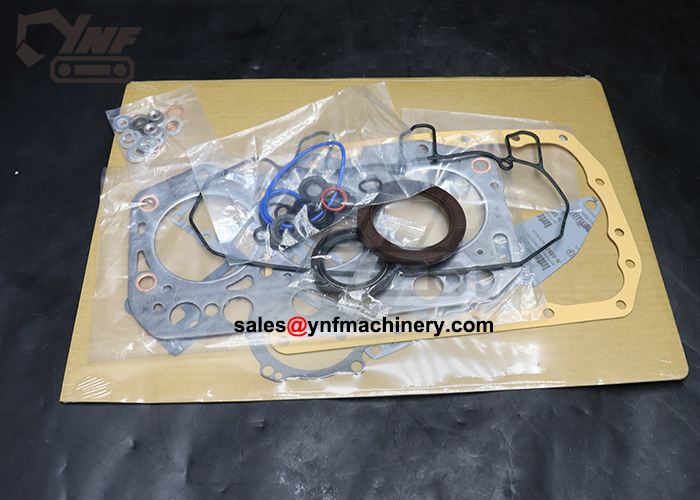

Cylinders

Function:

The bucket cylinder and other hydraulic cylinders control the movement of the boom, arm, and bucket. These cylinders provide the force needed to lift, lower, and articulate the front attachment, enabling precise and powerful operations.

Maintenance:

Inspect the hydraulic cylinders for leaks, dents, or scratches. Damaged seals or hoses can lead to hydraulic fluid loss, reducing efficiency. Lubricate the cylinder rods to prevent rust and ensure smooth operation. Regularly check the alignment of the cylinders to avoid uneven wear. Promptly address any issues to maintain the reliability of your excavator’s hydraulic system.

“A well-maintained front attachment ensures your excavator delivers consistent performance, even in the toughest conditions.”

By prioritizing the care of your front attachment, you extend the lifespan of your boom, arm, and bucket. This not only enhances productivity but also reduces the risk of unexpected breakdowns. Regular inspections and timely maintenance keep your excavator ready for any challenge.

Attachments

Function:

Attachments expand the capabilities of your excavator, making it a versatile tool for various tasks. These specialized tools allow you to perform grading, cutting, drilling, and other operations with precision. Whether you need to dig deeper, lift heavier loads, or shape the terrain, attachments transform your excavator into a multi-functional machine. For example, a grading bucket helps level surfaces, while a hydraulic breaker is ideal for demolishing concrete or rocks. Each attachment serves a specific purpose, turning your excavator into an essential attachment for diverse projects.

Maintenance:

Proper maintenance ensures your attachments remain reliable and efficient. Start by inspecting each attachment for signs of wear, such as cracks, dents, or loose parts. Pay close attention to the connection points where the attachment meets the boom and arm. A secure attachment prevents accidents and ensures smooth operation. Clean the attachments after every use to remove dirt, debris, or material buildup. Lubricate moving parts regularly to reduce friction and extend their lifespan. Replace worn-out components promptly to avoid compromising performance. By following these steps, you can maximize the utility of your attachments and keep your excavator ready for any task.

YNF Machinery’s Excavator Couplings

Highlight:

YNF Machinery offers high-quality excavator couplings that enhance the performance of your front attachments. These couplings ensure efficient power transmission between the engine and hydraulic system, enabling precise control of the boom, arm, and bucket. With YNF Machinery’s couplings, your excavator operates smoothly, even under demanding conditions.

“Efficient power transmission is the backbone of reliable excavator performance.”

YNF Machinery’s couplings are designed for durability and easy maintenance. They withstand harsh environments, reducing downtime and repair costs. Whether you’re using a grading bucket or a hydraulic breaker, these couplings provide the stability and efficiency needed for optimal performance. By choosing YNF Machinery, you invest in components that support the versatility and reliability of your excavator’s essential attachment.

Understanding the essential parts of an excavator is vital for maximizing its performance and efficiency. Each component, from the tracks to the bucket, plays a critical role in ensuring smooth operations. Routine maintenance, such as greasing, oil changes, and inspections, helps you identify potential issues early and prevents costly breakdowns. By prioritizing proper care, you enhance the safety, stability, and productivity of your machine. YNF Machinery offers high-quality excavator parts, including reliable engine components and couplings, to support your operations and keep your excavator running at its best.

FAQ

What are the most critical parts of an excavator to maintain?

The most critical parts include the tracks, hydraulic system, engine, and attachments.

How often should I change the hydraulic oil in my excavator?

You should change the hydraulic oil every 1,000 operating hours or as recommended by the manufacturer. Regular oil changes ensure smooth operation and prevent damage to the hydraulic system. Always check the oil level and quality during routine inspections to avoid potential issues.

What is the role of the counterweight in an excavator?

The counterweight balances the excavator during operations. It prevents tipping when lifting heavy loads or working on uneven terrain. A securely attached and undamaged counterweight ensures stability and safety, especially when the boom and arm extend far from the machine’s center of gravity.

How do I know when to replace the track pads?

Inspect the track pads for cracks, splits, or thinning rubber. If you see steel showing through the rubber, replace the pads immediately. Worn-out track pads reduce traction and stability, increasing the risk of slippage and accidents on the job site.

Why is proper lubrication important for excavator parts?

Lubrication reduces friction between moving parts, preventing wear and overheating. It ensures smooth operation and extends the lifespan of components like rollers, cylinders, and swing drives. Regular greasing also minimizes downtime caused by mechanical failures.

What makes YNF Machinery’s excavator parts reliable?

YNF Machinery offers high-quality parts crafted from durable materials. Their products undergo rigorous testing to meet industry standards. For example, their excavator couplings ensure efficient power transmission, while their engine parts like injectors and fuel pumps optimize performance. Choosing YNF Machinery means investing in reliability and efficiency.

How can I improve the efficiency of my excavator’s engine?

Use high-quality engine parts like those offered by YNF Machinery. Components such as injectors and fuel pumps ensure precise fuel delivery and combustion. Regular maintenance, including oil changes and cleaning the engine compartment, also enhances efficiency. Engines like the 3TNV76-QBVA Yanmar diesel engine demonstrate how robust power and reliability contribute to demanding excavation tasks.

What should I do if my excavator’s hydraulic system leaks?

Address hydraulic leaks immediately to prevent further damage. Inspect the hoses, seals, and cylinders for cracks or wear. Replace damaged parts promptly. Regularly checking and maintaining the hydraulic system minimizes the risk of leaks and ensures consistent performance.

Can attachments increase the versatility of my excavator?

Yes, attachments transform your excavator into a multi-functional machine. Tools like grading buckets, hydraulic breakers, and augers allow you to perform specialized tasks such as leveling, demolishing, or drilling. Proper maintenance of attachments ensures they remain reliable and efficient for various applications.

How does regular maintenance save costs in the long run?

Regular maintenance prevents small issues from becoming major problems. Tasks like greasing, oil changes, and inspections reduce the risk of breakdowns and costly repairs. Well-maintained parts last longer, minimizing replacement expenses. By investing time in upkeep, you ensure your excavator operates efficiently and reliably, saving money over time.