Excavator bucket wear parts help you keep your excavator working hard every day. These parts include bucket teeth, cutting edges, side wear plates, and shrouds. Each one plays a special role. Bucket teeth make contact with tough ground and need to be very strong. Cutting edges help your excavator bucket cut through soil and protect it from damage. Side wear plates shield the bucket’s sides, stopping early wear. Shrouds add extra protection in special jobs. You will learn how to choose and care for excavator wear parts, including china excavator bucket wear parts, so your machine lasts longer.

Key Takeaways

Excavator bucket wear parts, like bucket teeth and cutting edges, help with digging. They also protect the bucket from getting damaged.

You should check wear parts often and replace them when needed. This can make your excavator bucket last longer and lower repair costs.

Picking the right materials for wear parts makes them stronger and work better. This helps your excavator do hard jobs well.

Using better wear parts can make your machine work faster and use less fuel. It can also help you spend less money on fixing it over time.

Always get excavator wear parts from trusted sellers. This makes sure they fit your machine and are good quality.

Excavator Bucket Wear Parts

Excavator bucket wear parts keep your machine working at its best. You need to know each part and how it helps your excavator. These parts face tough jobs every day. They dig, cut, and protect your excavator bucket from damage. Let’s look at each main type of bucket wear part and see how they work.

Bucket Teeth

Bucket teeth are the first point of contact with the ground. You use them to break into soil, clay, or rock. These teeth must be strong and tough. Most bucket teeth are made from AISI 4130 or AISI 4140 steel. These steels resist corrosion and wear. The average lifespan of bucket teeth ranges from 200 to 800 hours, but this depends on the material you dig, how often you use your excavator, and how well you maintain the teeth.

The design of bucket teeth matters. For example, teeth for heavy clay are different from those for loose sand. Clay sticks to the bucket and resists digging, while sand flows easily but can spill out. You can improve digging efficiency by choosing the right tooth shape and keeping the teeth sharp. Tooth adapters connect the teeth to the bucket and help you change them quickly when they wear out.

Tip: Regularly check your bucket teeth and tooth adapters. Replace them when they show signs of wear to keep your excavator working smoothly.

Cutting Edges

Cutting edges run along the front lip of the excavator bucket. You use them to slice through soil and protect the bucket’s edge. Most cutting edges are made from hardened steel or abrasion-resistant materials. The right cutting edge profile can make a big difference. Standard cutting edges work well for most jobs. Serrated cutting edges help you cut through tough materials. Bolt-on cutting edges are easy to replace and are great for heavy-duty work.

Here is a quick look at different cutting edge profiles:

Standard: Good for general digging.

Serrated: Better for tough, compacted soil.

Bolt-on: Easy to replace, saves time and money.

Double-edged: You can flip and reuse them, which saves costs.

Cutting edges wear down over time. The main causes are the type of material you dig, how often you use your excavator, and how well you maintain the edges. Regular inspection and timely replacement help you avoid bigger repairs.

Cause of Wear | Description |

|---|---|

Material Selection | Using high-quality components and abrasion-resistant steel in high wear areas. |

Maintenance Practices | Regular inspections to catch minor damage early and replace worn parts promptly. |

Environmental Conditions | Continuous damage due to massive usage and harsh working conditions. |

Side Wear Plates

Side wear plates protect the sides of your excavator bucket. These plates are made from abrasion-resistant steel. You weld them onto the bucket’s sides, where they face the most friction and impact. Side wear plates absorb and spread out the forces from digging. This keeps the bucket strong and helps it last longer.

You can also use wear plates, wear buttons, and wear squares to cover more area. These extra layers reduce metal loss and shield the bucket from lateral wear. Heel blocks protect the lower corners of the bucket, where damage often starts.

Note: Adding wear plates and wear buttons to your bucket can save you money by reducing the need for full bucket repairs.

Shrouds

Shrouds cover the leading edges and corners of your excavator bucket. You use them to protect the bucket from direct hits and abrasion. Shrouds are usually made from quenched and tempered steel or high-strength alloys. They spread out impact forces and keep the bucket’s edges from wearing down too fast.

You can install shrouds by welding or bolting them on. Heel shrouds go on the rear corners to guard against impacts. Shrouds cost less than replacing a whole bucket, so they are a smart way to extend bucket life. Remember to check and replace shrouds and other bucket wear parts when they show signs of wear.

Here is a table showing common materials for excavator bucket wear parts:

Component | Material Used | Properties |

|---|---|---|

Bucket Teeth | AISI 4130, AISI 4140 | Chromium molybdenum steels, heat treated for wear resistance and toughness. |

Cutting Edges | Hardened Steel | Typically made of abrasion-resistant materials for durability. |

Side Wear Plates | Abrasion-resistant | Protects against wear and impact, extending the lifespan of the bucket. |

Shrouds | Quenched and tempered | Provides wear protection, economical but less durable than duplex wear plates. |

Remember: Bucket wear parts act as sacrificial layers. They take the damage so your excavator bucket stays strong and lasts longer.

Functions of Bucket Wear Parts

Digging and Penetration

Excavator bucket wear parts play a big role in digging. You rely on these parts to break into soil, clay, or rock during excavation. Bucket teeth and cutting edges help you cut through tough ground. Wear plates and shrouds protect the bucket so you can keep digging without stopping for repairs. When you work in abrasive soils like sand or gravel, wear-resistant materials prevent fast damage. High-quality wear plates spread out stress, which keeps the bucket strong and helps you dig more efficiently.

Bucket teeth keep your digging sharp and fast.

Cutting edges slice through soil, making excavation easier.

Wear plates protect against impact and friction, so you can dig longer.

Shrouds shield the bucket from direct hits during digging.

If you want to improve digging performance, always check for signs of wear. Worn teeth or edges make digging harder and slow down your work.

Protection and Durability

You need excavator bucket wear parts to protect your bucket and make it last longer. Cutting edges made from hardened steel boost penetration and loading. Side cutters and heel blocks guard the bucket’s sides and corners from damage. Wear plates and buttons give extra protection to high-wear spots. Shrouds cover the leading edges and heels, stopping cracks and dents.

Cutting edges and side cutters keep the bucket strong during excavation.

Heel blocks and shrouds prevent damage from heavy digging.

Wear plates and buttons add layers of defense against abrasion.

Look for common signs of wear like cracks, dents, or thin spots. If you spot these signs of wear early, you can fix them before they turn into bigger problems.

Efficiency and Performance

Excavator wear parts help you work faster and save fuel. When bucket teeth and edges stay sharp, you scoop and dump materials quickly. Worn parts slow down your cycle times and make the excavator use more fuel. This hurts your efficiency and costs you money.

Measurable Effect | Description |

|---|---|

Increased digging resistance | Worn teeth make digging harder and use more power. |

Higher drive power requirements | The excavator needs more energy to dig with worn parts. |

Reduced payload | Blunt teeth lower the amount of material you can move. |

Increased hydraulic power usage | Worn parts make the excavator work harder, using more fuel. |

You can keep your excavator running well by checking for signs of wear. Regular inspections help you spot common signs of wear like cracks, worn edges, or missing teeth. This keeps your excavation jobs smooth and helps with improving excavation efficiency.

Tip: Always inspect your excavator bucket wear parts before and after each excavation. Early action on signs of wear means less downtime and better digging results.

Benefits of Excavator Wear Parts

Extended Bucket Life

You want your excavator bucket to last longer. Advanced materials like tungsten carbide overlays make wear plates stronger. These materials help the bucket resist damage better than regular steel. Your bucket can handle tough jobs without breaking easily. You will need fewer repairs and replacements. This means your bucket works longer before needing service. High-quality wear plates protect the bucket from constant scraping and hits. This keeps your excavator working hard on every project.

Tip: If you upgrade your wear plates and bucket parts, you can avoid early bucket problems. Your equipment will stay strong and work well.

Improved Efficiency

Upgrading wear plates and bucket teeth makes your excavator work better. New wear parts help you dig into the ground faster. You can move more dirt with each scoop. Better wear parts keep soil and rocks inside the bucket. This means less spillage. Stronger parts mean you spend less time fixing things. You use less fuel, so you save money. Lower maintenance costs help you spend money on other things. Special designs let you pick wear plates for your job. Safety gets better, so your team stays safe. Attachments fit well, so you can do more jobs. The excavator runs smoother, so operators feel more comfortable.

If you upgrade the track group, you get better grip and digging power. This helps you work on rough ground and carry heavy loads. Your excavator spends less time in the shop. It works more, so your projects finish faster.

Cost Savings

You save money by changing wear plates and parts on time. High-quality bucket pins and bushings last up to 50% longer. You need fewer replacements and your equipment breaks less often. Good pins and bushes lower machine failure rates by 25%. Strong alloy wear plates and shrouds help your bucket last over 2,000 hours. You wait longer before buying new parts and have less downtime. Even though strong wear parts cost more at first, you save money later with fewer repairs. Checking and replacing parts often keeps your excavator working well. Stopping big problems early means you avoid expensive repairs and keep your projects on track.

Note: Check your wear plates and parts every day. Good care helps you find problems early. This simple step saves money and helps your equipment last longer.

Selecting and Maintaining China Excavator Bucket Wear Parts

Material and Compatibility

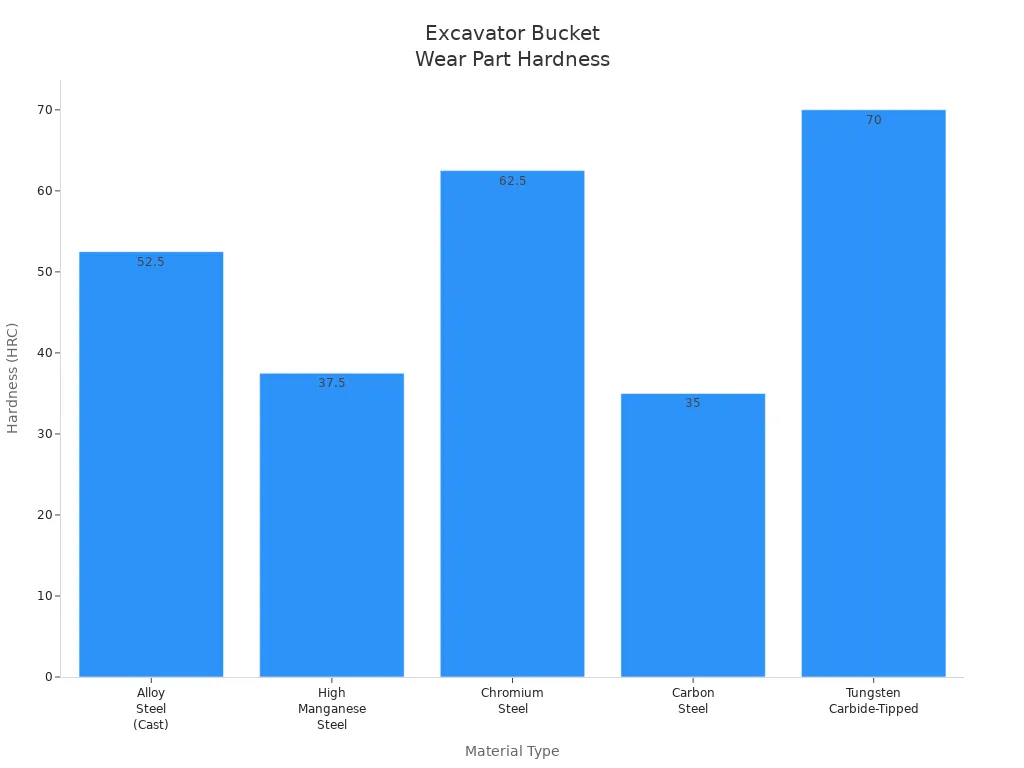

When picking china excavator bucket wear parts, you should think about the material and if it fits your machine. The material you pick changes how long the parts last. Hardness, toughness, and wear resistance are very important. Use abrasion-resistant materials for hard digging jobs. The table below shows how different materials compare:

Material Type | Hardness (HRC) | Toughness | Wear Resistance | Best Used For |

|---|---|---|---|---|

Alloy Steel (Cast) | 50-55 | High | High | General digging, sand, gravel |

High Manganese Steel | 35-40 | Very High | Moderate | Rock excavation, mining |

Chromium Steel | 60-65 | Low | Very High | Hard and abrasive materials |

Carbon Steel | 30-40 | Moderate | Low | Light-duty applications |

Tungsten Carbide-Tipped | 70+ | Low | Extremely High | Heavy-duty rock or demolition work |

You also need to make sure the parts fit your excavator model. Check the hydraulic needs, weight, and attachment details. If you use the wrong parts, your excavator can get damaged. It may not work as well. Always pick parts that match your machine for safe and good digging.

Inspection and Replacement

You should check your china excavator bucket wear parts often. Regular checks and changing old parts stop sudden breakdowns. Look for cracks, loose bolts, or uneven wear before and after each shift. Every week, wash the bucket, check welds, and grease the fittings. Watch for signs of abrasion, impact damage, and rust.

Inspection Frequency | Task Description |

|---|---|

Weekly (50–100 operating hours) | Wash bucket, check welds, grease fittings, inspect for deformities, test locks |

Before and after each shift | Visual check for cracks, loose fasteners, uneven wear |

Regularly | Look for abrasion, impact damage, cracks, corrosion |

Change worn parts quickly to keep your excavator working well. Use strong, high-quality parts for better results and longer life. These tips help you avoid big repairs and lost time. To make your wear parts last longer, always follow the maintenance schedule and check them often.

Sourcing Bucket Wear Parts

When you need china excavator bucket wear parts, pick a supplier you trust. YNF Machinery sells strong wear parts for many excavators. Find suppliers with ISO 9001 and ISO 14001 certificates. These show the supplier follows strict rules for quality and the environment. Always ask to see proof of these certificates before you buy.

Tip: Buy from trusted sellers to get real abrasion-resistant parts and make sure your replacements last longer.

If you use these tips and follow the right maintenance schedule, you will help your excavator wear parts last longer. Check your parts often, pick the right materials, and change them on time to keep your digging jobs going well.

It is important to know how each excavator bucket wear part works. Picking the right parts helps your excavator dig well. Your machine will last longer if you choose good parts. Check your excavator often to keep it safe. Follow the tips in this guide to help your excavator work better. YNF Machinery sells strong excavator parts if you need them. Take care of your excavator and you will get better results every time you use it.

FAQ

What are the most common signs of wear on an excavator bucket?

You might notice cracks or dents on the bucket. Sometimes, bucket teeth are missing. Worn cutting edges can look thin or damaged. Side plates may also get very thin. If your bucket does not dig well, check for these problems. Finding these signs early helps you stop bigger issues.

How often should you inspect excavator bucket wear parts?

Check your excavator bucket wear parts before and after every use. Clean and look at the bucket each week. This helps you find damage early. Regular checks keep your excavator safe. You can also avoid expensive repairs by checking often.

Can you replace excavator bucket wear parts yourself?

Many excavator bucket wear parts can be changed with simple tools. Always read the instructions from the manufacturer first. If you are not sure how to do it, ask a professional. Changing parts the right way keeps your excavator safe and strong.

Why do you need to use the right material for excavator wear parts?

Using the right material makes your bucket last longer. Hard and tough materials stop damage from rocks and dirt. If you pick the wrong material, your bucket may break faster. It can also cost more to fix later.

Where can you buy quality excavator bucket wear parts?

You can get strong and reliable excavator bucket wear parts from YNF Machinery. They have parts for many types of excavators. Always buy from a trusted seller. This helps your excavator work well and last longer.