Lift trucks & tables excavator hydraulic pump systems allow you to move heavy items with ease. By utilizing a hydraulic system powered by an excavator hydraulic pump, these lift trucks & tables make lifting safer and less strenuous. Manual lifting is a common cause of workplace injuries, but lift trucks & tables equipped with an excavator hydraulic pump significantly reduce these risks. Hydraulic systems also boost efficiency, saving time and effort when transporting materials.

Key Takeaways

Hydraulic lift tables help people move heavy things safely. They make it easier and lower the chance of getting hurt at work. These tables help workers do their jobs faster and better. Workers can lift and lower things quickly with them. Hydraulic lift tables also help keep workers safe from hurting their bodies. They stop workers from feeling pain or strain when lifting. Taking care of hydraulic systems often makes them last longer. It also helps them work well and saves money over time. Picking the right hydraulic lift table for your needs keeps everyone safe. It also helps work get done better and faster.

Hydraulic Lift Tables Overview

What Are Hydraulic Lift Tables

Hydraulic lift tables help people move heavy things at work. You can find these tables in places like warehouses and factories. They use hydraulic power to lift or lower a platform. This makes it easier to handle big or bulky items. Hydraulic lift tables are important for moving materials. They let you lift, lower, and place things safely and quickly.

Here is a table that shows what hydraulic lift tables do in industrial settings:

Functionality | Description |

|---|---|

Lifting Heavy Loads | Hydraulic lift tables raise or lower heavy loads with a hydraulic system. |

Improving Safety | They help stop injuries by removing the need to lift heavy things by hand. |

Enhancing Productivity | They make moving materials faster, so work gets done quicker. |

Ergonomic Working Height | Workers can use them at a height that helps prevent strain and injury. |

Precision in Lifting | You can adjust the table carefully to put things in the right spot, which keeps everyone safe. |

Hydraulic lift tables give you and your team many benefits:

You can work at a height that feels comfortable.

You do not have to lift things that are too heavy.

You avoid lifting things above your head, which can hurt you.

Most hydraulic lift tables come in different sizes and can hold different weights. For example, scissor lift tables can lift from 2,000 to 10,000 pounds. Some, like Wesco lift tables, can hold 200 to 6,000 pounds. There are custom tables for even heavier loads.

Hydraulic Scissor Lift Table Mechanism

A hydraulic scissor lift table uses a special way to move its platform up and down. Under the table, there are metal supports that cross each other. These supports look like scissors, so people call them scissor lift tables. When you turn on the hydraulic system, fluid goes into cylinders. The fluid pushes the cylinders out. This makes the scissor legs open wider. As the legs open, the platform goes up.

The hydraulic system has cylinders, hydraulic fluid, and a pump. When you start the pump, it sends fluid into the cylinders. This makes pressure that lifts the table. Valves control how much fluid moves. You can lower the table by letting fluid out slowly. This helps you put things exactly where you want them.

Hydraulic lift tables mean you do not have to lift things by hand. You can do tasks while standing or sitting comfortably. This helps stop injuries to muscles and joints. Using hydraulic lift tables at work leads to fewer injuries and better work results.

Tip: Always check how much weight your hydraulic lift table can hold before you use it. This keeps you safe and helps prevent accidents.

Key Components & Mechanics

Knowing how hydraulic lift tables work helps you use them right. Each part has a job in lifting heavy things. Let’s see what the main parts do together.

Platform, Base, and Scissor Legs

Every hydraulic lift table has three main parts. The platform is flat and holds your load. The base keeps the table steady when it lifts. The scissor legs link the platform and base. These legs move in a crisscross way to lift or lower the platform.

Most makers use strong stuff for these parts. The table below shows what materials are used:

Component | Material |

|---|---|

Platform | Steel |

Base | Steel |

Scissor Legs | Rugged .75″ steel plate |

Steel makes the table tough and long-lasting. The scissor legs use thick steel plates. They can hold heavy things and get used a lot. This design lets you lift big loads without bending or breaking the table.

Note: Always check the weight limit before you use your lift table. Picking the right table keeps you safe and protects your gear.

Hydraulic Cylinders and Pumps

The hydraulic system is the most important part of the lift table. You will find a hydraulic pump, cylinders, and control valves. The pump pushes oil into the cylinder. This makes pressure and moves a piston inside. When the piston goes up, it pushes the scissor legs apart. This lifts the platform.

Here is a table that explains what each hydraulic part does:

Component | Function |

|---|---|

Pumps oil into the cylinder, creating pressure to lift the platform. | |

Hydraulic Cylinder | Moves the piston upward when oil enters, raising the load. |

Valve | Controls oil flow, letting the platform lower safely by releasing oil. |

Most lift tables use a pump powered by electricity. When you press the button, the pump starts and sends oil into the cylinder. The system uses single acting cylinders. Oil pressure lifts the platform. Gravity lowers it when you let go of the valve. This makes lifting easy and safe for everyone.

Hydraulic lift tables use an electric motor for the pump.

The hydraulic cylinder lifts the platform when oil pressure goes up.

The valve lets you lower the platform slowly and safely.

If you take care of your hydraulic system, it can last many years. Many hydraulic cylinders are built to be very safe. With good care, they can last a lifetime. If you use your lift table up to eight times each hour and check it often, it can work for over 20 years.

Lift Trucks & Tables Excavator Hydraulic Pump

The lift trucks & tables excavator hydraulic pump is a key part of many material handling systems today. This pump powers the hydraulic system. It helps you lift and move heavy things easily. You will find this pump in lift tables and lift trucks. It works by moving oil into the hydraulic cylinder. This raises the platform or forks.

Lift trucks & tables excavator hydraulic pump systems have many good points:

They give strong and steady lifting power.

They help you move heavy things safely and fast.

They lower the chance of getting hurt from lifting by hand.

Many factories use lift trucks & tables excavator hydraulic pump systems because they work well and last long. You can count on these systems to do hard jobs every day.

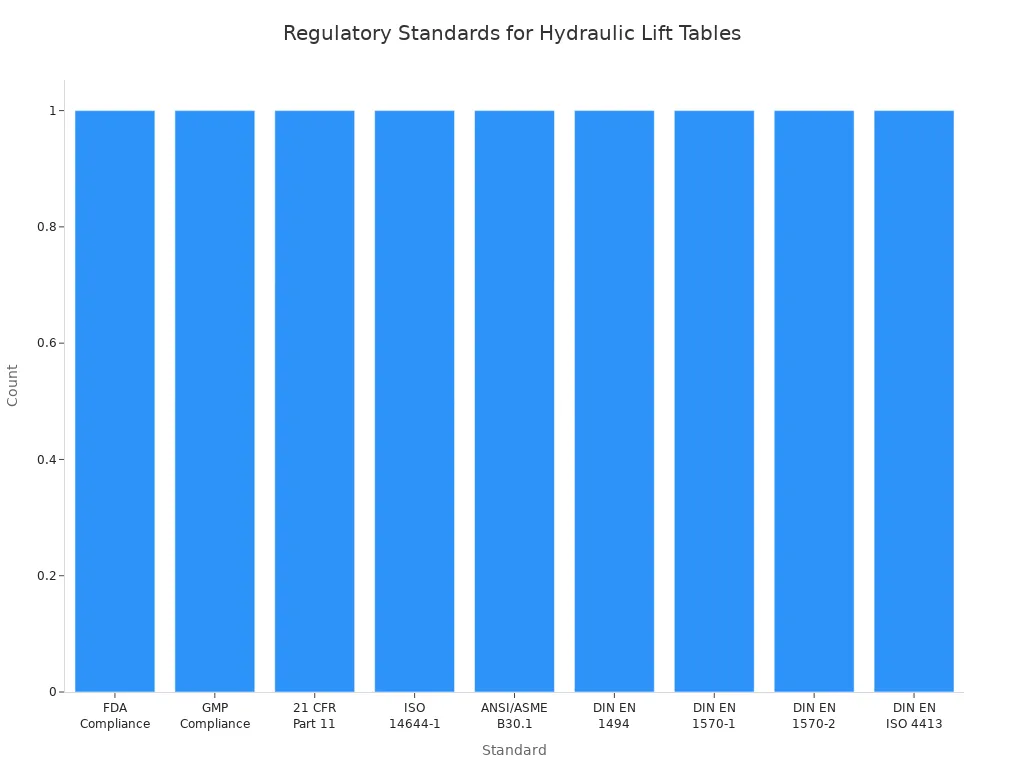

Hydraulic lift tables and trucks must follow strict safety rules. The table below lists some important rules:

Standard | Description |

|---|---|

FDA Compliance | Makes sure equipment does not spoil products and keeps quality. |

GMP Compliance | Makes sure making things is always controlled and the same. |

21 CFR Part 11 | Sets rules for electronic records and controls for equipment with software. |

ISO 14644-1 | Sets cleanroom classes and limits for particles. |

ANSI/ASME B30.1 | Gives design and safety rules for lift tables. |

DIN EN 1494 | Safety rules for mobile lifting devices. |

DIN EN 1570-1 | Safety rules for lift tables up to two levels. |

DIN EN 1570-2 | Safety rules for lift tables with more than two levels. |

DIN EN ISO 4413 | General safety rules for hydraulic systems. |

You can also see the main safety rules in the chart below:

Tip: Always follow safety rules and check your equipment often. This keeps your lift trucks & tables excavator hydraulic pump system working well and safely.

Operation Steps

Raising and Lowering Loads

You can use high-lift pallet trucks and hydraulic lift tables easily. First, put the load on the platform or forks. Make sure the load is in the middle so it does not tip. Use the control lever or button to lift the heavy load. The hydraulic pump sends fluid into the cylinder. This pushes the platform or forks up. You can stop at any height you need. This helps you handle or load heavy things.

To lower the load, let go of the control slowly. The valve lets the hydraulic fluid go back. The platform or forks move down gently. Always keep your hands and feet away from moving parts. High-lift pallet trucks make lifting heavy loads safer and quicker than lifting by hand.

Tip: Always check the weight limit before you lift anything. This helps you stay safe and keeps your equipment working well.

Safety Features

Modern high-lift pallet trucks and hydraulic lift tables have many safety features to protect you and your team:

Safety trip bars stop the table if something gets stuck.

Safety skirts or barriers cover moving parts.

Emergency stop buttons let you stop the lift fast.

Anti-slip platforms help prevent slips and falls.

Velocity fuses stop quick drops if a hose breaks.

Overload protection stops you from lifting too much.

The Guardian Lift can lift up to 1,100 lbs. It gives extra space between the scissor arms for safety. Always follow safety rules and check your equipment before you use it.

Manual vs. Hydraulic Lift Tables

You might wonder if manual or hydraulic high-lift pallet trucks are better for you. Manual tables use a hand crank or foot pedal. These need more effort and take more time to lift heavy loads. Hydraulic tables use a pump and motor. This makes lifting easier and faster.

Here is a table to help you compare:

Feature | Manual Lift Table | Hydraulic Lift Table |

|---|---|---|

Labor Needed | High | Low |

Cost | Lower upfront | Higher upfront |

Safety and Efficiency | Lower | Higher |

Best For | Light loads, small jobs | Heavy object loading, frequent use |

Hydraulic high-lift pallet trucks save time and lower strain. You get better safety and work faster in busy places.

Note: Operators must know equipment rules and safety features. Training should teach proper loading, emergency steps, and regular care. Certification makes sure you can use high-lift pallet trucks safely.

Benefits

Ergonomics and Safety

Lift tables help you work in a safer way. They stop many injuries from lifting heavy things by hand. You keep your body in a good position and lower muscle strain. Lift tables raise things to a height that feels right. You do not need to bend or stretch in odd ways. You also avoid doing the same motion over and over.

Here is a table that shows how lift tables keep you safe:

Ergonomic Risk | Description |

|---|---|

Awkward postures | Lift tables help you stay in a safe work zone. |

Repetitive motions | You bend less, so you get hurt less. |

Forceful exertions | You lift things in a strong spot, so it is safer. |

Pressure points | You avoid hurting yourself by lifting things higher. |

Static postures | You move around more, so you do not stay still too long. |

Tip: Using lift tables helps you stay healthy and lowers injuries at work.

Efficiency and Productivity

Lift tables help you finish jobs faster. You spend less time moving heavy things. You can focus on your main work instead of lifting by hand. Hydraulic lift tables make work go smoother and help warehouses run better. You get better results because you move things quickly and safely.

You save time by lifting with a button or lever.

You make your warehouse work better by moving more things fast.

Your team can do important jobs, not just heavy lifting.

Callout: Lift tables help you get more work done and stop delays.

Durability and Cost-Effectiveness

Lift tables last a long time if you care for them. You follow easy steps to keep your lift table working well. You check the table often, oil the moving parts, and look at the hydraulic system. You clean the table and teach your team to use it safely. You call experts for big repairs and write down all care steps.

Here is a list of ways to keep your lift tables strong and save money:

Check the table often for damage or wear.

Oil moving parts as the maker says.

Look at hoses, fittings, and fluid levels.

Test safety features to see if they work.

Clean the table and take away trash.

Teach workers how to use and care for the table.

Get experts for big repairs.

Write down all care and fixes.

Lift tables use less energy than other lifting machines. Hydraulic lift tables need less power for heavy jobs. You save money on energy and get more lifting strength than other systems.

Lifting System | Energy Consumption Comparison |

|---|---|

Hydraulic Lift Tables | Uses less power for heavy loads |

Electro-Mechanical Systems | Needs much more power |

Pneumatic Systems | Not as good as hydraulic systems |

You pick lift tables because they last long, use less energy, and save money over time.

Types & Configurations

Industrial Lift Tables

There are many kinds of lift tables used in factories. Each kind helps with different jobs. The table below shows the main types and what they do:

Type of Lift Table | Description |

|---|---|

Hydraulic Scissor Lift | Used for lifting heavy things. Good for moving pallets and setting work height. |

Multi-Stage Lift Table | Has stacked scissor parts for more height. Fits small spaces and works for tall tasks. |

Heavy-Duty Lift Table | Made for very heavy loads. Has strong parts for tough jobs. |

Post Lift Table | Uses straight posts to hold things up. Lets you reach under the table easily. Good for workbenches. |

Low Profile Lift Table | Sits close to the ground. Easy for forklifts to load things on it. |

Hydraulic lift tables are strong and can do many jobs. You can pick a table that fits your load, height, and workspace. These tables help you work faster and keep you safe in factories.

Hydraulic Scissor Lift Table Applications

Hydraulic lift tables are used in lots of places. You see them in factories, warehouses, and hospitals. Here are some ways people use hydraulic scissor lift tables:

Getting things from high shelves: You can reach and move products stored up high.

Loading and unloading: You lift heavy machines into trucks.

Moving things: You carry items around a warehouse when they are too heavy.

Helping workers: Construction teams use lift tables to reach tall spots.

Helping patients: Nurses use lift tables to move patients into better positions.

You can choose different styles. Some tables spin so you can reach things easier. Others lift very heavy things or go up very high. Custom sizes help you handle any job.

Tip: Hydraulic lift tables make work safer and easier. You do not have to bend or lift by hand, so you stay healthy and less tired.

Choosing the Right Hydraulic Lift Tables

Think about a few things before you buy a hydraulic lift table. Ask yourself these questions:

Why do you need to lift something?

How will you put things on the table?

Will you use it in cold or food areas?

Do you need the table to stop at different heights?

Will you put a conveyor belt on top?

Will you put the table in a pit?

Do you want the hydraulic system outside the table?

What motor do you need?

What power do you have?

Do you need controls that are safe for explosions?

Will people stand on the table?

New hydraulic lift tables have smart features and are easy to use. Some have remote controls, automatic lifts, and can lift very heavy things. These features help you work safely and get jobs done fast.

If you want a good supplier, you can pick YNF Machinery for hydraulic lift tables and trucks. They have many choices to help you move things easily.

Hydraulic lift tables and trucks make moving things easier at work. They help you lift heavy items safely. You can finish jobs faster with these tools. There are many types, so you can pick what you need. These tools help stop injuries and help your team do more. Your team stays healthy and works better. This means you save money as time goes on.

Benefit | Impact |

|---|---|

Safety | Fewer injuries |

Efficiency | Quicker load movement |

Versatility | Fits many work environments |

FAQ

How do you choose the right hydraulic lift table for your warehouse?

You look at the weight you need to lift, the height you want to reach, and the space in your warehouse. You check safety features and controls. You pick a table that matches your daily tasks.

What safety checks should you do before using a hydraulic lift table?

You inspect the platform, scissor legs, and hydraulic system for damage. You test emergency stops and safety bars. You make sure the load does not go over the weight limit.

Can you use hydraulic lift tables for moving fragile items?

Yes, you can move fragile items with hydraulic lift tables. You place the items carefully on the platform. You lift and lower them slowly to avoid damage.

How often should you maintain your hydraulic lift table?

You check your lift table every week. You look for leaks, worn parts, and test safety features. You clean the table and add oil when needed. You call experts for big repairs.

What is the difference between a manual and a hydraulic lift table?

Manual lift tables use a hand crank or foot pedal. You need more effort to lift loads. Hydraulic lift tables use a pump and motor. You lift heavy items faster and with less strain.