You need the right k3v112dt hydraulic pump for your equipment. This helps your machines work well and not break down. You should match the technical details, size, and control types to your system. This makes your hydraulic equipment work better and last longer. Every hydraulic system needs a certain flow and pressure. These needs change how well your equipment works. Pumps that fit right move fluid well and keep your system working well.

If you pick the wrong pump, parts can wear out faster. This can make repairs cost more. Your machine may not work well or could even break badly.

If you pick the right pump, you save money and time. You also stop your equipment from breaking down.

Key Takeaways

-

Pick the right K3V112DT pump so your equipment works well and lasts longer.

-

Always make sure the pump’s flow rate and pressure match what your equipment needs to stop breakdowns.

-

Check the pump’s size and how it mounts to make sure it fits right.

-

Think about the rotation direction and control type to make sure the pump works with your machine.

-

Talk to a hydraulic expert to avoid mistakes and make sure you pick the best pump for your needs.

K3V112DT and Kawasaki Hydraulic Pumps Overview

Key Features of K3V112DT

You want a pump that works well and lasts long. The K3V112DT is special in the k3v series. It uses advanced axial piston pumps technology. This helps the pump work better and stay strong. The pump has a variable displacement feature. This lets you change flow rates but keep pressure steady. You get good performance and save energy.

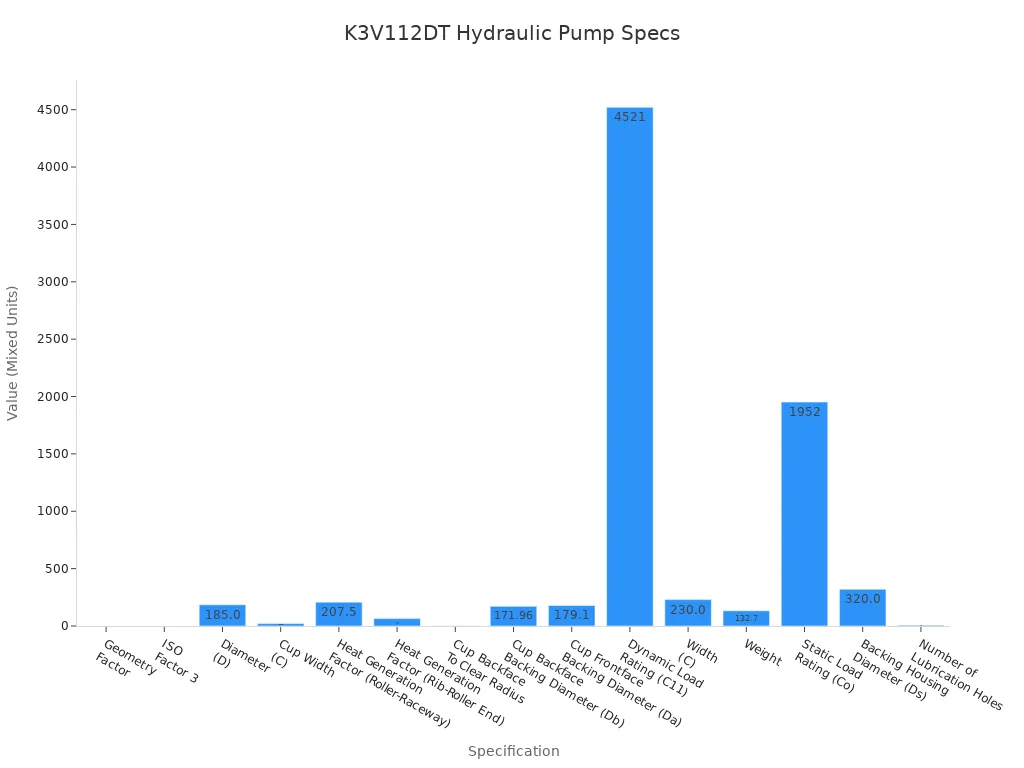

Here are some main technical specifications for the K3V112DT:

|

Specification |

Value |

|---|---|

|

Geometry Factor |

0.103 |

|

ISO Factor 3 |

0.47 |

|

Diameter (D) |

185.000 mm |

|

Cup Width (C) |

21.000 mm |

|

Heat Generation Factor (Roller-Raceway) |

207.5 |

|

Heat Generation Factor (Rib-Roller End) |

64.6 |

|

Cup Backface To Clear Radius |

3.05 mm |

|

Cup Backface Backing Diameter (Db) |

171.96 mm |

|

Cup Frontface Backing Diameter (Da) |

179.10 mm |

|

Dynamic Load Rating (C11) |

4521 kN |

|

Width (C) |

230.000 mm |

|

Weight |

132.700 lb |

|

Static Load Rating (Co) |

1952 kN |

|

Backing Housing Diameter (Ds) |

320.0 mm |

|

Number of Lubrication Holes |

6 |

Kawasaki hydraulic pumps like the K3V112DT are high-quality. They work well even in hard jobs. You get strong durability and less downtime with kawasaki pumps. The design helps you save energy. Your equipment runs smoothly.

Common Uses for Kawasaki Hydraulic Pumps

You can find kawasaki hydraulic pumps in many places. These pumps power machines that need strong hydraulic force. Kawasaki pumps last a long time and work well in tough jobs. Many companies pick kawasaki for their high-quality pumps and advanced axial piston pumps.

|

Industry |

Typical Applications |

|---|---|

|

Construction |

Excavators (main pumps for boom, arm, bucket, swing) |

|

Heavy Machinery |

Wheel loaders and crawler machines |

|

Lifting Equipment |

Cranes and piling equipment |

|

Concrete and Industrial Systems |

Concrete pumps and industrial hydraulic systems |

You see kawasaki pumps in construction and heavy machinery. They are also in lifting equipment. These axial piston pumps help you move, lift, and build. Kawasaki pumps give you strong and steady hydraulic power for every job.

Assessing Your Equipment’s Needs

Flow, Pressure, and Duty Cycle

You need to know how much power your equipment uses every day. When you look at kawasaki pumps, check the flow rate first. Flow rate tells you how much hydraulic fluid moves through the pump in one minute. If you use excavators, you want a pump that can keep up with fast and heavy work. Pressure is just as important. Pressure shows how much force the pump can create. Many kawasaki pumps work at high pressure, which helps your machines lift and move heavy loads.

Duty cycle means how long your equipment runs without stopping. Some excavators work all day, while others only run for a few hours. If you use your machines for long hours, pick kawasaki pumps built for heavy-duty cycles. This choice helps you get better performance and longer life from your hydraulic system. Always match the pump’s flow and pressure to your equipment’s needs. This step keeps your kawasaki pumps running smoothly and avoids damage.

Physical Dimensions and Mounting

You must check if the pump fits your machine. Start by looking at the size and shape of the kawasaki pump. Many excavators need a pump that matches the original equipment. If you use a K3V112DT, make sure the physical dimensions are the same as the OEM unit.

-

Check the flange dimensions to ensure a proper fit.

-

Match the shaft diameter to your current system.

-

Use the same mounting bolt pattern as the original pump.

These steps help you avoid problems during installation. If the pump does not fit, your equipment may not work right. Many kawasaki pumps have different sizes, so always compare the measurements. You can find this information in your equipment manual or by asking a kawasaki expert. When you pick the right pump, you get better performance and less downtime for your excavators. This careful check keeps your hydraulic system strong and reliable.

Matching K3V112DT Pump to Your Equipment

Rotation and Control Type

You need to check the rotation direction before you install a k3v112dt pump. Some kawasaki pumps turn clockwise, while others turn counterclockwise. If you use the wrong rotation, your hydraulic system will not work. Always look at your equipment manual or the old pump’s label to find the correct direction.

Control type is also important. The k3v112dt comes with different control options. You might see manual, electric, or hydraulic controls. Each type changes how you operate your equipment. For example, some excavators need electric control for fast response. Others use manual control for simple jobs. If you pick the wrong control type, your kawasaki pump for your equipment may not respond as you expect.

Tip: Always match the rotation and control type to your machine’s needs. This step helps you avoid costly mistakes and keeps your kawasaki pumps running smoothly.

Compatibility Checks for Kawasaki Pump

You must make sure the k3v112dt fits your equipment. Start by checking the mounting footprint. The pump should match the bolt pattern on your machine. Next, look at the shaft size. If the shaft does not fit, you cannot connect the pump to your system.

Port locations matter too. The hydraulic lines must connect easily to the pump. If the ports are in the wrong place, you may need extra parts or hoses. This can lower performance and cause leaks. Always measure the overall length of the pump. Some kawasaki pumps are longer or shorter than others. If the pump is too long, it may not fit in your equipment.

Here is a table that shows how equipment makers list compatibility for the k3v112dt:

|

OEM Model |

Compatible Equip |

Replacement P/N |

|---|---|---|

|

K3V112DT |

Hitachi SH210-5, SH240-5, ZX210, ZX240 |

YNF-K3V112DT |

You should also check these main points before you buy a kawasaki pump for your equipment:

-

Working pressure (Bar)

-

Flow rate (L/min)

-

Port size

If you skip these checks, you may face problems. Some common issues include low efficiency, oil contamination, leaks, and noise. These problems can hurt your hydraulic system and lower performance. You want your kawasaki pumps to work well and last long.

-

Efficiency issues can slow down your loaders or other machines.

-

Oil contamination can damage the k3v112dt and other parts.

-

Leaks can waste oil and cause safety risks.

-

Noise can mean something is wrong inside the pump.

Note: Always read your equipment manual or talk to a kawasaki expert. They can help you confirm if the k3v112dt is the right choice. This step protects your investment and keeps your hydraulic pumps working at their best.

By following these steps, you make sure your kawasaki pump for your equipment fits well and works right. You get better performance, less downtime, and a longer life for your hydraulic system.

Choosing New, Remanufactured, or Aftermarket Options

Pros and Cons of Each Option

When you pick kawasaki hydraulic pumps, you have three choices. You can buy new, remanufactured, or aftermarket kawasaki pumps. Each choice has good and bad points. You should know these before you decide. This helps your machine work well and last longer.

Here is a table that lists the main pros and cons for each option:

|

Type |

Pros |

Cons |

|---|---|---|

|

Remanufactured Pump |

Cost-effective, sustainable |

Inconsistent quality due to varying rebuild processes |

|

New Pump |

Latest technology, full warranties |

Higher cost |

|

Aftermarket Pump |

Balance of cost and reliability |

Quality variances |

New kawasaki pumps use the newest technology. You get a full warranty and top performance. These pumps cost more, but they last a long time. Remanufactured kawasaki pumps save money and help the planet. They work like new, but quality can change because rebuilds are different. Aftermarket kawasaki pumps cost less than new ones. They are often reliable, but quality can be different with each brand.

Tip: Always check if the supplier is trusted before you buy aftermarket kawasaki pumps. This helps you avoid bad products.

Cost, Warranty, and Support

Price is important when you choose kawasaki hydraulic pumps. New pumps cost the most, but you get strong support and a full warranty. Remanufactured kawasaki pumps are cheaper and may have a short warranty. Aftermarket kawasaki pumps usually cost the least, but their warranty may be short.

You should always ask about support. Good support helps you fix problems fast and keeps your machines working. YNF Machinery sells new, remanufactured, and aftermarket kawasaki pumps. They help you pick the right pump and answer questions about setup or care.

When you compare, look at more than just price. Think about how long the warranty lasts, how good the support is, and how each pump affects your machine. The right kawasaki hydraulic pumps help your machines work longer and stop breakdowns.

Tips and Mistakes to Avoid with Kawasaki Pumps

Expert Consultation

You want your kawasaki pumps to work well for a long time. Experts have some steps to help you pick the right kawasaki pump. These tips help you avoid problems and get good results:

-

Know your equipment. Check your machine’s make and model. Find out what hydraulic system you have and the original pump model.

-

Match the specs. Look at details like displacement, shaft style, mounting flange, rotation direction, and port locations. Make sure your kawasaki pump matches these things.

-

Think about how you use your equipment. Check the pressure range and how often you use it. Also, think about where your kawasaki pumps will run.

-

Choose between new, remanufactured, or aftermarket kawasaki pumps. Each one has good and bad points.

-

Get help from an expert. Ask a kawasaki specialist or supplier if you are not sure. They can help you check fit and specs.

Tip: Always talk to a kawasaki expert before you buy a pump. This helps you avoid mistakes and keeps your equipment working well.

Common Selection Errors

Many people make easy mistakes when picking kawasaki pumps. You can avoid these by checking a few important things:

-

Not checking rotation direction. If you pick the wrong rotation, your kawasaki system will not work.

-

Using the wrong mounting. Make sure the flange and bolt pattern match your machine.

-

Not checking shaft size. The shaft must fit your machine, or the kawasaki pump will not connect.

-

Forgetting about port locations. Ports must line up with your hydraulic lines for easy setup.

-

Not checking compatibility. Always compare your kawasaki pump specs with your equipment manual.

|

Mistake |

How to Avoid |

|---|---|

|

Wrong rotation |

Check manual and old pump label |

|

Incorrect mounting |

Match flange and bolt pattern |

|

Shaft mismatch |

Measure shaft size carefully |

|

Port misalignment |

Review port locations before buying |

|

Spec mismatch |

Consult kawasaki experts |

Note: Careful checks help you stop downtime and keep your kawasaki pumps working their best.

You now know the key steps to choose the right K3V112DT hydraulic pump. Always check the technical specs, size, and control type. Make sure the pump fits your equipment. Review your manual and compare all details. If you feel unsure, talk to a hydraulic expert or trusted supplier. They can help you avoid costly mistakes.

Need more help? Contact a professional for advice or check our resources for more support. 🛠️

FAQ

How do you know if the K3V112DT pump fits your equipment?

Look in your equipment manual for pump details. Check if the mounting, shaft size, and port spots match. If you are not sure, ask a supplier or expert. Make sure the pump’s rotation and control type fit your machine.

What maintenance does a K3V112DT hydraulic pump need?

Check for leaks and look at fluid levels often. Clean the filters to keep them clear. Change seals if they look worn out. Listen for strange noise or shaking. Taking care of your pump helps it last longer and work better.

Can you use aftermarket parts with a Kawasaki pump?

You can use aftermarket parts if they fit Kawasaki’s rules. Always buy from trusted sellers. Bad parts can cause leaks or break your pump. Ask an expert before you put in aftermarket parts.

What signs show your hydraulic pump needs replacement?

Look for slow movement, loud sounds, leaks, or heat. If your machine loses power or fluid, the pump may be bad. Change the pump fast to stop bigger problems.

Where can you get help choosing the right pump?

Talk to a hydraulic expert or your equipment dealer. Many sellers can give help and advice. You can also look online or ask Kawasaki experts for help. 🛠️