An elastic coupling joins two shafts. It helps them move together without problems. You see this device in machines. Machines can have small shifts or misalignments.

An elastic coupling lets shafts move a little.

It can handle small misalignments, but not big ones.

The right coupling stops equipment from breaking.

Did you know? Almost half of mechanical systems use elastic couplings.

Type of Coupling | Percentage Usage |

|---|---|

Elastic Couplings | 45% |

Rigid Couplings | 30% |

Key Takeaways

Elastic couplings join two shafts. They let them move together easily. The shafts do not need to be perfectly lined up.

These couplings take in shocks and vibrations. This helps keep machines safe from harm. It also helps them last longer.

Picking the right elastic coupling depends on torque needs. It also depends on speed and how much the machine might not line up.

Checking and caring for elastic couplings often can stop damage. It helps your equipment work well.

Elastic couplings are used in many machines. You can find them in motors, pumps, and compressors. They are important for smooth working.

Elastic Coupling Basics

Definition

An elastic coupling connects two spinning shafts. It lets them share movement and power, even if they are not lined up. The elastic part inside takes in small shifts and shakes. You see this coupling in machines that need to run smoothly. Picking an elastic coupling helps keep your equipment safe from damage. It protects against misalignment and sudden hits.

Main Parts

An elastic coupling has many key parts. Each part helps the system work right. Here is a table that lists the main pieces you find in a normal elastic coupling:

Essential Component |

|---|

Driver shaft |

Driver shaft/coupling fit |

Coupling |

Driven shaft/coupling fit |

Driven shaft |

Coupling spacer system |

Lubrication (if required) |

Cooling system (if required) |

The main body holds all the parts together. The elastic piece, made from strong polymers, sits between the shafts. This part makes the coupling bend and soak up shakes.

Function

You use an elastic coupling for three big jobs:

Move torque from one shaft to another so the machine works.

Fix misalignment, whether it is side-to-side, end-to-end, or at an angle.

Soak up shakes and hits, which helps your equipment last longer.

Tip: The elastic part is strong, bends easily, and is light. It can take lots of force and stops shakes while still moving power.

Using an elastic coupling lets you have small mistakes in alignment. The elastic material bends and stretches to protect your machine from sudden force. This twisting ability comes from how the material changes shape under pressure. You get smoother running and less damage to your equipment.

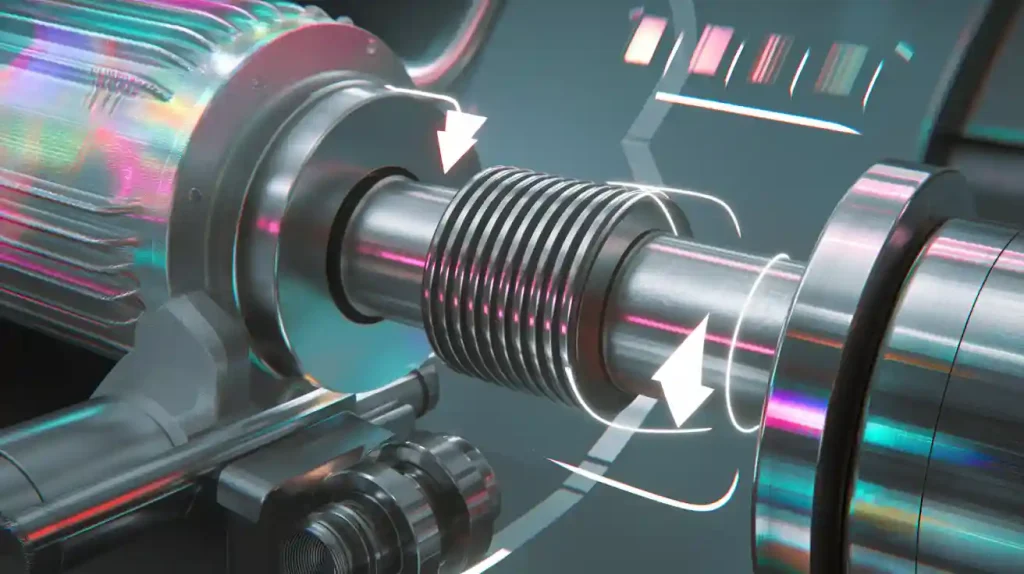

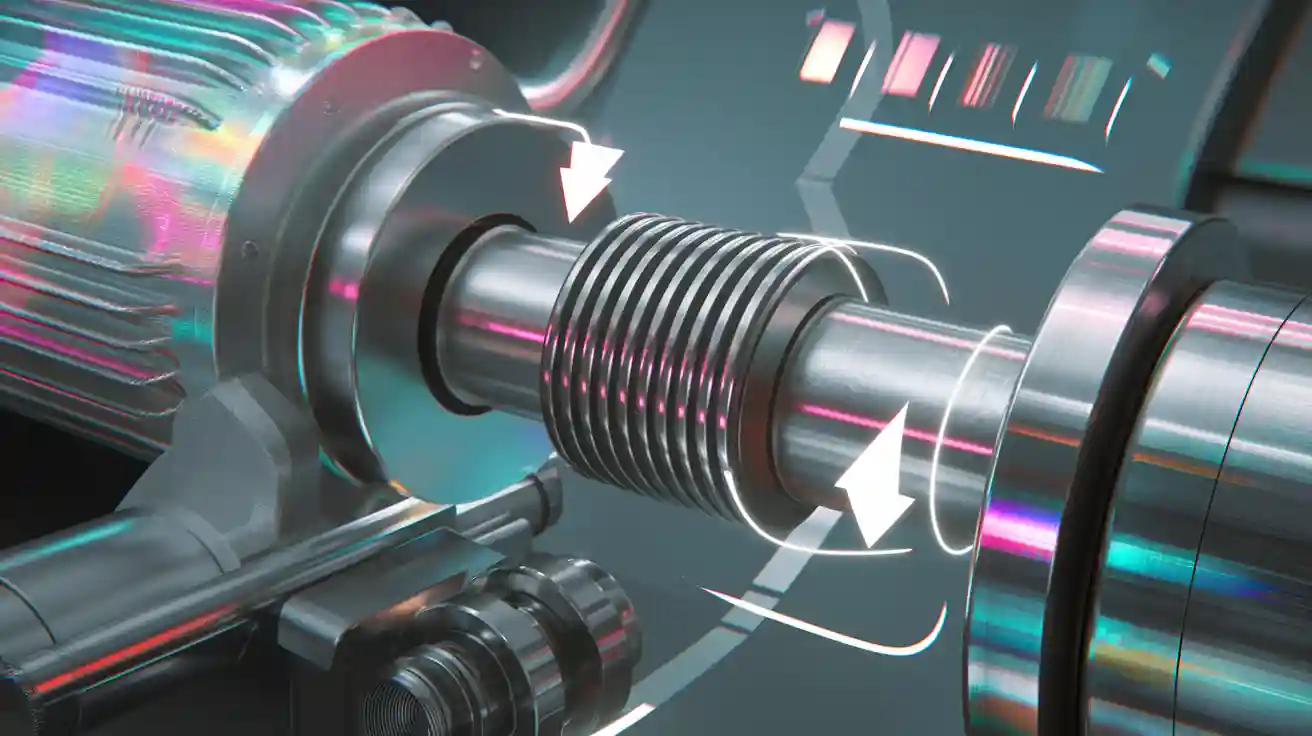

How Elastic Coupling Works

Torque Transmission

When you use an elastic coupling, it connects two shafts. The main job is to move torque from one shaft to another. The elastic part sits between the shafts. It is usually made from rubber or plastic. This material changes shape when force is applied. It can stretch and squeeze as the shafts turn. This lets the coupling move torque smoothly. The shafts do not need to be perfectly lined up.

Elastic couplings use compression and shear in their elastic parts. This helps absorb shocks during machine work. You get a steady flow of power. The coupling protects your equipment from sudden jolts. In factories, disc couplings are common. They have high torque density and last a long time. When picking a coupling, think about how much torque it can handle. If it is too strong, you spend more money than needed. If it is too weak, your machine might break.

Misalignment Compensation

Machines do not always stay lined up. Shafts can move out of place for many reasons. Sometimes, shafts are at an angle. This is called angular misalignment. Sometimes, shafts are side by side but not in line. This is parallel misalignment. Axial misalignment happens when shafts move closer or farther apart.

The types of misalignment are: Angular misalignment, parallel misalignment, and axial misalignment. Each type needs a special coupling to fix the problem and keep the shafts working right.

Elastic couplings help by fixing misalignments. The elastic part bends and stretches to keep shafts working together. This lowers vibration and noise. Your machine runs better and lasts longer. You can use different couplings for each misalignment:

Angular misalignment: Beam couplings work well.

Parallel misalignment: Oldham couplings are a good choice.

Axial misalignment: Flexible couplings handle changes from heat or movement.

Fixing misalignments helps avoid extra wear on your machine. The elastic coupling keeps things running smoothly, even when parts shift.

Vibration Damping

Machines make vibrations when they run. If you do not control these, they can hurt your equipment. Elastic couplings help with vibration damping. The elastic part absorbs shocks and spreads out the force. This keeps vibrations from reaching other machine parts.

Mechanism | Description |

|---|---|

Nonlinear Equivalent Stiffness | The elastic coupling has special features that help absorb and spread out vibrations. |

Damping Effects | The damping part of the coupling lowers the strength of vibrations that pass through the system. |

You can make vibration damping better by using bigger and heavier hubs. Some couplings have flywheel shapes to help with torsional vibration damping. Elastomer insert couplings spread out vibrations over a larger area. This gives extra protection against damage.

Using an elastic coupling gives three main benefits:

Absorbing shocks during machine use.

Lowering the amount of vibration that reaches your machine.

Helping your equipment last longer by reducing wear.

If your machine faces temperature changes, the elastic coupling can handle thermal expansion. The elastic part stretches or shrinks as needed. This keeps the shafts connected and safe.

Types: Elastomeric Couplings

Elastomeric couplings are a common kind of elastic coupling. Many machines use them to fix misalignment and stop vibration. These couplings have a flexible part made from special polymers. The flexible part sits between the shafts. It helps soak up shocks. This gives smoother running and less damage to your equipment.

Elastomeric Insert

The main part of elastomeric couplings is the elastomeric insert. This insert is made from materials like thermoplastic polyurethane (TPU) or HYTREL. Each material has its own good points. TPU works in temperatures from -30°C to +120°C. HYTREL can handle even hotter places, up to 150°C. You can pick the right insert for your needs.

Material Type | Hardness (Shore) | Temperature Range (°C) | Torque Capacity (Nm) |

|---|---|---|---|

Thermoplastic Polyurethane (TPU) | 80 Sh A – 98 Sh A | -30 to +120 | 2 to 20,000 |

HYTREL | 64-65 Sh D | -30 to +150 | up to 25,000 |

The elastomeric insert is a flexible part. It soaks up shocks and lowers vibrations. This helps protect your machine better. Soft elastomers give the best vibration control, but they work in smaller temperature and torque ranges. Hard elastomers are stiffer and can take bigger loads.

Tip: You can change the elastomeric insert for more torque or better heat resistance. This lets you match the coupling to your machine.

Flexibility

Elastomeric couplings are special because they are flexible. The flexible part lets the coupling fix misalignment between shafts. You do not need perfect alignment for smooth running. The coupling can bend and stretch to fit small mistakes.

Tire-type couplings can fix 2 to 4 degrees of misalignment.

Sleeve-type couplings also fix 2 to 4 degrees.

Jaw-type couplings work with up to 1 degree.

Coupling Type | Misalignment Capability (degrees) |

|---|---|

Tire-type | 2 to 4 |

Sleeve-type | 2 to 4 |

Jaw-type | Up to 1 |

You get the best results when you pick the right flexible shaft coupling for your machine. Elastomeric couplings use their flexible part to move torque and soak up shocks. This means your equipment runs smoother and lasts longer. You can use these couplings in many places, like electric motors and pumps.

Elastomeric polymer inserts help move torque while letting things move. You can trust them to keep your machine safe from vibration and misalignment. If you want a flexible coupling that protects your equipment, elastomeric couplings are a smart pick.

Benefits and Uses

Resilience

You want your machines to keep working, even if things move. An elastic coupling helps your system stay strong. It takes in misalignment, so the shafts stay joined. Your machine keeps running smoothly. You do not have to worry about small shifts. The coupling bends and stretches to handle different misalignments.

Scenario | Description | Alternative A | Alternative B |

|---|---|---|---|

0 | Original system | Idealized motor-shaft-gear system | Same system with jaw coupling |

1 | Disruptive event | Requires larger shaft | Jaw coupling absorbs misalignment |

2 | New force requirement | Needs motor replacement | Jaw coupling adapts without structural changes |

Great misalignment handling keeps your equipment safe.

The coupling changes to fit many misalignments, so you save money on repairs.

Efficiency

You want your machines to use less energy. An elastic coupling helps by soaking up vibrations. It also lowers wear, so your system works better and lasts longer. You do not need to check or oil it as much as a rigid coupling.

Feature | Rigid Couplings | Flexible Couplings |

|---|---|---|

Alignment Requirements | Cannot tolerate misalignment | Can handle slight misalignment |

Maintenance Requirements | Requires routine checks and lubrication | Absorbs vibrations, reducing wear |

Applications | Best for high-torque and support | Suitable for low/moderate torque with misalignment potential |

Torsional vibrations can make elastic parts heat up. You should control these vibrations to keep the coupling working well.

The right coupling helps you save energy and keeps your system running well.

Durability

You want your machines to last a long time. How long an elastic coupling lasts depends on its materials and care. Good materials fight wear and rust. Checking and oiling it often helps stop problems.

Rubber couplings can last about 10 years or 50,000 hours.

Tough places, like very hot or harsh areas, can make them wear out faster.

Tip: Keep your coupling lined up and away from bad chemicals to help it last longer.

Applications

You see elastic couplings in many machines. They work in factories, cars, and power systems. Jaw couplings are used in pumps, compressors, and turbines. Elastomeric couplings fit motors and special machines.

The most torque and speed matter when picking a coupling.

You should check how stiff it is, how much it can dampen, and the temperature around it.

Look for possible misalignment problems in your shafts.

Factor | Description |

|---|---|

Alignment | Good alignment is important when you install; bad alignment causes extra force. |

Load Types | Couplings must handle certain loads and misalignment limits. |

Speed of Rotation | As shafts spin faster, they can handle less misalignment. |

Reactionary Loads | More misalignment means more force on your equipment. |

If you need a good place to buy elastic couplings, YNF Machinery has quality products for many uses. You can trust their couplings to help your machines run well.

Elastic couplings make machines work better and last longer. They lower vibration, make setup easier, and protect your equipment. Here are some main benefits:

Key Point | Benefit |

|---|---|

Misalignment Compensation | Shafts stay working together, even if not lined up |

Vibration Damping | Less noise and shock, so your workplace is safer |

Easy Maintenance | Easy to check and change, which saves you time |

Elastic couplings can do hard jobs and keep your system working well. Pick the right type for your machine and take care of it for the best results.

FAQ

What is the main job of an elastic coupling?

An elastic coupling links two shafts together. It lets power move from one shaft to the other. The elastic part takes in shocks and helps with small misalignments.

How do you choose the right elastic coupling?

Think about how much torque your machine needs. Check how fast it runs and if the shafts are lined up. Look at the temperature and how much vibration there is. YNF Machinery has many choices for different machines.

Can elastic couplings handle high temperatures?

Some elastomeric inserts work well in hot places. HYTREL inserts can handle heat up to 150°C. Always check what the insert is made of before buying.

How often should you check or replace an elastic coupling?

Check your coupling every few months. Look for cracks or signs of wear. Change the insert if you see any damage. Checking often helps your machine last longer.

Where can you buy quality elastic couplings?

You can get elastic couplings from YNF Machinery. They sell strong and dependable products for many machines. Their couplings help your equipment work better.