Caterpillar excavators parts arms utilize hydraulic power to lift heavy objects and dig through tough terrain. There are four main components: the boom, the stick (also referred to as the arm), the bucket, and the hydraulic system. Each of these parts works in harmony with the others, allowing for precise control of the excavator. The design of Caterpillar excavators parts arms enables you to dig, lift, and position materials exactly where you need them.

Key Takeaways

Caterpillar excavator arms have four main parts. These are the boom, stick, bucket, and hydraulic system. Each part helps with lifting, digging, and moving things.

You must take care of the hydraulic system often. Clean oil and good filters stop leaks. They also help the machine work well. This can stop expensive repairs.

Picking the right bucket for your job saves time and money. Using the wrong bucket can cost up to 20% more.

Check the boom, stick, and bucket often for damage. Finding problems early can make your excavator last longer. It also lowers repair costs.

Knowing how the boom, stick, and bucket work together helps you control the machine better. Good teamwork between parts lets you dig and lift more exactly.

Caterpillar Excavators Parts Arms

When you look at caterpillar excavators parts arms, you notice they are made for strength and accuracy. Each main part has its own job in making the excavator work. The boom, stick (arm), bucket, and hydraulic system all connect to the engine and tracks. Together, they make a strong machine for digging and lifting.

Boom

The boom is the biggest part of the excavator arm. It connects to the main body above the tracks. You use the boom to lift and lower the arm. The boom moves up and down and holds heavy things. Booms are made from tough steel plates. They are made stronger with castings and hard pins. This helps the boom last longer and handle stress, even in hard jobs.

Tip: Check the boom often for cracks or worn welds. Strong materials like 50000 lb yield plate and malleable steel castings help the boom stay strong.

Here is a quick table that shows the main differences between the boom, stick, and bucket:

Component | Description | Function |

|---|---|---|

Boom | Large, curved arm connected to the main body, designed for vertical lift and handling stress. | Gives vertical lift for digging and loading. |

Stick | Connects to the boom and extends the reach of the excavator. | Lets you dig deeper and reach farther. |

Bucket | Used for digging and scooping, available in various sizes. | Used for different digging jobs. |

Stick (Arm)

The stick, also called the arm, is attached to the end of the boom. You use the stick to reach out and dig deeper. The stick’s length changes how far you can dig and how much force you use. For example, a stick that reaches 2.9 meters can dig down 21.5 feet and make straight walls up to 16 feet deep. The stick can push with 23,830 pounds-force, so it is strong for hard jobs.

The stick wears out most at the pivot points and pin holes. These spots can get loose if you do not oil them often. You should check the pins, bushings, and pivot points to keep the arm working well.

Common wear spots on the stick (arm):

Pins and bushings

Pivot-point holes

Swing arm connections

Note: Oil the pivot holes often so they do not wear out and make the arm loose.

Bucket (Attachment)

The bucket is the part that digs and scoops. There are many types of buckets, like clean-up buckets, digging buckets, ditch cleaning buckets, extreme duty buckets, general duty buckets, heavy duty buckets, severe duty buckets, and special buckets for certain jobs. Picking the right bucket helps you work faster and saves money. Using the wrong bucket can cost you up to 20% more. General duty buckets are best for light stuff, while heavy and severe duty buckets are for tough jobs.

Types of buckets for caterpillar excavators parts arms:

Clean-up Buckets

Digging Buckets

Ditch Cleaning Buckets

Extreme Duty Buckets

General Duty Buckets

Heavy Duty Buckets

Severe Duty Buckets

Specialty Buckets

Most buckets last between 7,000 and 10,000 hours before you need a new one. Contractors usually stop using buckets after about 9,800 hours.

Hydraulic System

The hydraulic system makes the boom, stick, and bucket move. Hydraulic pumps push fluid through control valves to the actuators and hydraulic cylinders. These parts work together to move the arm with a lot of power and control. Filters and seals keep the fluid clean and stop leaks, so the system works well.

Main parts of the hydraulic system:

Hydraulic pumps

Control valves

Actuators

Hydraulic cylinders

Filters

Seals

Hydraulic systems can lift more, last longer, give better control, and are quieter than mechanical or electric systems. You get safer and cheaper work, especially near the engine and tracks.

Feature | Hydraulic Systems | Mechanical Systems | Electric Systems |

|---|---|---|---|

Load Capacity | Lifts heavier loads | Limited by gears and pulleys | Varies, usually less |

Durability | Lasts longer, breaks less | Wears out faster | Varies, can be tricky |

Precision | More control and accuracy | Not as exact | Varies, can be exact |

Safety | No sparks, safer in danger zones | Can catch fire | Varies, can be safe |

Noise Level | Quieter | Noisy from moving parts | Usually quiet |

Cost-Effectiveness | Cheaper to fix | Costs more to fix | Varies, can be high |

How the Parts Work Together

You control the caterpillar excavators parts arms from inside the cab with levers and pedals. The engine gives power to the hydraulic motors, which move the boom, stick, and bucket. The tracks keep the machine steady when you dig or lift. The tracks also help you drive over rough ground. The arm, engine, and tracks all work together so you can finish jobs fast and safely.

Remember: The boom, stick, bucket, and hydraulic system must work together. Each part needs the others to give you the strength, reach, and control you need for every job.

Excavator Arm Function

Lifting and Reaching

You use the excavator arm to lift and reach heavy objects or materials on a job site. The boom gives you the height to raise the arm above the ground, while the stick lets you extend your reach forward. The bucket attaches at the end and grabs or holds the load. The hydraulic system powers each movement, so you can lift rocks, pipes, or debris with steady force.

When you operate the controls, the working mechanism responds quickly. The hydraulic cylinders push or pull the boom and stick, letting you move the arm up, down, or out. This design helps you place materials exactly where you want them. For example, you can lift a concrete block from a truck and set it into a trench with just a few smooth motions.

Tip: Always check the load chart for your excavator. This helps you know the safe lifting limits for your machine and keeps you working safely.

Depth and Precision

Precise digging is one of the most important jobs for an excavator arm. The working mechanism allows you to control how deep you dig and how straight you make the trench walls. The telescopic arm design lets you extend or retract the stick, so you can adjust the depth with great accuracy. Advanced hydraulic systems give you smooth, fine movements, which help you avoid over-digging or damaging underground pipes.

Modern excavators use several smart features to help you dig with precision:

GPS systems show your exact position on the job site, so you can follow plans closely.

Computerized controls give you real-time feedback, letting you adjust the arm instantly for perfect depth.

2D and 3D grade control systems guide you as you cut or fill, so you do not need to use ground stakes.

The 330C model, for example, has an auxiliary hydraulic system with an expandable main valve. This makes it easy to add new tools or attachments. You can stack extra valve sections, which gives you more control over rotating tools and helps you dig with even more precision.

Digging and Scooping

The bucket at the end of the excavator arm does the main digging and scooping. You use the controls to lower the arm, push the bucket into the soil, and pull back to fill it. The hydraulic system gives you the power to break through hard ground or scoop up loose dirt. The design of the bucket matters a lot. Caterpillar buckets have a dual radius shell profile, which helps material flow smoothly into the bucket. The heel clearance keeps the bucket from dragging, so you do not waste energy or wear out the parts too fast.

You can choose different buckets for different jobs. Some buckets are made for digging, while others are better for cleaning ditches or moving rocks. The right bucket helps you fill loads faster and hold more material, which saves fuel and time. The working mechanism of the excavator arm, combined with the strong hydraulic system, lets you scoop, lift, and dump materials with speed and accuracy.

Note: A well-designed bucket not only improves how much you can carry but also lowers maintenance costs and boosts your productivity.

Function of an Arm in Excavator Operation

Coordinated Movement

When you use an excavator, the boom, stick, and bucket must work together. The hydraulic system lets you move each part with care. You can lift the boom, stretch the stick, and close the bucket all at once. This teamwork helps you dig, level, and lift things with good aim. The arm works best when all parts move together well. The hydraulic cylinders react fast, so you can switch moves smoothly. You notice this when you dig a trench or load dirt into a truck. The excavator arm acts like one piece, but every part has its own job.

You might have problems when you try to match all the moving parts. Many things can make it hard to keep everything lined up and working right:

Matching three or more cylinders is tricky.

Double-acting cylinders need careful moves both ways.

Parts can wear out and change how they move.

Hot or cold weather changes how the fluid and cylinders act.

Heavy loads and pressure can change how things move.

Dirty fluid can stop smooth movement.

Broken seals or rods can slow things down.

Bad valve controls can make fluid move unevenly.

Soft hoses can bend and mess up alignment.

Loose mounts can make cylinders not line up.

Mistakes happen if you use the controls wrong.

Operator Control

You use special systems inside the excavator to control the arm. The Tool Control System (TCS) in some models, like the Caterpillar 330C, helps you handle the stackable-valve system. You can set up to five settings, like flow, pressure, engine speed, and pump numbers. You pick these settings using an electronic controller on the screen. This system lets you move attachments with more care than just simple switches.

How well the excavator arm works depends on your skill. Training and practice help you use the controls safely and well. If you do not know the parts and tools, you could cause accidents or break things. You must follow safety rules and pay attention while you work. You should stop and check tough spots before you do anything. The arm works best when the hydraulic system and your control work together.

Maintenance for Excavator Arm Parts

You need to take care of your excavator often. This helps your machine last longer and keeps it safe. Doing regular checks can stop big repairs from happening. You also save money by fixing small problems early. Here are some easy tips to help your equipment work well.

Hydraulic System Care

Check the hydraulic system often to keep it strong. Clean oil and good filters help the arm move with power. If you forget, you might see leaks or slow movement. Bad seals or leaking valves can make the boom or arm drop fast. This is dangerous and can cost a lot to fix.

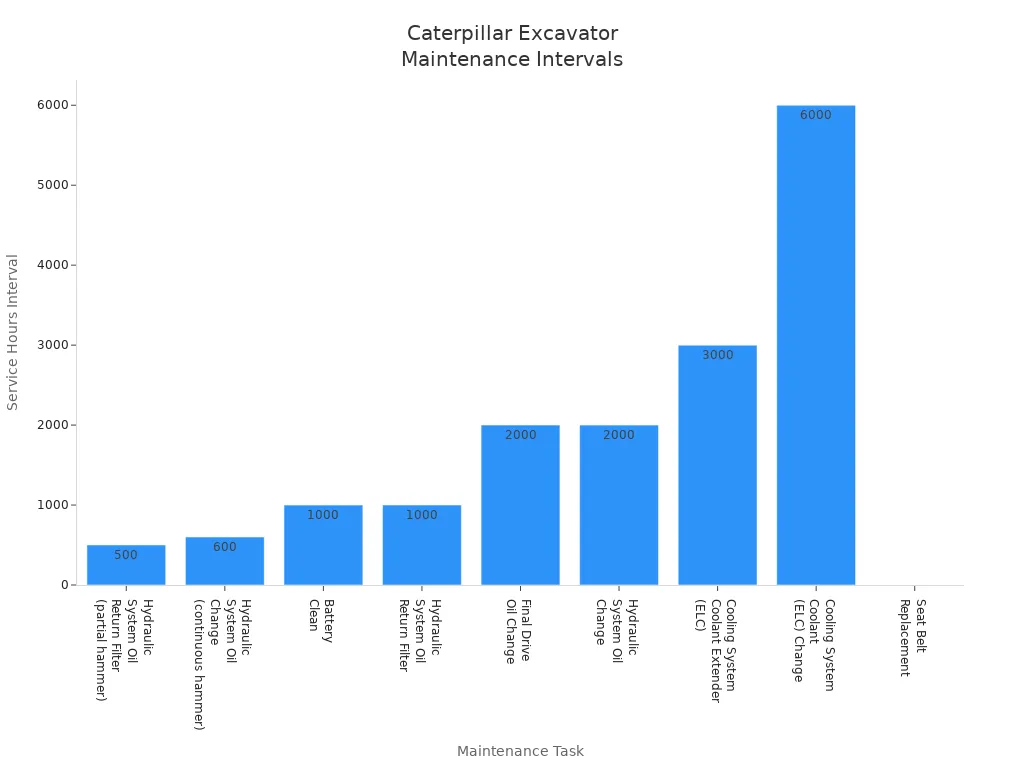

Here is a table to help you remember when to do important hydraulic maintenance:

Maintenance Task | Frequency |

|---|---|

Hydraulic System Oil Return Filter | Every 500 service hours (partial hammer use) |

Hydraulic System Oil Change | Every 600 service hours (continuous hammer use) |

Battery Clean | Every 1000 service hours or 6 months |

Hydraulic System Oil Return Filter | Every 1000 service hours |

Final Drive Oil Change | Every 2000 service hours or 1 year |

Hydraulic System Oil Change | Every 2000 service hours or 1 year |

Cooling System Coolant Extender (ELC) | Every 3000 service hours or 3 years |

Cooling System Coolant (ELC) Change | Every 6000 service hours or 6 years |

Seat Belt Replacement | Every 3 years |

Tip: Always use real parts from YNF Machinery when you replace things. This keeps your machine safe and working right.

Inspecting Joints and Attachments

Look at the joints and attachments every week. If you work in hard places, check them every day. Watch for loose bolts, leaks, or worn parts. Check the boom and attachments for cracks or oil leaks. Put grease on all cylinders and sliding parts to stop wear. Look at the pins and bushings for looseness or pin walking. Make sure the track hardware is tight and not missing. Watch for strange wear or leaks in the idler, and keep carrier rollers clean.

Daily checks help you find problems early.

Greasing often keeps the arm moving well.

Replacing broken parts fast keeps your excavator safe.

Preventative care costs less than fixing big problems.

Note: If you skip arm care, you might pay three to four times more later. Finding problems early saves money and helps your machine last longer.

If you need new parts or help, YNF Machinery has good solutions for your excavator.

You rely on each part of the excavator arm to get the job done right.

The boom gives you reach and height for deep digging.

The stick adds length and helps you control the bucket.

The bucket scoops, lifts, and moves soil or rocks.

The hydraulic system powers every movement with strength and precision.

Part | Description | Function |

|---|---|---|

Boom | Long arm from the undercarriage | Lifts and positions the bucket |

Dipper | Connects boom to bucket | Extends reach and controls digging |

Bucket | Scoops and moves material | Handles different tasks with attachments |

Regular checks and greasing keep your arm working safely and help you avoid costly repairs.

FAQ

What is the most important part of a Caterpillar excavator arm?

Every part matters, but the hydraulic system gives you the power to move the boom, stick, and bucket. Without strong hydraulics, the arm cannot lift or dig well.

How often should you check the hydraulic oil?

You should check the hydraulic oil level every day before you start work. Clean oil helps your excavator arm move smoothly and prevents damage.

Can you use different buckets on the same excavator arm?

Yes, you can switch buckets for different jobs. Make sure the bucket fits your machine. Using the right bucket helps you work faster and saves money.

What should you do if you see a crack on the boom?

Stop using the machine right away. Cracks can get worse and cause accidents. Call a professional or contact YNF Machinery for help with repairs or replacement parts.

Where can you buy reliable excavator arm parts?

You can buy high-quality excavator arm parts from YNF Machinery. They offer strong, durable parts that help your machine last longer and work better.