Excavator wheel parts are tyres, rims, sprockets, rollers, and idlers. Each part helps the excavator move and stay steady. This is true for machines with rubber wheels or tracks. You must know these parts to keep your excavator safe. This also keeps the bucket, excavator arm, and excavator boom working well. Studies show that checking and fixing wheel parts often helps your machine last longer.

Looking after excavator parts, mainly the undercarriage, stops expensive repairs. It also keeps your excavator working for more time.

Key Takeaways

Excavator wheel parts include tyres, rims, sprockets, rollers, and idlers. These parts work together to help the machine move safely. They also help the machine last longer. Rubber wheels and strong tyres give smooth rides on roads. Sprockets and rollers help tracks move well on rough ground. Check tyres, rims, sprockets, rollers, and idlers often for wear or damage. This helps you avoid expensive repairs and keeps your excavator safe. Looking after undercarriage parts stops breakdowns. It also protects important parts like the bucket and makes the machine last longer. Clean and lubricate parts often, especially in hard places. This helps your excavator work better and saves money.

Overview

Excavator Wheel Parts

You will find several main types of excavator wheel parts in every machine. These include rubber wheels, sprockets, rollers, idlers, and the track frame. Each part plays a unique role in helping the excavator move and work safely. In wheeled excavators, you see rubber wheels and wheel rims. Crawler excavators use tracks, which include sprockets, rollers, idlers, and the track frame. The tracks help the excavator move over rough ground, while the wheels work best on smooth surfaces.

Note: Research shows that the rim is a key load-bearing part. It must have strong structural stiffness and safety performance. Engineers test rims for fatigue life and weight loss to make sure they last under heavy use.

Here is a quick look at the main excavator wheel parts and their functions:

Part Name | Main Function |

|---|---|

Rubber Wheels | Support movement on roads and smooth surfaces |

Sprockets | Drive the tracks and help the excavator move |

Rollers | Guide and support the tracks |

Idlers | Keep the tracks tight and aligned |

Holds all undercarriage parts together |

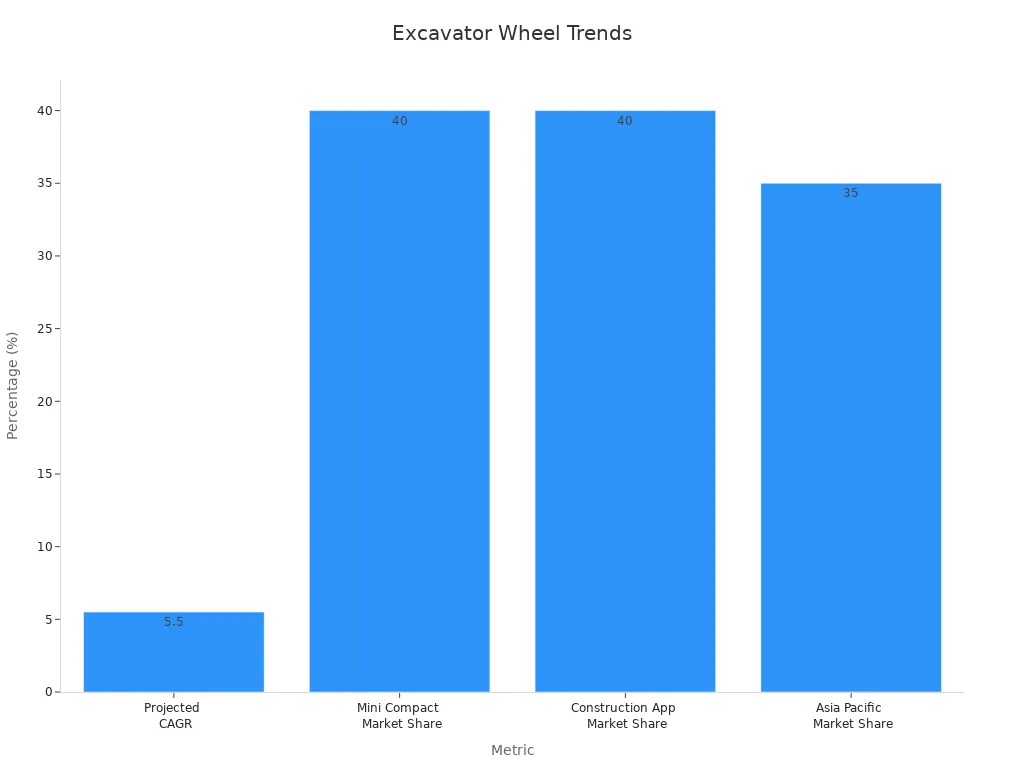

You can see how important these parts are in the industry. The market for excavator wheel parts reached USD 10.7 billion in 2022. Mini and compact excavators made up over 40% of the market. Construction projects use about 40% of all excavators. The Asia Pacific region leads with over 35% of the market share. New technology, like electric wheel excavators, is also growing fast.

Functions

Each part of an excavator has a special job. Rubber wheels let you drive the excavator on roads. Sprockets push the tracks forward or backward. Rollers keep the tracks in place and help them move smoothly. Idlers keep the tracks tight so they do not slip off. The track frame holds all these parts together and supports the weight of the bucket, arm, and boom. When you know how these excavator wheel parts work, you can spot problems early and keep your machine running longer. You also help protect the bucket and other important excavator parts. If you use your excavator for digging, lifting, or moving soil, you rely on these parts every day.

Rubber Wheels

Rubber wheels play a key role in how your excavator moves and works. You find these wheels on wheeled excavators. They help you drive the machine on roads and hard surfaces. If you use your excavator in cities or on paved ground, you rely on rubber wheels every day. These wheels give you better speed and smoother rides than tracks. They also cause less damage to roads.

Tyres

Tyres are the outer part of the wheel. They touch the ground and carry the weight of your excavator. You need strong tyres because they face heavy loads and rough surfaces. Good tyres help you keep control of your machine. They also protect the undercarriage and other parts of an excavator from shock and vibration.

You can choose from different types of tyres. Some tyres have deep treads for better grip. Others have smooth treads for less rolling resistance. Here are some main features you should look for in excavator tyres:

Durability: Tyres must last a long time, even when you use your excavator every day.

Traction: Good tyres stop your machine from slipping, especially on wet or loose ground.

Load Capacity: Tyres must support the full weight of your excavator, including the bucket and any load you lift.

Puncture Resistance: Strong tyres help you avoid flats and downtime.

Tip: Check your tyres often for cuts, cracks, or low pressure. Worn tyres can make your excavator unsafe and less efficient.

Wheel Rims

Wheel rims hold the tyres in place. They connect the tyres to the axle and help transfer power from the engine to the ground. You need strong rims because they carry the full weight of your excavator. Rims also help keep your tyres in the right shape, so you get the best grip and stability.

You can find rims made from steel or special alloys. Steel rims give you strength and last a long time. Alloy rims are lighter, which can help your excavator move faster and use less fuel. When you choose rims, you must match them to your tyre size and the weight of your machine.

Here is a simple table to help you understand the main differences:

Feature | Steel Rims | Alloy Rims |

|---|---|---|

Weight | Heavier | Lighter |

Strength | Very strong | Strong |

Cost | Lower | Higher |

Fuel Efficiency | Lower | Higher |

If you notice dents or cracks in your rims, you should replace them at once. Damaged rims can cause tyre failure and put your excavator at risk. You also protect the bucket and other key parts when you keep your rims in good shape.

Note: Wheel rims are one of the most important parts of an excavator. They help you keep your machine safe and working well.

Sprockets and Rollers

Sprockets and rollers are very important for an excavator. You need them every time you move your machine. They help the excavator travel smoothly and keep the tracks in place. Sprockets and rollers are extra useful on rough ground or with heavy loads. If you want your excavator to last longer, you should know how these parts work.

Sprockets

Sprockets are wheels with teeth that drive the tracks. When you use the excavator, sprockets grip the track links. This pushes the tracks forward or backward. It lets the excavator move over soft or rocky ground. Sprockets must handle a lot of force and stress. This is true when lifting heavy buckets or climbing slopes.

Modern sprockets use strong materials like tempered steel. Some also use composites. These materials make sprockets last longer and resist wear. New sprocket designs help them work better and last longer. Sprockets with well-shaped teeth keep working well as they wear down. The tooth shape lets rollers ride farther out as the chain stretches. This spreads the load over more teeth and reduces wear.

Tip: Pick sprockets with at least 17 teeth for fast work. Sprockets with 19 or 21 teeth give a good balance of speed and efficiency.

You can choose from different sprocket types for your excavator:

Steel plate sprockets: No hubs, best for lighter jobs.

Cast iron or steel with hubs: Stronger, used for heavy work.

Split type sprockets: Easy to change, good for quick fixes.

Double-duty sprockets: Made to last longer in tough places.

If you look after your undercarriage, including sprockets, it can last 4,000 to 6,000 hours. Bad care can make it last only half as long. Worn sprocket teeth can stretch the tracks and make things unsafe. Checking and fixing sprockets saves money and stops big repairs. Emergency repairs can cost three times more.

Note: Always check your sprockets for sharp or hooked teeth. Change them before they hurt the tracks or other excavator parts.

Rollers

Rollers hold up the excavator’s weight and guide the tracks. There are two main types: top rollers and bottom rollers. Top rollers keep the top of the tracks in place. Bottom rollers carry most of the weight and help the tracks roll on the ground.

Rollers must handle heavy loads and rough ground. They also deal with lots of movement. Modern rollers use strong steel and special coatings. Bearings inside the rollers cut down friction and help them turn smoothly. You often see ball bearings or roller bearings in rollers.

Ball bearings cut friction and support different loads. They help rollers move smoothly and last longer.

Roller bearings spread the load over a bigger area. They are good for hard, non-stop work.

Spherical roller bearings handle heavy loads and misalignment. They help when working on uneven ground.

Bushings are small and self-lubricating. They lower friction in tight spaces.

Rollers are judged by how much weight they hold, how well they resist wear, and how they handle heat. Big rollers made from strong materials can carry more weight. Special coatings protect rollers from harsh places. Good bearings keep rollers steady and lower friction. This helps the excavator move well.

Common roller problems are:

Wear and tear: Heavy loads and rough ground wear rollers out faster. Check and oil rollers often.

Abnormal noise: Loose parts or not enough oil cause noise. Tighten parts and change worn ones.

Roller stuck: Dirt or bad bearings stop rollers from turning. Clean and check bearings often.

Oil leakage: Old seals let oil leak out. Change seals and use good oil.

Deformation or damage: Hard hits or long use can bend or break rollers. Avoid hard hits and change broken rollers fast.

Tip: Looking after rollers and sprockets saves money and keeps your excavator working well. Good rollers support the tracks and protect other parts like the bucket and arm.

When you care for sprockets and rollers, your excavator lasts longer. These parts work together to keep your machine safe and steady on any job site.

Idlers and Track Frame

Idlers

Idlers help guide and support the tracks on your excavator. You find them at the ends of the undercarriage. Idlers keep the tracks tight and aligned, so your machine moves smoothly. When you work in mud, sand, or snow, idlers face more stress. These tough conditions can cause faster wear and failure. If you do not check your idlers often, you risk problems with the whole excavator undercarriage.

You should know that operator mistakes and rough terrain can make idlers wear out quickly. Mud and debris can build up around the idlers. This causes extra tension and can damage seals. You can prevent many failures by cleaning, checking, and adjusting the idlers. Regular lubrication also helps. If you work in places like Florida’s sugar sand, you may need to keep the tracks a bit looser to avoid early wear. You will not find fixed maintenance intervals for idlers, but you should inspect them more often in harsh environments.

Tip: Clean your idlers after each job. Look for signs of wear or leaks. Early action saves money and keeps your excavator safe.

Track Frame

The track frame holds all the main parts of an excavator undercarriage together. It supports the idlers, rollers, sprockets, and tracks. The frame must be strong because it carries the weight of the excavator, the bucket, and any load you lift. A good track frame keeps everything in line, so your machine stays stable.

Track frames use high-strength steel to handle heavy loads and rough ground. If you see cracks or bends in the frame, you should stop work and get repairs. A damaged frame can lead to bigger problems with the tracks and other parts of an excavator.

Parts of an Excavator: Undercarriage

The excavator undercarriage is the base that lets your machine move and work safely. It includes the track frame, idlers, rollers, sprockets, and tracks. Each part works together to spread the weight and keep the excavator steady. If one part fails, the whole system can suffer.

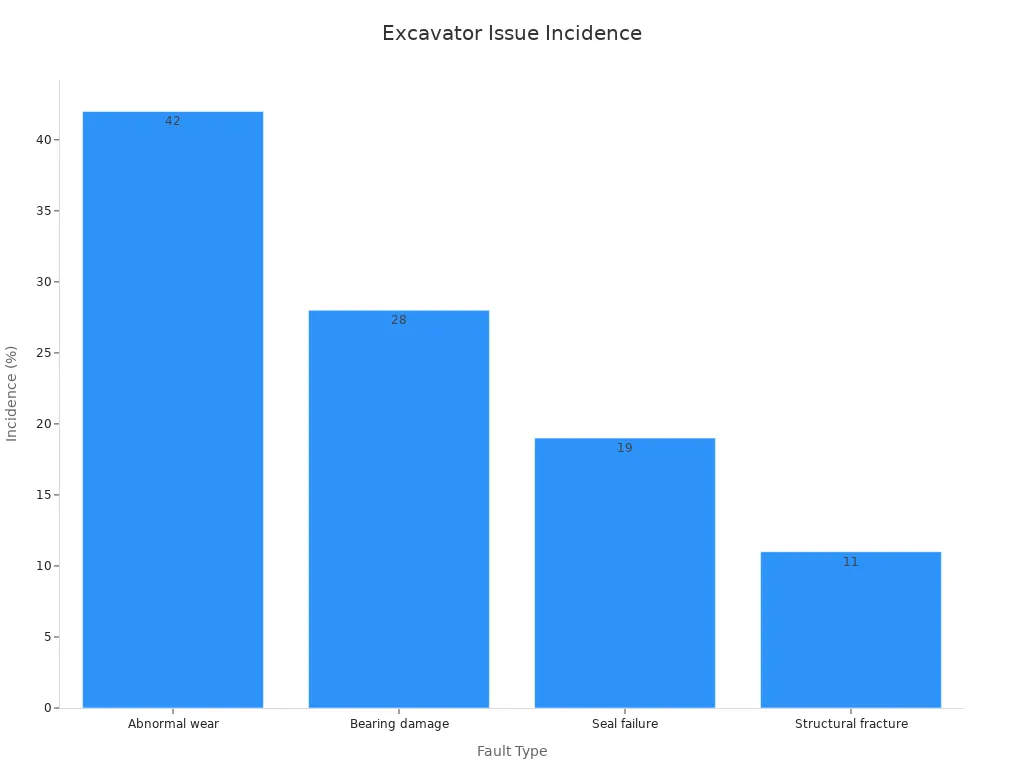

You can see from the data below how common undercarriage issues are:

Fault Type | Approximate Incidence (%) | Typical Equipment Model |

|---|---|---|

Abnormal wear | 42% | 20-30 ton excavator models |

Bearing damage | 28% | Mining equipment |

Seal failure | 19% | Equipment used in wet environments |

Structural fracture | 11% | Overloaded equipment |

Undercarriage failures can slow down your work and cost a lot to fix. They also put your safety at risk. You should inspect all parts of an excavator undercarriage often. This helps you spot problems early and avoid bigger breakdowns. When you look after the undercarriage, you help your excavator last longer and work better.

You now see why every excavator wheel part is important. When you learn how wheels, rollers, and idlers work, you help keep your excavator safe. This knowledge lets you find problems early and stop damage to the bucket. Checking your machine often helps it last longer. If you want more details about your excavator, read the manual or ask an expert. This way, your machine is always ready for work.

Tip: Always use the maintenance guide for your excavator to stop expensive repairs.

FAQ

What is the most important part of an excavator undercarriage?

You should pay close attention to the rollers. They support the machine’s weight and help the tracks move. If you keep the rollers in good condition, your excavator will work better and last longer.

How often should you check your excavator wheel parts?

You should inspect wheel parts before each job. Look for signs of wear, leaks, or damage. Regular checks help you spot problems early and avoid costly repairs.

Can you use an excavator with damaged tyres or rims?

You should never use an excavator with damaged tyres or rims. These parts keep your machine stable and safe. Damaged tyres or rims can cause accidents or more damage to other parts.

Why do idlers wear out quickly in some environments?

Idlers wear out faster in muddy, sandy, or wet places. Dirt and debris can build up and cause extra tension. You should clean and check idlers often if you work in these conditions.