Imagine you start work and your excavator will not start. This can happen if you do not take care of a part. Doing regular maintenance helps stop surprise problems. It keeps cat mini excavator parts working their best. You save both money and time by caring for your excavator. Many companies see big changes:

One company saved $10,000 in one year. They did this after preventive maintenance lowered costs by 20%.

Another company spent $1,000 each year on regular care. They did not have to pay a $3,000 repair bill.

You get easy steps for daily, routine, and seasonal care. This helps your equipment stay dependable.

Key Takeaways

Regular maintenance stops big breakdowns. Daily checks find small problems early. This keeps things from getting worse.

Keeping a maintenance log is very important. It helps you remember repairs. It also helps you plan future services.

Check fluid levels every day. Clean the undercarriage often. These steps help your excavator work well. They also keep it safe.

Use the right lubricants for your machine. Grease parts as the manual says. This makes your excavator last longer. It also lowers repair costs.

Ask a professional for help with tough problems. Some issues need an expert to fix. This keeps your machine safe and working right.

Why Maintenance Matters

Benefits for Cat Mini Excavator Parts

When you take care of your excavator, it works better. Doing daily checks helps you find small problems early. This stops them from turning into big issues. You help cat mini excavator parts last longer and stay safe. Many studies show that good maintenance brings many good things:

Benefit | Description |

|---|---|

Prevents Major Failures | Daily checks can catch small problems before they get worse. |

Maximizes Uptime | Cleaning and checking often keeps your machine working. |

Reduces Repair Costs | Taking care of your machine saves money on repairs. |

Enhances Safety | Good maintenance helps everyone stay safe while working. |

Extends Operating Life | Doing regular tasks helps your excavator last longer. |

Keeping up with maintenance also makes your mini excavator worth more. People want to buy machines that are well cared for. They will pay more for them. If you write down what you fix, buyers trust you more. Greasing and servicing often can help your machine work for 6,000 to 10,000 hours. You protect your money and your team by following safety rules and wearing PPE during checks.

Tip: Making a maintenance schedule is a smart way to keep your machine safe and avoid surprise bills.

Risks of Skipping Maintenance

If you do not do maintenance, your cat mini excavator parts can break. Not greasing enough makes parts wear out faster. This can cause breakdowns. If the track is too loose or tight, parts can break sooner. Dirt and rocks can get stuck underneath and hurt parts. This also makes your machine use more fuel. If you skip checks, the hydraulic system can leak or lose power.

If you do not care for your mini excavator, it may break before 7,000 hours. Fixing problems late can cost $45,000 to $85,000 more each year for each machine. You could also have motor failures and overheating. Not following safety rules or skipping PPE can cause accidents. You lose safety, value, and good performance if you ignore regular care.

Daily Checks for Maintaining Your Excavator

Doing daily checks is very important. It helps your Cat mini excavator stay in good shape. These checks let you find problems early. You spend less money fixing things. Your machine stays safe to use. Make sure you do these checks every morning before work.

Inspect Fluid Levels

Begin by looking at all fluid levels. This keeps your excavator working well. It stops damage to important parts. Use this checklist each day:

Open the side doors and look at the engine oil. If oil is low, the engine can get damaged.

Check the hydraulic fluid level. The system needs enough fluid to work right.

Look at the coolant in the radiator. If it gets too hot, the engine can break.

Check the fuel so you do not run out while working.

Look inside the engine area for dirt or leaks. Clean out any dirt you see. These checks help you avoid big repair bills. Your excavator will be ready to use.

Check for Leaks and Damage

Looking for leaks and damage is very important. You need to check for cracks and other problems. Focus on these places:

Hydraulic cylinders, rods, hoses, and seals

Swivel joints, swing bearings, and slew rings

The cab and outside lights

Hydraulic leaks often happen at connections, broken seals, or damaged lines.

Leaks can make you lose fluid. Your machine can lose power or get too hot. Fix leaks as soon as you see them. Look for loose bolts and broken switches in the cab. Tighten or change them if needed. These checks keep your excavator safe and working well.

Clean Tracks and Undercarriage

Cleaning the undercarriage is needed every day. Dirt and rocks can pile up fast. If you leave them, they can block parts and make the machine work harder. Use a brush or water to clean the tracks and undercarriage.

Cleaning often helps you see wear and problems early.

A clean undercarriage makes it easier to spot issues.

Removing dirt stops it from getting hard and saves fuel.

Check the tracks for loose spots, cracks, or deep marks. Tracks need to be tight to stop expensive repairs. Cleaning and checking the undercarriage every day helps your mini excavator last longer and work better.

Tip: Make daily checks a habit. This helps you find small problems before they get worse. It also keeps everyone safe at work.

Routine Maintenance Schedule

Doing routine maintenance helps your cat mini excavator parts last longer. You keep your machine safe and protect your money. A regular schedule makes your excavator work better. Use these tips to plan when to do service.

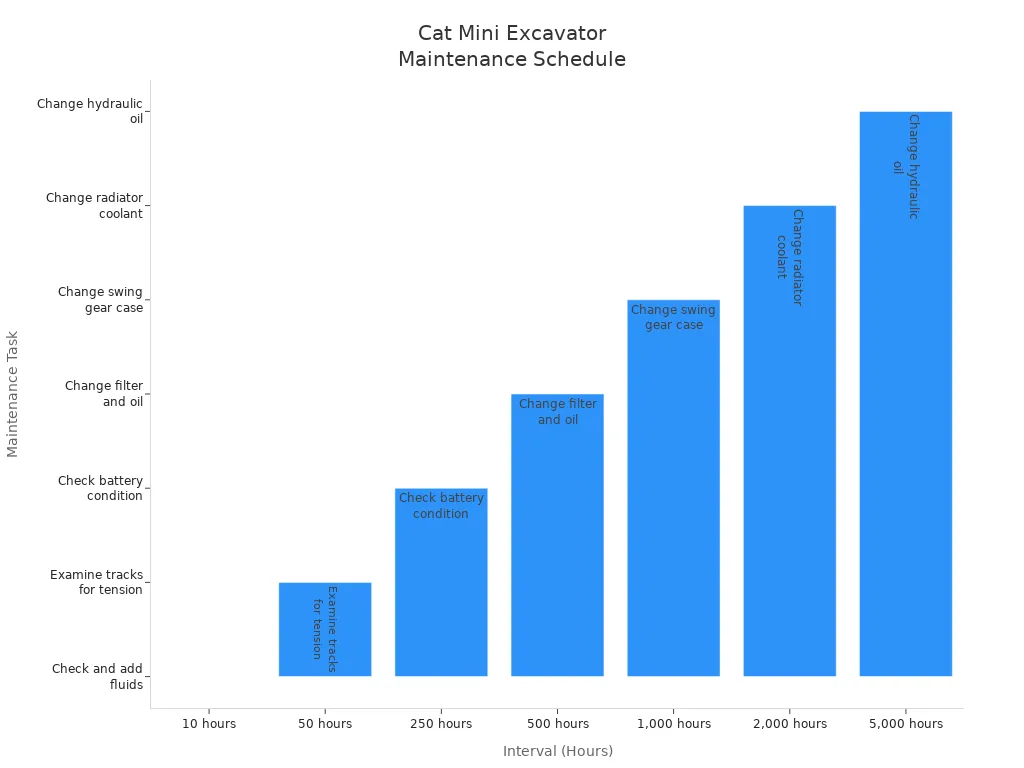

Interval (Hours) | Maintenance Task |

|---|---|

10 | Check and add fluids (hydraulic, radiator, engine) |

50 | Examine tracks for proper tension |

250 | Check battery condition and clean if necessary |

500 | Change filter and engine oil |

1,000 | Change swing reduction gear case |

2,000 | Change radiator coolant |

5,000 | Change hydraulic oil |

Oil and Filter Changes

You should change the engine oil and oil filter every 100 hours. Clean oil helps the engine run well. Use synthetic 5W-30 engine oil and a new oil filter. Here are the steps for changing the oil:

Lower the bucket and turn off the engine.

Find the oil drain bolt, oil fill port, and oil filter.

Drain all the old oil from the engine.

Take out the old oil filter and put in a new one. Make sure it is tight.

Pour in new oil. Use the dipstick so you do not add too much.

Wipe up any oil spills and check for leaks.

Changing oil often helps your mini excavator last longer. You avoid big repair bills and keep your machine ready.

Tip: Always wear gloves and eye protection when working with oil.

Hydraulic System Care

Taking care of the hydraulic system is very important. Check the hydraulic fluid level often. Change the hydraulic filter every 500 hours. Look at hoses for damage and change them if needed. Clean the connections and check for leaks. Upgrades can make lifting and digging better.

Performance Metric | Improvement |

|---|---|

Travel Performance | Up to 10% increase |

Trenching Performance | Up to 10% increase |

Lifting Performance | Enhanced through upgrades |

Good hydraulic care gives you more power. Your excavator can work harder in tough jobs. High pressure and good flow help the hydraulic system. You get faster work and better fuel use.

Upgrades help your excavator lift more.

Faster cycle times mean you finish jobs quicker.

You can change settings for different jobs.

Note: Always wear safety gear and check for leaks when working on hydraulics.

Track and Undercarriage Service

Track and tire checks help your excavator move well. Check track tension every day. The best sag is about 15 mm. Clean the undercarriage to get rid of dirt and rocks. Look for cracks, loose spots, or deep marks on the tracks. If you use your machine a lot, check undercarriage parts every 1,000 to 2,000 hours.

Check track tension every day.

Look at undercarriage parts every week or month.

For machines used a lot, check every 1,000 to 2,000 hours.

Track and tire care helps stop breakdowns. You save money and keep your machine safe.

Electrical System Checks

Checking the electrical system stops sudden problems. Look at the battery every 250 hours. Clean the battery and check for rust. Check all lights and switches in the cab. Change broken bulbs and fix loose wires. Test alarms and signals to make sure they work.

Doing these checks keeps your excavator safe and ready. Routine maintenance helps you find problems early. You protect your cat mini excavator parts and keep your team safe.

Lubrication and Greasing

Lubricating your Cat mini excavator helps protect important parts. It also makes your machine work better. Lubrication lowers the chance of breakdowns and accidents. This keeps everyone safer. You should watch the hydraulic system and moving parts closely.

Key Parts to Lubricate

Some parts need lubrication more than others. These parts move a lot and rub together every day. The table below shows which parts need regular care:

Part | Lubrication Requirement |

|---|---|

Pivot Points | Lubricate as indicated in the manufacturer’s manual to reduce wear and tear. |

Idlers | Check for oil leakage around seals and lubricate to prevent bearing failure. |

Rollers | Ensure proper lubrication to avoid seizing due to friction and heat. |

Lubricating these parts stops expensive repairs. It helps your excavator run smoothly. Always look at hydraulic connections for leaks or worn spots.

Greasing Frequency

Greasing too much or too little is not good. You must follow the right schedule for each part. The table below explains what happens if you do not grease the right way:

Consequence | Explanation |

|---|---|

High operating temperatures | Excessive grease can cause the bearing elements to churn the grease, leading to increased heat. |

Collapsed seals | Overpressure from overgreasing can rupture seals, allowing contaminants to enter the bearing housing. |

Energy loss | Churning grease results in energy loss due to increased friction and heat generation. |

Component failures | The combination of high temperatures and seal failure can lead to accelerated wear and eventual failure. |

You should grease pivot points and rollers every day or as your manual says. Clean the fittings before you add grease. This keeps the hydraulic system working well.

Tip: Use a grease gun with the right nozzle. This helps you not use too much grease and keeps seals safe.

Choosing Lubricants

Picking the right lubricant is very important. You need to use the right grease for your job. Here are the main types:

General-purpose grease is good for most jobs.

Heavy-duty grease is best for hard work and longer times.

Marine grease protects parts in wet or underwater places.

Extreme temperature grease works in very hot or cold weather.

Use marine grease if you work in wet places or need extra protection from rust. Extreme temperature grease helps in hot or cold weather and means you do not have to grease as often. Always check your manual to find the best grease for your hydraulic system.

Note: Using the right lubricant helps your excavator last longer and work its best.

Troubleshooting Cat Mini Excavator Parts

Common Warning Signs

It is important to notice warning signs early. Small problems can turn into bigger ones if you ignore them. Watch for these signs in your excavator.

Warning Sign | Description |

|---|---|

Jerky or Unresponsive Movement | The machine might move in a rough way or not react. This can mean something is worn out inside or there is a problem with the hydraulic flow. |

Delayed Track Response | Sometimes one track does not move right away. This could mean there is a problem with the final drive on that side. |

Difficult Steering | If steering feels strange, there could be a hydraulic or mechanical problem. |

Performance Degradation | The excavator may start strong but lose power as it gets warmer. This can show there are bigger problems inside. |

Hydraulic Fluid Issues | If the hydraulic fluid is low or dirty, the machine can move roughly. Check the fluid right away. |

Other signs are clogged radiator cores from dirt, broken fan blades, water pump bearing problems, thermostat issues, and coolant that is dirty. These things can make the machine overheat and not work as well. Always listen and feel for changes in your machine.

Tip: Finding problems early helps you save money and keeps everyone safe.

Basic Troubleshooting Steps

If you see a problem, follow simple steps to find out what is wrong. This helps you fix it fast. Here are some steps for checking your mini excavator:

Check the hydraulic fluid every week. Low fluid can cause many problems.

Look at hoses, connectors, clamps, cylinders, and seals for leaks or damage.

Watch for worn parts in the hydraulic system. Change them right away.

Fix any leaks, loss of power, or overheating as soon as you notice them.

Clean dirt from the radiator and check the fan blades and water pump for problems.

Checking for problems early keeps your machine safe and working well. Doing regular checks and good care helps you avoid stopping work. You protect your machine and keep everyone safe on the job.

Seasonal and Storage Maintenance

Preparing for Weather Changes

You should get your excavator ready for each season. Weather can change how your machine works. Cold weather makes engines hard to start. It can also slow down the hydraulic system. Change your machine’s settings for each season. This helps your excavator work well and not break down.

Check the heating system before winter comes. Use it to keep the engine in good shape.

Try not to let the engine run too long in the cold. This saves fuel and keeps engine parts safe.

Get your excavator ready for winter by using the right fluids. Also, check if the battery is strong.

If you work in freezing weather, take extra care with storage and maintenance.

Make a plan for snow. Decide if you will keep working or put your machine away safely.

Tip: Always read your operator’s manual for seasonal changes. This helps you follow safety rules and keeps your machine ready.

Storage Best Practices

Storing your excavator the right way keeps it safe from damage and rust. Good storage means your machine will be ready to use. You also save money on repairs. Follow these steps for the best results:

Look over your machine before you store it. Check for damage and fill up all fluids.

Clean off grease and dirt. This stops rust and keeps parts in good shape.

Put grease on all moving parts. This keeps out water and stops rust.

Fix or change any broken parts before you store the machine.

Write down all the maintenance you do.

Pick a dry, covered place like a warehouse or shipping container.

Add fuel stabilizer to stop fuel problems.

Check your machine often while it is stored.

Storage Step | Why It Matters |

|---|---|

Inspect | Finds problems before storage |

Clean | Prevents rust and corrosion |

Lubricate | Protects moving parts |

Repair/Replace | Keeps machine ready to use |

Choose Location | Shields from weather and theft |

Restarting After Storage

When you start your excavator after storage, follow some easy steps. This helps you stop problems and keeps your machine safe.

Look at your maintenance log. Make sure you did all the jobs before storage.

Check the machine for leaks, rust, or damage.

Look at fluid levels and fill them if needed.

Test the battery and electrical parts.

Start the engine and let it run for a few minutes. Listen for any strange sounds.

Test all controls and safety features before you start working.

Note: Start slowly and check each part. This helps you find problems early. It keeps your team safe and protects your machine.

Maintenance Records and Scheduling

Keeping a Maintenance Log

It is important to keep a maintenance log for your excavator. This log lets you see every repair and service done. Good planning starts when you know what work was done before. Writing down each job helps you notice patterns and find problems early. This makes it easier to plan ahead.

You can check how your machine is doing.

You can write down repairs and plan for what is needed next.

You can stop breakdowns that do not have to happen.

A maintenance log also helps keep things safe. You know when parts were last checked or changed. This makes your plans better and keeps your excavator working well. You can use a notebook, a spreadsheet, or an app. Always update your log after each service.

Log Entry Example | Details |

|---|---|

Date | 2024-06-01 |

Service Performed | Changed engine oil and filter |

Next Service Due | 2024-07-01 or 100 hours |

Technician | John Smith |

Writing down details helps you plan better and avoid big repair bills.

Setting Service Reminders

Service reminders help you remember when to do maintenance. You can use your excavator’s computer to set these reminders. This makes it easy to plan and you will not forget a service.

Go to the service screen by pressing the button with the gear icon.

Use the up and down buttons to pick the part you worked on.

Press the reset button to turn off the reminder light.

Service reminders help your machine work its best. When you use reminders, you save time and spend less on repairs. The reminder tool helps you know when it is time for service. This helps you plan and keeps your excavator ready to use.

Planning and reminders help keep your machine safe and working well for a long time.

When to Seek Professional Help

Issues Beyond DIY Repair

You can fix small problems by doing regular maintenance. But sometimes, you need an expert to help. If leaks keep coming back or you hear odd noises, call a professional. If the engine loses power or the hydraulic system does not work, get help. These signs mean there are bigger problems inside the machine.

Here are times when you should ask for help:

You see cracks in the frame or boom.

The engine will not start after you check the basics.

Hydraulic fluid keeps leaking after you change hoses and seals.

Warning lights stay on even after you reset them.

You see smoke or smell burning from the engine.

Trying to fix these problems alone can be unsafe or make things worse. A professional can keep your equipment safe and working well.

Finding Qualified Service

You need a trusted company for Cat mini excavator parts and repairs. YNF Machinery gives expert service and real parts for your machine. Their team can solve hard problems and fix your excavator. You get quick help and clear advice for every repair.

When you pick YNF Machinery, you get:

Skilled workers who know Cat mini excavator repairs.

Real parts that fit your machine.

Fast help to keep your machine working.

Careful safety checks before and after repairs.

Contact YNF Machinery if you need help with repairs you cannot do yourself. Their service keeps your excavator safe and running well. You protect your money and avoid big mistakes.

Tip: Always use trained experts for big repairs. This keeps your machine safe and helps your team stay safe too.

Comprehensive Guide to Maintaining Your Excavator

Quick-Reference Maintenance Checklist

It is important to remember each step for taking care of your excavator. This guide gives you a checklist for every day, week, and season. You help your mini excavators work well and avoid big repair bills. Follow these steps to keep your machine safe and working better.

Daily Tasks for Maintaining Your Excavator:

Check engine oil, hydraulic fluid, coolant, and fuel levels.

Look for leaks, cracks, and loose bolts.

Clean tracks and undercarriage to get rid of dirt and rocks.

Grease all pivot points and rollers.

Weekly and Monthly Tasks:

Check track tension and fix it if needed.

Look at the battery and clean the ends.

Test all lights, alarms, and switches.

Check for damage on hydraulic hoses and connections.

Routine Service Intervals:

Interval (Hours) | Task |

|---|---|

100 | Change engine oil and filter |

250 | Check battery condition |

500 | Replace hydraulic filter |

1,000 | Change swing reduction gear case |

2,000 | Change radiator coolant |

5,000 | Replace hydraulic oil |

Seasonal and Storage Steps:

Get ready for hot or cold weather by checking fluids and battery.

Clean and grease all moving parts before putting it away.

Store your excavator in a dry, covered spot.

Use fuel stabilizer if you will store it for a long time.

Check your machine and start it carefully after storage.

Tip: Doing regular maintenance keeps your excavator safe and ready to use. You lower risks and help your team stay safe. Use this guide to plan each step for your excavator.

You can print this checklist or save it on your phone. This helps you finish every part of taking care of your excavator on time. If you need expert help or real parts, contact YNF Machinery. Their team can help with repairs and advice for mini excavators.

Taking care of cat mini excavator parts helps your machine work better and last longer. You keep everyone safe and save money by following each step. Use the quick checklist and write down all the work you do. Mini excavators do a better job when you check cat mini excavator parts every day. Pick YNF Machinery if you want cat mini excavator parts you can trust. Begin your maintenance routine now to keep your excavator working well.

Paying attention to cat mini excavator parts makes jobs safer and gives you better results.

FAQ

How often should you perform maintenance on your Cat mini excavator?

Check your machine every day. Follow the schedule in your manual. Regular care helps you find problems early. It also helps your excavator last longer.

What fluids do you need to check every day?

Check engine oil, hydraulic fluid, coolant, and fuel each day. These fluids help your excavator work well. They stop damage to important parts.

Why is cleaning the undercarriage important?

Cleaning the undercarriage gets rid of dirt and rocks. This helps you see damage or wear early. A clean undercarriage saves fuel and lowers repair costs.

Who can you contact for Cat mini excavator parts and repairs?

Contact YNF Machinery for expert help and real parts. Their team can fix hard problems. They keep your excavator safe and working well.

What should you do before storing your excavator for winter?

Look over your machine and fill all fluids. Clean off dirt and grease moving parts. Store it in a dry, covered spot. Write down all maintenance in your log.