You want to make sure you get the right china hydraulic excavator parts for your machine in 2026. Choosing the correct parts means less downtime and better value for every project. When you focus on finding the right parts, you avoid the risks that come with counterfeit china excavator parts. Studies show that using certified parts can lower failure rates by 15% and boost project speed by 30%. The right china excavator parts also last longer, with many working over 3,000 hours. Always check the specific part number and supplier to get genuine excavator parts. After-sales support adds even more value, making your investment safer. A simple step-by-step plan will help you feel confident and avoid costly mistakes.

Key Takeaways

-

Always identify your excavator’s make, model, and serial number before ordering parts to ensure a perfect fit and avoid costly mistakes.

-

Check the OEM codes and verify part compatibility by comparing old and new parts carefully to keep your excavator running smoothly.

-

Choose suppliers with strong reputations, proper certifications, and good customer reviews to get genuine, high-quality parts and reliable support.

-

Avoid counterfeit parts by buying only from trusted dealers and looking for authentic packaging, serial numbers, and warranties.

-

Balance cost and quality by investing in certified parts with good warranty coverage to reduce downtime and save money in the long run.

Identify Parts

Make, Model, Serial Number

You need to start by gathering the basic details of your excavator. Write down the make, model, and serial number. These three pieces of information help you find the right china excavator parts every time. Manufacturers like Caterpillar, Komatsu, and Hitachi place serial numbers in specific spots on their machines. You can check the technical documentation or look for a metal plate on the frame. Serial numbers are not just random codes. They tell you exactly which version of the excavator you own.

Tip: Serial numbers can change even within the same model. Always double-check before you order any parts.

Knowing the make, model, and serial number helps you avoid mistakes. For example, two excavators with the same model name but different serial numbers may use different parts. Equipment makers often update part numbers during production. If you use the wrong part, your excavator may not work as expected. Reliable suppliers use this information to match the right china excavator parts to your machine. This step reduces downtime and saves money.

Technical guides from ConEquip show where to find serial numbers on many excavator models. These guides also explain how serial numbers help track machine specifications. When you use the correct serial number, you make sure the parts fit and work well. This also helps with warranty claims and safety updates.

OEM Codes

After you have the make, model, and serial number, look for the OEM codes. OEM stands for Original Equipment Manufacturer. These codes are unique numbers given to each part by the manufacturer. You can find OEM codes in your excavator’s manual or on the old part itself. Using the right OEM code ensures you get the exact china excavator parts you need.

Many suppliers list OEM codes in their catalogs. When you give them the correct code, they can quickly check compatibility. This step is important for both new and used excavator machinery parts. Some suppliers also offer parts from well-maintained machines, but you still need to match the OEM code. This helps you avoid getting the wrong excavator parts and keeps your excavator running smoothly.

Note: Always compare the OEM code on your old part with the one listed for the new part. Even a small difference can affect compatibility.

By following these steps, you make sure you order the right china excavator parts. You protect your investment and keep your excavator working at its best.

Compatibility Check

When you buy excavator parts, you need to make sure they fit your machine. A good compatibility check helps you avoid costly mistakes. You want every part to work well with your excavator. This step keeps your equipment safe and running smoothly.

Documentation Review

Start by reading the manuals and technical sheets for your excavator. These documents list the right parts for your model. You can find details about compatibility in the parts catalog. Always compare the part number in your manual with the number on the new part. This helps you get an accurate match.

Tip: If you cannot find the manual, ask your supplier for a digital copy. Many suppliers keep these records for popular excavator models.

You should also look for any updates or changes in the documentation. Sometimes, manufacturers update parts to improve performance. When you review the latest documents, you make sure you do not miss these changes. This step helps you check compatibility and avoid using the wrong parts.

Fit Verification

After you review the documents, you need to check the physical fit. Take the old part from your excavator and compare it to the new one. Look at the size, shape, and connection points. You want every part to fit perfectly. This step gives you an accurate match and ensures the excavator works as it should.

-

Check the mounting holes and seals.

-

Make sure the new part lines up with the old one.

-

Test the part on your excavator before full installation.

If you use aftermarket parts, always ensure compatibility of aftermarket parts with your machine. Some aftermarket parts may look similar but have small differences. Careful fit verification helps you avoid problems later.

Remember: A careful compatibility check saves time and money. It keeps your excavator safe and working hard.

Excavator Parts Supplier

Supplier Reputation

You need to choose an excavator parts supplier with a strong reputation. Suppliers who serve brands like Komatsu, Caterpillar, Volvo, and Hitachi have proven their reliability in the market. These brands lead the construction equipment industry and set high standards for quality and service. When you buy from reputable sources, you lower your risk of getting poor-quality parts or facing unexpected breakdowns.

A good supplier stands out by offering a wide inventory, fast delivery, and expert support. You want a supplier who can answer your questions and help you find the right parts for your excavator. Look for suppliers who provide detailed product information, including fit, compatibility, and warranty terms. This information helps you make smart choices and keeps your excavator running smoothly.

Tip: Suppliers with a global distribution network and over 1.3 million SKUs can guarantee inventory availability for most excavator models.

You can use customer reviews and industry reports to check supplier reputation. Market leaders like Caterpillar and Komatsu hold strong market shares because they focus on quality, warranty, and customer support. User reviews often mention fewer breakdowns and lower maintenance costs when using reputable aftermarket parts. Real-world testimonials show that customers experience 30% fewer breakdowns and save up to 25% on costs over five years with reputable aftermarket parts.

Here is a table comparing genuine and aftermarket excavator parts:

|

Feature |

CNH Genuine Parts |

Aftermarket Parts |

|---|---|---|

|

Fit & Compatibility |

Guaranteed |

Often variable |

|

Longevity |

High |

Unpredictable |

|

Warranty |

Full coverage |

Limited or none |

|

Resale Value |

Maintained |

Potentially reduced |

|

Safety Standards |

Fully compliant |

May lack certification |

You should always check if the supplier offers a full warranty and complies with safety standards. Suppliers who provide reputable aftermarket parts often include packaging with unique part numbers, holographic stickers, and certificates to verify authenticity. Some even use QR codes or barcodes for instant part verification.

Certifications and Reviews

Certifications show that an excavator parts supplier meets strict industry standards. You should look for suppliers with ISO9001/2015 certification and compliance with ASTM, AWS, or EN specifications. These certifications mean the supplier uses quality testing protocols, such as coordinate measuring machines for accuracy, ultrasonic scans for hidden flaws, and material hardness testing. Suppliers who pass these tests can guarantee the quality of their parts.

Note: Certified suppliers often use tamper-evident packaging, UV-coated security holograms, and digital verification platforms to ensure you get genuine parts.

A reputable aftermarket parts supplier will also keep detailed records of inspections, repairs, and maintenance. They will share these reports with you to build trust and show transparency. Some suppliers use advanced tools like drones and digital data analysis to improve inspection accuracy. You can ask for machinery test reports or video inspections before you buy.

Customer reviews play a big role in choosing the right supplier. Companies encourage customers to leave reviews and share their experiences. Positive reviews often mention fast delivery, helpful support, and reliable warranty service. Suppliers who offer after-sales support help you solve problems quickly and reduce downtime. This support includes easy access to spare parts, fast diagnostics, and clear refund policies.

-

Comprehensive equipment inspections cover all critical parts, including engine, hydraulics, and electrical systems.

-

Certification is only granted after successful inspection and repairs.

-

Periodic audits and re-inspections keep the supplier’s quality high.

-

Customer-centric support and after-sales service build long-term trust.

You should always choose excavator parts suppliers who provide reputable aftermarket parts, clear certification, and strong customer support. This approach protects your investment and keeps your excavator working at its best.

Certified and Genuine Parts

Avoid Counterfeit Parts

You need to avoid counterfeit parts when buying excavator components from China. Counterfeit parts look similar to real ones, but they can cause serious problems. These parts often use low-quality materials and poor manufacturing methods. You may see rough finishes, faded colors, or even spelling mistakes on the packaging. Counterfeit parts can break easily and put your excavator at risk.

You can spot counterfeit parts by checking for these signs:

-

Poor-quality packaging with missing or incorrect logos.

-

No unique serial numbers or holograms for authenticity.

-

Unrealistically low prices that seem too good to be true.

-

No clear warranty or vague service terms.

Tip: Always buy from authorized dealers or trusted suppliers. This step helps you avoid counterfeit parts and keeps your excavator safe.

Counterfeit parts can lead to more breakdowns and higher repair costs. Data shows that using genuine parts reduces operational downtime by 40% and mechanical breakdowns by 30%. You also save up to 25% on repairs over five years. Counterfeit parts often cause more frequent replacements and safety risks for operators.

You should always inspect the part’s condition before installation. Use remote sensors or diagnostic tools if possible. Genuine parts have clean finishes, precise edges, and uniform color. Counterfeit parts may show defects, rough surfaces, or faded markings. When you avoid counterfeit parts, you protect your investment and keep your excavator running smoothly.

Quality Standards

Certified and genuine parts meet strict quality standards. These parts use high-grade materials and pass tough tests before reaching you. Manufacturers engrave unique serial numbers and use holograms or security stickers for authenticity. You can check high-quality excavator parts by looking for these features.

|

Quality Indicator |

Certified & Genuine Parts |

Counterfeit Parts |

|---|---|---|

|

Packaging |

High-quality, branded, clear labeling |

Low-quality, missing or incorrect logos |

|

Price |

Market-consistent, reflects certification costs |

Unrealistically low, steep discounts |

|

Material Quality |

Durable, high-grade, ensures longevity and performance |

Inferior, degrades quickly, compromises safety |

|

Warranty & Certification |

Clear warranty, ISO/CE/OEM certifications |

No warranty, lack of recognized certifications |

You should always check for proper documentation. Certified and genuine parts come with certificates like ISO or CE. These documents prove the parts meet international standards. Third-party testing agencies often confirm the stable performance of these parts under tough conditions. Standardized procurement and replacement processes help you avoid system failures.

Note: Professional installation by trained technicians reduces operational errors to below 5%. This step supports long-term stability for your excavator.

Genuine parts are made for specific applications and working conditions. They last longer and perform better under high loads. Certified aftermarket excavator parts, when tested, can reduce equipment failure rates by about 15%. You get longer replacement intervals and improved operator safety. Counterfeit parts, on the other hand, use substandard materials and often fail quickly.

You should always choose certified and genuine parts for your excavator. These parts guarantee exceptional quality and reliability. When you use certified and genuine parts, you avoid counterfeit parts and keep your excavator working at its best.

Price and Support

Cost vs. Quality

When you choose excavator parts, you face a choice between cost and quality. Many buyers want to save money, but you need to think about long-term value. High-quality parts may cost more at first, but they help your excavator work better and last longer. Market research shows that durable parts keep your equipment running and reduce downtime. This means you spend less on repairs and get more value for money over time.

You should look at both the price and the quality of the parts. If you buy cheap parts, you may face more breakdowns and higher repair bills. Investing in quality parts supports your excavator’s performance and protects your investment. Market analysis highlights that balancing cost and quality leads to better fuel efficiency and a longer equipment lifespan. You can also lower your maintenance costs by choosing quality parts.

Tip: Always do your research before buying. Ask industry experts and compare different suppliers. This helps you find the best value for money and ensures your excavator gets the right parts.

Warranty coverage also plays a big role in your decision. Companies that offer strong warranty coverage show confidence in their parts’ quality. Warranty claims data from leading brands prove that better quality parts lead to fewer warranty claims and lower costs for repairs. You get more value and peace of mind when you choose parts with good warranty coverage.

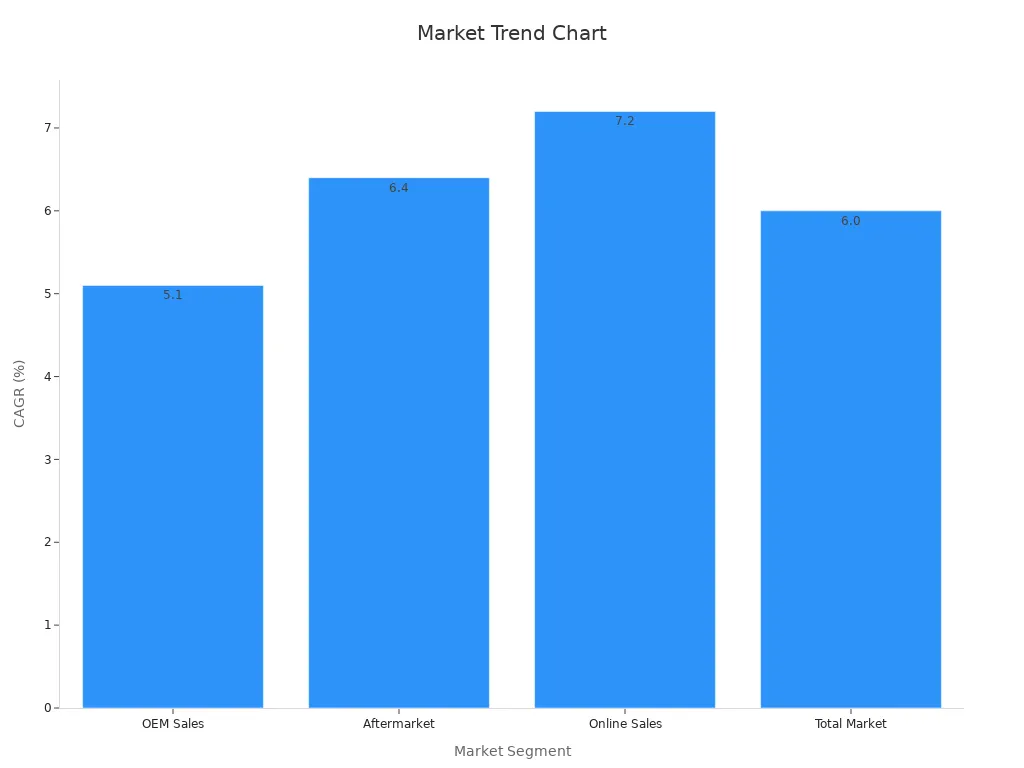

Delivery and Warranty

Fast delivery and strong warranty coverage add even more value to your excavator parts purchase. You want your parts to arrive quickly so your excavator can get back to work. Many suppliers now offer online ordering and tracking, making it easier to get the parts you need. The growth of online sales channels has improved pricing and made it easier to compare warranty coverage.

-

Some suppliers offer limited warranties on second-hand excavators, giving you extra protection.

-

After-sales support includes replacement parts, technical help, and maintenance services.

-

Newer excavators often come with advanced technology, adding value and making warranty coverage more important.

The market for excavator parts is changing. More buyers use online platforms to find the best prices and warranty coverage. The table below shows how different sales channels and market segments focus on warranty and value:

|

Market Segment |

Market Share (2026) |

Key Drivers |

|---|---|---|

|

OEM Sales |

~42% |

Demand for certified parts with warranty coverage |

|

Aftermarket |

>58% |

Affordability, longer equipment lifespan, warranty coverage |

|

Online Sales |

~28% of total sales |

Digital transformation, easy warranty tracking |

Warranty coverage protects you from unexpected costs. If a part fails, you can get a replacement or repair without extra charges. Companies that manage warranty claims well save money and improve customer trust. You should always check the warranty coverage before you buy. This ensures you get the best value and support for your excavator.

Choosing the right china hydraulic excavator parts starts with identifying your excavator’s make, model, and serial number. You then verify compatibility and select a reliable supplier for china excavator parts. Always ensure you get certified and genuine parts. Avoid counterfeit parts to protect your excavator and keep it running. Regular inspections and preventative maintenance help reduce downtime. AI-powered maintenance can cut equipment failures by 73%. Warranty and after-sales support give you peace of mind. Follow these steps to keep your excavator working and share your experiences or questions with others.

Reliable china hydraulic excavator parts and strong warranty support keep your projects on track.

-

Regular maintenance and quality parts prevent unexpected failures.

-

Warranty coverage ensures you get help when you need it.

FAQ

How do you verify if a part is genuine?

You should check for serial numbers, holograms, and certificates. Ask your supplier for proof of authenticity. Genuine parts come with clear documentation and high-quality packaging.

What should you do if a part does not fit your excavator?

First, compare the part number and OEM code. Contact your supplier for support or a replacement. Many suppliers offer return or exchange options for incorrect parts.

Can you use aftermarket parts instead of OEM parts?

You can use quality aftermarket parts if they meet industry standards. Always check for certifications and reviews. Reliable aftermarket parts can perform as well as OEM parts.

How long does shipping usually take from China?

Shipping times vary by supplier and shipping method. Most orders arrive within 7 to 21 days. Ask your supplier for tracking information and estimated delivery dates.