You want a china excavator engine parts supplier you can trust. Focus on suppliers who provide strong quality checks and hold certifications. Many suppliers in China offer a wide selection of excavator parts at lower prices. Look for a supplier with a full after-sales system and a professional team. Top suppliers deliver a one-year warranty, quick replacement parts, and ongoing support. These steps help you avoid poor-quality excavator parts and costly delays. Choose suppliers who make quality, service, and customer satisfaction their business goals.

Key Takeaways

Choose suppliers with verified business licenses, certifications, and strong after-sales support to ensure quality and reliability.

Compare prices and quality from multiple Chinese suppliers to find the best value and avoid hidden costs.

Request product samples and inspect key engine parts before buying to avoid fake or substandard components.

Build long-term relationships with suppliers for better service, faster shipping, and exclusive deals.

Understand shipping options and customs requirements to prevent delays and keep your excavator running smoothly.

Why Choose China Excavator Parts

Cost Benefits

You can save a lot when you choose china excavator parts. Chinese suppliers offer some of the most competitive prices in the global market. Many suppliers operate at a large scale, which helps keep prices low for buyers like you. When you compare prices from different suppliers, you will notice that china excavator parts often cost less than parts from other countries. This cost advantage allows you to maintain your excavator fleet without breaking your budget.

Tip: Always ask for a detailed price list from multiple suppliers. This helps you spot the best deals and avoid hidden costs.

Here is a quick look at why china excavator parts stand out:

Aspect | Evidence | Explanation |

|---|---|---|

Market Size and Output | China accounts for about 40% of global excavator output; domestic brands hold over 70% market share in 2021 | China’s scale leads to lower prices and more choices for buyers |

Supply Chain Resilience | COVID-19 disruptions increased opportunities for domestic suppliers | Reliable supply keeps prices stable |

Export Growth | Leading companies like Sany exported over 20,000 excavators in 2021 | Shows global trust in Chinese suppliers |

Wide Selection

You get access to a huge variety of china excavator parts. Chinese suppliers lead the world in the number of available options. Whether you need a specific engine part or a rare component, you can find it from one of the many suppliers in China. The wide selection means you can match parts to almost any excavator model.

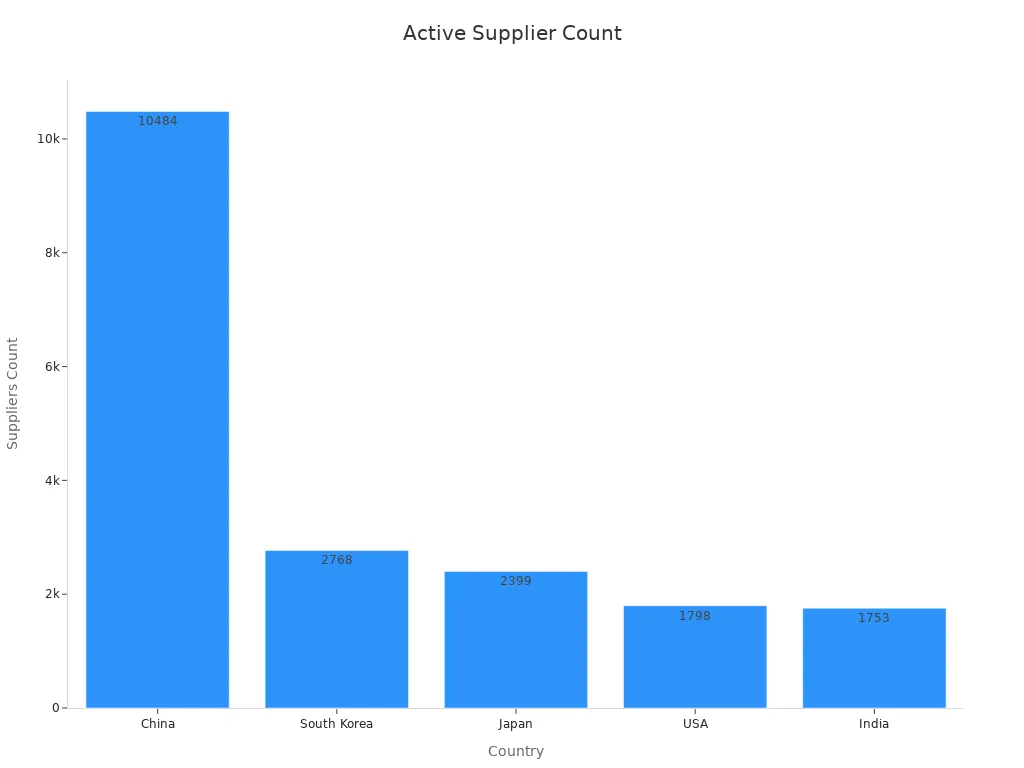

The chart above shows that China has over 10,000 active suppliers, far more than any other country. This large network ensures you always have choices and can compare prices and quality before making a decision.

Brand Compatibility

You want parts that fit your excavator perfectly. Chinese suppliers understand the importance of compatibility. They offer parts designed for many global brands, so you can find the right fit for your machine. Many suppliers provide detailed product descriptions and support to help you check compatibility before you buy.

You can ask suppliers for compatibility charts or sample parts.

Reliable suppliers will help you match parts to your excavator’s brand and model.

Choosing china excavator parts gives you the flexibility to keep your machines running smoothly, no matter the brand.

What Makes a Reliable China Excavator Engine Parts Supplier

Business Credentials

You need to check business credentials before you trust any china excavator engine parts supplier. A reliable supplier always provides clear proof of their legitimacy. Start by asking for the company’s registration, business license, and import/export permits. These documents should show that the supplier’s business scope includes manufacturing, not just trading.

You can use the National Enterprise Credit Information Publicity System (NECIPS) to verify the supplier’s registration. This government database helps you confirm the supplier’s official status. Always check the Unified Social Credit Code for authenticity.

Tip: Call the supplier’s landline number to confirm registration details. Landlines are harder to fake than mobile numbers.

You should also request product samples. This step lets you check the quality of the parts and see how the supplier responds to your requests. If possible, visit the factory or hire a third-party auditor. Factory audits help you see the real production environment and separate genuine manufacturers from trading companies.

Here is a checklist to help you verify business credentials:

Request and review the business license and import/export permits.

Confirm the supplier’s registration on NECIPS using the Unified Social Credit Code.

Ask for product samples and check payment goes to the registered company account.

Visit the factory or arrange a third-party audit.

Check the supplier’s minimum order quantity and VAT invoices.

Investigate the supplier’s reputation and history through online searches and B2B directories.

Confirm the physical address and ask for references from previous customers.

A reliable supplier will always cooperate with these checks. This process helps you avoid scams and ensures you work with a real manufacturer.

Certifications and Compliance

Certifications and compliance matter when you choose a china excavator engine parts supplier. Reliable suppliers hold certificates that prove their products meet industry standards. Look for ISO 9001:2015 quality certification. This certificate shows the supplier follows strict quality management systems.

You should also check for a Certificate of Origin and CE marking if you plan to sell or use excavator parts in the EU. These documents confirm the parts meet local and international standards. Reliable suppliers provide product compliance certificates from government agencies or independent labs.

Note: Always ask for customs documentation and import licenses. These papers help you avoid legal trouble and delays at the border.

Factory audits and quality control inspections by third-party agencies add another layer of trust. These inspections confirm the supplier’s legal status and the quality of their products.

A table of key certifications and compliance documents:

Document Type | Purpose |

|---|---|

ISO 9001:2015 | Quality management system |

Certificate of Origin | Confirms manufacturing location |

CE Marking | EU conformity |

Product Compliance Certificate | Meets safety and quality standards |

Import/Export License | Legal trade authorization |

Factory Audit Report | Confirms production capability and compliance |

You need these documents to ensure the supplier delivers quality parts that meet your country’s regulations. This step protects your business from costly mistakes.

After-Sales Support

After-sales support sets a reliable supplier apart in the china excavator engine parts market. You want a supplier who stands behind their products and helps you after the sale. Reliable suppliers provide spare parts and ensure replacements match the original quality.

You should receive operation and maintenance manuals with your order. These guides help you use and maintain your excavator engines properly. Some suppliers include toolboxes with spare parts and repair kits for quick fixes.

🛠️ Pro Tip: Choose suppliers who offer ongoing support and fast communication. This reduces downtime and keeps your excavator running.

Reliable suppliers test every product before shipping. They check for leaks, engine problems, and other defects. After delivery, you should have a direct line to the supplier for questions or support. Good suppliers encourage you to send photos or videos if you have issues. This helps them solve problems faster.

You also benefit from flexible parts replacement options. Some suppliers let you buy parts locally or through their partners. This flexibility keeps your excavator working and reduces waiting time.

Strong after-sales support means you get more than just quality parts. You gain peace of mind, knowing your supplier will help you keep your equipment in top condition.

Finding Excavator Parts Suppliers

Trusted Platforms

You can start sourcing Chinese excavator parts by using trusted platforms. Many buyers rely on Alibaba, Made-in-China, and Global Sources to connect with suppliers. These platforms list thousands of excavator parts suppliers and allow you to filter by product type, certification, and location. Volza’s Import Trade Data also helps you find established networks. This platform provides shipment records, supplier profiles, and direct contact details. You can use these resources to identify trusted suppliers and avoid unreliable options.

🛡️ Tip: Always check if the supplier has verified business credentials and a history of successful shipments.

Industry directories and trade shows offer more ways to meet trusted suppliers. You can attend events in China or join online exhibitions. These opportunities help you build relationships and compare suppliers in person.

Sourcing Chinese Excavator Parts

Sourcing Chinese excavator parts presents both challenges and opportunities. You may face risks such as fake or weak parts, hidden fees, and unreliable shipping. Some suppliers offer poor after-sales support, which can lead to downtime. However, you can overcome these issues by following a few steps:

Select suppliers with strong warranties and maintenance services.

Verify certifications like ISO 9001 for quality assurance.

Request samples to test part quality and compatibility.

Build long-term relationships with suppliers for better pricing and steady supply.

Prioritize suppliers with transparent pricing and efficient shipping.

Volza’s data shows that using established networks improves your sourcing results. You gain access to shipment records, contact information, and credit checks. This helps you negotiate fair prices and secure exclusive supply contracts. You can also monitor real-time data to assess supplier reliability.

Checking Reviews

You should always check reviews before choosing excavator parts suppliers. Customer feedback reveals important details about supplier credibility and service quality. Follow these steps to assess suppliers:

Read customer reviews and feedback to judge reliability.

Check for quality certifications and management systems.

Compare pricing, but focus on quality first.

Confirm delivery times to match your project schedule.

Assess after-sales service and technical support.

Review product variety to meet your needs.

Verify financial health and production capacity.

Use negotiation and evaluation methods.

Consider supplier location for lower logistics costs.

Refer to industry reports for market insights.

Ensure compliance with safety standards.

Community forums and industry reports also provide real-world feedback on excavator performance and supplier support. You can spot common issues and avoid suppliers with poor reputations. Reliable reviews help you make informed decisions and choose trusted suppliers for sourcing Chinese excavator parts.

Quality Checks for China Excavator Parts

EPA Certification

If you plan to import excavator engine parts into the United States, you must check for EPA certification. This certification proves that the parts meet strict emission standards. Without it, customs may reject your shipment or delay delivery. EPA-certified quality parts help you avoid legal issues and ensure your excavator engines run cleanly. Reliable suppliers provide EPA documents and test results. They often use Portable Emissions Measurement Systems to check emissions and fuel consumption. These tests confirm that the parts meet both environmental and performance standards.

Inspecting Key Components

You should always inspect key engine components before purchase. Focus on the fuel injection pump, cylinder nozzle, oil pipe, filter, radiator, and cylinder head. Each part plays a vital role in your excavator’s performance and reliability. Quality checks include:

Factory audits to verify the supplier’s technical and production abilities.

Live inspections for welding, material, and safety standards.

Physical checks for size, labels, and documentation.

Functional tests to confirm safety and part integrity.

Performance evaluations to match design specifications.

Safety checks for reliability and compliance.

Certification verification for industry standards.

Inspections during loading and unloading to prevent damage.

Suppliers use advanced tools like common rail test benches and CNC machines. They test for fuel injection uniformity, durability, and leakage. These steps ensure you receive quality parts that last under tough conditions.

Requesting Samples

Requesting samples before buying helps you avoid substandard parts. Samples let you check the quality and fit of each component. You can test for power output, fuel efficiency, and overall performance. Reliable suppliers offer samples and support your inspection process. This step protects your investment and ensures your excavator operates at its best.

🛡️ Tip: Always ask for samples before buying large quantities. This simple step helps you spot quality issues early.

Negotiating and Comparing Suppliers

Comparing Quotes

You should always compare quotes from several suppliers before making a decision. Start by collecting detailed offers from at least three suppliers. This approach helps you understand the range of prices and services available in the market. When you review quotes, look beyond just the prices. Focus on these important metrics:

Product quality: Check for certifications, sample testing, and quality control processes.

Supplier reliability: Review background checks, financial health, and site visit reports.

Production capacity: Make sure the supplier can meet your current and future excavator needs.

Cost efficiency: Consider discounts for bulk orders and the overall value, not just the lowest prices.

Sustainable practices: Confirm the supplier follows environmental and ethical standards.

A simple table can help you compare suppliers:

Supplier Name | Product Quality | Prices | Delivery Time | After-Sales Support |

|---|---|---|---|---|

Supplier A | High | $ | 2 weeks | 1-year warranty |

Supplier B | Medium | $ | 3 weeks | 6-month warranty |

Supplier C | High | $$ | 1 week | 2-year warranty |

Tip: Let suppliers know you are comparing multiple offers. This often leads to better prices and extra services.

Negotiating Payment Terms

Negotiating payment terms with suppliers protects your business and improves cash flow. You should never accept the first offer. Instead, discuss all elements, including prices, payment schedules, and extras like training or extended warranties. Follow these best practices:

Ask for flexible payment options, such as deposits or installment plans.

Set up auto-pay to avoid late fees and keep a strong payment record.

Review contract terms carefully. Focus on interest rates, early payoff options, and insurance requirements.

Plan your payments to match your business cycles and excavator usage.

Watch for red flags, such as pressure to decide quickly or hidden fees.

Suppliers respect buyers who negotiate clearly and know what they want. This approach helps you secure fair prices and reliable supply.

Building Relationships

Strong relationships with suppliers lead to better deals and long-term success. You should communicate openly and build trust from the start. Reliable suppliers value customers who provide clear feedback and pay on time. Over time, you may receive priority service, faster shipping, and exclusive prices.

Visit the supplier’s facility if possible.

Keep detailed records of all transactions and agreements.

Share your business goals and future excavator needs.

Building a partnership with your supplier ensures you get the best support and consistent quality for your excavator fleet.

Shipping and Importing

Customs Regulations

You must prepare the right documents before importing excavator parts from China. Suppliers should provide a proforma invoice, commercial invoice, bill of lading, packing list, certificate of origin, and export license. Customs authorities also require a customs declaration from China and US Customs entry documents, such as CBP Form 7501, HS code, and a customs bond. EPA compliance certificates and engine certifications are essential for meeting US emission standards. Importer Security Filing and proof of payment for duties and tariffs help you avoid delays. Some countries restrict used machinery, so always confirm if your excavator is new or second-hand.

Tip: Work with suppliers who understand customs codes and import licenses. This step helps you avoid costly mistakes and keeps your shipment on track.

Shipping Logistics

You have several shipping options for excavator parts. Suppliers often recommend container shipping for smaller parts and Roll-on/Roll-off (RoRo) for larger equipment. Flat rack shipping works well for oversized items. Each method has its own benefits and costs. You should ask suppliers about shipping insurance to protect your investment. Correct HTS classification ensures you pay the right customs duties, which usually range from 2% to 10%. Inspection upon arrival helps you spot damage early. Suppliers can also help you arrange final delivery to your site. For smaller shipments, consolidation can save money, but it may take longer.

Payment methods like Letter of Credit or wire transfer add security.

Warranty and after-sales support from suppliers reduce risks and extra expenses.

Local Standards Compliance

You need to make sure your excavator parts meet local mechanical, electrical, and environmental standards. Many suppliers in China produce parts for their domestic market, which may not match foreign regulations. Always ask suppliers for certifications like CE, EPA, or ASTM. These documents prove compliance and help you avoid fines or confiscation. Suppliers should also offer after-sales service and spare parts to keep your excavator running. Choose suppliers who understand your country’s rules and can provide all necessary paperwork.

🛡️ Note: Verifying supplier certifications and local compliance protects your business and ensures smooth importing.

Common Pitfalls to Avoid

Fake or Substandard Parts

You may find many suppliers offering excavator engine parts at very low prices. This can be tempting, but it often leads to fake or substandard parts. These parts may look similar to genuine ones, but they fail to meet strict quality standards. Poor quality parts can cause engine failure, safety risks, and costly repairs. You should always check if the supplier has ISO certifications and follows industry standards. Reliable suppliers provide pre-shipment inspections and allow you to use third-party quality assurance services. Trusted suppliers like YNF Machinery use strict quality controls to protect your investment.

🚩 Always verify the supplier’s business license and ask for references. This step helps you avoid fake suppliers and ensures you receive high quality parts.

Hidden Costs

Hidden costs can quickly turn a good deal into a financial headache. Some suppliers do not include shipping fees, import duties, or taxes in their initial quotes. You may also face extra charges for handling or customs clearance. To avoid surprises, ask suppliers for a full breakdown of all costs before you place an order. Analyze every fee, including shipping methods and delivery times. Reliable suppliers provide transparent pricing and help you understand the total cost. This approach ensures you get high quality parts without unexpected expenses.

A simple checklist to avoid hidden costs:

Request detailed quotes from all suppliers.

Confirm shipping and handling fees.

Check import duties and local taxes.

Review customs clearance procedures.

Unreliable Shipping

Unreliable shipping can delay your project and increase costs. Some suppliers promise fast delivery but fail to meet deadlines. Others use poor logistics partners, which can lead to lost or damaged parts. You should choose suppliers with proven logistics and shipping management. Ask about their shipping methods, such as air freight or sea freight, and select the best option for your needs. Reliable suppliers plan delivery times and offer tracking support. They also provide insurance to protect your high quality parts during transit.

📦 Choose suppliers who communicate clearly about shipping and provide updates. This step helps you avoid delays and ensures your parts arrive in top quality condition.

You can find a reliable China excavator engine parts supplier by checking business credentials, verifying certifications, and demanding strong after-sales support. Always inspect product quality and compare multiple suppliers. These steps help you avoid risks and secure the best value. For more practical knowledge, explore these industry resources:

Comprehensive guides on sourcing machinery and excavator parts

Insights on manufacturing injection molds

Tips for sourcing chemicals from China

These readings help you navigate sourcing and reduce risks in your supply chain.

FAQ

What documents do you need to import excavator engine parts from China?

You need a commercial invoice, bill of lading, packing list, certificate of origin, and import licenses. Ask your supplier for EPA or CE certificates if your country requires them.

How can you verify a supplier’s reliability?

Check business licenses, certifications, and customer reviews. Request product samples. Use third-party audits for extra assurance. Reliable suppliers respond quickly and provide clear documentation.

What should you do if you receive damaged parts?

Contact your supplier immediately. Provide photos or videos of the damage. Good suppliers offer replacements or refunds. Always check warranty terms before you buy.

Can you order small quantities for testing?

Yes, many suppliers allow small trial orders or samples. This helps you check quality before making a large purchase. Always confirm minimum order requirements first.

How long does shipping usually take?

Shipping times vary. Air freight takes about 5–10 days. Sea freight usually takes 20–40 days. Ask your supplier for tracking and estimated delivery dates.