If you are new to taking care of excavators, learning about engine parts can feel hard at first. Doing regular maintenance is very important. Regular maintenance can lower emergency repairs by up to 80%. You can also save more than $42,000 for each machine every year. Look at this:

Benefit | Value |

|---|---|

Emergency repairs reduction | Up to 80% |

Annual savings per excavator | Over $42,000 |

You do not have to be an expert to find problems or do simple replacements. Using the right parts and picking a good excavator engine parts shop helps your machine last longer and work better.

Key Takeaways

Doing regular maintenance can stop most emergency repairs. It can save you a lot of money each year. You can save over $42,000 for each excavator.

Learn about important engine parts like pistons and crankshaft. Know what fuel injectors do. This helps you find problems fast.

Watch for signs of wear like lower performance. Listen for strange noises. Check for leaks to stop big repairs.

Always use real parts from trusted suppliers like YNF Machinery. This keeps your excavator working well. It also protects your warranty.

Check fluid levels, filters, and hoses often. This helps your excavator last longer. It can help you avoid expensive breakdowns.

Excavator Engine Parts Overview

Main Components

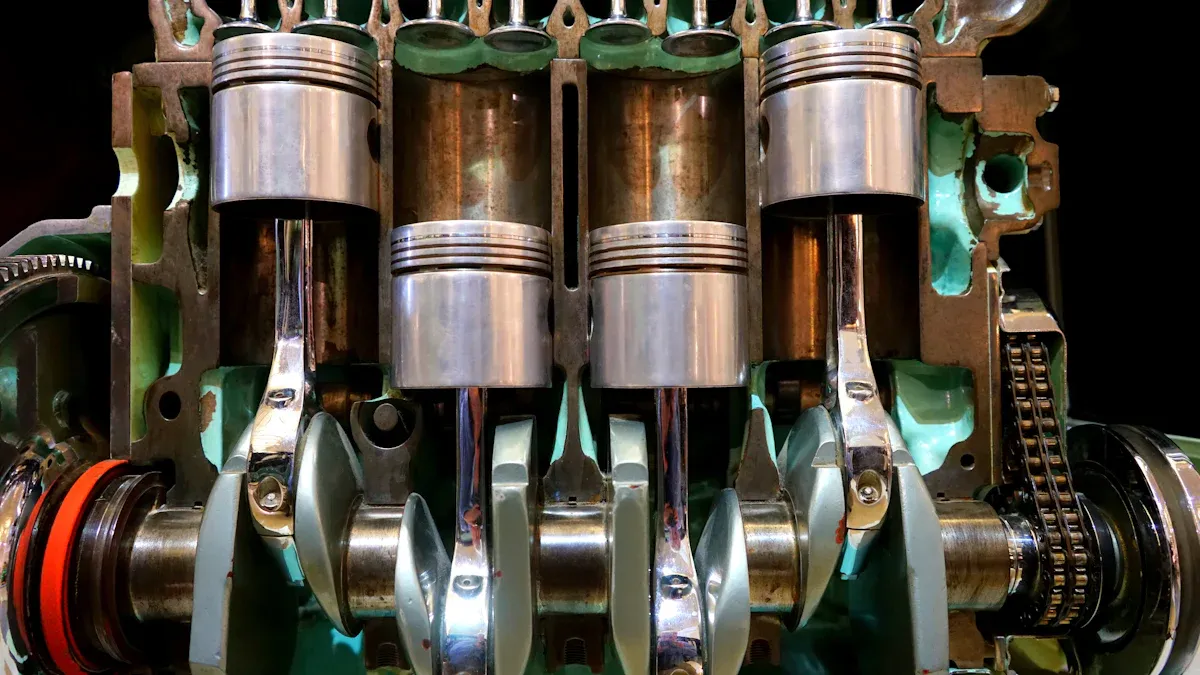

Excavator engines have many parts that work together. You should know these important replacement parts. They help your excavator run well and last longer. Here are the main engine components you will see in most excavators:

Pistons: These go up and down to make power from fuel.

Crankshaft: This part turns the pistons’ movement into energy.

Cylinder Block: It holds engine parts and handles heat and pressure.

Fuel Injectors: They spray fuel for the engine to burn.

Fuel Pump: This sends fuel to the injectors with high pressure.

Turbocharger: It pushes more air into the engine for extra power.

Exhaust Manifold: This collects exhaust gases and moves them out.

Radiator: It cools the engine by removing heat.

Water Pump: This moves coolant to stop engine parts from getting too hot.

Tip: Learning about these replacement parts helps you find problems faster. It also helps your excavator last longer.

Functions

Every part in your excavator engine has a job. Pistons and crankshaft work together to make power. The cylinder block keeps all the parts safe and in place. Fuel injectors and the fuel pump give the engine the right amount of fuel. The turbocharger helps the engine work harder without using more fuel. The exhaust manifold takes away bad gases. The radiator and water pump keep the engine cool so it does not get too hot.

Some excavator engine parts wear out faster than others. You should check hydraulic seals and O-rings often because they can break from pressure changes. Track chains and rubber tracks wear down fast on rough ground. Common problems are hydraulic fluid leaks, undercarriage wear, and engine trouble from dirty fuel or bad oil.

Here is a quick look at how long some main engine parts last if you take care of them:

Engine Component | Average Lifespan | Maintenance Tips |

|---|---|---|

Pistons | 10,000-12,000 hours | Change oil often, use good fuel |

Air Filters | 1,000-2,000 hours | Clean or replace often |

Turbochargers | 5,000-6,000 hours | Check for leaks, keep oil filled |

If you know which spare parts break the most, you can plan ahead. This helps your excavator keep working without problems. You will save time and money by changing important parts before they break.

Identifying Replacement Needs

Common Signs

You want your excavator to work well every day. Sometimes, engine parts get old or stop working. Knowing when to change parts can stop bigger problems. Here are signs your excavator needs a replacement:

Decreased Performance

Your excavator may not lift or dig as well. It feels weaker than before. This can mean hydraulic components or engine parts are worn out.Unusual Noises

You hear grinding, squeaking, or knocking from the engine. These sounds can mean problems with bearings, hydraulic pumps, or other moving parts.Leaking Fluids

You see puddles under your excavator. Leaking oil, coolant, or hydraulic fluid means seals or hoses may need to be changed.Uneven Track Wear

You notice tracks wearing down faster on one side. This can show alignment problems or worn-out undercarriage parts.

Tip: Finding engine wear early helps you avoid big repairs. Listen for odd noises and check for leaks often.

Strange engine noises can also make the machine shake. You can use these shakes to find the problem. If you hear new sounds or feel shaking, act fast. Waiting too long can cause more damage and cost more money.

Troubleshooting

Troubleshooting engine problems does not have to be hard. You can follow easy steps to find what is wrong. Here is a simple troubleshooting guide for beginners:

Identify Common Issues

Think about what could be wrong. Fuel problems, battery issues, and bad starter motors are common.Check Fuel Quality

Look at the fuel. Make sure it is clean and there is enough. Dirty or low fuel can cause engine trouble.Test the Battery

Use a multimeter to check battery voltage. If the battery is weak, charge or replace it.Inspect the Starter Motor

Look for signs of damage or wear. If the starter motor does not work, you may need to change it.Perform Regular Maintenance

Check fuel, battery, and starter motor often. This helps stop engine failures.

You can also use a diagnostic oscilloscope. This tool gives you details about electrical and mechanical parts. It is quick and accurate. Beginners find it easy to use for testing single parts or whole systems.

Here is a step-by-step troubleshooting process you can follow:

Gather Information

Write down what is wrong and when it started.Identify the Problem

Decide what is not working in your excavator.Develop a Hypothesis

Think about what could cause the problem.Test the Hypothesis

Check each part to see if it is the problem.Implement Repairs

Change or fix the parts that are broken.Verify Repairs

Start your excavator and make sure it works well.

Note: Do not rush repairs. Take your time with each step. This helps you avoid changing good parts.

Troubleshooting engine problems gets easier with practice. You learn more about your excavator each time you fix something. If you are not sure, ask for help or use trusted guides.

Excavator Engine Parts Replacement

Safety Steps

You must think about safety before you fix anything. Protect yourself and your team every time. Here are some safety steps you should follow:

Put on personal protective equipment (PPE). Wear hard hats, bright clothes, safety boots, hearing protection, gloves, and eye protection.

Make sure your work area is clean and flat. Remove things you could trip on. You need space to move around the excavator.

Check for hydraulic leaks and fuel levels. Make sure all safety gear works before you start.

Talk with your team. Use hand signals or safety boards to keep everyone safe.

Watch out for accidents. You could get hit by the vehicle, caught in machinery, or hurt while lifting. Rollover crashes, traffic crashes, cave-ins, sinkholes, and electrocutions can happen too.

Tip: Do not rush safety checks. Taking a few extra minutes can stop serious injuries and keep your repairs safe.

Tools Needed

You need the right tools to replace excavator engine parts. The correct tools make the job easier and safer. Here are basic tools you should have ready:

Tool Name | Purpose |

|---|---|

Socket Set | Remove bolts and nuts |

Wrenches | Loosen and tighten connections |

Screwdrivers | Remove covers and panels |

Pliers | Grip and pull small parts |

Torque Wrench | Tighten bolts to correct specs |

Multimeter | Test electrical connections |

Lifting Equipment | Move heavy engine parts safely |

Oil Drain Pan | Collect old oil during removal |

Funnel | Add new oil and fuel |

Safety Gloves | Protect hands from sharp edges |

Rags | Clean up oil and fuel spills |

Note: Check your tools before you start. Broken tools can slow you down and cause accidents.

Replacement Process

You want your excavator to work well and not get too hot. Follow these steps to replace excavator engine parts. This helps you fix fuel system problems, change spare parts, and keep your excavator working hard.

Engine Removal Preparation

Disconnect the battery ground wire. This stops electrical shocks.

Take off the hood, cover, and lower cover. Remove the air cleaner hose.

Remove the counterweight. Take off the heat pipe and oil pipe.

Disconnect the heating pipe and air conditioner pipe if needed.

Remove the pump, muffler, and radiator when needed.

Unplug all electrical wiring connectors.

Disassembly

Remove the bolts from the engine bracket.

Hang the engine body with lifting equipment.

Lift the engine out of the excavator. Put it on a safe platform for repairs.

Installation

Put all parts back in the reverse order.

Use genuine spare parts for every replacement. This keeps your warranty safe and helps your excavator work better.

Fill the engine with fresh oil and fuel. Check for leaks and overheating before you finish.

Maintenance and replacement tips: Always use OEM parts for your excavator engine parts. Aftermarket parts can break your warranty. For big repairs, you may need a licensed technician. If you want to keep your warranty, follow the rules and use genuine parts.

Maintenance and replacement tips: Check your fuel system and oil levels often. Clean up any oil or fuel spills right away. This helps you avoid overheating and keeps your excavator running longer.

Maintenance and replacement tips: Plan your repairs before you start. Gather all spare parts and tools. This saves time and helps you avoid mistakes.

If you want good replacement and upgrade options, choose YNF Machinery for your excavator engine parts. They offer high-quality spare parts and expert advice. You get great value and keep your excavator working well.

Fixing overheating issues: Always check your oil and fuel system after every replacement. Overheating can damage your engine and cost you more in repairs.

Excavator Engine Parts Shop Tips

Choosing Genuine Parts

When you go to buy excavator engine parts, you want to spend your money wisely. Picking genuine spare parts is the best choice. These parts protect your engine and help your excavator work well. Here are some things to check when picking good excavator spare parts:

Quality and real parts are important. Always buy from a trusted excavator engine parts shop. Genuine spare parts last longer and help your machine do better work.

The parts must fit your excavator model. If you use the wrong parts, your machine can break down and slow your job.

Good materials make parts strong. Strong parts can handle hard work and heavy loads.

Using real engine parts helps your machine use less fuel and dig better.

Warranty and help after you buy are important. Good shops give you a warranty and help if you have problems.

If you use fake excavator spare parts, your machine can get damaged. You may see your excavator work worse, break more, and cost more to fix. Some shops sell cheap parts made from weak stuff. These can be unsafe and hurt other engine parts. Many makers say you must use OEM spare parts to keep your warranty. If you use non-OEM parts, you might lose your warranty and pay for repairs yourself.

Look for certifications when you buy new parts. Here is a quick guide:

Certification | Description |

|---|---|

ISO 9001 | Makes sure the product is always good. |

CE | Follows health and safety rules in Europe. |

API | Good for parts used in oil and gas. |

Finding Reliable Suppliers

You need a supplier you can trust for every part you buy. Find an excavator engine parts shop that sells real spare parts and stands by what they sell. YNF Machinery is a great place for excavator spare parts. They give you strong replacement parts, good warranties, and expert help. You get tough engine parts that keep your excavator safe and working hard.

When you pick YNF Machinery, you know you get spare parts that meet high standards. Their excavator spare parts help you stop repairs from happening too often and keep your machine running longer. You save money and your excavator does not stop working as much. If you want the best for your excavator, choose a trusted excavator engine parts shop like YNF Machinery.

Tip: Always ask about certifications and warranty before you buy. Good suppliers will answer your questions and help you pick the right parts for your engine.

Maintenance Best Practices

Routine Checks

You want your excavator to work well every day. Doing regular checks helps you find problems early. This keeps your machine running longer. Here is a simple table with tips for daily and weekly checks:

Maintenance Task | Description |

|---|---|

Check Fluid Levels | Look at engine oil, hydraulic oil, and coolant. Add more if needed. |

Monitor Gauges | Watch all gauges and warning lights. Fix anything strange right away. |

Inspect Filters | Check air, fuel, and hydraulic filters. Change dirty filters. |

Look for Leaks | Walk around your machine. Look for oil, coolant, or fuel leaks. |

Inspect Hoses | Make sure hydraulic hoses have no cracks or leaks. |

You should also check the coolant level often. Look for leaks near the radiator and oil cooler. Clean filters help your engine get air and use less fuel. If you do these checks, you will stop big repairs. Your replacement parts will last longer.

Tip: Make a checklist for your daily and weekly checks. This helps you remember each step and keeps your excavator safe.

Preventive Care

Preventive care means you fix small problems before they get big. Follow the manufacturer’s schedule for oil changes and filter replacements. Most experts say to change engine oil every 250 to 500 hours. Change hydraulic fluid and coolant every 1,000 to 2,000 hours. Check your parts between 250 to 500 hours.

Here are some best practices to help you save money and stop breakdowns:

Change oil and filters on time. This keeps your engine healthy and saves fuel.

Watch your temperature gauges. If you see a warning, stop and check your parts.

Change worn or clogged filters. Dirty filters can make your engine weak or break it.

Always use the right replacement parts. Genuine parts from YNF Machinery last longer and protect your machine.

Keep coolant levels up and check belts for damage.

Many people make mistakes by skipping checks or using the wrong parts. Low coolant, dirty filters, and ignoring warning lights can hurt your engine. If you follow these tips, you can cut costs by up to 40%. You can make your equipment last 35% longer. You can also reduce downtime by 60%. This means you get more work done and spend less time fixing your machine.

Note: Good maintenance helps you save money and stop breakdowns. Stick to your schedule and use good parts for the best results.

You can help your excavator work well by checking the engine often. Use real parts and fix small problems right away. Real parts make your machine work better and last longer. You also spend less money on repairs. Here are some good things that happen when you do this:

Benefit | Description |

|---|---|

Ensure efficient operation | Taking care of your engine stops sudden trouble and keeps it running well. |

Extend engine service life | Good care helps your engine last for many years. |

Save costs and reduce risk | Fixing problems early means fewer big repairs and less time not working. |

Improve safety and environment | Engines that are cared for are safer and make less pollution. |

Keep learning new things and use help from trusted places. YNF Machinery gives you good parts and support. If you stay ready and fix things early, you protect your machine and make your job easier. 🚜

FAQ

How often should you replace excavator engine parts?

Check your engine parts every 250 to 500 hours. Change any worn parts right away. Following the manufacturer’s schedule helps your excavator work well and last longer.

What signs show your engine needs attention?

Listen for odd noises or look for leaks. Watch for weak performance or shaking. If your engine loses power, check it soon. Fixing problems early stops bigger trouble.

Can you use aftermarket parts for your excavator?

Always use genuine parts from YNF Machinery. Aftermarket parts might not fit or last long. Genuine parts protect your engine and keep your warranty safe.

What tools do you need for engine part replacement?

You need a socket set, wrenches, screwdrivers, and pliers. Use a torque wrench for bolts. Lifting equipment helps with heavy parts. Safety gloves and rags keep you safe and clean.

Where can you buy reliable excavator engine parts?

YNF Machinery sells strong, genuine engine parts. You get expert help and good warranties. Their parts help your excavator work better and last longer.