When you buy excavator wear parts online, you want each step to be reliable. You need excavator parts that fit right and last during hard work. Compatibility, wear resistance, and supplier reliability are very important for your excavator. Many buyers have trouble with quality and reliability when buying excavator wear parts. This guide will help you learn the best ways to buy, so you can trust every excavator part you pick and count on your machine to work well.

Key Takeaways

Find out your excavator’s make, model, and serial number first. This helps you get the right parts and avoid errors. Use your equipment manual and online tools to look up part numbers. Check if the parts will work with your machine. Pick high-quality parts by looking at materials and how they are made. Check if the supplier has certifications. This helps your excavator last longer. Choose between OEM and aftermarket parts. Think about what you need, your budget, and if you want a warranty. Buy from trusted suppliers with good reviews. Make sure they offer clear warranties and safe payment options. This keeps your money safe.

Guide to Buy Excavator Wear Parts

Identify Machine Details

Start by learning about your machine before you buy excavator wear parts. Each excavator is different. The make, model, and serial number tell you what kind of machine you have. These details help you pick the right spare parts and avoid mistakes. Always look at the identification plate on your excavator. Write down the model and serial number. This information helps you match the right excavator bucket parts and other wear items.

Tip: Keep a record of your excavator’s maintenance and usage. Good records help you know when to replace important spare parts. They also help you plan for future needs. Most excavators reach about 9,800 hours of use in six years. Big parts like the engine may need a rebuild after eight years. Tracking these numbers helps you plan for replacement and save money.

Check how much you use your machine. If you use it a lot, you will need new wear parts more often. Working in tough places makes your excavator bucket and undercarriage wear out faster. Knowing this helps you plan ahead and stop work delays.

When you buy digger equipment spares, ask the seller for maintenance records. Do not buy from sellers who cannot show clear records. Good sellers have proof of regular maintenance and part changes. This step keeps your investment safe and your excavator working well.

Find Essential Spare Parts

After you know your machine details, look for the right essential spare parts. Start by reading your equipment manual. The manual has diagrams and part numbers for every part, including excavator bucket parts and other high-wear items. Use the manual to find the exact spare parts you need.

Check the list of essential spare parts for your excavator. This list usually has:

Bucket teeth and adapters

Cutting edges

Side cutters

Pins and bushings

Hydraulic hoses

Filters and seals

Keep common spare parts in stock. This helps you avoid delays and keeps your construction projects moving. Manufacturers say you should replace wearable parts as they suggest. Not following this advice can break your machine and cost more to fix.

Note: Experts always use parts manuals to help customers get the right excavator parts. Using the wrong part number can make parts not fit and hurt machine performance. Always check part numbers before you buy.

Online part finders can help you pick the right replacement parts for your excavator. Many suppliers have these tools on their websites. Type in your machine’s make, model, and serial number to see a list of matching spare parts. This helps you avoid buying the wrong excavator bucket parts or other construction equipment parts.

Customer reviews and supplier ratings are important too. Look for comments about delivery, support, and warranty service. Good suppliers give you access to essential spare parts, technical help, and maintenance services. Certification and regular checks make sure you get quality construction equipment parts every time.

When you buy excavator wear parts online, always check prices with other listings. Very low prices may mean fake or bad replacement parts. Make sure you get warranty and certification papers with your order. Keep good records of every purchase, including warranty dates, to help with future maintenance and claims.

Checklist for Finding Essential Spare Parts:

Check your machine’s make, model, and serial number.

Look in the equipment manual for part numbers.

Use online part finders to check compatibility.

Read supplier reviews and check certifications.

Compare prices and make sure parts are real.

Keep records of all spare parts you buy.

If you follow this guide, you can buy digger equipment spares and replacement parts for your excavator with confidence. Your construction projects will run smoothly and you will avoid expensive delays.

Check Compatibility & Specifications

Verify Fitment

You must check that every excavator part fits your machine. Start by using your equipment manual. The manual lists all spare parts and shows which ones match your excavator. Look for the right part numbers for your bucket and other wear items. If you do not have the manual, use online part finders. Many suppliers offer these tools. Enter your excavator’s make, model, and serial number. The tool will show you a list of matching spare parts.

Contact supplier support if you have questions. Good suppliers help you confirm fitment for all excavator bucket parts. They can check if the replacement part matches your machine. You should never guess about fitment. Wrong parts can damage your excavator and cause more wear. Always double-check before you order.

Tip: Take clear photos of your old bucket or worn parts. Share these with the supplier. This helps them find the right replacement and avoid mistakes.

Match Application Needs

You need to match spare parts to your job site and work type. Not all excavator bucket parts work for every task. Some buckets handle rock and heavy wear. Others work best for digging soft soil. Check the specifications for each replacement part. Look at the material, size, and design. Make sure the bucket and other spare parts meet your needs.

Think about how often you use your excavator. Heavy use means you need stronger spare parts. If you work in tough conditions, choose parts with extra wear protection. This keeps your excavator performance high and reduces downtime. Good fitment and the right specifications help with preventive maintenance. You will save money and keep your machine running longer.

Note: Always compare the specs of new spare parts with your old ones. This step helps you avoid buying the wrong excavator bucket parts.

You can use this checklist to match your needs:

Review your equipment manual for part specs.

Use supplier support for questions.

Compare old and new bucket parts.

Choose spare parts made for your work type.

Confirm all replacement parts fit your excavator.

Quality & Material Inspection

Assess Durability

You want your excavator to last a long time. First, check what materials are in each bucket and wear part. High-quality components use strong metals or tough rubber. These materials help your excavator carry heavy things and work on rough ground. Picking high-quality components lowers the chance of early wear. Your excavator will work better for longer.

Find suppliers who give details about their material tests. Many do lab tests like pulling, bending, and hitting parts. These tests show if the bucket and other excavator parts can handle hard work. You should also ask for numbers about how often parts fail. This information helps you see problems early and plan repairs. Some suppliers use special tools, like heat cameras or vibration checks, to find hidden problems before they get worse.

Tip: Always ask for test papers or certificates when you buy high-quality components. This step proves your excavator bucket parts meet the right standards.

Inspect Workmanship

You need to check how well each excavator part is made before buying. Good workmanship means the bucket and other high-quality components fit right and last longer. Look for smooth welds, flat surfaces, and no sharp corners. Bad workmanship can make parts wear out faster and not work as well.

Many good suppliers follow strict rules, like ISO 9001, to check quality. These rules include checking raw materials, looking at parts during making, and final checks at the factory. They make sure each excavator bucket and wear part is the right size, shape, and strength. Some suppliers use special checks to keep making parts the same way. Others test new bucket designs to make sure they work well.

You should always compare the quality of OEM and aftermarket excavator bucket parts. OEM parts can sometimes change from batch to batch if checks are weak. Aftermarket parts may skip some tests, which can make them less reliable. Pick suppliers who do careful checks and share their quality records.

Note: Never pick the cheapest price over value and how long parts last. High-quality components might cost more, but they save money by lasting longer and stopping work delays.

A quick checklist for checking quality and material:

Look for high-quality metals or tough rubber in every bucket.

Ask for lab test results and numbers on part failures.

Check welds, surfaces, and edges for good workmanship.

Pick suppliers with strong quality rules.

Compare OEM and aftermarket parts for steady quality and trust.

OEM vs Aftermarket Replacement

Compare Options

When you need a new part for your excavator, you have two choices. You can pick OEM parts or aftermarket parts. OEM parts are made by the company that built your machine. These parts fit your excavator perfectly. They use high-quality components and go through tough tests. You know they will last a long time and work well. OEM parts cost more money, but they help keep your warranty safe and stop problems.

Aftermarket parts are made by other companies. These replacement solutions usually cost less at first. Some aftermarket parts use high-quality components, but not all do. The quality can change depending on who makes them. You should always check if the supplier is trusted and has certifications. Many people buy aftermarket parts because they want to save money and get parts faster.

Tip: Always buy genuine excavator parts from good suppliers. Fake or bad replacement parts can break your machine and make it unsafe.

Here is a quick comparison:

Factor | OEM Parts | Aftermarket Parts |

|---|---|---|

Quality | High, tested, reliable | Varies, check supplier and certifications |

Cost | Higher upfront | Lower upfront, may cost more over time |

Durability | Long lifespan, less frequent replacement | Can wear faster, depends on quality |

Compatibility | Perfect fit | Must verify fit for each replacement |

Availability | Sometimes limited | Often more available |

Warranty & Support | Strong manufacturer support | Varies, often less comprehensive |

When to Choose Each

Pick OEM parts if you want the best quality and a perfect fit. Both OEM and aftermarket parts are replacement solutions, but OEM gives you peace of mind. Buy genuine excavator parts if you want to keep your warranty and avoid fixing your machine often. OEM parts are best for new machines, heavy work, or when you need your excavator to last a long time.

Aftermarket parts are good if you need a quick fix or want to spend less money. Always check the quality before you buy. Read reviews, ask for certifications, and compare the specs to your old part. If you buy genuine excavator parts from a trusted aftermarket seller, you can get a good deal. Never buy replacement parts from sellers you do not know. Fake parts can break your machine and even get you in trouble.

Use OEM parts for:

New machines

Warranty protection

Expensive equipment

When you need the most reliability

Use aftermarket parts for:

Older machines

Cheaper repairs

When you need parts fast

Jobs that are not as important

Note: Studies show OEM parts cost more at first but save money later. They last longer and help stop work delays. Aftermarket parts can be a good replacement if you check the quality and buy genuine excavator parts.

Supplier Reputation

Read Reviews

You should always check customer reviews before buying genuine excavator parts. Reviews help you know if a supplier is good or bad. Many people write about their experiences on Google, Yelp, and forums. Look for patterns in what people say. Good suppliers usually have high ratings and nice comments about delivery and support.

Look for the same problems or praise in reviews.

Read about how suppliers fix problems and handle warranties.

See if dealers talk openly and share clear records.

Customer stories and records can show if a supplier is reliable.

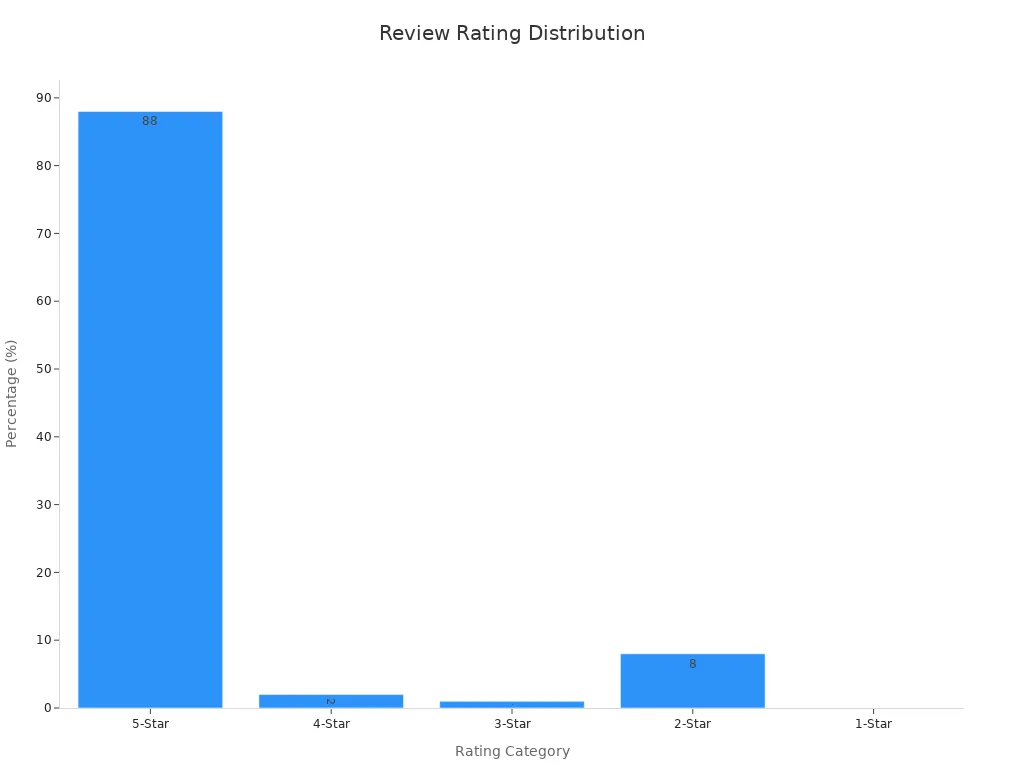

You can use review numbers to see if a supplier is trustworthy. For example, if a supplier has thousands of ratings and a score of 4.7 out of 5, that is a good sign. In one example, 88% of customers gave 5 stars, and only 1% gave 3 stars or less. This means most people are happy and trust these suppliers for quality.

Metric | Value |

|---|---|

Total Ratings | 21,527 |

Total Reviews | 1,191 |

Overall Rating | 4.7 out of 5 |

5-Star Ratings | 88% |

4-Star Ratings | 2% |

3-Star Ratings | 1% |

2-Star Ratings | 8% |

1-Star Ratings | 0% |

Pick suppliers for brands like Hitachi, Komatsu, and Caterpillar. These brands are known for being good and reliable.

Verify Certifications

You need to check certifications before buying genuine excavator parts. Certifications show that suppliers follow strict rules for quality and safety. The process checks the engine, hydraulics, and structure. It also tests fluids and repairs to meet safety laws. Certified suppliers use special IDs, QR codes, and safe packaging to stop fake parts.

Look for certifications from groups like the Texas National Equipment Register or the Association of Equipment Manufacturers.

Check for tests like ultrasonic scans and hardness tests.

Make sure suppliers work with trusted manufacturers for reliability.

Certifications from SGS and EPA mean suppliers follow big rules. These certifications show you get oem parts that are safe and high quality. Certified suppliers help you avoid breakdowns and save money on repairs. Always ask for proof of certification when you buy oem or aftermarket parts.

Tip: Good suppliers share their certification papers and test results. This helps you trust their parts and know they are reliable.

Warranty & Support

Check Guarantees

When you buy excavator wear parts online, always check the warranty. Good suppliers give clear return and exchange choices. You should see written guarantees for every oem part you order. These guarantees help if you get the wrong item or if a part breaks early. A strong warranty lets you get a new part fast and keeps your work going.

Look for suppliers who show their warranty rules on their website. Some companies have a table that lists coverage for each oem part. For example:

Part Type | Warranty Period | Coverage Details |

|---|---|---|

OEM Bucket Teeth | 12 months | Replacement for defects |

OEM Hydraulic Hoses | 6 months | Free exchange for leaks |

OEM Pins & Bushings | 12 months | Full refund or replacement |

Tip: Always keep your receipts and warranty papers. These documents help you get support if you need it.

A clear guarantee makes you feel safe. You know you can fix problems fast if something goes wrong.

After-Sales Service

Good customer support is just as important as a good warranty. You need a supplier who answers questions fast and solves problems quickly. Many people like Safe Spare Online for their helpful after-sales service. They say the team fixes shipping delays or wrong products right away. This kind of help keeps your work moving and stops long delays.

Pick suppliers who offer help by phone, email, or chat. Good after-sales service means you can ask about oem parts or get help with returns. Suppliers with clear return and refund rules are easy to trust. You know you can fix problems fast if you ever have one.

Customers often say that good after-sales help makes them feel sure when buying oem parts online.

When you choose a supplier with strong support, you protect your money. You also make sure your excavator works well with the right oem parts.

Compare Prices & Delivery

Buying Heavy Equipment Parts Online

When you buy heavy equipment parts, check prices from many vendors. This helps you avoid fake products and save money. Many online stores sell the same spare parts, but prices are different. Always look at each listing closely. Check the brand, warranty, and what other buyers say. These things help you choose the best part for your job.

You can use a table to compare prices and features:

Vendor | Price | Warranty | Availability | Customer Rating |

|---|---|---|---|---|

Vendor A | $250 | 12 mo | In Stock | 4.8/5 |

Vendor B | $230 | 6 mo | 2 Days | 4.5/5 |

Vendor C | $270 | 12 mo | In Stock | 4.9/5 |

Tip: Check if the part is in stock and how fast it ships. Fast shipping means less waiting and less time your machine is not working.

Buying heavy equipment parts online gives you more options and better deals. You can find spare parts for many machines. Always read the product details and make sure the part fits your machine.

Shipping & Import Duties

Shipping and import duties can change the total price you pay. Some vendors ship for free, but others charge more for fast shipping. Always check if the part is in stock and how long shipping takes. Quick shipping helps you finish your work on time.

If you buy from another country, you might pay extra import fees. These fees depend on where you live and what kind of part you buy. Always ask the seller about these costs before you order. This helps you plan your money and avoid surprises.

Note: Good vendors tell you about shipping times, costs, and if the part is in stock. Planning ahead helps you keep your work going without delays.

Order with Confidence

Secure Payment

When you buy excavator wear parts online, keep your money safe. Always pick secure ways to pay. Trusted suppliers let you use credit cards, PayPal, or bank transfers. These ways give you clear records of your payment. Before you pay, check if the bank account name matches the supplier’s name. If you see a different name, ask for proof of who owns the account. This step helps you stay away from scams.

Some businesses lost money because they did not check payment details. Do not trust only refund programs or trade assurance. Take time to check the supplier’s information. If you feel unsure, do not buy from them. You can ask for a video showing your order being loaded and sealed. This helps stop tampering and helps with insurance if something goes wrong.

Tip: Always save proof of your payment and ask for a receipt. This makes it easier to fix problems later.

Here is a quick checklist for a safe buy:

Use trusted ways to pay.

Make sure bank names match the supplier.

Ask for proof of who owns the account.

Ask for a video of loading if you can.

Keep all payment records and receipts.

What If Issues Arise

Sometimes, even if you do everything right, problems can happen. You might get the wrong part or a broken replacement. If this happens, contact the supplier right away. Good suppliers answer fast and help you fix the problem. Give them your order number, photos of the part, and explain what is wrong.

Most suppliers have rules for returns or exchanges. Read these rules before you buy. If you need to send a part back, follow the steps the supplier gives you. Keep all emails and messages about your order. This helps you track your request and get a quick answer.

If the supplier does not help or you feel unsafe, contact your payment provider. Many payment services can help you get your money back if you do not get what you ordered. Always be careful and protect your money when buying replacement parts online.

When you shop online for excavator wear parts, you want to keep your machine safe. Focus on making sure the parts fit, are good quality, and come from a trusted seller. Always look at your excavator’s bucket. Check for damage or signs of use. Compare the quality of parts from different sellers. Use this checklist to help you buy the right parts and make your machine last longer:

Key Performance Indicator | Description |

|---|---|

Depreciation Rate | New equipment can lose up to 40% of value in the first year. |

Signs of Wear and Tear | Look for coolant in oil, leaks, welds, and engine smoke colors on your excavator bucket. |

Operational Checks | Test drive, inspect the cab, and check bucket operation for precision. |

Total Cost of Ownership (TCO) | Add up all costs, including bucket maintenance and downtime, to measure true reliability. |

This guide will help you feel sure when buying excavator wear parts. You can keep your bucket and excavator working well and strong.

FAQ

How do you make sure a part fits your excavator?

Check your machine’s make, model, and serial number. Use your equipment manual or an online part finder. Contact the supplier’s support team for help. Always compare part numbers before you buy.

What should you do if you receive the wrong part?

Contact the supplier right away. Provide your order number and photos of the part. Follow the supplier’s return or exchange process. Keep all receipts and emails for your records.

How can you spot fake or low-quality excavator parts online?

Look for supplier certifications and customer reviews. Genuine parts come with warranty papers and clear branding. Avoid deals that seem too good to be true.

What shipping details should you check before ordering?

Confirm the part is in stock.

Ask about delivery times and shipping costs.

Check if import duties apply to your location.

Request tracking information for your order.