When you decide between genuine parts and aftermarket yanmar excavator parts, your best choice depends on what matters most to you. Genuine parts come from the original manufacturer. They fit perfectly, go through strict testing, and help keep your warranty safe. You get strong reliability and fewer surprises. Aftermarket options often save you cost and can be easier to find. Your decision will depend on how much you use your machine, what part you need, and how much you want to spend.

Key Takeaways

OEM parts offer the best fit, quality, and reliability, making them ideal for critical components and heavy use.

Aftermarket parts save money and provide more choices but vary in quality and may lack strong warranties.

Check part compatibility carefully when choosing aftermarket parts to avoid fit and performance issues.

Consider your machine’s age, usage, and part importance to decide between OEM and aftermarket options.

Buy high-quality aftermarket parts from trusted suppliers with certifications and positive reviews to protect your investment.

Aftermarket Yanmar Excavator Parts

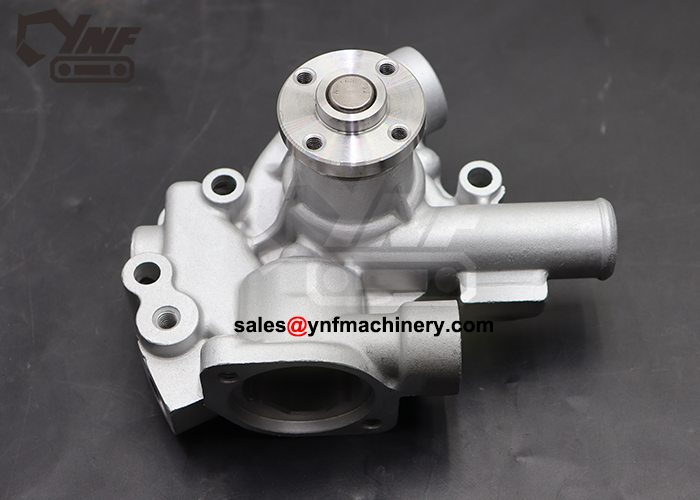

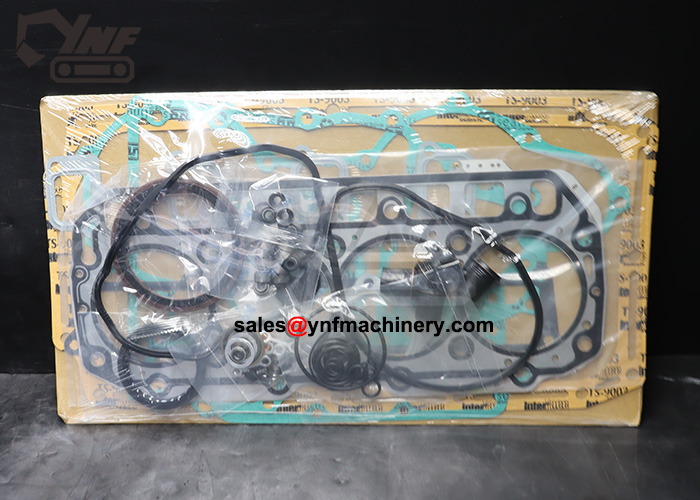

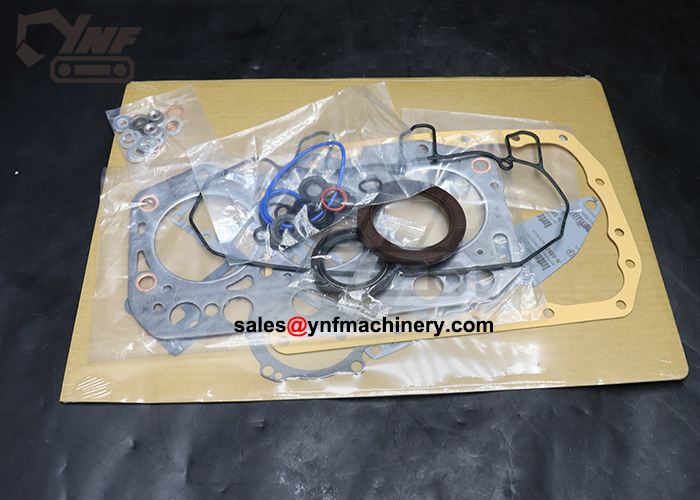

What Are Aftermarket Parts

You may see many choices when you shop for parts for your Yanmar excavator. Aftermarket yanmar excavator parts come from companies other than the original manufacturer. These companies design parts to fit and work like the originals. You can find a wide range of aftermarket parts for almost every part of your machine. Some brands focus on high-performance aftermarket parts, while others offer basic replacements. Many people choose aftermarket parts because they want more options and better prices.

Pros and Cons

When you look at aftermarket yanmar excavator parts, you will notice several advantages.

You can save a lot of money. Studies show that aftermarket parts often cost 30% to 70% less than new OEM parts. For example, replacing an alternator with aftermarket parts may save you $300 compared to OEM.

You get more choices. Aftermarket companies offer many types, from basic to high-performance aftermarket parts.

You can find parts more easily. Aftermarket suppliers often have better stock and faster shipping.

Tip: Always check the reputation of the supplier before you buy. Quality aftermarket parts can last a long time, but low-quality parts may not give you the durability or performance you expect.

However, aftermarket parts also have some drawbacks.

The quality can vary. Some parts work as well as OEM, but others may not last as long.

You may not get a warranty like you do with genuine parts.

Sometimes, fit or compatibility issues can happen, especially if you choose a less-known brand.

You should weigh these advantages and disadvantages before you decide. Many owners find that aftermarket yanmar excavator parts offer real cost savings and flexibility. If you pick trusted brands and check reviews, you can get high-performance aftermarket parts that meet your needs.

OEM Parts

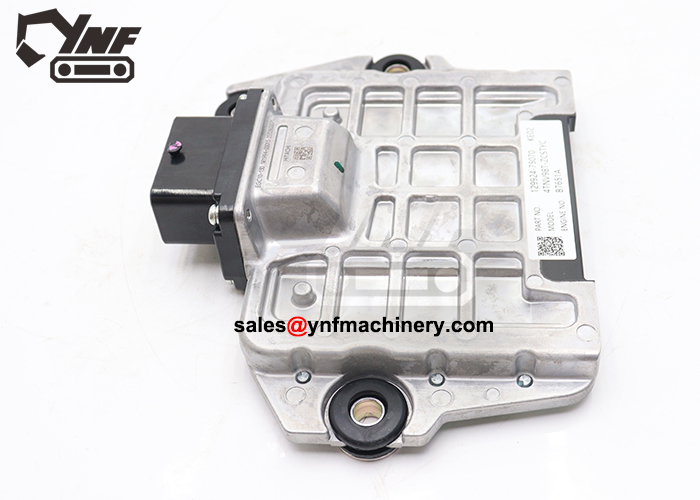

What Are OEM Parts

When you choose oem parts for your Yanmar excavator, you get parts made by the original equipment manufacturer. These oem parts match the exact specifications of your machine. The company that built your excavator also makes these oe parts. You can trust that oem parts will fit perfectly and work as intended. Many people call these parts oe parts because they come straight from the source.

You will notice that oem parts go through strict testing. The original equipment manufacturer checks each part for quality and performance. You can expect oem parts to last a long time. When you buy oe parts, you know you are getting the same parts that came with your machine when it was new.

Note: If you want to keep your excavator running like new, oem parts are a safe choice.

Pros and Cons

You should look at the advantages and disadvantages before you decide on oe parts. Here are some key points:

Advantages of OEM Parts:

You get the highest quality and reliability. Oem parts meet the standards set by the original equipment manufacturer.

Oem parts always fit your machine. You do not need to worry about compatibility.

Most oem parts come with a warranty. This gives you peace of mind.

Using oe parts can help keep your machine’s value high.

Disadvantages of OEM Parts:

Oem parts often cost more than aftermarket options.

Sometimes, you may have to wait longer for oem parts if they are not in stock.

You may have fewer choices compared to aftermarket suppliers.

You should weigh these advantages and disadvantages. If you want the best fit, quality, and support, oem parts are a strong option. Many owners choose oe parts for important repairs or when they want to protect their investment.

Quality and Reliability

Comparing Quality

When you look at Yanmar excavator parts, you want to know how the quality compares between genuine and aftermarket options. OEM parts come straight from the original manufacturer. These parts match your machine’s exact needs. You get high-quality parts that pass strict tests before they reach you. This means you can expect better engine performance and fewer problems over time.

Aftermarket parts give you more quality options. Some brands make parts that work almost as well as OEM. Others may not meet the same standards. You might find cheaper parts, but the quality can change from one brand to another. If you choose aftermarket parts, always check part numbers and reviews. This helps you avoid fit issues and keeps your machine running smoothly.

OEM parts guarantee compatibility and top quality.

Aftermarket parts cost less but may not last as long.

Certification and warranty differences affect long-term value.

For Yanmar engines, matching part numbers is very important.

Tip: If you want proven reliability and top performance, OEM parts are a safe bet. Aftermarket parts can work well if you pick trusted brands and double-check compatibility.

Reliability Differences

Reliability matters when you depend on your excavator for tough jobs. OEM parts offer manufacturer reliability because they fit perfectly and use strong materials. You can trust these parts to keep your machine working day after day. Most OEM parts come with longer warranties, so you get extra peace of mind.

Aftermarket parts can save you money, but reliability may not always match OEM. Some aftermarket parts work well for light jobs or older machines. Others might wear out faster or cause performance issues. Shorter warranties are common with aftermarket parts, so you may face more risk if something goes wrong.

You should think about how hard you use your excavator. If you need durability and want to avoid downtime, OEM parts give you the best chance for long-term success. For less critical repairs, high-quality aftermarket parts can still offer good performance at a lower price.

Feature | OEM Parts | Aftermarket Parts |

|---|---|---|

Quality | Consistent, high | Varies by brand |

Reliability | Very high | Can be lower |

Warranty | Longer, stronger | Shorter, limited |

Performance | Optimized | May vary |

Durability | Excellent | Depends on quality |

Remember: The right choice depends on your needs. If you want the best reliability and performance, OEM parts stand out. If you want to save money and can accept some risk, aftermarket parts may work for you.

Cost Comparison

Price Differences

When you shop for Yanmar excavator parts, you will notice a big difference in price between OEM and aftermarket options. OEM parts usually have a higher price because you pay for the brand and the original design. This is often called the “name-brand price.” For example, you might see an OEM part that costs $400, while an aftermarket version can cut that cost in half. Aftermarket parts come from many manufacturers, so they compete on price and often offer lower costs.

In the past, OEM parts could cost up to 800% more than generic alternatives. For instance, a fender once cost $500 as an OEM part but only $75 as a non-OEM part. As more aftermarket companies entered the market, OEM prices dropped by about 30%. This competition helps you find better deals and makes it easier to control your repair costs.

Part Type | OEM Price | Aftermarket Price |

|---|---|---|

Alternator | $400 | $200 |

Fender | $500 | $75 |

Hydraulic Filter | $120 | $60 |

You can save a lot on upfront cost by choosing aftermarket parts, especially for non-critical repairs.

Value for Money

You want to get the most out of every dollar you spend. OEM parts often give you better value over time, even though the initial cost is higher. These parts are made to fit your machine perfectly and use the same materials as the original. They also come with strong warranties, which protect you from extra repair costs later.

Independent tests show that OEM parts last longer and keep your machine running smoothly. For example, OEM batteries kept 95% of their power after long use, while aftermarket batteries dropped below 85%. Machines with OEM parts had 30% fewer surprise repairs. This means you spend less on fixing problems and avoid costly downtime.

OEM parts offer:

Reliable performance

Fewer breakdowns

Better warranty coverage

Aftermarket parts may save you money at first, but you might face more repairs and shorter part life.

If you want the best cost-effectiveness, think about how long you plan to keep your excavator and how much you use it. For heavy use or important parts, OEM parts often give you better value in the long run.

Compatibility and Fit

OEM Fit

When you choose oem parts for your Yanmar excavator, you get a perfect fit every time. These oe parts match your machine’s make, model, and serial number. You do not need to worry about compatibility. The manufacturer designs oem parts to meet strict standards. This means you avoid problems like leaks, loose fittings, or poor performance.

Oem parts keep your machine running smoothly.

You protect your equipment warranty when you use oe parts.

You do not face surprises with installation or function.

Using oem parts gives you peace of mind. You know each part will fit and work as intended. This level of compatibility helps you avoid costly mistakes or damage.

Aftermarket Fit

Aftermarket parts give you more choices and can save you money. However, you must pay close attention to compatibility. Not all aftermarket parts fit the same way as oe parts. Some brands make high-quality parts that match oem standards, but others may not.

Always check the part number in your service manual.

Look for aftermarket parts from reputable brands with good reviews.

Make sure the part matches your machine’s model and serial number.

If you pick the wrong part, you might face issues like poor fit or even damage to your excavator. Some aftermarket parts offer more flexibility, especially for older machines or when oem parts are hard to find. Still, you must balance cost savings with the risk of lower quality or compatibility problems.

Tip: Careful selection and research help you avoid low-quality or counterfeit parts. Always verify compatibility before you buy.

Availability

Sourcing OEM Parts

You may find that getting OEM parts for your Yanmar excavator depends on where you live and what part you need. In some regions, like Asia Pacific and North America, you have more choices because these areas have strong manufacturing and supply chains. Companies like Siemens AG and Genuine Parts Company have a global presence, so you can often find genuine parts in many countries.

However, you might face some challenges:

Supply chain disruptions can delay delivery, especially for special or rare parts.

High costs can make genuine parts harder to get, especially in developing regions.

Counterfeit and low-quality parts sometimes enter the market, so you need to buy from trusted sources.

Online platforms now help you find OEM parts more easily. Many suppliers use digital tools and even AI to manage inventory and speed up delivery. On-demand services can ship parts quickly, even to remote areas. This means you can keep your excavator running with less downtime.

Region | Availability of OEM Parts | Key Features |

|---|---|---|

Asia Pacific | Very High | Strong manufacturing, fast delivery |

North America | High | Advanced technology, trusted suppliers |

Europe | Moderate to High | Quality focus, reliable brands |

Latin America | Moderate | Growing access, some delays |

Middle East & Africa | Lower | Higher costs, longer wait times |

Tip: Always check the supplier’s reputation and look for warranty support when you buy OEM parts.

Sourcing Aftermarket Parts

You have many options when you look for aftermarket yanmar excavator parts. Aftermarket parts come from different brands and suppliers, so you can often find what you need quickly. Many online stores and local dealers stock a wide range of aftermarket yanmar excavator parts. This makes your selection process easier, especially if you want to save money or need a part fast.

Aftermarket suppliers often offer better availability than OEM sources. They keep large inventories and ship parts quickly. You can find aftermarket parts for both common and hard-to-find components. Some brands focus on high-quality replacements, while others offer budget-friendly options.

When you choose aftermarket yanmar excavator parts, you should:

Compare brands and read reviews to avoid low-quality products.

Check that the part matches your machine’s model and year.

Ask about return policies and support in case you have issues.

Aftermarket parts help you keep your excavator working, even if OEM parts are out of stock or too expensive. Many owners use aftermarket parts for routine repairs or when they need a quick fix. Your selection of aftermarket parts can make a big difference in cost and convenience.

Note: Fast shipping and wide selection make aftermarket yanmar excavator parts a popular choice for many owners.

Warranty and Support

OEM Warranty

When you choose OEM parts for your Yanmar excavator, you get strong warranty protection. OEMs stand behind their products with clear warranty terms. If a part fails, you can file a claim directly with the manufacturer or their dealer. This process gives you peace of mind because you know help is available if something goes wrong.

OEMs handle many warranty claims each year. For example, Cummins Inc., a major OEM, paid $704 million in warranty claims in 2024. This high number shows that OEMs take responsibility for their products. They often absorb minor warranty costs to keep customers satisfied. OEMs also use strict rules to manage claims and recover costs from their suppliers when needed. These rules help keep the warranty process fair and reliable for you.

You may notice that OEMs have higher warranty expense rates than aftermarket suppliers. This happens because OEMs deal directly with end-users and handle more claims. You benefit from this direct support, especially during recalls or large warranty campaigns.

Tip: Always keep your receipts and service records. These documents make warranty claims easier and faster.

Aftermarket Support

Aftermarket parts suppliers offer different support compared to OEMs. Most aftermarket companies provide basic warranties, but these are often shorter and less detailed. You may need to contact the retailer or distributor instead of the manufacturer if you have a problem.

Aftermarket suppliers handle fewer warranty claims. They have less direct contact with end-users, so their warranty expense rates stay lower. Companies like LKQ Corp. and AutoZone focus on quick replacements rather than complex claim processes. This means you might get a fast solution for small issues, but you may not receive the same level of support as with OEM parts.

Category | Warranty Expense Rate | Example Companies |

|---|---|---|

OEMs (Powertrain Manufacturers) | Higher | Cummins Inc. |

Aftermarket Parts Suppliers | Lower | LKQ Corp., AutoZone |

If you want strong support and clear warranty terms, OEM parts offer more protection. Aftermarket parts can save you money, but you may need to accept less support if problems arise.

How to Decide

Key Factors

Choosing between genuine and aftermarket parts for your Yanmar excavator can feel overwhelming. You want to make the best choice for your machine and your wallet. To help you decide, look at the most important factors that experts and studies highlight.

1. Consider the Key Factors

You should start by thinking about these main points:

Key Factors Influencing Maintenance Prioritization | Description |

|---|---|

Machine Age | Older machines may benefit from more affordable replacement parts, while newer machines often need genuine parts to protect value. |

Usage Intensity (Utilization Rate) | Machines that work hard every day need reliable parts. Less-used machines can sometimes use aftermarket options. |

Component Criticality | Some parts, like engine mounts or rubber tracks, are critical. Others, like mirrors or covers, are less important. |

Maintenance Cost | Your budget matters. Aftermarket parts often cost less, but may not last as long. |

Failure Frequency and Root Cause | If a part fails often, you may want the reliability of genuine parts. |

Availability of Support/Alternative Services | Easy access to parts and service can influence your choice. |

Studies show that these factors help you predict when and why a part might fail. Experts use scoring systems to rate how important each factor is. For example, they look at how hard a part is to replace, how much it costs, and how risky a failure would be.

2. Use a Step-by-Step Decision Framework

You can follow a simple process to make your choice:

List your needs: Write down your machine’s age, how often you use it, and which part you need.

Rate the part’s importance: Is it critical for safety or performance? If yes, lean toward genuine parts.

Check your budget: Decide how much you want to spend. Aftermarket replacement parts can save money, but may not last as long.

Look at availability: Can you get the part quickly? Sometimes aftermarket suppliers have faster shipping.

Think about legal rules: Some states, like California, have strict emissions laws. You may need genuine parts to stay legal.

Review support and warranty: Genuine parts often come with better support and longer warranties.

A multi-criteria decision-making framework helps you weigh these factors. Experts use methods like AHP and fuzzy logic to rank what matters most—quality, cost, reliability, and delivery. You can use a simple checklist or table to compare your options.

3. Match Part Type to the Right Choice

Choose genuine parts for:

Engine mounts

Hydraulic pumps

Rubber tracks

Electrical systems

Any part linked to safety or emissions

Choose aftermarket parts for:

Body panels

Mirrors

Lights

Older machines where value is less of a concern

Hard-to-find or discontinued parts

Tip: If you use your excavator every day or for heavy jobs, genuine parts give you peace of mind. For less critical repairs or older equipment, high-quality aftermarket replacement parts can be a smart way to save money.

4. Remember Legal and Environmental Rules

Some areas have strict rules about emissions and safety. For example, California requires certain parts to meet emissions standards. Using non-genuine parts could lead to fines or failed inspections. Always check local laws before you buy.

5. Make Your Final Choice

You know your machine best. Use the table above and your own needs to guide your decision. If you want the best reliability and warranty, choose genuine parts. If you need to save money and the part is not critical, aftermarket replacement parts may work well.

Note: No single answer fits everyone. Your decision depends on your machine, your work, and your budget. Take your time and choose what works best for you.

Buying High-Quality Aftermarket Parts

Tips for Buyers

When you start buying high-quality aftermarket parts, you want to make smart choices. You should always research brands before you buy. Look for suppliers with a strong reputation and positive reviews from other excavator owners. Trusted dealers often provide better support and stand behind their products.

Here are some steps you can follow:

Purchase from authorized dealers to avoid counterfeits.

Check for security labels or QR codes on the packaging. Scan them to confirm the part’s traceability.

Inspect the packaging and logos. Genuine parts have clear, consistent branding.

Ask for certification or compliance reports to make sure the part meets quality standards.

Be careful with prices that seem too low. Very cheap parts may be fake or low quality.

Emphasize the Importance of Community Feedback and Certifications

Community feedback helps you find high-quality aftermarket parts. Read online forums and customer reviews. Other owners share their experiences and warn about bad products. This feedback can guide you to reliable brands.

Certifications also matter. Look for parts with CAPA or ISO 9001 certification. CAPA certification means the part is functionally equal to OEM and passes strict tests, including crash safety. ISO 9001 shows the manufacturer follows strong quality management rules. Many factories that make OEM parts also make aftermarket parts in ISO 9001 certified facilities. These certifications help you trust that the parts will last and perform well.

Quality Aspect | OEM Parts | High-Quality Aftermarket Parts | Low-Quality Aftermarket Parts |

|---|---|---|---|

Material Quality | High-grade materials per OEM specs | Often matches or slightly deviates | Uses inferior or substandard materials |

Certification & Testing | Meets original manufacturer’s standards | Certified by third-party regulators | No certification or proof of quality |

Manufacturer Reputation | Established OEM brands | Trusted aftermarket brands with proven reliability | Unknown or unverified manufacturers |

Price | Expensive but ensures longevity | Mid-range pricing with good value | Extremely cheap with compromised durability |

Warn About Risks of Low-Quality Parts and How to Avoid Them

Low-quality parts can cause big problems for your excavator. They may wear out quickly, break during use, or even damage your machine. You might lose money and face more repairs.

To avoid these risks:

Always check for certifications and security features.

Use advanced tools like QR code scanning or hologram labels to verify authenticity.

Stay away from unknown brands or sellers with poor reviews.

Remember, if a deal looks too good to be true, it probably is.

Tip: High-quality aftermarket parts protect your investment and keep your excavator running safely. Take your time to research and choose wisely.

You have many choices when you buy parts for your Yanmar excavator. Both genuine and aftermarket parts serve important roles. Genuine parts give you strong reliability and warranty. Aftermarket parts help you save money and find parts quickly. Use the table below to compare your options:

Aspect | OEM Parts | Aftermarket Parts |

|---|---|---|

Quality | High, consistent | Varies by brand |

Cost | Higher | Lower |

Durability | Long-lasting | Can be shorter |

Availability | Sometimes limited | Widely available |

Compatibility | Guaranteed | May vary |

Choose the parts that fit your needs and budget. Use the tips in this guide to make a smart, confident decision.

FAQ

What is the main difference between OEM and aftermarket parts?

OEM parts come from the original manufacturer. Aftermarket parts come from other companies. OEM parts fit perfectly and meet strict standards. Aftermarket parts can save you money and offer more choices, but quality may vary.

Will using aftermarket parts void my Yanmar excavator warranty?

Using aftermarket parts may affect your warranty. If a non-OEM part causes damage, the warranty may not cover repairs. Always check your warranty terms before you install aftermarket parts.

How can you tell if an aftermarket part is high quality?

You should check for certifications like ISO 9001 or CAPA. Read reviews from other users. Buy from trusted brands and suppliers. Look for clear packaging and security labels.

Are aftermarket parts safe for critical components?

You should use OEM parts for critical components like engines or hydraulic pumps. Aftermarket parts may not always meet the same safety or performance standards. For less important parts, high-quality aftermarket options can work well.

Can you mix OEM and aftermarket parts on the same machine?

Yes, you can mix them. Many owners do this to save money. Always make sure each part fits your model. Mixing parts does not harm your machine if you choose quality products.