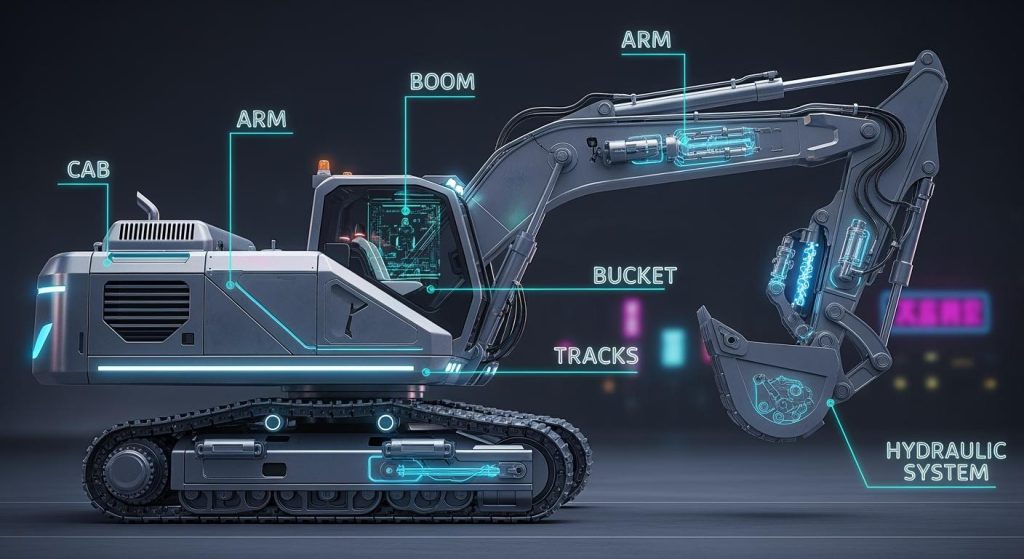

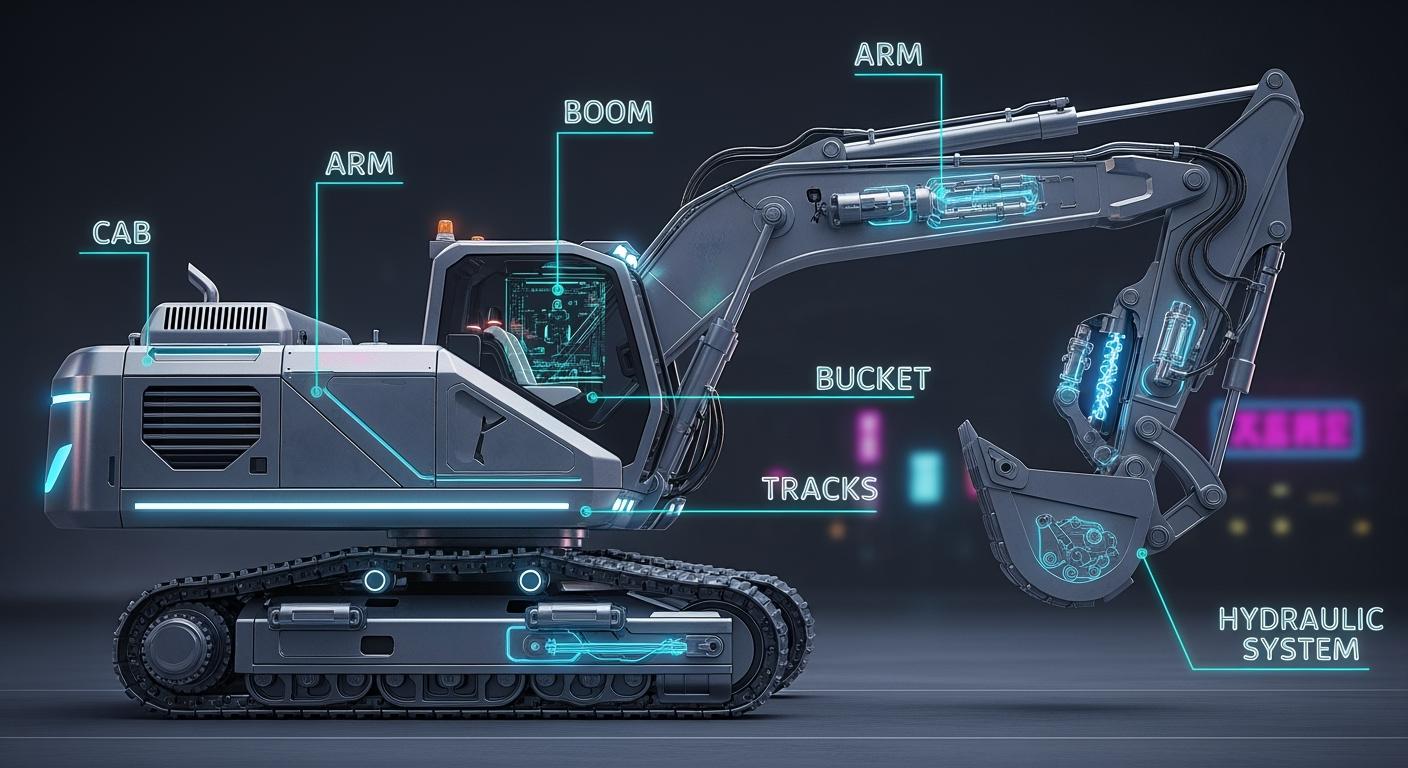

You can see the main parts of an excavator in this detailed excavator description of parts. These include the undercarriage, cab, boom, arm, bucket, hydraulic system, engine, counterweight, and swing gear. The undercarriage helps the excavator move and stay steady. The cab allows you to control the machine and provides a clear view. The boom, arm, and bucket work together to dig and lift materials. The hydraulic system is essential for making all the parts move efficiently. The engine supplies power to the machine, while the counterweight ensures the excavator remains balanced. The swing gear enables the top part to rotate smoothly. You can find these parts in models like the Kubota KX057 and Cat 320D.

|

Excavator Type |

Model |

|---|---|

|

Small |

Kubota KX057 |

|

Medium |

Cat 320D |

Each part has a specific function, but they must work together harmoniously. This collaboration keeps the excavator safe and operating effectively. This comprehensive description of excavator parts helps you understand how to use it optimally on any job site.

Key Takeaways

-

Learn the main parts of an excavator. These are the undercarriage, cab, boom, arm, bucket, hydraulic system, engine, counterweight, and swing gear. Each part is important for how the machine works.

-

It is important to do regular maintenance. Check the undercarriage, hydraulic fluid, and engine oil every day. This helps stop problems and makes your excavator last longer.

-

Pick the right bucket for your job. Buckets come in different sizes and shapes. This can change how much work you get done and how much fuel you use. Use the right bucket for the job to get the best results.

-

Use attachments to make your excavator do more jobs. Quick couplers help you switch tools fast. This makes your work easier and lets you do more tasks.

-

Safety and being able to see well in the cab are very important. A good cab has clear views and easy controls. This helps you work better and not get tired as quickly.

Excavator Description of Parts

When you look at an excavator, you see many important parts. Each part has a special job. This excavator description of parts explains how these parts work together. They help the machine dig, lift, and move things. You need to know about these parts to use, fix, or pick the right excavator.

Undercarriage Components

The undercarriage is the bottom part of the excavator. It holds up the whole machine and helps it move on different ground. Here are the main undercarriage parts and what they do:

-

Track Chains (Track Links): These connect the tracks and hold up the machine as it moves.

-

Track Shoes (Grousers): These give grip and spread out the weight. This helps the excavator work on soft or bumpy ground.

-

Sprockets: These move power from the engine to the tracks so the excavator can move.

-

Idlers: These keep the track chain tight and help take in bumps when moving.

-

Rollers (Top & Bottom): These help the tracks roll smoothly and spread out the weight.

-

Track Adjusters: These keep the tracks tight for safe and easy use.

-

Track Frame: This makes the undercarriage strong and keeps all the parts lined up.

Tip: Check the undercarriage often for damage or wear. This stops problems and keeps your excavator working well.

Here are some common numbers for undercarriage parts:

|

Specification |

Value |

|---|---|

|

Typical Drill Rig Weight Range |

36-50 mtons |

|

U/C Weight |

14.8 t |

|

Track Gauges K1/K2 |

2300/3570 mm |

|

Lower Width (retracted) |

3000 mm |

|

Lower Width (extended) |

4270 mm |

|

Shoe Width |

700 mm |

|

Wheel Base |

4400 mm |

|

Bearing Riser Height |

930 mm |

|

Max. Tractive Eff. |

40 t |

|

Machine Speed |

2.31 km/h |

You can pick steel or rubber tracks for your excavator. Steel tracks last longer and are good for tough jobs. But they can hurt the ground and make more noise. Rubber tracks are quieter and protect the ground. They are better for city work but wear out faster.

Cab and Controls

The cab is where you sit and run the excavator. New cabs are made for comfort, safety, and seeing well. You get seats you can move, air control, and controls that are easy to reach. These things help you work longer without getting tired.

-

Automated control systems use GPS and lasers to help you dig right and not make mistakes.

-

Custom sensors watch the excavator parts and warn you if something is wrong.

-

Air control and less noise make the cab nice, even for long work.

-

360-degree cameras let you see all around the machine so you can spot danger fast.

-

Touchscreens show live data, so you can control the excavator and check how it is working.

Note: Seeing well in the cab helps you stay safe. Studies show that better views and seat spots help you work better and get less tired. You can work safer and faster when you see everything.

Boom, Arm, and Bucket

The boom, arm, and bucket are the main working parts. People call this the boom and arm mechanism. You use these parts to dig, lift, and move things.

-

Boom: The boom connects to the main body and reaches out to the work area. It lifts and lowers the arm.

-

Arm (Stick): The arm, or stick, goes from the boom and moves the bucket closer or farther.

-

Bucket: The bucket scoops, lifts, and dumps stuff. You can pick different bucket sizes and shapes for each job.

Medium buckets hold about 0.8 to 2.0 cubic meters. For example, a bucket for a 10-15 ton excavator might hold 0.8-1.2 cubic meters and be 1200-1600 mm wide. Bigger machines use buckets up to 2.0 cubic meters and over 2000 mm wide. The breakout force shows how strong the digging is. For medium machines, it is 80 to 200 kilonewtons.

The bucket’s design changes how well you dig and how much fuel you use. Here is a quick look at what matters:

|

Factor |

Influence on Efficiency and Fuel Consumption |

|---|---|

|

Geometry |

Shallow buckets work faster for light stuff; deep buckets carry more but need more power. |

|

Teeth and Cutting Edges |

Sharp teeth dig better and save energy; good spacing helps you dig easily and right. |

|

Weight and Capacity Balance |

The right bucket size saves fuel and keeps the excavator steady; lighter buckets help small machines move fast. |

You can get all the excavator parts you need, like undercarriage parts, cabs, and buckets, from YNF Machinery. They have good choices to keep your machine working well.

This excavator description of parts gives you a clear idea of how each part works. When you know these things, you can use your excavator safely and easily.

Essential Parts of an Excavator

Hydraulic System

The hydraulic system helps the excavator move. It uses pressurized fluid to make parts work. The boom, arm, bucket, and tracks all need this system. When you use the controls, pumps send fluid through hoses. The fluid goes to cylinders. These cylinders push and pull. This makes the excavator dig, lift, and turn. Most excavators in 2026 use pressures from 3,130 to 4,980 PSI. Some machines can go up to 5,260 PSI for a short time when more power is needed.

|

Excavator Size |

Hydraulic Pressure Range (PSI) |

|---|---|

|

1-ton machines |

3,130 – 3,555 |

|

Larger models |

Up to 4,980 |

|

Power boost mode |

5,260 (for 10-15 seconds) |

Hydraulic system problems often stop excavators from working. If the hydraulic pump breaks, repairs take a long time. This costs more money and slows down your work.

Engine and Power

The engine gives the excavator its strength. It powers the tracks and the hydraulic system. Most new excavators use turbocharged diesel engines. DOOSAN models have these engines. They meet strict rules for pollution and give lots of power. Komatsu engines use less fuel. This helps you save money on long jobs. Fuel use changes how much you spend each day. Picking a good engine is important.

-

DOOSAN excavators have DOOSAN Infracore engines.

-

Turbocharged engines give extra power for hard jobs.

-

Komatsu engines help save fuel and work well.

|

Brand |

Fuel Efficiency Features |

Notes |

|---|---|---|

|

Komatsu |

New engine technology uses less fuel |

Known for saving money and working well |

|

Other Brands |

Features change with each model |

How well they work depends on conditions |

Counterweight and Swing Gear

The counterweight keeps the excavator steady. It sits at the back and stops tipping when lifting heavy things. The swing gear lets the top part turn smoothly. This helps you move the boom, arm, and bucket where you want. Both parts help the excavator stay safe and work well.

You should check these parts often. Look at filters, add grease, and inspect parts every 250 to 500 hours. Watch for damage in the bucket, track shoes, rollers, and engine oil filters.

|

Part |

Lifespan (Hours) |

|---|---|

|

Buckets |

7,500 to 10,000 |

|

Track Shoes |

2,000 to 3,000 |

|

Rollers |

3,000 to 5,000 |

|

Engine Oil Filters |

250 to 500 |

All these parts work together. They help the excavator dig, lift, and move things.

Components of an Excavator in Action

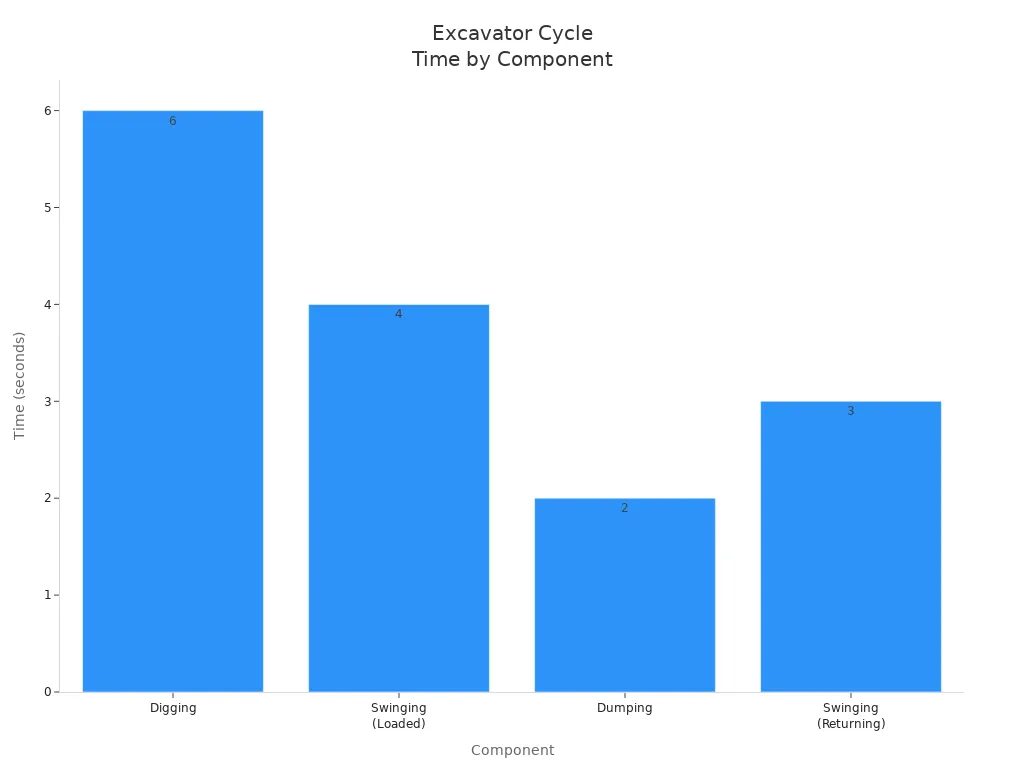

How Parts Work Together

You use the components of an excavator to finish jobs fast and safe. The undercarriage helps the machine move into place. The cab lets you see well and reach all controls. The boom lifts and stretches out. The arm moves the bucket to dig or lift. This digging mechanism helps you take away dirt or trash with care. When you use the boom, arm, and bucket together, you can dig, swing, and dump things easily. Working as a team makes you get more done, even in small spaces.

|

Component |

Time (seconds) |

|---|---|

|

Digging |

6 |

|

Swinging (Loaded) |

4 |

|

Dumping |

2 |

|

Swinging (Returning) |

3 |

|

Total Cycle Time |

15 |

Tip: Moving smoothly and working together helps you finish jobs faster. It also keeps your machine from wearing out too soon.

Common Attachments

You can make your excavator do more by adding attachments. The bucket is the most used because it works for many jobs. In 2026, it has a 35.7% market share. Grapples are used a lot in demolition, with 55.8% of that market. Compact excavators are liked for tight spots, with a 49.7% share, since they fit in small places and do many jobs.

-

Buckets are for digging, loading, and grading.

-

Grapples pick up and move big things.

-

Hydraulic breakers help break things fast, with up to 1,500 hits each minute.

-

Quick couplers let you change attachments quickly, making work up to 35% faster.

|

Evidence Type |

Description |

|---|---|

|

Productivity Increase |

Changing attachments fast can make equipment work 25–35% more. |

|

Operational Efficiency |

Hydraulic breakers can hit up to 1,500 times each minute. |

|

Versatility |

Special attachments let excavators do many different jobs. |

Maintenance Tips

You keep your excavator working longer by taking care of it often. Start every day by checking the machine all around. Put grease on moving parts like joints and bearings to stop wear. Look at hydraulic fluid levels so the machine works right. Change air filters often to keep the engine safe and make it last up to 30% longer. Clean the radiator so it does not get too hot. Use clean fuel to stop injector problems. Write down all care in a logbook. Machines that are cared for sell for up to 15% more. Buyers trust machines with full records.

Note: Taking good care of your excavator saves money and keeps it ready for any job.

Knowing the main parts of an excavator helps you stay safe. It also helps you work faster and better. If you know what each part does, you can find problems early. This keeps repair costs down. You can fix hydraulic problems by looking for leaks. You should also check the fluid to see if it is clean. When you understand these things, you can pick the right tool for your job. You can also choose the best excavator for what you need. Training classes teach you how to use your machine safely. They help you do your job well. Use what you learn to get the most from your excavator every day.

FAQ

What is the most important part of an excavator?

You need every part for safe operation, but the hydraulic system stands out. It powers the boom, arm, and bucket. Without it, your excavator cannot dig, lift, or move materials.

How often should you check your excavator for maintenance?

You should check your excavator daily before use. Look at the tracks, hydraulic fluid, and engine oil. Regular checks help you spot problems early and keep your machine running well.

Can you use one excavator for different jobs?

Yes, you can use one excavator for many tasks. You only need to change the attachments. Buckets, grapples, and breakers let you dig, lift, or break materials with the same machine.

What size excavator do you need for small spaces?

You should pick a compact excavator for tight areas. These machines fit in small spaces and work well for landscaping, trenching, or home projects.

How do you choose the right bucket for your excavator?

You should match the bucket size to your excavator and the job. A small bucket works best for digging hard soil. A wide bucket moves more loose material. Always check the weight limit.