You need the right hydraulic pump for your excavator. It helps your machine work its best. The pump’s size, power, flow rate, and pressure must fit your excavator. This makes sure everything runs smoothly. Check if your job site has very hot or cold weather. Look for fluid contamination or small spaces too. These things can change how your pump works. When you look for an excavator hydraulic pump for sale, watch for these details. This helps you stop problems and keeps your machine safe.

Key Takeaways

Picking the right hydraulic pump helps your excavator work better. It makes the machine run smoothly. You can finish jobs faster. It also uses less fuel.

There are three main types of hydraulic pumps. Gear pumps work for low pressure. Vane pumps are quiet when running. Piston pumps handle high pressure. Each type fits different jobs.

Always make sure the pump matches your excavator model. Use original parts to stop breakdowns. This keeps you safe.

Think about flow rate and pressure needs. These things show how well your excavator can lift and move stuff.

Choose a trusted supplier like YNF Machinery. Good suppliers give quality products and help. This helps you avoid expensive mistakes.

Why Pump Selection Matters

Excavator Performance

You want your excavator to work well and last long. The hydraulic pump gives power to your machine. If you choose the wrong pump, your excavator will not work right. The bucket might move slow. The arm might not lift heavy things. You could see weak digging power. When the pump matches your excavator, it moves smooth and lifts strong. Your machine can finish jobs faster. You use less fuel and your machine does not wear out as fast.

Tip: Always look at the pump’s flow rate and pressure. These numbers show how well your excavator works.

Safety and Efficiency

A good hydraulic pump helps keep you safe. If the pump does not fit, parts can break. Oil might leak. The machine could get too hot. This can cause accidents and cost a lot to fix. You also lose time fixing these problems.

When you pick the right pump, your machine works better. Your excavator uses less energy. The controls work fast. You finish your work on time.

Here is a quick list of what happens when you pick the right pump:

You stop breakdowns.

You keep workers safe.

You spend less money fixing things.

You make your excavator work better.

Benefit | Result |

|---|---|

Safety | Fewer accidents |

Efficiency | Faster job completion |

Reliability | Less downtime |

Hydraulic Pump Types

When you pick a hydraulic pump, you need to know the main types. Each type works best for certain jobs. You should learn about gear pumps, vane pumps, and piston pumps before you choose.

Gear Pumps

Gear pumps use gears that spin to move fluid. These pumps are found in many big machines like excavators and wheel loaders. The design is easy to understand and very dependable. Gear pumps cost less than other pumps. They last longer because they do not have many moving parts.

Attribute | Gear Pumps | Other Pump Types |

|---|---|---|

Simplicity | Simple design | More complicated designs |

Reliability | Very reliable | Depends on the type |

Cost-Effectiveness | Usually cheaper | Often costs more |

Pressure Suitability | Works at low or medium pressure | Handles high pressure |

Common Applications | Excavators, wheel loaders | Used in many industries |

Gear pumps are good for jobs that do not need high pressure. They are reliable and need little fixing. These pumps can be loud and lose power if the pressure is too high. Gear pumps are best for easy jobs and machines that do not need high pressure.

Gear pumps are used in:

Excavators

Wheel loaders

Other heavy machines

Vane Pumps

Vane pumps use vanes that slide to move fluid. You find these pumps in machines that must be quiet and work well. Vane pumps are good for places with not much room. They give smooth and exact control.

Advantages of Vane Pumps | Disadvantages of Vane Pumps |

|---|---|

Very efficient and precise | Do not work well with thick fluids |

Small size for tight spaces | Cannot handle high pressure well |

Quiet when running | Dirty fluid can break them |

Works with many fluids | Not good for rough fluids |

Cheap to make and fix | |

Strong and lasts long | |

Easy to check and fix |

Vane pumps work at 80% to 95% efficiency. They are quiet and last a long time. These pumps need clean oil to work right. Dirty oil can break them. Vane pumps do not work well at high pressure. Use vane pumps for jobs that need quiet and exact control, but not for hard digging.

Piston Pumps

Piston pumps are the best for most excavator hydraulic pump systems. They can handle high pressure, are tough, and work very well. Piston pumps work in hard places and with many kinds of fluids.

Feature | Description |

|---|---|

High-Pressure Capability | Piston pumps work at very high pressure, over 10,000 psi. |

Durability | Strong build makes them last in tough places. |

Fluid Handling | Can use many fluids, even thick or rough ones. |

Precision Control | Good for jobs that need exact moves, like building. |

Versatility | Can be changed to fit different needs. |

Most excavators use piston pumps because they give the power needed for digging and lifting. You get exact control and long life. Piston pumps work in high-pressure jobs where gear and vane pumps cannot.

Tip: Pick a piston pump if you want your excavator to do hard jobs and last longer.

Comparing Pump Types

You should look at how well each pump works and how much pressure it can handle before you choose. Here is a quick guide:

Gear Pumps:

Work at 60% to 80% efficiency

Good for easy jobs and low pressure

Can be loud

Vane Pumps:

Work at 80% to 95% efficiency

Quiet and exact

Needs clean oil

Not for high pressure

Piston Pumps:

Best for high pressure

Very efficient and tough

Good for hard jobs

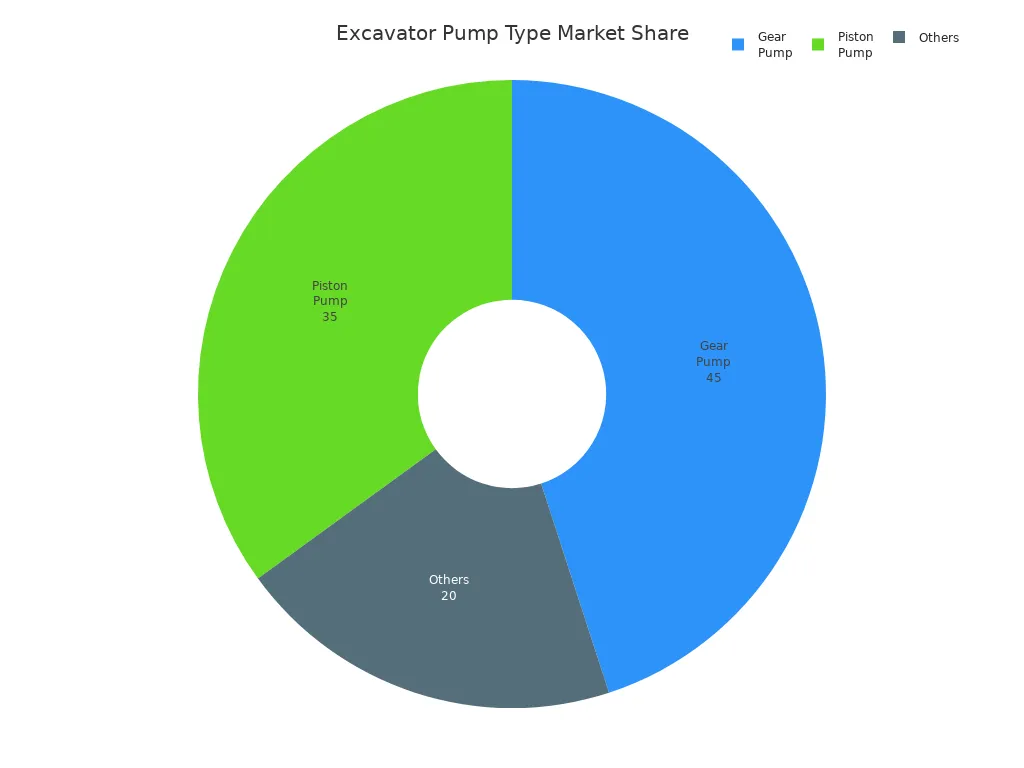

Market Share in Excavators

Different pumps are used in excavators. Gear pumps are used the most, but piston pumps are picked for high-pressure work.

Pump Type | Market Share |

|---|---|

Gear Pump | 45% |

Piston Pump | 35% |

Others | 20% |

You should think about what your excavator needs and what jobs you do. If you need high pressure and a strong pump, pick a piston pump. For easy jobs, gear pumps are good. Vane pumps are best for quiet and exact work.

Pump Selection Criteria

When you pick a hydraulic pump, you need to think about a few things. You want your excavator to be safe and work well. These pump selection rules can help you choose.

Compatibility

The hydraulic pump must fit your excavator model. Look at the maker’s guide for part numbers and details. Use original parts so your hydraulic pump excavator works right. If you use the wrong pump, your machine may break early or not work well.

Always check the pump’s model and serial number.

Make sure the pump fits your excavator’s brand and model.

Remanufactured pumps should be high quality.

The right pump stops fitting problems and keeps your machine safe.

Tip: Write down your excavator’s model and pump serial number before shopping for a new hydraulic pump.

Flow Rate and Pressure

Hydraulic flow and pressure decide how strong and fast your excavator works. If you pick a pump with the wrong flow or pressure, your machine may move slow or not lift heavy things. Medium excavators often need 150 gallons per minute and 4,500 psi.

Flow Rate (gallons per minute) | Pressure (psi) |

|---|---|

150 | 4500 |

Write down your hydraulic flow needs before you buy. Check your excavator’s manual for the right numbers. If you work in mud or water, you need high pressure and changing flow. Piston pumps give changing flow and high pressure, so they are good for hard jobs.

Power Requirements

Your hydraulic pump must give enough power for your excavator’s work. Power depends on flow and pressure. Use these formulas to find what you need:

Parameter | Formula | Description |

|---|---|---|

Flow Rate | Q = D n / 1000 | Flow rate in liters per minute |

Shaft Torque | T = D p / 20 π | Torque in Newton meters |

Shaft Power | P_s = T n / 9554 | Shaft power in kilowatts |

Hydraulic Power | P_h = Q p / 600 | Hydraulic power in kilowatts |

More flow and pressure mean you need a stronger pump. If you dig, lift, or work in water, check your power needs. This helps you stop breakdowns and keeps your machine working hard.

Special Conditions

Think about where you use your excavator. Very hot or cold weather can change how your hydraulic pump works. Cold makes oil thick. Hot makes oil thin. Your pump must handle these changes. Dirty oil is also a problem. Dirty oil can break some pumps. Gear pumps work better with dirty oil, but piston pumps need clean oil.

Pick pumps that work from -20°C to +80°C.

Use good filters to keep oil clean.

Make sure your pump can handle water, dirt, and trash if you work in wet places.

Note: Clean oil and good filters help your hydraulic pump last longer.

Safety Margin

You need a safety margin to keep your excavator and pump safe. First, find the most your machine can lift. Double this number for your safety margin. This keeps your hydraulic pump excavator safe from too much weight and stops accidents.

Use a margin of 1.0 to 1.3 for safe work.

Add 5% to 10% more if your job is hard or your pump works in tough places.

Check the Net Positive Suction Head (NPSH) to stop pump problems and keep it working well.

Callout: Always plan for the worst. A bigger safety margin means fewer breakdowns and safer jobs.

Pump Selection Criteria Table

Here is a simple table to help you compare pump types for different jobs:

Selection Factor | Gear Pump Suitability | Piston Pump Suitability | Amphibious Excavator Needs |

|---|---|---|---|

Pressure Requirements | Low to medium | High | High pressure needed |

Flow & Speed | Fixed flow | Variable flow | Variable flow is crucial |

Efficiency | Lower | Higher | High efficiency saves fuel |

Cost & Complexity | Lower cost, simple | Higher cost, complex | Reliability is key |

Durability | Less robust | More robust | Must resist water, debris |

Use this table to match your hydraulic pump to your excavator and job needs.

Excavator Hydraulic Pump for Sale

Comparing Options

When you shop for an excavator hydraulic pump for sale, you see lots of choices. You need to pick a pump that fits your machine and job. First, check the most popular brands and models. You will find pumps from Hitachi, John Deere, and Kobelco. These brands make pumps for many excavator models.

Hitachi Main Pump: ZX470LC-5, ZX470LC-5B, ZX470LC-5G, ZX470LC-6, ZX200, ZX200F, ZX230, ZX250F, ZX270LC

John Deere Main Pump: 470GLC, 350D, 350DLC, 350GLC, 3754D, 380, 380GLC

Kobelco Main Pump: SK210LC-8, SK250-8, SK260-8, SK260LC-9, SK295-8, SK295-9

You should look at features before you buy. Check these important things:

Pump type

Needed pressure and flow ratings

Electronic control compatibility

Warranty

Local service

A table can help you compare options:

Feature | Why It Matters |

|---|---|

Pump type | Matches your job needs |

Pressure and flow ratings | Makes sure it works strong |

Electronic controls | Works with your excavator |

Service availability | Helps with repairs |

Tip: Write down your excavator model and job needs before you shop. This helps you find the right hydraulic pump excavator fast.

Evaluating Suppliers

You want a trusted supplier when you look for an excavator hydraulic pump for sale. A good supplier gives you quality products and help. YNF Machinery is a reliable choice for hydraulic pump excavator parts. You get pumps that fit many excavator brands and models. YNF Machinery gives strong warranties and quick service. You can ask questions and get help with installation.

YNF Machinery offers:

Many pumps for Hitachi, John Deere, and Kobelco

Clear warranty terms

Local service and support

Fast delivery

Note: Pick a supplier that answers your questions and helps you after you buy. This keeps your excavator working and saves you time.

Hydraulic Pump Excavator Compatibility

Model Matching

You must pick a hydraulic pump that fits your excavator. Every excavator has its own needs. The pump should match your machine’s size and power. Look in the manual for the right pump type and model. Write down your excavator’s serial number before you shop. This helps you avoid buying the wrong pump. If you use the wrong pump, your excavator might lose power or stop working. YNF Machinery sells pumps for many excavator models. You can ask their team for help if you are not sure.

Tip: Always check the pump’s details and make sure they match your excavator before you buy.

Installation Tips

Putting a hydraulic pump on your excavator takes care. You want your machine to work well and be safe. Here are some problems you might face when installing:

If you miss a part like an O-ring, you cannot finish. Check all parts before you start.

Air stuck in the hydraulic system can break things. Remove air from the system after you put in the pump.

Make sure fluid levels are right before you turn on the pump. Low fluid can break the pump.

Follow the guide from the pump supplier. Clean all the connections and use the correct tools. Check seals and fittings to stop leaks. After you install the pump, test it slowly first. Listen for weird sounds or look for leaks. If you see something wrong, stop and check everything. YNF Machinery can help with installation and answer your questions.

Note: Careful installation helps your excavator last longer and stops expensive repairs.

Quick Reference Checklist

Selection Steps

You want to choose the right hydraulic pump for your excavator. Use this checklist to guide you through each step:

Write down your excavator’s model and serial number.

Check your machine’s manual for the correct pump type and specifications.

List the required flow rate, pressure, and displacement.

Think about the job site. Note if you work in hot, cold, wet, or dirty places.

Decide if you need a gear, vane, or piston pump.

Make sure the pump matches your excavator’s power needs.

Add a safety margin to your calculations.

Compare pumps using a table of key features.

Choose a trusted supplier like YNF Machinery.

Review the warranty and support options before you buy.

Tip: Keep this checklist handy when you shop for a new hydraulic pump. It helps you avoid mistakes and saves time.

Comparison Table

Use this table to compare the main pump types. Look at the key specifications for each one. This makes it easier to match the pump to your excavator and your job.

Pump Type | Max Pressure (psi) | Flow Rate (GPM) | Displacement (cc/rev) | Efficiency (%) | Best Use Case |

|---|---|---|---|---|---|

Gear Pump | 3,000 | 60-120 | 10-200 | 60-80 | Light to medium work |

Vane Pump | 2,500 | 40-100 | 20-160 | 80-95 | Quiet, precise jobs |

Piston Pump | 6,000+ | 80-200 | 30-250 | 85-98 | Heavy-duty digging |

Note: Always match the pump’s pressure and flow to your excavator’s needs. This helps your machine work safely and efficiently.

Common Mistakes

When you pick a hydraulic pump for your excavator, you need to watch out for mistakes. These mistakes can waste money. They can make work unsafe. They can break your machine. Learn about these problems so you can make smart choices.

Ignoring Compatibility

Some people think any pump will fit their excavator. That is not right. Pumps must match your machine’s model and system. If you do not check, your excavator may not work well. It can wear out faster. Wrong parts make your hydraulic system weak. You might see more breakdowns. Your machine may not last long. Extra strain can cause sudden failures.

Hydraulic systems do not work well

More wear and tear happens

Equipment does not last as long

Always check the pump’s details. Make sure it fits your excavator. This helps you avoid expensive repairs and lost time.

Overlooking Supplier Reputation

You might want to save money by buying from unknown sellers. This can cause big trouble. Pumps from bad suppliers use weak parts. These parts may not handle heavy work. Your equipment can break. Accidents can happen at the job site. Repairs cost more with cheap pumps. Some people even get into legal trouble after accidents.

Weak parts cause equipment to break

Maintenance costs go up

Accidents can lead to legal problems

Pick a supplier with a good name. YNF Machinery gives strong pumps and good help. You feel safe and get better results.

Focusing Only on Price

Low prices may look good, but they can hide bigger problems. Cheap pumps may not meet the right standards. You may see poor performance and more breakdowns. Non-OEM pumps lose power. Studies show these pumps waste more energy. You could lose $1,100 to $3,700 each year for every pump. You pay more for repairs and energy over time.

Non-OEM pumps work worse

Efficiency drops by more than 10%

Energy and repair costs go up

Look at quality, fit, and supplier help. Price is important, but it should not be the only thing you think about.

Tip: Stay away from these mistakes to keep your excavator safe and working well.

Verifying Quality and Supplier Credibility

Inspecting Pump Quality

You want your excavator to be safe and last long. Before buying a hydraulic pump, check its quality. Good pumps break less and work better. You can use these steps to check the pump:

Quality Assurance Check | Description |

|---|---|

Pressure Testing | Use a gauge to see if the pump meets standards. |

Fluid Level Check | Look at the fluid tank. It should be filled right. |

Fluid Quality Check | Check for dirt in the fluid. Clean fluid keeps the pump safe. |

Filter Inspection | Look at the filters. Change any that are dirty or blocked. |

Component Inspection | Check all parts for cracks or damage. |

Performance Evaluation | Test the pump. Make sure it runs smooth and does not lose power. |

Always check these things before you put in a new pump. This helps you stop problems and keeps your pump working well. Clean fluid and strong parts help your excavator do hard jobs.

Tip: If you check often, you find problems early and keep your machine safe.

Checking Supplier Trustworthiness

You need a supplier you can trust. A good supplier gives strong pumps and answers your questions. YNF Machinery is a trusted choice for hydraulic pumps. You can use these ways to see if a supplier is good:

Look at their quality systems.

Check for certificates like ISO 9001.

Ask about audits to see how they make pumps.

Talk with them often to build trust.

YNF Machinery does these things and helps you after you buy. You feel safe and get good service. If you pick a trusted supplier, you protect your money and keep your excavator working well.

Note: Good suppliers help you avoid big mistakes and keep your work going. 🛠️

You should follow easy steps to pick a hydraulic pump. First, write down your excavator’s model. Next, check the manual for details. Then, look at different pump types. Find the flow rate and pressure that match your machine. Always add a safety margin to be safe. Picking carefully helps your excavator work well and stay safe. Ask experts if you need help. Read product listings before you buy. YNF Machinery gives good help and strong pumps for your needs.

FAQ

What is the most important factor when choosing a hydraulic pump for my excavator?

You should always match the pump’s specifications to your excavator’s needs. Check flow rate, pressure, and compatibility first. This helps your machine work safely and efficiently.

How often should I replace my excavator’s hydraulic pump?

Most pumps last several years with good care. You should check your pump regularly. Replace it if you see leaks, slow movement, or strange noises.

Can I install a hydraulic pump by myself?

You can install a pump if you follow the manual and use the right tools. Always clean parts and check for leaks. If you feel unsure, ask YNF Machinery for help.

Why should I choose YNF Machinery for hydraulic pumps?

YNF Machinery offers reliable pumps, strong warranties, and helpful support. You get quality products that fit many excavator models. Their team answers your questions and helps with installation.

What happens if I use the wrong hydraulic pump?

Using the wrong pump can damage your excavator. You may see weak power, leaks, or even system failure. Always check compatibility before you buy.