When you look at an excavator, you see many main parts. These parts are the power device, working device, slewing mechanism, control mechanism, and transmission mechanism. Hydraulic components are very important for hydraulic movement and power. They make up about 35% of the total cost. The main working parts, like motors, bearings, and electronic control systems, work together to do hard jobs. It is important to know these main parts of an excavator. Each part, from the working device to other common parts, is the base of any china excavator structural component part product.

Key Takeaways

Excavators have three main parts. These are the upper body, lower body, and working device. Knowing these parts helps you see how excavators work.

The hydraulic system gives power to the boom, arm, and bucket. You should check the hydraulic fluid and filters often. This keeps the excavator working well.

The slewing mechanism lets the upper body turn. It does this without moving the tracks. This helps the excavator move easily in small spaces.

Picking the right attachments makes your excavator more useful. Different buckets and tools help you do many jobs well.

Checking all parts often is important. Pay special attention to the hydraulic system and undercarriage. This stops breakdowns and helps your excavator last longer.

Main Parts of an Excavator

Excavators have three main sections. These are the upper body, lower body, and working device. Each section does a special job. All three work together as the base of every excavator. You should know how these parts work together. This helps you understand how excavators are built and how they work.

Upper Body

The upper body is also called the house. It sits above the lower body. This part holds the operator cab, engine, hydraulic systems, and counterweight. The swing drive lets the upper body turn all the way around. This helps you move things without moving the whole excavator. The counterweight keeps the machine steady when lifting heavy stuff. The control system helps you move the excavator exactly how you want. These parts help you work safely and get the job done.

Section | Description |

|---|---|

House | Has the operator cab, counterweight, engine, and hydraulic systems. These are important for the excavator to work. |

Lower Body

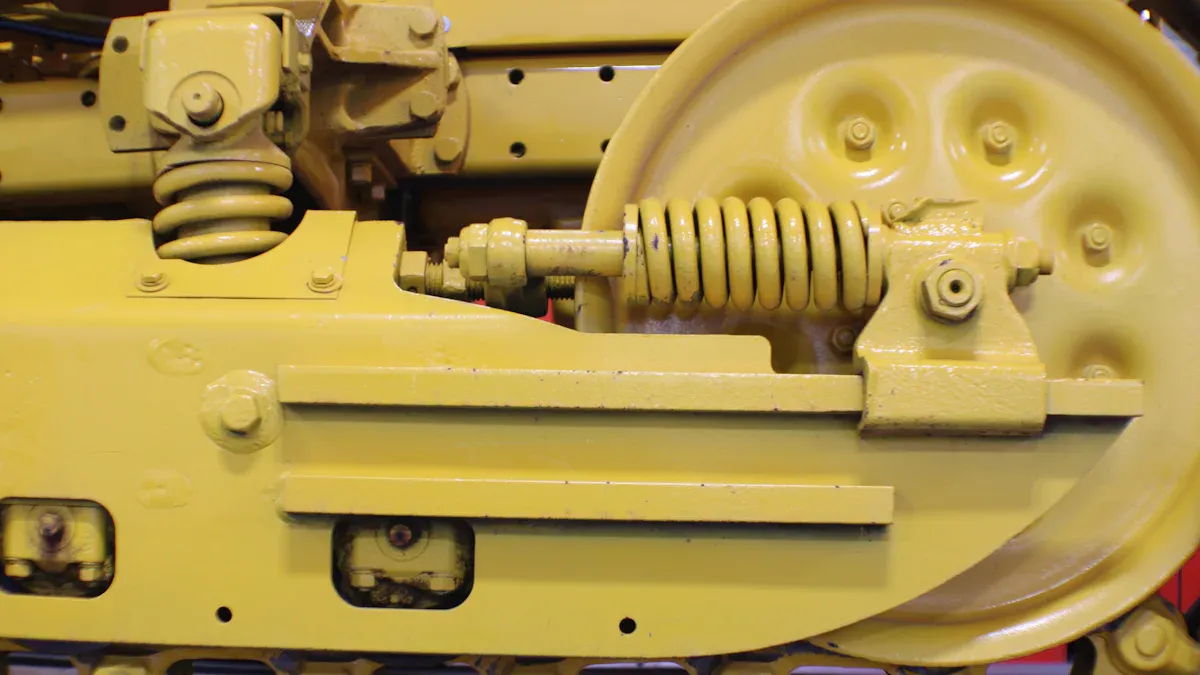

The lower body is called the undercarriage. It helps the excavator move and stay steady. It has tracks, track frame, rollers, idlers, and track shoes. The tracks let the excavator go over rough ground. The track frame holds the tracks and lets them bend a little. Track chains and shoes make the tracks strong and help them grip the ground. Rollers and idlers keep the tracks in place and help them move smoothly. These parts help you move the excavator where you need it.

Component | Description |

|---|---|

Tracks | Help the excavator move over rough ground. They are made of tough rubber and steel. |

Track Frame | Holds the tracks and lets them bend. It has strong parts that help the tracks move. |

Track Chains | Make a loop with metal plates. They are strong and hold the tracks together. |

Track Shoes | Have jagged edges for grip. They are tough and can handle rough ground. |

Rollers | Guide the tracks and keep them from slipping. They help the tracks move easily. |

Idlers | Keep the tracks in place and help them turn. They make sure the tracks stay lined up. |

Working Device

The working device does the digging, lifting, and moving. It has the boom, arm, and bucket. The hydraulic system gives power to these parts. This lets you control how they move and how hard they work. The boom and arm help you reach and dig. The bucket scoops and carries dirt or rocks. The control systems help you use these parts safely and easily. The working device connects to the upper and lower bodies. This keeps the excavator strong and steady during hard jobs.

Hydraulic system: Moves the boom, arm, and bucket with power.

Boom and arm: Reach out and dig into the ground.

Bucket: Picks up and moves dirt or rocks.

Control systems: Help you use all the parts safely.

Tip: If you know the main parts of an excavator and how they work together, you can use excavators safely and do better work.

The upper body, lower body, and working device work together to make excavators strong and steady. The way these parts are built helps you lift heavy things and dig tough ground without tipping over or losing power. Knowing about these main parts helps you pick the right excavator and keep it working well.

Excavator Parts and Their Functions

Knowing about excavator parts helps you use machines safely. Each part works with others to give power and control. These systems make excavators strong and dependable.

Power Device

The power device gives energy to the excavator. It powers the hydraulic system. This lets you dig, lift, and move heavy things. Most excavators use diesel engines. Diesel engines have strong torque and save fuel. They last a long time. Some new excavators use electric engines. Electric engines are quiet and make less pollution. Hybrid engines use both diesel and electric power. They give balanced performance for many jobs.

Powers hydraulic systems for digging and lifting.

Common engine types:

Diesel engines: Strong torque and good fuel use.

Electric engines: Quiet and clean.

Hybrid engines: Mix diesel and electric power.

Excavators have different power levels. Machines with 0-300 HP are good for farms and landscaping. Models with 301-500 HP fit building and road jobs. For mining or very heavy work, use excavators above 501 HP. You can pick the right power device for your job.

Hydraulic System

The hydraulic system is the heart of the excavator. It moves the boom, arm, and bucket. This system uses fluid under pressure. The fluid moves power from the engine to working parts. The main hydraulic system parts are:

Component | Description |

|---|---|

Oil Reservoir | Holds and cools fluid, keeps it clean. |

Hydraulic Pump | Moves fluid from the reservoir; piston pumps work well. |

Main Control Valve | Sends fluid to different excavator parts. |

Filters | Keep fluid clean and stop breakdowns. |

Hydraulic Fluid | Moves power and greases moving parts. |

Hydraulic Hoses | Carry fluid under high pressure; made of strong rubber. |

Safety Release Valve | Lets out extra pressure to protect the system. |

All excavators have hydraulic systems. These systems can reach up to 400 bar pressure. Some models have flow rates up to 500 liters per minute. High pressure and flow give strong and fast movements. Knowing how the hydraulic system works helps you keep your excavator running well.

Tip: Always check hydraulic fluid and filters. Clean fluid helps your excavator last longer and stops big repairs.

Slewing Mechanism

The slewing mechanism lets you turn the upper part of the excavator. You can spin the cab, boom, and arm all the way around. You do not need to move the tracks. This makes work faster and easier. The slewing mechanism has important parts:

Component | Function | Impact on Maneuverability |

|---|---|---|

Slewing Gear Ring | Turns the upper part in a full circle | Makes work more flexible |

Driving Pinion | Helps the gear ring turn smoothly | Lets you move quickly |

Rolling Bearing | Supports the gear ring for easy turning | Reduces friction for smooth movement |

The slewing bearing links the upper part to the undercarriage. You can turn the upper body without moving the whole machine. This helps you work in small spaces. The slewing mechanism uses a hydraulic motor and strong gears. You get smooth and controlled movement. You can dig, load, and swing things with less effort.

Transmission Mechanism

The transmission mechanism sends power from the engine to other parts. You use it to change speed, direction, and torque. The gearbox changes rotation and torque from the engine. It matches the job you are doing. It works with the hydraulic system to control the boom, arm, and bucket.

The gearbox changes torque and rotation from the engine.

It adjusts power for digging and lifting.

Gearboxes let you change speed and direction.

The gear shaft sends power to moving parts.

It controls torque and speed with different gears.

You get smooth and strong performance when the transmission works well. This system helps you do hard jobs and move the excavator safely.

Control Mechanism

The control mechanism helps you use the excavator safely and accurately. You use joysticks, pedals, and switches to move the boom, arm, and bucket. Modern controls respond fast. You can make small or big moves easily. This helps you dig, grade, or lift with accuracy.

The control mechanism also keeps you safe. Emergency stop buttons let you shut down the excavator quickly. Custom settings help you work comfortably and reduce tiredness. New technology, like 3D guidance and real-time tracking, helps you work faster and make fewer mistakes. GPS, machine learning, and smart diagnostics improve performance and cut downtime.

Note: Advanced control systems help you work smarter. You get better results and stay safe at work.

When you know excavator parts and what they do, you can pick the right machine. You can keep it in good shape and get great performance every day.

Important Parts of Excavators

When you look at excavators, you see many important parts. Each part works with the others to give power, reach, and control. These parts help you do hard jobs and keep your machine working longer. Let’s talk about the boom, stick, bucket, and attachments.

Boom

The boom is a key part of excavators. You use the boom to lift, reach, and move heavy things. The boom connects the upper body to the stick and bucket. Most Chinese excavators use strong steels like Q355 and Q460 for the boom. These steels are very tough and can handle a lot of weight. The boom has a box shape with plates of different thickness. This makes it strong but not too heavy. Factories use special machines to cut and shape the boom. They also use special welding to put it together. The boom gets many layers of coating to stop rust and wear. You can use the boom for big jobs like building, railways, and tearing down buildings.

Characteristic | Description |

|---|---|

Material Grades | Q355 and Q460 high-strength steels |

Structural Design | Box-section with variable thickness |

Surface Treatments | Multi-layer coatings for corrosion and wear resistance |

Applications | Heavy-duty construction, railway, demolition |

Tip: A strong boom helps your excavator last longer. It can handle tough jobs without bending or breaking.

Arm

The arm is also called the stick. The stick connects the boom to the bucket. This part lets you reach out and dig deep holes. If you use a longer stick, you can reach farther and dig deeper. Some long sticks can reach up to 30 meters and dig down 12,200mm. The stick helps you work in small spaces and reach over things. You can use the stick for deep digging and high demolition. The stick gives you more control and makes your job easier.

The extension stick lets you work farther away.

You can reach places that are hard to get to.

You can dig deeper and higher than with a normal stick.

Bucket

The bucket is used the most on any excavator. You use the bucket to dig, scoop, and carry stuff. There are many kinds of buckets for different jobs. Each bucket has a special shape for its job.

Bucket Type | Description | Applications |

|---|---|---|

Digging Excavator Bucket | Digs hard soil and rock | General digging |

Rock Excavator Bucket | Has strong edges and sharp teeth | Rocky places |

Cleaning Excavator Bucket | Small, no teeth, cleans work areas | Removing debris |

Skeleton Excavator Bucket | Separates small materials | Sorting materials |

Hard-Pan Excavator Bucket | Extra teeth for tough soil | Hard dig sites |

V Bucket | V-shaped for trenches | Utility cable installation |

Auger Excavator Bucket | Used for digging, scraping, cleaning | Many excavation tasks |

You can pick the right bucket for your job. This helps you work faster and keeps your excavator in good shape.

Attachments

Attachments make your excavator do more jobs. You can add different parts for many tasks. Some common attachments are:

Buckets in many sizes for digging and special jobs

Hydraulic hammers for breaking hard things

Grapples for lifting and moving heavy stuff

Thumb attachments for better grip when picking up debris

Augers for drilling holes for foundations or pipes

These attachments let you change jobs quickly. You can dig, break, lift, or drill with one machine. This makes your excavator more useful and flexible.

Note: Picking good parts and attachments helps your excavator last longer and work better. Look for strong steel, smart design, and easy care.

Critical Part | Importance |

|---|---|

Structural Integrity | Strong steel helps your machine handle heavy loads and last longer. |

Component Quality | Good suppliers give you parts that work well and last. |

Wear and Tear Resistance | Reinforced parts last longer, even with tough jobs. |

Maintenance and Serviceability | Easy-to-reach parts and good service help you keep your excavator running. |

China Excavator Structural Component Part Product

When you pick a china excavator structural component part product, you get strong parts made with new technology. Chinese companies use smart factories and pay less for workers. This means you get good quality parts at lower prices than other countries. Many people like these parts because they last long and are a good deal.

Track Frame

The track frame is the main support for the excavator’s undercarriage. It holds the tracks and connects them to the main body. The track frame keeps rollers, idlers, and track chains in place. This helps the tracks move easily over bumpy ground. You need a tough track frame to keep the undercarriage safe and steady. Most china excavator structural component part products use strong steel to make it stronger. If you want your machine to work well, always check the track frame for damage or wear.

Swing Assembly

The swing assembly lets you turn the top part of your excavator. This system helps you dig, lift, and move things without moving the bottom part. The swing assembly has important parts:

Component | Function |

|---|---|

Swing Motor | Changes hydraulic power into turning, which keeps the machine steady. |

Gearbox | Slows down speed and makes torque stronger, so the top can turn. |

Pinion Gear | Sends the strong turning force to the swing bearing for smooth turning. |

Planetary Gears | Shares the load so the swing assembly lasts longer and works well. |

A good swing assembly gives you smooth and steady turning. This is an important part of every china excavator structural component part product.

Counterweight

The counterweight helps your excavator stay balanced. It keeps the center of gravity close to the turning point. You need the right amount of counterweight to work safely. The weight depends on how heavy the excavator is and if you change the arm length. If you want to add more weight, talk to the designer first. This keeps your machine safe and working well.

The counterweight keeps the machine balanced by holding the center of gravity near the turning point.

Its weight is chosen based on how heavy the excavator is and any changes to the arm.

Always ask the designer before adding more weight to stay safe.

Operation Cab

The operation cab keeps you safe and helps you work in comfort. New china excavator structural component part products have many features for safety and comfort:

Feature | Description |

|---|---|

Structural Frame | Strong steel frame that protects you and meets safety rules (ROPS, FOPS). |

Windows and Visibility | Big, tough windows for a wide view; some have cameras for blind spots. |

Operator Seat | Seat you can adjust, with back support and springs to stop shaking. |

Control Console | Easy-to-use controls that help you not get tired. |

Instrument Panel | Shows important info like fuel and engine speed. |

Climate Control System | Heating and cooling to keep you comfortable in any weather. |

Lighting | Lights inside and outside so you can see in the dark. |

Communication Systems | Radios to talk to people on the ground. |

Storage Compartments | Places to keep tools and your things organized. |

Safety Features | Emergency exits, fire extinguishers, first aid kits, and new safety tech. |

A good cab keeps you safe and comfortable. This helps you pay attention to your job and not get hurt.

If you want good china excavator structural component part products, look at YNF Machinery. They have strong undercarriage parts, tough tracks, and modern cabs. You can trust their parts for your excavator and other needs.

You have learned about the main parts of Chinese excavators and what each does. The table below lists the important parts and what they do:

Component | Function |

|---|---|

Main Frame | Holds all the parts together and keeps the excavator strong. |

Undercarriage | Has tracks, rollers, sprockets, and idlers for moving and staying steady. |

Swing System | Lets the top part turn, which helps you work better. |

Maintenance Tips | Check bolts, track pads, and oil often to stop problems. |

Knowing these parts helps you:

Pick the right equipment and see how brands work

Think about how much it costs to use over time

Find the best models and features for your needs

Checking your excavator often keeps it safe and working well. Use this guide to make good choices and keep your machine running strong.

FAQ

What is the most important part of a Chinese excavator?

All parts are important, but the hydraulic system gives power. You need a strong hydraulic system to dig and lift heavy things. Always look for leaks or damage in this system.

How often should you check excavator parts for wear?

Check your excavator before you use it each time. Look for cracks, leaks, or loose bolts. Regular checks help you find problems early and keep your machine safe.

Can you use different attachments on Chinese excavators?

Yes, you can use many attachments like buckets, hammers, and grapples. Make sure the attachment fits your excavator model. This helps you do more jobs with one machine.

Where can you buy reliable excavator parts?

You can buy strong and dependable parts from YNF Machinery. They sell quality parts for Chinese excavators. Good parts help your machine last longer.

Why does the counterweight matter on an excavator?

The counterweight keeps your excavator balanced. It stops the machine from tipping over when lifting heavy things. Always use the right counterweight for your excavator model.