You need many electric parts to keep your E330C excavator working well. The main E330C components for electric parts are the C7 controller, monitor display panel (157-3198), relays, sensors, wiring harness, alternator, starter motor, batteries, and switches. Each part is important for how the machine works and stays safe. Learning about these parts helps you spot problems faster and change broken parts without worry.

Key Takeaways

Learn what the C7 controller does. It controls the engine and hydraulic systems. This helps your excavator work well and stay safe.

Check the monitor display panel often. It shows important things like engine speed and warning signs. This helps you find problems early.

Look at relays and magnetic switches a lot. They help control electricity flow. They also keep your system safe from too much power.

Watch the sensors closely. They check important things like oil temperature and pressure. This makes sure your excavator works safely and well.

Take care of the wiring harness. It links all electric parts together. If it gets damaged, many problems can happen.

E330C components for electric parts overview

C7 Controller

The C7 controller is in the middle of the E330C’s electric system. It controls the engine and hydraulic systems. It sends signals to many parts. This lets your excavator move, lift, and dig. The controller helps the machine work smoothly. It also keeps the machine safe from too much power or mistakes. If you know how the C7 controller works, you can find problems faster. This helps your excavator stay in good shape.

Monitor Display Panel (157-3198)

The monitor display panel is called part number 157-3198. It is inside the cab. You use this panel to see how the excavator is doing. It shows things like engine speed, oil pressure, and hours worked. The panel also gives you warning messages and fault codes. This helps you find problems quickly and fix them before they get worse.

Tip: The monitor display panel shows charging status, oil temperature, pressure, and coolant flow. You can use this information to plan repairs and stop breakdowns.

Here is a table that shows what the monitor display panel does:

Feature | Description |

|---|---|

Information Display | Shows engine speed, oil pressure, and working hours |

Fault Diagnosis | Gives fault codes and warning messages |

Part Number | 157-3198, 260-2160 |

Functions | Operation control, performance monitoring, maintenance reminders |

Relays / Magnetic Switches

Relays and magnetic switches work like traffic lights for electricity. They turn circuits on or off when you press a button or turn a key. These parts protect the electric system from too much power. You need them to start the engine, turn on lights, and run other electric parts. If a relay breaks, some things may stop working.

Sensors

Sensors collect information from different parts of the excavator. They measure oil temperature, pressure, and coolant flow. The sensors send this data to the controller and monitor display panel. You use these numbers to make sure the machine works safely and well. If a sensor gives wrong data, the excavator may not work right.

Wiring Harness

The wiring harness connects all the electric parts. It is like the nervous system of your E330C. Wires carry signals and power from the battery to the controller, sensors, and switches. If the wiring harness is damaged, you can have many problems. You might see warning lights or lose power. Check the wiring harness often to keep your excavator safe.

Alternator

The alternator makes electricity when the engine runs. It charges the battery and powers the electric system. If the alternator does not work, the battery will lose power. The machine may stop working. You need the alternator to keep all e330c components for electric parts working during long jobs.

Starter Motor

The starter motor helps you start the engine. When you turn the key, the starter motor spins the engine until it starts. If the starter motor breaks, you cannot start the excavator. This part works with the battery and relays.

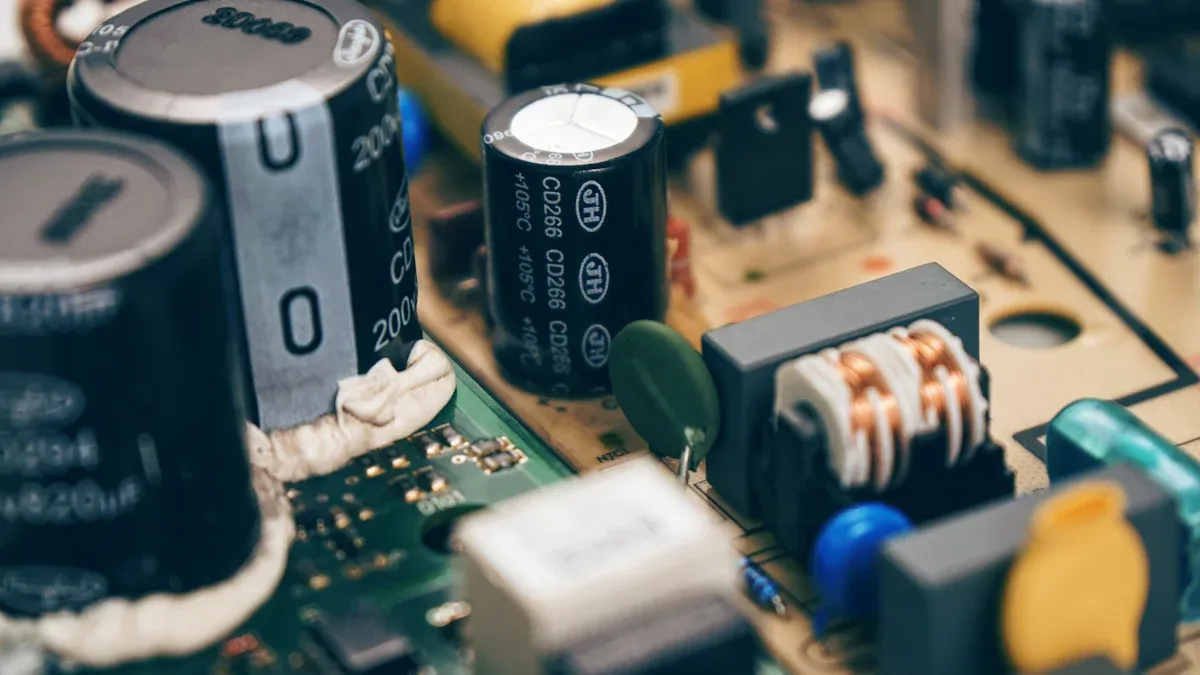

Batteries

Batteries store energy for your E330C. They give power to the starter motor, controller, and monitor display panel. Good batteries help you start the machine in any weather. Weak batteries can make the machine slow to start or make the display panel flicker. Check your batteries often to avoid problems.

Switches

Switches let you control different e330c components for electric parts. You use switches to turn on lights, start the engine, or use the wipers. Each switch sends a signal to a relay or controller. If a switch breaks, you may not be able to use that part. Check switches often to find problems early.

Note: Some other important e330c components for electric parts are the fan motor, hydraulic piston motor, and vane motor. The fan motor keeps the excavator cool. The hydraulic piston motor and vane motor help move the tracks, booms, and buckets.

If you learn about these e330c components for electric parts, you can keep your excavator working well and save money on repairs.

Component functions and importance

C7 Controller Role

The C7 controller helps run the engine and hydraulic systems. It works like the brain of your excavator. It sends signals to other parts so everything works together. When you use the excavator, the controller helps you move, lift, and dig. It keeps your equipment safe by stopping unsafe actions. It also stops electrical overloads. If you know how the C7 controller works, you can keep your machine running well and avoid mistakes.

Monitor Display Panel Use

The monitor display panel shows you important information as you work. You see things like charging status, oil temperature, and pressure. The panel helps you find problems early and plan repairs. You can check engine speed, oil pressure, and working hours on the display. Warning messages and fault codes show up on the screen. These help you find where a problem is.

The monitor display panel checks many things. You can look at the table below to see what it shows:

Operating Condition | Examples of Data Displayed |

|---|---|

Engine Monitor | Boost Pressure, Oil Pressure, Oil Temperature |

Transmission | Oil Pressure, Oil Temperature, Warning Indicators |

This information helps you keep your e330c components for electric parts working well.

Relays / Magnetic Switches Function

Relays and magnetic switches control how electricity moves in your excavator. You use them to turn circuits on and off. When you start the engine or turn on lights, relays send power to the right parts. These parts protect your electric system from damage. If a relay breaks, you may lose power to some systems. Checking relays often helps you find problems before they stop your work.

Sensor Purpose

Sensors measure things like oil temperature, pressure, and coolant flow. You need sensors to keep your excavator safe and working well. Sensors send data to the controller and monitor display panel. If a sensor gives wrong numbers, your machine may not work right. Good sensors help you avoid overheating, low oil pressure, or other problems.

Wiring Harness Role

The wiring harness connects all the electric parts in your excavator. It is like the nervous system of your machine. The harness carries signals and power from the battery to the controller, sensors, and switches. It must stay in good shape for strong electrical connections. A good wiring harness helps your excavator work its best.

The wiring harness sends electrical signals and power to different systems.

It must stay in good shape for strong connections.

A good wiring harness is needed for the E330C excavator to work well.

If you check the wiring harness often, you can stop electrical problems and keep your e330c components for electric parts working right.

Alternator and Starter Motor Function

The alternator makes electricity when the engine runs. You need it to charge the battery and power the electric system. If the alternator stops working, the battery loses power and the machine may stop. The starter motor helps you start the engine. When you turn the key, the starter motor spins the engine to start it. Both parts are needed every day. Without them, you cannot start or use your excavator.

Battery Importance

Batteries store energy for your excavator. You use them to power the starter motor, controller, and monitor display panel. Good batteries help you start the machine in any weather. Weak batteries can make starting slow or make the display flicker. You should check your batteries often to stop problems and keep your equipment working.

Switches Use

Switches let you control different electric parts of your excavator. You use switches to turn on lights, start the engine, or use the wipers. Each switch sends a signal to a relay or controller. If a switch breaks, you lose control of that part. Checking switches often helps you find problems before they get worse.

If you know how each component works and why it matters, you can keep your excavator safe and working well. You will find problems faster and know when to change parts, saving time and money.

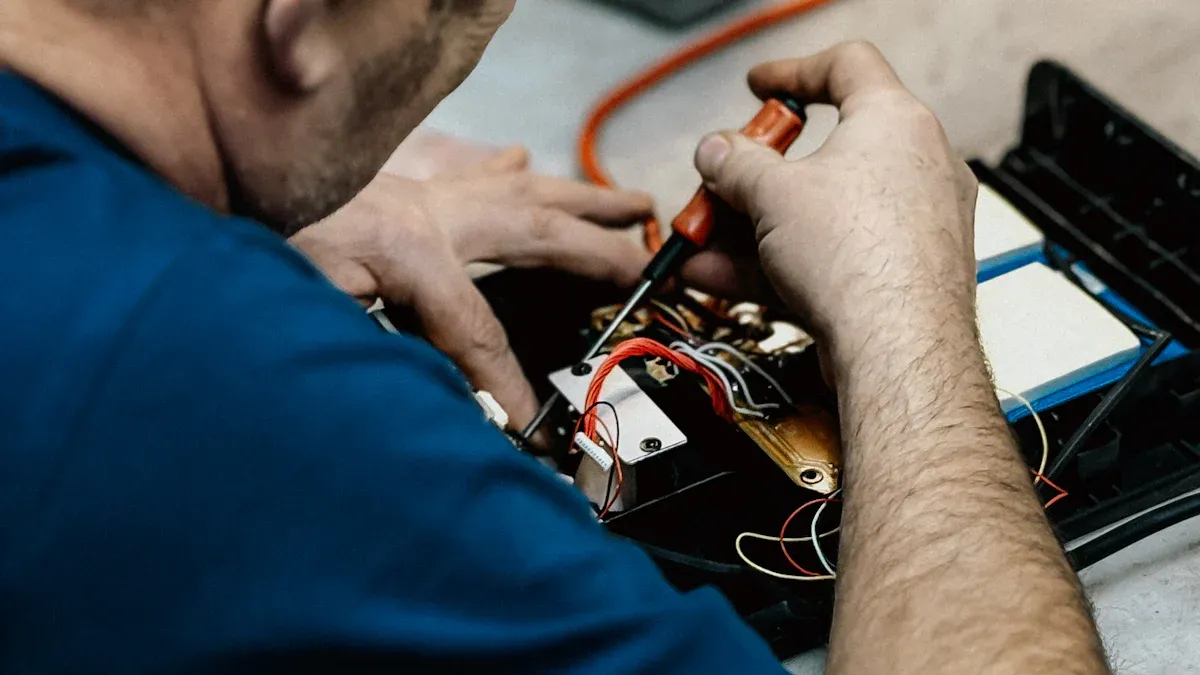

Maintenance and troubleshooting tips

C7 Controller Care

Keep the C7 controller clean and dry. Dust and water can cause trouble. Check if the mounting and wiring are tight. If you see warning lights or error codes, use a diagnostic tool to find problems. Always turn off power before you look at or change the controller.

Monitor Display Panel Checks

Check the monitor display panel often. First, test battery voltage and check fuses. Look for water or dirt near the panel. Check all wires and connections for damage. Use a scanner to read error codes from the ECU. Make sure the software is updated. If the screen flickers or buttons do not work, you may need a new panel.

Tip: Wipe the display panel with a soft cloth. Do not use strong chemicals.

Relays / Magnetic Switches Maintenance

Relays and magnetic switches need regular checks. Look for rust or burnt spots. Test each relay by listening for a click when you turn it on. Replace any relay that does not work or looks bad. Keep the area around relays clean from oil and dust.

Sensor Troubleshooting

Sensors can stop working if they get dirty or wet. Check each sensor for loose wires or broken parts. Clean the sensor pins with a dry cloth if you see oil or grease. If the monitor shows wrong numbers, test the sensor with a multimeter. Change broken sensors right away.

Wiring Harness Inspection

Look at the wiring harness for damage. Check for broken wires, bad crimps, or loose connectors. Pull connectors by the housing, not the wires. Do not spray high-pressure water near connectors. Keep connectors clean and dry to stop rust.

Common Wiring Issues | Prevention Tip |

|---|---|

Poor Contact | Lock connectors fully |

Wire Breakage | Handle connectors carefully |

Water Intrusion | Dry connectors before restoring power |

Alternator and Starter Motor Checks

Check the alternator and starter motor for loose bolts and old wires. Listen for odd sounds when you start the engine. Test battery voltage to make sure the alternator charges well. Change worn brushes or broken parts fast.

Battery Upkeep

Check battery ends for rust. Clean them with a wire brush. Make sure the battery is tight and cables are secure. Test battery voltage often. Change weak batteries before they stop working.

Switches Maintenance

Test each switch to see if it works. Look for sticky or broken buttons. Change switches that do not respond. Keep switches clean and dry to stop electrical problems.

Regular checks and simple care help you stop most electrical problems in your E330C excavator.

Signs of failure and replacement

C7 Controller Failure Signs

You may notice the engine does not respond or the hydraulic system acts strange. Warning lights can stay on the monitor. The machine may not start or may shut down by itself. If you see these signs, check the controller first. Replace the C7 controller if you find burnt smells, melted wires, or error codes that do not clear.

Tip: Always use a trusted supplier like YNF Machinery for a new C7 controller.

Monitor Display Panel Faults

A faulty monitor display panel can show blank screens, flickering, or unreadable numbers. You may not see warning messages or data. Sometimes, buttons stop working. If you cannot read the display or get error codes, you should replace the panel.

Relays / Magnetic Switches Issues

Relays or magnetic switches can fail if you hear no click when you turn the key. Lights or the starter may not work. Burnt smells or melted plastic are warning signs. Replace faulty relays right away to keep your excavator safe.

Sensor Malfunction Indicators

Sensors can give wrong readings or show error codes. The engine may overheat or lose power. If you see strange numbers on the monitor, test the sensors. Replace any sensor that does not work.

Wiring Harness Damage Signs

You may see warning lights, flickering displays, or lose power to parts. Check for broken wires, burnt smells, or melted insulation. If you find damage, replace the wiring harness to stop more problems.

Alternator and Starter Motor Warning Signs

If the battery does not charge or the engine will not start, check these parts. Listen for grinding or clicking sounds. Dim lights or slow cranking mean you need to replace the alternator or starter motor.

Battery Replacement Signs

Weak batteries can make the engine slow to start. The display may flicker or reset. If you see rust, leaks, or swelling, replace the battery soon.

Switches Faults

Broken switches may not turn on lights or start the engine. Sticky or loose buttons are warning signs. Replace switches that do not work.

For all replacement electric parts, choose YNF Machinery to keep your E330C excavator running strong and safe.

You should learn about E330C electric components. This helps your excavator stay safe and work well. If you check these parts often, you can find problems early. This stops your machine from breaking down. When you know what each part does, you can fix issues fast. You can also change broken parts quickly.

Look at electric parts often.

Find out how each part works.

Change damaged parts as soon as you can.

If you need new parts, pick YNF Machinery. They give you good quality and help for your E330C excavator.

FAQ

What should you do if your E330C monitor display panel stops working?

Check the battery and fuses first. Look for loose wires or water near the panel. If the screen stays blank, you may need a new panel. Choose YNF Machinery for reliable replacement parts.

How often should you check the wiring harness?

You should inspect the wiring harness every month. Look for broken wires, loose connectors, or signs of wear. Regular checks help you prevent electrical problems and keep your excavator safe.

Why does your E330C need good batteries?

Good batteries help your excavator start quickly and run well. Weak batteries can cause slow starts or flickering displays. You should test your batteries often and replace them with quality parts from YNF Machinery.

How can you tell if a relay is bad?

A bad relay may not click when you turn the key. Lights or the starter may not work. You might smell burnt plastic. Replace faulty relays right away to keep your machine running.

Where can you buy trusted E330C electric parts?

You can buy trusted E330C electric parts from YNF Machinery. They offer quality components and helpful support for your excavator.